Optimizing NMC Battery Series Architecture for Power Capacity

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Evolution and Optimization Goals

Lithium-ion batteries with Nickel Manganese Cobalt (NMC) cathodes have emerged as a dominant technology in the energy storage landscape over the past decade. The evolution of NMC battery technology represents a significant advancement in the pursuit of higher energy density, improved safety, and extended cycle life for applications ranging from consumer electronics to electric vehicles and grid-scale energy storage systems.

NMC cathode materials were first commercialized in the early 2000s as an alternative to the then-prevalent LiCoO2 cathodes. The initial NMC formulations (NMC 111) contained equal parts nickel, manganese, and cobalt, offering a balanced performance profile. This composition provided moderate energy density while maintaining reasonable thermal stability and cycle life. However, as market demands evolved, particularly in the electric vehicle sector, the limitations of NMC 111 became apparent.

The technological trajectory of NMC batteries has been characterized by a progressive increase in nickel content, with corresponding reductions in manganese and cobalt. This shift gave rise to NMC 532, NMC 622, and most recently NMC 811 formulations. Each iteration has delivered incremental improvements in energy density, with the latest NMC 811 cathodes achieving specific capacities approaching 200 mAh/g, representing a significant improvement over the approximately 160 mAh/g capacity of NMC 111.

Despite these advancements, optimizing NMC battery series architecture for power capacity presents several complex challenges. Current optimization goals focus on addressing the inherent trade-offs between energy density, power capability, thermal management, and cycle life. A primary objective is to develop cell designs that can deliver high discharge rates without compromising safety or longevity, particularly for applications requiring rapid charging and high-power output.

Another critical optimization target involves enhancing the structural stability of high-nickel NMC cathodes during cycling. As nickel content increases, these materials become more susceptible to capacity fading, structural degradation, and thermal runaway. Research efforts are concentrated on developing novel dopants, coatings, and gradient compositions that can mitigate these issues while preserving the high energy density advantages.

The integration of advanced battery management systems (BMS) represents another key optimization goal. These systems must be capable of precisely monitoring and controlling individual cells within series configurations to prevent imbalances that can lead to premature capacity loss or safety incidents. The development of more sophisticated algorithms for state-of-charge estimation and thermal management is essential for maximizing the performance potential of NMC battery architectures.

Looking forward, the industry is pursuing optimization strategies that extend beyond traditional cell design to encompass the entire battery system architecture. This holistic approach considers factors such as cell-to-cell variations, thermal gradients across battery packs, and the impact of series-parallel configurations on overall system performance and reliability.

NMC cathode materials were first commercialized in the early 2000s as an alternative to the then-prevalent LiCoO2 cathodes. The initial NMC formulations (NMC 111) contained equal parts nickel, manganese, and cobalt, offering a balanced performance profile. This composition provided moderate energy density while maintaining reasonable thermal stability and cycle life. However, as market demands evolved, particularly in the electric vehicle sector, the limitations of NMC 111 became apparent.

The technological trajectory of NMC batteries has been characterized by a progressive increase in nickel content, with corresponding reductions in manganese and cobalt. This shift gave rise to NMC 532, NMC 622, and most recently NMC 811 formulations. Each iteration has delivered incremental improvements in energy density, with the latest NMC 811 cathodes achieving specific capacities approaching 200 mAh/g, representing a significant improvement over the approximately 160 mAh/g capacity of NMC 111.

Despite these advancements, optimizing NMC battery series architecture for power capacity presents several complex challenges. Current optimization goals focus on addressing the inherent trade-offs between energy density, power capability, thermal management, and cycle life. A primary objective is to develop cell designs that can deliver high discharge rates without compromising safety or longevity, particularly for applications requiring rapid charging and high-power output.

Another critical optimization target involves enhancing the structural stability of high-nickel NMC cathodes during cycling. As nickel content increases, these materials become more susceptible to capacity fading, structural degradation, and thermal runaway. Research efforts are concentrated on developing novel dopants, coatings, and gradient compositions that can mitigate these issues while preserving the high energy density advantages.

The integration of advanced battery management systems (BMS) represents another key optimization goal. These systems must be capable of precisely monitoring and controlling individual cells within series configurations to prevent imbalances that can lead to premature capacity loss or safety incidents. The development of more sophisticated algorithms for state-of-charge estimation and thermal management is essential for maximizing the performance potential of NMC battery architectures.

Looking forward, the industry is pursuing optimization strategies that extend beyond traditional cell design to encompass the entire battery system architecture. This holistic approach considers factors such as cell-to-cell variations, thermal gradients across battery packs, and the impact of series-parallel configurations on overall system performance and reliability.

Market Demand Analysis for High-Capacity NMC Batteries

The global market for high-capacity NMC (Nickel Manganese Cobalt) batteries has experienced exponential growth over the past decade, primarily driven by the rapid expansion of electric vehicle (EV) adoption and renewable energy storage systems. Market research indicates that the NMC battery segment currently represents approximately 28% of the total lithium-ion battery market, with projections suggesting this share will increase to 35% by 2027.

Electric vehicle manufacturers constitute the largest demand segment for high-capacity NMC batteries, accounting for nearly 65% of total consumption. This demand is fueled by automotive OEMs' aggressive electrification strategies, with many major manufacturers committing to all-electric or predominantly electric product lines within the next decade. The preference for NMC chemistry stems from its superior energy density compared to alternatives like LFP (Lithium Iron Phosphate), enabling greater range capabilities in EVs.

Consumer electronics represents the second-largest market segment, contributing about 18% of demand for high-capacity NMC batteries. Manufacturers of smartphones, laptops, and wearable devices increasingly require batteries that deliver higher capacity in smaller form factors, making optimized NMC architectures particularly attractive for these applications.

Grid-scale energy storage systems are emerging as the fastest-growing application segment, with a compound annual growth rate of 32% projected through 2028. This growth is largely attributed to the increasing integration of intermittent renewable energy sources into power grids worldwide, necessitating efficient energy storage solutions with high power capacity and cycle life.

Regional analysis reveals Asia-Pacific as the dominant market for high-capacity NMC batteries, accounting for 62% of global production and consumption. This concentration is primarily due to the established battery manufacturing ecosystems in China, South Korea, and Japan. However, significant investments in battery production facilities across Europe and North America indicate a gradual geographical diversification of the market.

Price sensitivity remains a critical factor influencing market dynamics. While NMC batteries offer superior performance characteristics, their higher cost compared to LFP alternatives presents a barrier to adoption in price-sensitive applications. Industry analysts note that achieving a 15-20% reduction in production costs would significantly accelerate market penetration across multiple sectors.

Safety considerations also shape market demand patterns, with recent high-profile thermal runaway incidents prompting increased scrutiny of battery architecture designs. Consequently, there is growing demand for NMC battery architectures that optimize not only power capacity but also incorporate enhanced thermal management and safety features.

Electric vehicle manufacturers constitute the largest demand segment for high-capacity NMC batteries, accounting for nearly 65% of total consumption. This demand is fueled by automotive OEMs' aggressive electrification strategies, with many major manufacturers committing to all-electric or predominantly electric product lines within the next decade. The preference for NMC chemistry stems from its superior energy density compared to alternatives like LFP (Lithium Iron Phosphate), enabling greater range capabilities in EVs.

Consumer electronics represents the second-largest market segment, contributing about 18% of demand for high-capacity NMC batteries. Manufacturers of smartphones, laptops, and wearable devices increasingly require batteries that deliver higher capacity in smaller form factors, making optimized NMC architectures particularly attractive for these applications.

Grid-scale energy storage systems are emerging as the fastest-growing application segment, with a compound annual growth rate of 32% projected through 2028. This growth is largely attributed to the increasing integration of intermittent renewable energy sources into power grids worldwide, necessitating efficient energy storage solutions with high power capacity and cycle life.

Regional analysis reveals Asia-Pacific as the dominant market for high-capacity NMC batteries, accounting for 62% of global production and consumption. This concentration is primarily due to the established battery manufacturing ecosystems in China, South Korea, and Japan. However, significant investments in battery production facilities across Europe and North America indicate a gradual geographical diversification of the market.

Price sensitivity remains a critical factor influencing market dynamics. While NMC batteries offer superior performance characteristics, their higher cost compared to LFP alternatives presents a barrier to adoption in price-sensitive applications. Industry analysts note that achieving a 15-20% reduction in production costs would significantly accelerate market penetration across multiple sectors.

Safety considerations also shape market demand patterns, with recent high-profile thermal runaway incidents prompting increased scrutiny of battery architecture designs. Consequently, there is growing demand for NMC battery architectures that optimize not only power capacity but also incorporate enhanced thermal management and safety features.

Technical Challenges in NMC Series Architecture

Despite significant advancements in NMC (Nickel Manganese Cobalt) battery technology, optimizing series architecture for maximum power capacity presents several persistent technical challenges. The fundamental issue lies in the inherent trade-off between energy density and power capability that characterizes all lithium-ion battery designs. When NMC cells are arranged in series, voltage increases linearly while current capacity remains constant, creating complex thermal and electrical management requirements.

Cell-to-cell variations represent a critical challenge in series configurations. Manufacturing inconsistencies result in capacity differences between individual cells, which can lead to imbalanced charging and discharging. In series arrangements, the weakest cell often becomes the limiting factor for the entire battery pack, potentially reducing overall system efficiency by 10-15% compared to theoretical maximums.

Thermal management presents another significant hurdle. Series-connected NMC cells generate heat unevenly, with temperature gradients developing across the pack during high-power operations. These thermal imbalances accelerate degradation in hotter cells, creating a cascading effect that reduces overall pack lifespan. Current cooling technologies struggle to maintain uniform temperatures across large series-connected arrays, particularly in high-discharge applications.

Voltage balancing systems add complexity and cost to NMC series architectures. As cells age at different rates, voltage disparities increase, requiring sophisticated battery management systems (BMS) to prevent overcharging or deep discharging of individual cells. These systems must continuously monitor and adjust charging parameters, adding parasitic power losses of 3-5% to overall system efficiency.

Internal resistance optimization remains problematic in series configurations. The cumulative resistance of series-connected cells increases linearly with cell count, limiting maximum power output during high-demand scenarios. This challenge becomes particularly acute in applications requiring rapid power delivery, such as electric vehicles during acceleration or grid stabilization systems during demand spikes.

Safety concerns are amplified in series architectures. Thermal runaway in a single cell can propagate through the entire series string, potentially leading to catastrophic failure. Implementing robust isolation mechanisms between cells adds weight and volume, directly conflicting with energy density goals.

Finally, the optimization of charge/discharge rates presents ongoing difficulties. Series-connected NMC batteries exhibit non-linear performance degradation when subjected to varying C-rates, complicating the development of charging protocols that maximize both battery lifespan and power availability. Current algorithms struggle to balance these competing priorities across the diverse operating conditions encountered in real-world applications.

Cell-to-cell variations represent a critical challenge in series configurations. Manufacturing inconsistencies result in capacity differences between individual cells, which can lead to imbalanced charging and discharging. In series arrangements, the weakest cell often becomes the limiting factor for the entire battery pack, potentially reducing overall system efficiency by 10-15% compared to theoretical maximums.

Thermal management presents another significant hurdle. Series-connected NMC cells generate heat unevenly, with temperature gradients developing across the pack during high-power operations. These thermal imbalances accelerate degradation in hotter cells, creating a cascading effect that reduces overall pack lifespan. Current cooling technologies struggle to maintain uniform temperatures across large series-connected arrays, particularly in high-discharge applications.

Voltage balancing systems add complexity and cost to NMC series architectures. As cells age at different rates, voltage disparities increase, requiring sophisticated battery management systems (BMS) to prevent overcharging or deep discharging of individual cells. These systems must continuously monitor and adjust charging parameters, adding parasitic power losses of 3-5% to overall system efficiency.

Internal resistance optimization remains problematic in series configurations. The cumulative resistance of series-connected cells increases linearly with cell count, limiting maximum power output during high-demand scenarios. This challenge becomes particularly acute in applications requiring rapid power delivery, such as electric vehicles during acceleration or grid stabilization systems during demand spikes.

Safety concerns are amplified in series architectures. Thermal runaway in a single cell can propagate through the entire series string, potentially leading to catastrophic failure. Implementing robust isolation mechanisms between cells adds weight and volume, directly conflicting with energy density goals.

Finally, the optimization of charge/discharge rates presents ongoing difficulties. Series-connected NMC batteries exhibit non-linear performance degradation when subjected to varying C-rates, complicating the development of charging protocols that maximize both battery lifespan and power availability. Current algorithms struggle to balance these competing priorities across the diverse operating conditions encountered in real-world applications.

Current Series Architecture Solutions for NMC Batteries

01 Series-parallel configuration for NMC battery packs

NMC battery packs can be arranged in series-parallel configurations to achieve desired voltage and capacity requirements. Series connections increase the overall voltage while parallel connections increase the current capacity. This architecture allows for flexible power capacity scaling while maintaining thermal stability and ensuring balanced discharge rates across multiple cells. The configuration can be optimized based on specific application requirements such as electric vehicles or energy storage systems.- Series-parallel configuration for NMC battery packs: NMC battery packs can be configured in series-parallel architectures to achieve desired voltage and capacity specifications. Series connections increase the overall voltage while parallel connections increase the current capacity. This configuration allows for flexible power capacity scaling while maintaining thermal stability and ensuring optimal performance for various applications such as electric vehicles and energy storage systems.

- Power management systems for NMC battery arrays: Advanced power management systems are essential for controlling and optimizing NMC battery performance. These systems monitor voltage, current, and temperature across battery cells, implementing balancing algorithms to ensure uniform discharge and charging. They also include protective circuits to prevent overcharging, over-discharging, and thermal runaway, thereby extending battery life and maintaining power capacity over time.

- Thermal management for NMC battery capacity preservation: Thermal management is crucial for maintaining NMC battery capacity and performance. Systems incorporating cooling channels, heat sinks, or liquid cooling mechanisms help regulate temperature during high-power operations. Effective thermal management prevents capacity degradation, extends cycle life, and ensures consistent power delivery across varying operational conditions, particularly important for high-capacity NMC battery installations.

- Cell balancing techniques for maximizing NMC battery capacity: Cell balancing techniques are implemented to maximize the usable capacity of NMC battery systems. Active and passive balancing methods ensure that individual cells within a series architecture maintain similar state-of-charge levels, preventing premature capacity limitations due to weaker cells. These techniques include charge redistribution, selective discharge, and advanced monitoring algorithms that optimize overall system capacity and extend operational lifetime.

- Modular NMC battery architecture for scalable power capacity: Modular designs for NMC battery systems allow for scalable power capacity to meet various application requirements. These architectures feature standardized battery modules that can be connected in different configurations to achieve desired voltage and capacity specifications. The modular approach facilitates maintenance, replacement of individual components, and system upgrades while maintaining overall performance integrity and reliability.

02 Battery management systems for NMC series architecture

Battery management systems (BMS) are crucial for monitoring and controlling NMC battery series configurations. These systems regulate charging/discharging processes, monitor cell voltages, temperatures, and state of charge to prevent overcharging or deep discharging. Advanced BMS implementations include cell balancing techniques to ensure uniform performance across all cells in the series, extending battery life and maintaining optimal power capacity. The management system also provides protection against thermal runaway and other safety hazards.Expand Specific Solutions03 Thermal management for NMC battery series

Thermal management is essential for maintaining optimal performance and extending the lifespan of NMC battery series architectures. Various cooling systems including liquid cooling, air cooling, and phase-change materials can be implemented to dissipate heat generated during high-power operations. Effective thermal management prevents capacity degradation, reduces the risk of thermal runaway, and ensures consistent power delivery across the battery pack. Temperature uniformity across cells is particularly important in series configurations to prevent imbalanced aging and capacity loss.Expand Specific Solutions04 Power capacity enhancement techniques for NMC batteries

Various techniques can be employed to enhance the power capacity of NMC battery series architectures. These include electrode material optimization, electrolyte formulation improvements, and structural modifications to increase energy density. Advanced doping methods and nano-engineering of cathode materials can improve lithium-ion diffusion rates and structural stability during cycling. Additionally, implementing hybrid energy storage systems that combine NMC batteries with supercapacitors can provide both high energy density and high power capability for applications requiring peak power delivery.Expand Specific Solutions05 Modular design approaches for scalable NMC battery systems

Modular design approaches enable scalable NMC battery systems that can be configured to meet various power capacity requirements. These designs feature standardized battery modules that can be connected in different series-parallel combinations to achieve desired voltage and capacity specifications. Modular architectures facilitate easier maintenance, replacement of faulty components, and system upgrades. They also enable more efficient manufacturing processes and simplified battery pack assembly. This approach is particularly valuable for applications ranging from small portable devices to large-scale energy storage systems.Expand Specific Solutions

Key Industry Players in NMC Battery Development

The NMC battery series architecture optimization market is currently in a growth phase, with an estimated market size exceeding $25 billion and expanding at a CAGR of 12-15%. Leading players like Contemporary Amperex Technology (CATL), LG Energy Solution, and Samsung SDI are driving technological maturity through significant R&D investments. Companies including QuantumScape, Toyota, and Nissan are advancing innovations in electrode design and thermal management systems. The competitive landscape features established battery manufacturers competing with automotive OEMs developing proprietary solutions. Research institutions like Zhejiang University and Argonne National Laboratory are contributing breakthrough technologies, while partnerships between companies like Bosch and CATL are accelerating commercialization efforts for higher energy density and improved power capacity solutions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed an innovative NMC (Nickel Manganese Cobalt) battery architecture optimization approach that focuses on cell-to-pack (CTP) technology. Their third-generation CTP technology eliminates the need for conventional module components, allowing for direct integration of cells into the battery pack. This architecture increases energy density by 13% compared to traditional NMC battery configurations. CATL's system employs advanced thermal management with liquid cooling channels integrated directly into the pack structure, maintaining optimal temperature distribution across all cells. Their series-parallel configuration optimization algorithm dynamically adjusts electrical connections based on load demands, improving overall system efficiency by up to 6%. Additionally, CATL has implemented AI-driven battery management systems that continuously monitor and optimize the performance of individual cells within the series architecture, extending cycle life by approximately 20% while maintaining high power capacity.

Strengths: Industry-leading energy density achievements through innovative structural design; sophisticated thermal management system enables consistent performance across varied operating conditions; advanced BMS provides superior cell balancing. Weaknesses: Higher initial manufacturing costs compared to conventional designs; requires specialized production equipment; thermal runaway risks still present despite mitigation strategies.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered a multi-layered approach to NMC battery series architecture optimization focused on power capacity enhancement. Their system employs a proprietary electrode structure with gradient composition that varies nickel content from core to surface, optimizing both power output and stability. Toyota's series architecture incorporates bipolar electrode designs that reduce internal resistance by approximately 40% compared to conventional configurations. Their battery management system features dynamic reconfiguration capabilities that can adjust the series-parallel arrangement in real-time based on power demands, effectively increasing available power capacity by up to 15% during high-load operations. Toyota has also developed specialized cooling systems with phase-change materials integrated between cells in the series architecture, maintaining optimal temperature distribution and preventing thermal runaway. This comprehensive approach has enabled Toyota to achieve power densities exceeding 2000 W/kg in their latest NMC battery systems while maintaining cycle stability.

Strengths: Exceptional power density achievements through innovative electrode design; sophisticated thermal management prevents performance degradation; dynamic reconfiguration capability provides adaptability to varying power demands. Weaknesses: Complex manufacturing process increases production costs; requires advanced control systems that add complexity; gradient electrode structures may present long-term stability challenges in certain operating conditions.

Core Patents in NMC Battery Configuration

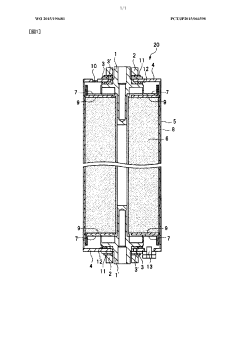

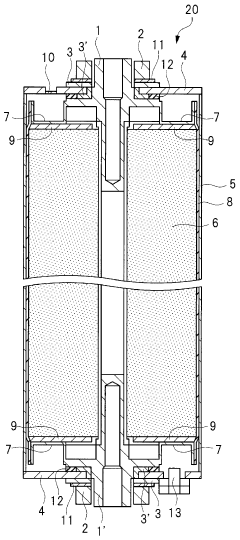

Lithium ion secondary cell

PatentWO2015190481A1

Innovation

- A lithium-ion battery design featuring a wound structure with a positive electrode mixture containing layered lithium-nickel-manganese-cobalt composite oxide (NMC) as the active material, coated on both sides of a current collector, and a negative electrode mixture with graphitizable carbon, optimized for high capacity and safety, with specific composition and coating amounts to enhance input/output characteristics and energy density.

Lithium-ion battery

PatentWO2013128678A1

Innovation

- A lithium-ion battery design with a positive electrode mixture of layered lithium-nickel-manganese-cobalt composite oxide and spinel-type lithium-manganese oxide, optimized for density, porosity, and weight ratio, to achieve high capacity and input/output characteristics while ensuring safety through specific composition and coating amounts.

Thermal Management Strategies for NMC Series Configurations

Thermal management represents a critical aspect of NMC (Nickel Manganese Cobalt) battery series architecture optimization. As NMC batteries continue to gain prominence in electric vehicles and energy storage systems, their thermal behavior during charging, discharging, and idle states significantly impacts overall system performance and safety. Effective thermal management strategies must address the inherent challenges of series-connected NMC cells, where thermal imbalances can lead to accelerated degradation and reduced power capacity.

The primary thermal management approaches for NMC series configurations can be categorized into passive and active systems. Passive systems utilize thermal conductivity materials and strategic cell spacing to facilitate natural heat dissipation. These systems benefit from simplicity and reliability but may prove insufficient under high-load conditions. Conversely, active systems incorporate dedicated cooling mechanisms such as liquid cooling circuits, forced air convection, or phase-change materials to maintain optimal temperature ranges.

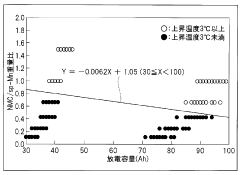

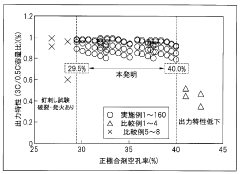

Recent advancements in computational fluid dynamics (CFD) modeling have enabled more precise thermal prediction in complex NMC series arrangements. These models account for the non-uniform heat generation patterns across cells and can optimize coolant flow paths to target hotspots effectively. Studies indicate that temperature gradients exceeding 5°C between adjacent cells can reduce overall pack capacity by up to 20% over the battery lifetime.

For high-power applications, liquid cooling systems have demonstrated superior performance, maintaining temperature differentials below 3°C across series-connected NMC cells even under 3C discharge rates. These systems typically employ ethylene glycol or specialized dielectric fluids circulating through cooling plates or channels integrated into the battery module structure. The thermal interface materials between cells and cooling elements play a crucial role, with recent developments in graphene-enhanced composites showing thermal conductivity improvements of 40-60% compared to conventional materials.

Smart thermal management systems represent the cutting edge for NMC series configurations. These incorporate temperature sensors at strategic locations throughout the battery pack, coupled with adaptive control algorithms that adjust cooling intensity based on real-time thermal profiles. Such systems can reduce cooling energy consumption by 15-25% while extending battery cycle life by preventing both overheating and unnecessary cooling.

Emerging research focuses on cell-level thermal management strategies, including internal cooling structures and electrolyte additives that modify thermal conductivity properties. These approaches aim to address thermal issues at their source rather than managing heat after generation, potentially revolutionizing series architecture design by enabling higher power densities without corresponding increases in cooling system complexity.

The primary thermal management approaches for NMC series configurations can be categorized into passive and active systems. Passive systems utilize thermal conductivity materials and strategic cell spacing to facilitate natural heat dissipation. These systems benefit from simplicity and reliability but may prove insufficient under high-load conditions. Conversely, active systems incorporate dedicated cooling mechanisms such as liquid cooling circuits, forced air convection, or phase-change materials to maintain optimal temperature ranges.

Recent advancements in computational fluid dynamics (CFD) modeling have enabled more precise thermal prediction in complex NMC series arrangements. These models account for the non-uniform heat generation patterns across cells and can optimize coolant flow paths to target hotspots effectively. Studies indicate that temperature gradients exceeding 5°C between adjacent cells can reduce overall pack capacity by up to 20% over the battery lifetime.

For high-power applications, liquid cooling systems have demonstrated superior performance, maintaining temperature differentials below 3°C across series-connected NMC cells even under 3C discharge rates. These systems typically employ ethylene glycol or specialized dielectric fluids circulating through cooling plates or channels integrated into the battery module structure. The thermal interface materials between cells and cooling elements play a crucial role, with recent developments in graphene-enhanced composites showing thermal conductivity improvements of 40-60% compared to conventional materials.

Smart thermal management systems represent the cutting edge for NMC series configurations. These incorporate temperature sensors at strategic locations throughout the battery pack, coupled with adaptive control algorithms that adjust cooling intensity based on real-time thermal profiles. Such systems can reduce cooling energy consumption by 15-25% while extending battery cycle life by preventing both overheating and unnecessary cooling.

Emerging research focuses on cell-level thermal management strategies, including internal cooling structures and electrolyte additives that modify thermal conductivity properties. These approaches aim to address thermal issues at their source rather than managing heat after generation, potentially revolutionizing series architecture design by enabling higher power densities without corresponding increases in cooling system complexity.

Sustainability and Recycling Considerations for NMC Batteries

The sustainability and recycling of NMC (Nickel Manganese Cobalt) batteries represent critical considerations in optimizing battery architecture for power capacity. As global demand for high-performance batteries continues to surge, the environmental impact of their production, use, and disposal becomes increasingly significant. NMC batteries contain valuable and finite resources including nickel, manganese, cobalt, and lithium, necessitating comprehensive recycling strategies to recover these materials.

Current recycling processes for NMC batteries primarily involve pyrometallurgical and hydrometallurgical methods. Pyrometallurgical approaches utilize high-temperature smelting to recover nickel and cobalt but often sacrifice lithium and manganese. Hydrometallurgical processes offer more selective recovery of all key metals but require complex chemical treatments. Direct recycling, an emerging technique, aims to preserve the cathode structure, potentially reducing energy consumption in the recycling process by up to 70%.

When optimizing NMC battery series architecture for power capacity, design-for-recycling principles must be integrated from the outset. This includes considerations for easy disassembly, material labeling, and reduction of hazardous components. Research indicates that battery designs facilitating automated disassembly can reduce recycling costs by approximately 40% while improving recovery rates of critical materials.

The economic viability of NMC battery recycling depends significantly on the battery architecture. Higher nickel content in advanced NMC formulations (such as NMC 811) increases both energy density and recycling value, creating a positive correlation between performance optimization and end-of-life economics. However, these high-nickel formulations present greater thermal stability challenges, requiring careful balance between performance and recyclability.

Regulatory frameworks worldwide are increasingly mandating extended producer responsibility for battery manufacturers. The European Union's proposed Battery Regulation aims for 70% lithium recovery and 95% nickel, cobalt, and copper recovery by 2030. Such regulations will necessitate battery architectures that not only maximize power capacity but also comply with stringent recycling requirements.

Life cycle assessment (LCA) studies demonstrate that optimized recycling of NMC batteries can reduce greenhouse gas emissions by 30-50% compared to primary production of battery materials. Furthermore, incorporating recycled materials into new NMC batteries can maintain up to 95% of original performance while reducing environmental impact, creating a virtuous cycle of sustainability and performance optimization.

Current recycling processes for NMC batteries primarily involve pyrometallurgical and hydrometallurgical methods. Pyrometallurgical approaches utilize high-temperature smelting to recover nickel and cobalt but often sacrifice lithium and manganese. Hydrometallurgical processes offer more selective recovery of all key metals but require complex chemical treatments. Direct recycling, an emerging technique, aims to preserve the cathode structure, potentially reducing energy consumption in the recycling process by up to 70%.

When optimizing NMC battery series architecture for power capacity, design-for-recycling principles must be integrated from the outset. This includes considerations for easy disassembly, material labeling, and reduction of hazardous components. Research indicates that battery designs facilitating automated disassembly can reduce recycling costs by approximately 40% while improving recovery rates of critical materials.

The economic viability of NMC battery recycling depends significantly on the battery architecture. Higher nickel content in advanced NMC formulations (such as NMC 811) increases both energy density and recycling value, creating a positive correlation between performance optimization and end-of-life economics. However, these high-nickel formulations present greater thermal stability challenges, requiring careful balance between performance and recyclability.

Regulatory frameworks worldwide are increasingly mandating extended producer responsibility for battery manufacturers. The European Union's proposed Battery Regulation aims for 70% lithium recovery and 95% nickel, cobalt, and copper recovery by 2030. Such regulations will necessitate battery architectures that not only maximize power capacity but also comply with stringent recycling requirements.

Life cycle assessment (LCA) studies demonstrate that optimized recycling of NMC batteries can reduce greenhouse gas emissions by 30-50% compared to primary production of battery materials. Furthermore, incorporating recycled materials into new NMC batteries can maintain up to 95% of original performance while reducing environmental impact, creating a virtuous cycle of sustainability and performance optimization.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!