Benchmark NMC Battery Mechanisms for Compliance in EVs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Evolution and Performance Targets

Nickel Manganese Cobalt (NMC) battery technology has evolved significantly since its introduction in the early 2000s, establishing itself as a dominant chemistry in electric vehicle (EV) applications. The evolution trajectory has been characterized by progressive improvements in energy density, cycle life, and safety parameters, with each generation addressing specific limitations of its predecessors.

The first-generation NMC111 (equal parts nickel, manganese, and cobalt) offered balanced performance but limited energy density. Subsequent iterations have strategically increased nickel content while reducing costly and ethically problematic cobalt, leading to NMC532, NMC622, and the current mainstream NMC811 formulations. This evolution has delivered approximately 50% improvement in specific energy capacity, from ~160 Wh/kg to ~240 Wh/kg at the cell level.

Performance targets for NMC batteries in EVs are increasingly stringent as the market matures. Current benchmarks demand energy densities exceeding 250 Wh/kg at the cell level and 750 Wh/L volumetrically, with next-generation targets pushing toward 300 Wh/kg to enable 500+ km range vehicles without significant battery weight penalties.

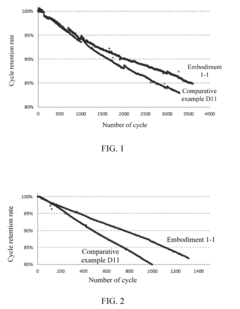

Cycle life requirements have similarly intensified, with current standards requiring 1,000+ full cycles while maintaining at least 80% capacity retention. Premium EV manufacturers are now targeting 1,500-2,000 cycles to support battery warranties extending to 8-10 years or 150,000+ kilometers. This longevity metric directly impacts total cost of ownership calculations that remain critical for EV adoption.

Fast-charging capability represents another crucial performance target, with current benchmarks requiring 80% charge in 30 minutes. Industry leaders are pushing toward 15-minute charging capabilities without compromising battery longevity, necessitating innovations in electrode design and thermal management systems.

Safety performance targets have become increasingly stringent following high-profile thermal runaway incidents. Current compliance standards require NMC batteries to withstand nail penetration, crush, and overcharge tests without catastrophic failure. The industry is moving toward inherently safer chemistries with higher thermal runaway onset temperatures (>200°C) and reduced exothermic reaction severity.

Cost targets remain perhaps the most challenging benchmark, with current industry goals set at $100/kWh at the pack level—a threshold widely considered necessary for price parity with internal combustion vehicles. Leading manufacturers have achieved approximately $130-140/kWh, with further reductions dependent on manufacturing scale, material innovations, and supply chain optimization.

These evolving performance targets are driving research into advanced NMC variants, including concentration-gradient cathodes, silicon-composite anodes, and solid-state electrolyte integration—all aimed at simultaneously addressing multiple performance benchmarks while maintaining compliance with increasingly stringent regulatory frameworks.

The first-generation NMC111 (equal parts nickel, manganese, and cobalt) offered balanced performance but limited energy density. Subsequent iterations have strategically increased nickel content while reducing costly and ethically problematic cobalt, leading to NMC532, NMC622, and the current mainstream NMC811 formulations. This evolution has delivered approximately 50% improvement in specific energy capacity, from ~160 Wh/kg to ~240 Wh/kg at the cell level.

Performance targets for NMC batteries in EVs are increasingly stringent as the market matures. Current benchmarks demand energy densities exceeding 250 Wh/kg at the cell level and 750 Wh/L volumetrically, with next-generation targets pushing toward 300 Wh/kg to enable 500+ km range vehicles without significant battery weight penalties.

Cycle life requirements have similarly intensified, with current standards requiring 1,000+ full cycles while maintaining at least 80% capacity retention. Premium EV manufacturers are now targeting 1,500-2,000 cycles to support battery warranties extending to 8-10 years or 150,000+ kilometers. This longevity metric directly impacts total cost of ownership calculations that remain critical for EV adoption.

Fast-charging capability represents another crucial performance target, with current benchmarks requiring 80% charge in 30 minutes. Industry leaders are pushing toward 15-minute charging capabilities without compromising battery longevity, necessitating innovations in electrode design and thermal management systems.

Safety performance targets have become increasingly stringent following high-profile thermal runaway incidents. Current compliance standards require NMC batteries to withstand nail penetration, crush, and overcharge tests without catastrophic failure. The industry is moving toward inherently safer chemistries with higher thermal runaway onset temperatures (>200°C) and reduced exothermic reaction severity.

Cost targets remain perhaps the most challenging benchmark, with current industry goals set at $100/kWh at the pack level—a threshold widely considered necessary for price parity with internal combustion vehicles. Leading manufacturers have achieved approximately $130-140/kWh, with further reductions dependent on manufacturing scale, material innovations, and supply chain optimization.

These evolving performance targets are driving research into advanced NMC variants, including concentration-gradient cathodes, silicon-composite anodes, and solid-state electrolyte integration—all aimed at simultaneously addressing multiple performance benchmarks while maintaining compliance with increasingly stringent regulatory frameworks.

EV Market Demand for Advanced Battery Technologies

The electric vehicle (EV) market has witnessed unprecedented growth over the past decade, driving substantial demand for advanced battery technologies. Global EV sales surpassed 10 million units in 2022, representing a 55% increase from the previous year. This rapid market expansion has created an urgent need for batteries that deliver superior performance, longer range, and enhanced safety profiles.

NMC (Nickel Manganese Cobalt) batteries have emerged as a preferred chemistry for many EV manufacturers due to their balanced performance characteristics. Market research indicates that approximately 70% of current EV models utilize some variant of NMC chemistry. This dominance stems from NMC's ability to deliver higher energy density compared to earlier lithium-ion formulations while maintaining reasonable cost structures.

Consumer expectations are increasingly shaping battery technology requirements. Range anxiety remains a primary concern, with surveys showing that 80% of potential EV buyers consider driving range as a critical purchase factor. This has pushed manufacturers to prioritize energy density improvements in NMC formulations, with each generation (NMC 111, 532, 622, 811) offering incremental gains in vehicle range capabilities.

Regulatory frameworks across major markets are simultaneously driving demand for advanced battery technologies. The European Union's stringent CO2 emission targets for vehicle fleets have accelerated EV adoption, while China's dual-credit policy system has created strong incentives for manufacturers to improve battery performance. In North America, evolving CAFE standards and state-level zero-emission vehicle mandates are similarly influencing battery technology requirements.

Safety compliance represents another critical market driver. High-profile thermal runaway incidents have heightened consumer awareness of battery safety issues. Consequently, demand has grown for NMC variants with improved thermal stability profiles, even at the expense of marginal energy density trade-offs. This has accelerated research into modified NMC cathode structures and advanced battery management systems.

Cost considerations remain paramount in the competitive EV landscape. While early adopters demonstrated willingness to pay premium prices, mass-market penetration requires battery pack costs below $100/kWh. This threshold has driven innovation in NMC manufacturing processes, with particular focus on reducing cobalt content due to both cost and ethical sourcing concerns.

The sustainability dimension has emerged as an increasingly important market factor. Consumers and regulators are demanding batteries with reduced environmental footprints, longer lifespans, and improved recyclability. This has created market pull for NMC formulations that not only deliver performance but also address end-of-life considerations through improved material recovery pathways.

NMC (Nickel Manganese Cobalt) batteries have emerged as a preferred chemistry for many EV manufacturers due to their balanced performance characteristics. Market research indicates that approximately 70% of current EV models utilize some variant of NMC chemistry. This dominance stems from NMC's ability to deliver higher energy density compared to earlier lithium-ion formulations while maintaining reasonable cost structures.

Consumer expectations are increasingly shaping battery technology requirements. Range anxiety remains a primary concern, with surveys showing that 80% of potential EV buyers consider driving range as a critical purchase factor. This has pushed manufacturers to prioritize energy density improvements in NMC formulations, with each generation (NMC 111, 532, 622, 811) offering incremental gains in vehicle range capabilities.

Regulatory frameworks across major markets are simultaneously driving demand for advanced battery technologies. The European Union's stringent CO2 emission targets for vehicle fleets have accelerated EV adoption, while China's dual-credit policy system has created strong incentives for manufacturers to improve battery performance. In North America, evolving CAFE standards and state-level zero-emission vehicle mandates are similarly influencing battery technology requirements.

Safety compliance represents another critical market driver. High-profile thermal runaway incidents have heightened consumer awareness of battery safety issues. Consequently, demand has grown for NMC variants with improved thermal stability profiles, even at the expense of marginal energy density trade-offs. This has accelerated research into modified NMC cathode structures and advanced battery management systems.

Cost considerations remain paramount in the competitive EV landscape. While early adopters demonstrated willingness to pay premium prices, mass-market penetration requires battery pack costs below $100/kWh. This threshold has driven innovation in NMC manufacturing processes, with particular focus on reducing cobalt content due to both cost and ethical sourcing concerns.

The sustainability dimension has emerged as an increasingly important market factor. Consumers and regulators are demanding batteries with reduced environmental footprints, longer lifespans, and improved recyclability. This has created market pull for NMC formulations that not only deliver performance but also address end-of-life considerations through improved material recovery pathways.

Current Limitations and Technical Challenges of NMC Batteries

Despite significant advancements in NMC (Nickel Manganese Cobalt) battery technology, several critical limitations and technical challenges persist that impact their widespread adoption in electric vehicles (EVs). Energy density constraints remain a primary concern, with current NMC formulations achieving 250-300 Wh/kg, falling short of the 400+ Wh/kg threshold needed for next-generation EVs with extended range capabilities. This limitation directly affects vehicle range and performance expectations in competitive markets.

Thermal stability presents another significant challenge, particularly in high-nickel content variants (NMC 811, NMC 622) which offer improved energy density but demonstrate compromised thermal safety profiles. These formulations exhibit lower onset temperatures for thermal runaway (approximately 180-200°C compared to 220-240°C in more stable variants), creating substantial engineering challenges for battery management systems.

Cycle life degradation manifests through multiple mechanisms including structural instability at the cathode-electrolyte interface, transition metal dissolution, and lithium inventory loss. Current NMC batteries typically deliver 1,000-1,500 cycles before capacity falls below 80% of initial ratings—insufficient for the 8-10 year/150,000+ mile warranty expectations in premium EV markets.

Fast charging capabilities remain constrained by lithium plating risks and accelerated degradation mechanisms. Most commercial NMC systems can safely handle only 1-1.5C charging rates without significant lifetime impact, whereas market expectations increasingly demand 3C+ rates for 15-minute charging sessions.

Cost factors continue to challenge mass-market adoption, with current NMC cathode materials contributing approximately $35-45/kWh to overall battery costs. The nickel and cobalt supply chains introduce significant price volatility and geopolitical dependencies, with cobalt particularly problematic due to concentration in politically unstable regions and ethical mining concerns.

Manufacturing scalability faces challenges in quality control and consistency across high-volume production. Precise control of particle morphology, size distribution, and elemental homogeneity remains difficult to maintain at industrial scales, resulting in performance variations between cells and batches.

Low-temperature performance degradation presents another barrier, with typical capacity retention dropping to 50-70% at -20°C compared to room temperature operation. This limitation significantly impacts consumer confidence in cold-climate regions and requires oversizing battery packs to compensate.

Regulatory compliance challenges are increasing as safety standards evolve, particularly regarding thermal propagation prevention, off-gassing management during failure modes, and end-of-life recycling requirements that demand design modifications and additional control systems.

Thermal stability presents another significant challenge, particularly in high-nickel content variants (NMC 811, NMC 622) which offer improved energy density but demonstrate compromised thermal safety profiles. These formulations exhibit lower onset temperatures for thermal runaway (approximately 180-200°C compared to 220-240°C in more stable variants), creating substantial engineering challenges for battery management systems.

Cycle life degradation manifests through multiple mechanisms including structural instability at the cathode-electrolyte interface, transition metal dissolution, and lithium inventory loss. Current NMC batteries typically deliver 1,000-1,500 cycles before capacity falls below 80% of initial ratings—insufficient for the 8-10 year/150,000+ mile warranty expectations in premium EV markets.

Fast charging capabilities remain constrained by lithium plating risks and accelerated degradation mechanisms. Most commercial NMC systems can safely handle only 1-1.5C charging rates without significant lifetime impact, whereas market expectations increasingly demand 3C+ rates for 15-minute charging sessions.

Cost factors continue to challenge mass-market adoption, with current NMC cathode materials contributing approximately $35-45/kWh to overall battery costs. The nickel and cobalt supply chains introduce significant price volatility and geopolitical dependencies, with cobalt particularly problematic due to concentration in politically unstable regions and ethical mining concerns.

Manufacturing scalability faces challenges in quality control and consistency across high-volume production. Precise control of particle morphology, size distribution, and elemental homogeneity remains difficult to maintain at industrial scales, resulting in performance variations between cells and batches.

Low-temperature performance degradation presents another barrier, with typical capacity retention dropping to 50-70% at -20°C compared to room temperature operation. This limitation significantly impacts consumer confidence in cold-climate regions and requires oversizing battery packs to compensate.

Regulatory compliance challenges are increasing as safety standards evolve, particularly regarding thermal propagation prevention, off-gassing management during failure modes, and end-of-life recycling requirements that demand design modifications and additional control systems.

Benchmark Methodologies for NMC Battery Performance

01 Safety compliance mechanisms for NMC batteries

Various safety compliance mechanisms are implemented in NMC (Nickel Manganese Cobalt) batteries to prevent hazards such as overheating, explosion, or fire. These mechanisms include thermal management systems, pressure relief designs, and protective circuitry that monitor battery conditions. Safety standards compliance ensures that NMC batteries meet international regulations for transportation, storage, and operation under various environmental conditions.- Safety and thermal management systems for NMC batteries: NMC batteries require robust safety mechanisms to prevent thermal runaway and ensure safe operation. These systems include temperature monitoring sensors, cooling systems, and thermal insulation materials. Advanced compliance mechanisms involve the integration of battery management systems that can detect abnormal temperature rises and activate protective measures such as current limitation or emergency shutdown. These safety features are essential for meeting international safety standards and regulations for lithium-ion batteries containing nickel, manganese, and cobalt.

- Structural design and mechanical compliance mechanisms: The structural integrity of NMC batteries is crucial for compliance with mechanical stress requirements. This includes designs that accommodate cell expansion during charging/discharging cycles and protective housings that prevent physical damage. Compliance mechanisms involve flexible interconnects between cells, shock-absorbing materials, and reinforced casings. These structural elements ensure the battery can withstand vibration, impact, and pressure changes while maintaining electrical performance and safety standards required by automotive and industrial applications.

- Electrical compliance and battery management systems: Electrical compliance mechanisms for NMC batteries include sophisticated battery management systems that monitor and control voltage, current, and state of charge. These systems ensure the battery operates within safe electrical parameters and complies with electrical safety standards. Key components include voltage regulators, current limiters, and protection circuits that prevent overcharging and deep discharging. Advanced systems incorporate cell balancing technology to maximize battery life and performance while maintaining compliance with electrical safety regulations.

- Environmental and recycling compliance frameworks: Environmental compliance for NMC batteries encompasses manufacturing standards, usage guidelines, and end-of-life management protocols. These mechanisms include systems for reducing toxic emissions during production, ensuring proper disposal, and facilitating the recycling of valuable materials like nickel, manganese, and cobalt. Compliance frameworks involve tracking systems for battery components, environmentally friendly manufacturing processes, and recycling technologies that recover critical materials while minimizing environmental impact, in accordance with international environmental regulations.

- Quality control and certification compliance processes: Quality control mechanisms for NMC batteries involve comprehensive testing protocols and certification processes to ensure compliance with international standards. These include capacity testing, cycle life verification, and performance validation under various conditions. Compliance processes incorporate quality management systems throughout the manufacturing chain, from raw material sourcing to final assembly. Certification procedures verify that batteries meet industry standards for performance, safety, and reliability, with documentation systems that track compliance throughout the battery lifecycle.

02 Environmental and recycling compliance for NMC batteries

Environmental compliance mechanisms for NMC batteries focus on sustainable production, reduced toxic materials usage, and end-of-life management. These include recycling protocols for recovering valuable metals like nickel, manganese, and cobalt, reducing environmental impact. Manufacturers implement systems to comply with regulations such as RoHS, REACH, and regional battery directives that govern the collection, recycling, and disposal of battery materials.Expand Specific Solutions03 Manufacturing quality control compliance for NMC batteries

Quality control compliance mechanisms ensure NMC batteries meet performance and safety specifications during manufacturing. These include automated inspection systems, material purity verification, electrode coating uniformity checks, and cell assembly precision monitoring. Manufacturers implement statistical process control, batch testing, and certification procedures to maintain consistent quality and comply with industry standards like ISO 9001 and battery-specific quality management systems.Expand Specific Solutions04 Electrical performance compliance for NMC batteries

Electrical performance compliance mechanisms ensure NMC batteries meet specified capacity, voltage, charge/discharge rates, and cycle life requirements. These include testing protocols for capacity verification, internal resistance measurement, self-discharge rate assessment, and cycle life validation. Advanced battery management systems monitor cell balancing, temperature distribution, and voltage regulation to maintain performance within compliance parameters throughout the battery lifecycle.Expand Specific Solutions05 Transportation and storage compliance for NMC batteries

Transportation and storage compliance mechanisms address the safe movement and warehousing of NMC batteries across global supply chains. These include specialized packaging requirements, state-of-charge limitations during shipping, temperature-controlled environments, and proper labeling according to hazardous materials regulations. Compliance systems track battery shipments, maintain chain of custody documentation, and ensure adherence to international air transport regulations (IATA), maritime shipping codes (IMDG), and regional transportation safety standards.Expand Specific Solutions

Key Industry Players in NMC Battery Manufacturing

The NMC battery market for EVs is in a growth phase characterized by rapid technological advancement and increasing adoption. The global market size is expanding significantly, driven by the EV industry's accelerated growth and stringent emissions regulations. Technologically, NMC batteries are reaching maturity with companies like CATL, Hyundai, and NIO leading innovation in energy density and thermal stability improvements. State Grid Corp. of China and Bosch are developing advanced battery management systems, while automotive manufacturers including Daimler Truck, Rivian, and Changan New Energy are integrating NMC technology into their EV platforms. Research institutions like Hefei University of Technology and Shandong University are collaborating with industry players to address compliance challenges related to safety standards, performance optimization, and sustainable manufacturing processes.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed advanced NMC (Nickel Manganese Cobalt) battery technologies specifically designed for EV compliance requirements. Their NMC 811 chemistry (80% nickel, 10% manganese, 10% cobalt) represents their flagship solution, offering energy densities exceeding 300 Wh/kg. CATL implements a multi-layer safety mechanism including thermal propagation prevention technology that isolates cells to prevent cascading thermal events. Their Cell-to-Pack (CTP) technology eliminates module components, increasing energy density by 15-20% while improving compliance with safety regulations. CATL's battery management system continuously monitors cell parameters and can detect potential failures before they occur, meeting stringent automotive safety standards. Their NMC batteries undergo rigorous testing protocols including nail penetration tests, crush tests, and overcharging scenarios to ensure compliance with international standards such as UN38.3, IEC62133, and GB/T 31485.

Strengths: Industry-leading energy density with reduced cobalt content, lowering costs while maintaining performance. Advanced thermal management systems provide superior safety compliance. Weaknesses: Higher nickel content can lead to thermal stability challenges requiring more sophisticated cooling systems, potentially increasing system complexity and cost.

Robert Bosch GmbH

Technical Solution: Bosch has developed comprehensive NMC battery systems focusing on compliance through advanced manufacturing processes and control systems rather than just cell chemistry. Their approach includes precision laser welding techniques for cell connections that reduce resistance variations to below 5%, ensuring consistent performance across production batches. Bosch's battery management system features redundant monitoring channels and sophisticated algorithms that can detect internal short circuits before they become critical failures. Their NMC battery packs incorporate a modular design with standardized interfaces that simplify compliance testing and certification across different vehicle platforms. Bosch has implemented a multi-stage quality control process including automated optical inspection, impedance spectroscopy testing, and thermal imaging to identify potential defects that could affect compliance. Their battery systems undergo extensive electromagnetic compatibility (EMC) testing to ensure they meet international standards for electromagnetic emissions and immunity, a critical aspect of regulatory compliance often overlooked by competitors.

Strengths: Industry-leading manufacturing precision and quality control processes ensure exceptional consistency across production units. Comprehensive EMC compliance testing addresses regulatory requirements beyond just safety and performance. Weaknesses: More conservative approach to energy density optimization compared to some pure EV manufacturers, reflecting their position as a tier-one supplier rather than an end-product manufacturer.

Critical Patents and Research in NMC Battery Technology

Positive electrode material for li-ion battery, method for preparing the same, and li-ion power battery containing the same

PatentActiveUS20180090753A1

Innovation

- A positive electrode material for Li-ion batteries is developed, comprising a substrate material with a boron-based coating layer, where the substrate material is a combination of large and small particles with specific size ratios and nickel content, and the coating layer is made of B2O3, improving pellet density and reducing direct current resistance.

Cathode active material for lithium secondary battery, and lithium secondary battery comprising same

PatentActiveUS20220093920A1

Innovation

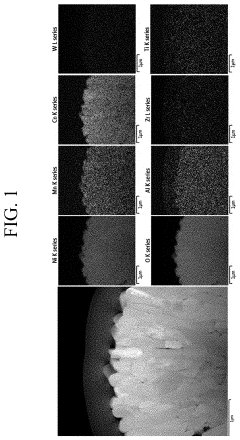

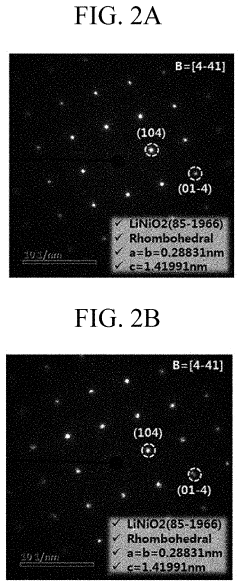

- A positive active material for lithium secondary batteries is developed, incorporating lithium, nickel, cobalt, manganese, and doping elements such as Zr, Al, and Ti, with specific doping ratios, which are integrated into the material's structure to stabilize the crystal structure and reduce ion mixing, thereby enhancing electrochemical characteristics and thermal stability.

Regulatory Compliance Framework for EV Batteries

The regulatory landscape for electric vehicle (EV) batteries is complex and multifaceted, encompassing international, national, and regional frameworks that manufacturers must navigate. For NMC (Nickel Manganese Cobalt) batteries specifically, compliance requirements focus on safety, performance, environmental impact, and end-of-life management. Key international standards include UN GTR No. 20 for electric vehicle safety, ISO 6469 series for electrically propelled road vehicles, and IEC 62660 for secondary lithium-ion cells for EV propulsion.

At the national level, significant variations exist in regulatory approaches. The European Union implements the Battery Directive (2006/66/EC) and its recent update, the Battery Regulation (2023), which introduces stringent requirements for carbon footprint declarations, recycled content, and due diligence in battery supply chains. The United States relies on standards from organizations like SAE International and UL, with Federal Motor Vehicle Safety Standards (FMVSS) providing overarching safety requirements.

China, as the world's largest EV market, has established GB/T standards specific to power batteries, with GB/T 31484, 31485, and 31486 addressing performance, safety, and reliability requirements. These standards are increasingly influential in global markets due to China's manufacturing dominance.

Testing protocols for NMC batteries are particularly rigorous, requiring validation under extreme conditions. These include thermal runaway tests, mechanical abuse tests (crush, penetration, drop), electrical abuse tests (overcharge, short circuit), and environmental tests (temperature cycling, humidity, vibration). The UN Manual of Tests and Criteria, specifically Test Series T, outlines transportation safety requirements that all lithium-ion batteries must meet.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches, with increasing focus on battery passport systems that track materials from mining through recycling. The EU's Battery Regulation pioneers this approach, requiring digital battery passports by 2026. Additionally, regulations are evolving to address specific characteristics of NMC chemistry, including thermal stability concerns and the use of critical raw materials like cobalt and nickel.

For EV manufacturers, compliance strategies must be proactive rather than reactive, incorporating regulatory requirements into early design phases. This includes establishing robust battery management systems (BMS) that monitor cell performance and safety parameters, implementing comprehensive testing programs that exceed minimum requirements, and developing transparent supply chain documentation systems that can adapt to evolving disclosure requirements.

At the national level, significant variations exist in regulatory approaches. The European Union implements the Battery Directive (2006/66/EC) and its recent update, the Battery Regulation (2023), which introduces stringent requirements for carbon footprint declarations, recycled content, and due diligence in battery supply chains. The United States relies on standards from organizations like SAE International and UL, with Federal Motor Vehicle Safety Standards (FMVSS) providing overarching safety requirements.

China, as the world's largest EV market, has established GB/T standards specific to power batteries, with GB/T 31484, 31485, and 31486 addressing performance, safety, and reliability requirements. These standards are increasingly influential in global markets due to China's manufacturing dominance.

Testing protocols for NMC batteries are particularly rigorous, requiring validation under extreme conditions. These include thermal runaway tests, mechanical abuse tests (crush, penetration, drop), electrical abuse tests (overcharge, short circuit), and environmental tests (temperature cycling, humidity, vibration). The UN Manual of Tests and Criteria, specifically Test Series T, outlines transportation safety requirements that all lithium-ion batteries must meet.

Emerging regulatory trends indicate a shift toward lifecycle assessment approaches, with increasing focus on battery passport systems that track materials from mining through recycling. The EU's Battery Regulation pioneers this approach, requiring digital battery passports by 2026. Additionally, regulations are evolving to address specific characteristics of NMC chemistry, including thermal stability concerns and the use of critical raw materials like cobalt and nickel.

For EV manufacturers, compliance strategies must be proactive rather than reactive, incorporating regulatory requirements into early design phases. This includes establishing robust battery management systems (BMS) that monitor cell performance and safety parameters, implementing comprehensive testing programs that exceed minimum requirements, and developing transparent supply chain documentation systems that can adapt to evolving disclosure requirements.

Sustainability and Lifecycle Analysis of NMC Batteries

The sustainability assessment of NMC (Nickel Manganese Cobalt) batteries reveals significant environmental implications throughout their lifecycle. From raw material extraction to end-of-life management, these batteries present both challenges and opportunities for sustainable development in the electric vehicle (EV) industry.

Material sourcing represents a critical sustainability concern, particularly regarding cobalt extraction, which is often associated with ethical issues including child labor and unsafe working conditions in regions like the Democratic Republic of Congo. Nickel mining also contributes to substantial environmental degradation through deforestation, soil erosion, and water pollution. These extraction processes generate considerable carbon emissions, undermining the environmental benefits of EVs.

Manufacturing NMC batteries is energy-intensive, with production facilities consuming large amounts of electricity and water. Studies indicate that battery production can account for up to 40% of an EV's total carbon footprint. However, advancements in manufacturing efficiency and increased use of renewable energy in production facilities are gradually reducing this environmental impact.

During the operational phase, NMC batteries demonstrate superior environmental performance compared to internal combustion engines. The carbon footprint of these batteries decreases significantly when charged with renewable energy sources, highlighting the importance of clean electricity generation in maximizing sustainability benefits.

End-of-life management presents both challenges and opportunities. Currently, only about 5% of lithium-ion batteries are recycled globally, with the remainder often ending up in landfills. However, emerging recycling technologies show promise in recovering valuable materials like cobalt, nickel, and lithium, potentially reducing the need for virgin material extraction and associated environmental impacts.

Life Cycle Assessment (LCA) studies indicate that NMC batteries typically achieve carbon payback within 1-2 years of EV operation compared to conventional vehicles, depending on the electricity mix used for charging. This favorable carbon balance improves as battery technology advances and renewable energy penetration increases in power grids worldwide.

The industry is actively pursuing sustainability improvements through several pathways: reducing cobalt content in NMC formulations, developing closed-loop recycling systems, extending battery lifespans through improved battery management systems, and exploring second-life applications for batteries that no longer meet EV performance requirements but remain suitable for stationary energy storage.

Regulatory frameworks are evolving globally to address sustainability concerns, with the EU's proposed Battery Regulation establishing requirements for carbon footprint declarations, recycled content, and extended producer responsibility. These regulations are expected to drive further improvements in the environmental performance of NMC batteries across their entire lifecycle.

Material sourcing represents a critical sustainability concern, particularly regarding cobalt extraction, which is often associated with ethical issues including child labor and unsafe working conditions in regions like the Democratic Republic of Congo. Nickel mining also contributes to substantial environmental degradation through deforestation, soil erosion, and water pollution. These extraction processes generate considerable carbon emissions, undermining the environmental benefits of EVs.

Manufacturing NMC batteries is energy-intensive, with production facilities consuming large amounts of electricity and water. Studies indicate that battery production can account for up to 40% of an EV's total carbon footprint. However, advancements in manufacturing efficiency and increased use of renewable energy in production facilities are gradually reducing this environmental impact.

During the operational phase, NMC batteries demonstrate superior environmental performance compared to internal combustion engines. The carbon footprint of these batteries decreases significantly when charged with renewable energy sources, highlighting the importance of clean electricity generation in maximizing sustainability benefits.

End-of-life management presents both challenges and opportunities. Currently, only about 5% of lithium-ion batteries are recycled globally, with the remainder often ending up in landfills. However, emerging recycling technologies show promise in recovering valuable materials like cobalt, nickel, and lithium, potentially reducing the need for virgin material extraction and associated environmental impacts.

Life Cycle Assessment (LCA) studies indicate that NMC batteries typically achieve carbon payback within 1-2 years of EV operation compared to conventional vehicles, depending on the electricity mix used for charging. This favorable carbon balance improves as battery technology advances and renewable energy penetration increases in power grids worldwide.

The industry is actively pursuing sustainability improvements through several pathways: reducing cobalt content in NMC formulations, developing closed-loop recycling systems, extending battery lifespans through improved battery management systems, and exploring second-life applications for batteries that no longer meet EV performance requirements but remain suitable for stationary energy storage.

Regulatory frameworks are evolving globally to address sustainability concerns, with the EU's proposed Battery Regulation establishing requirements for carbon footprint declarations, recycled content, and extended producer responsibility. These regulations are expected to drive further improvements in the environmental performance of NMC batteries across their entire lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!