Benchmark NMC Battery Energy Management Systems

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Technology Evolution and Objectives

Nickel Manganese Cobalt (NMC) battery technology has evolved significantly since its introduction in the early 2000s, establishing itself as a dominant chemistry in the lithium-ion battery landscape. The evolution began with first-generation NMC111 (equal parts nickel, manganese, and cobalt), which offered improved thermal stability compared to earlier lithium cobalt oxide (LCO) batteries while maintaining reasonable energy density. This initial formulation provided a foundation for subsequent advancements in the field.

The technological trajectory has been primarily driven by the strategic reduction of cobalt content while increasing nickel proportion, resulting in the development of NMC532, NMC622, and most recently NMC811 formulations. This evolution addresses both economic and ethical concerns related to cobalt mining while simultaneously enhancing energy density capabilities. Each generation has demonstrated approximately 5-10% improvement in specific energy capacity, with modern NMC811 batteries achieving over 200 Wh/kg at the cell level.

Parallel to material composition advancements, significant progress has occurred in manufacturing processes, electrode design, and electrolyte formulations. Innovations in silicon-doping of anodes, advanced coating technologies for cathodes, and the implementation of single-crystal structures have collectively contributed to enhanced cycle life, improved rate capability, and better thermal management characteristics of NMC batteries.

The primary technical objectives for NMC battery development center around five key parameters: energy density, power density, cycle life, safety, and cost. Current research aims to push energy density beyond 300 Wh/kg at the cell level while maintaining cycle life of 1,000+ cycles at 80% depth of discharge. Safety enhancement remains paramount, with focus on reducing thermal runaway risks through advanced battery management systems and improved cell design.

Cost reduction represents another critical objective, with industry targets of below $100/kWh at the pack level to achieve price parity with internal combustion vehicles. This necessitates innovations in manufacturing efficiency, material sourcing, and recycling technologies to create sustainable supply chains.

The evolution of NMC battery technology is increasingly intertwined with advancements in battery management systems (BMS). Modern BMS architectures must adapt to the specific characteristics of different NMC formulations, particularly regarding voltage profiles, thermal behavior, and aging mechanisms. The integration of artificial intelligence and machine learning algorithms into BMS represents the cutting edge of technology development, enabling predictive maintenance, adaptive charging protocols, and enhanced state-of-health estimation.

Looking forward, the technological roadmap for NMC batteries includes exploration of cobalt-free variants, solid-state electrolyte integration, and advanced manufacturing techniques such as dry electrode processing. These developments aim to address the persistent challenges of energy density, safety, and sustainability that will define the next generation of energy storage solutions.

The technological trajectory has been primarily driven by the strategic reduction of cobalt content while increasing nickel proportion, resulting in the development of NMC532, NMC622, and most recently NMC811 formulations. This evolution addresses both economic and ethical concerns related to cobalt mining while simultaneously enhancing energy density capabilities. Each generation has demonstrated approximately 5-10% improvement in specific energy capacity, with modern NMC811 batteries achieving over 200 Wh/kg at the cell level.

Parallel to material composition advancements, significant progress has occurred in manufacturing processes, electrode design, and electrolyte formulations. Innovations in silicon-doping of anodes, advanced coating technologies for cathodes, and the implementation of single-crystal structures have collectively contributed to enhanced cycle life, improved rate capability, and better thermal management characteristics of NMC batteries.

The primary technical objectives for NMC battery development center around five key parameters: energy density, power density, cycle life, safety, and cost. Current research aims to push energy density beyond 300 Wh/kg at the cell level while maintaining cycle life of 1,000+ cycles at 80% depth of discharge. Safety enhancement remains paramount, with focus on reducing thermal runaway risks through advanced battery management systems and improved cell design.

Cost reduction represents another critical objective, with industry targets of below $100/kWh at the pack level to achieve price parity with internal combustion vehicles. This necessitates innovations in manufacturing efficiency, material sourcing, and recycling technologies to create sustainable supply chains.

The evolution of NMC battery technology is increasingly intertwined with advancements in battery management systems (BMS). Modern BMS architectures must adapt to the specific characteristics of different NMC formulations, particularly regarding voltage profiles, thermal behavior, and aging mechanisms. The integration of artificial intelligence and machine learning algorithms into BMS represents the cutting edge of technology development, enabling predictive maintenance, adaptive charging protocols, and enhanced state-of-health estimation.

Looking forward, the technological roadmap for NMC batteries includes exploration of cobalt-free variants, solid-state electrolyte integration, and advanced manufacturing techniques such as dry electrode processing. These developments aim to address the persistent challenges of energy density, safety, and sustainability that will define the next generation of energy storage solutions.

Market Analysis for NMC Battery Management Systems

The global market for NMC (Nickel Manganese Cobalt) Battery Management Systems has experienced significant growth in recent years, primarily driven by the expanding electric vehicle (EV) sector and increasing adoption of renewable energy storage solutions. Current market valuations indicate that the NMC battery management systems market reached approximately 5.8 billion USD in 2022, with projections suggesting a compound annual growth rate (CAGR) of 15-18% through 2030.

The automotive sector represents the largest application segment, accounting for nearly 62% of the total market share. This dominance stems from the superior energy density and thermal stability of NMC batteries compared to other lithium-ion variants, making them particularly suitable for EV applications where range and safety are paramount concerns. Major automotive manufacturers including Tesla, Volkswagen Group, and BYD have significantly increased their investments in NMC battery technology and associated management systems.

Consumer electronics constitutes the second-largest market segment at approximately 21%, where the demand for longer battery life and faster charging capabilities continues to drive innovation in battery management systems. The remaining market share is distributed across industrial applications, grid storage solutions, and emerging applications in aerospace and marine sectors.

Geographically, Asia-Pacific dominates the market landscape, representing approximately 48% of global demand. This regional strength is attributed to the concentration of battery manufacturing facilities in China, South Korea, and Japan, coupled with aggressive government policies promoting electric mobility. North America and Europe follow with market shares of 27% and 22% respectively, with both regions showing accelerated growth rates due to stringent emission regulations and substantial investments in clean energy infrastructure.

Key market drivers include the declining cost of lithium-ion batteries, which has decreased by approximately 89% over the past decade, making NMC-based energy storage solutions increasingly competitive with traditional alternatives. Additionally, technological advancements in battery management systems, particularly in thermal management and state-of-charge estimation algorithms, have significantly improved battery performance and longevity.

Market challenges primarily revolve around supply chain vulnerabilities, particularly concerning cobalt sourcing, which faces ethical and geopolitical complications. Furthermore, the emergence of alternative battery chemistries such as LFP (Lithium Iron Phosphate) presents competitive pressure in certain application segments, particularly in markets where cost considerations outweigh energy density requirements.

Customer demand patterns indicate growing preference for integrated battery management solutions that offer advanced features such as predictive maintenance, remote monitoring capabilities, and seamless integration with broader energy management ecosystems. This trend is particularly pronounced in premium automotive and high-performance industrial applications.

The automotive sector represents the largest application segment, accounting for nearly 62% of the total market share. This dominance stems from the superior energy density and thermal stability of NMC batteries compared to other lithium-ion variants, making them particularly suitable for EV applications where range and safety are paramount concerns. Major automotive manufacturers including Tesla, Volkswagen Group, and BYD have significantly increased their investments in NMC battery technology and associated management systems.

Consumer electronics constitutes the second-largest market segment at approximately 21%, where the demand for longer battery life and faster charging capabilities continues to drive innovation in battery management systems. The remaining market share is distributed across industrial applications, grid storage solutions, and emerging applications in aerospace and marine sectors.

Geographically, Asia-Pacific dominates the market landscape, representing approximately 48% of global demand. This regional strength is attributed to the concentration of battery manufacturing facilities in China, South Korea, and Japan, coupled with aggressive government policies promoting electric mobility. North America and Europe follow with market shares of 27% and 22% respectively, with both regions showing accelerated growth rates due to stringent emission regulations and substantial investments in clean energy infrastructure.

Key market drivers include the declining cost of lithium-ion batteries, which has decreased by approximately 89% over the past decade, making NMC-based energy storage solutions increasingly competitive with traditional alternatives. Additionally, technological advancements in battery management systems, particularly in thermal management and state-of-charge estimation algorithms, have significantly improved battery performance and longevity.

Market challenges primarily revolve around supply chain vulnerabilities, particularly concerning cobalt sourcing, which faces ethical and geopolitical complications. Furthermore, the emergence of alternative battery chemistries such as LFP (Lithium Iron Phosphate) presents competitive pressure in certain application segments, particularly in markets where cost considerations outweigh energy density requirements.

Customer demand patterns indicate growing preference for integrated battery management solutions that offer advanced features such as predictive maintenance, remote monitoring capabilities, and seamless integration with broader energy management ecosystems. This trend is particularly pronounced in premium automotive and high-performance industrial applications.

Technical Challenges in NMC Battery Management

NMC (Nickel Manganese Cobalt) battery management systems face several significant technical challenges that impede optimal performance and widespread adoption. The primary challenge lies in accurately estimating the State of Charge (SoC) and State of Health (SoH) in real-time operating conditions. Traditional voltage-based estimation methods prove inadequate due to the flat voltage curve characteristics of NMC chemistry, particularly in the mid-range of charge (20-80%), where voltage changes minimally despite significant capacity utilization.

Thermal management presents another critical challenge, as NMC batteries exhibit narrow optimal operating temperature windows (typically 15-35°C). Outside this range, performance degradation accelerates dramatically, with high temperatures catalyzing unwanted side reactions and low temperatures increasing internal resistance. Current thermal management systems struggle to maintain uniform temperature distribution across large battery packs, leading to cell imbalance and reduced overall pack life.

Cell balancing mechanisms face particular difficulties with NMC chemistry due to its sensitivity to overcharge and over-discharge conditions. The varying degradation rates between cells in a pack necessitate sophisticated balancing algorithms that must continuously adapt to changing cell characteristics throughout the battery lifecycle. Existing passive balancing techniques waste energy as heat, while active balancing solutions add complexity, cost, and potential points of failure.

Safety concerns represent perhaps the most pressing challenge, as NMC batteries contain relatively high cobalt content compared to other lithium-ion chemistries, increasing thermal runaway risks. Current Battery Management Systems (BMS) must implement multiple redundant safety mechanisms to prevent catastrophic failures, adding complexity to system design and increasing costs.

Data analytics and predictive modeling capabilities remain underdeveloped for NMC battery systems. The complex electrochemical behaviors of these batteries, influenced by numerous interdependent factors including temperature, charge/discharge rates, and aging mechanisms, create significant challenges for developing accurate predictive models. Current systems typically rely on simplified models that fail to capture the full complexity of battery behavior across diverse operating conditions.

Fast charging protocols present particular difficulties for NMC batteries, as aggressive charging regimes can accelerate degradation through lithium plating, structural changes to the cathode, and electrolyte decomposition. Developing charging protocols that balance speed with longevity requires sophisticated control algorithms that few current systems successfully implement.

Integration challenges with diverse applications further complicate NMC battery management, as systems designed for electric vehicles may not translate effectively to stationary storage applications, necessitating application-specific optimization that increases development costs and time-to-market.

Thermal management presents another critical challenge, as NMC batteries exhibit narrow optimal operating temperature windows (typically 15-35°C). Outside this range, performance degradation accelerates dramatically, with high temperatures catalyzing unwanted side reactions and low temperatures increasing internal resistance. Current thermal management systems struggle to maintain uniform temperature distribution across large battery packs, leading to cell imbalance and reduced overall pack life.

Cell balancing mechanisms face particular difficulties with NMC chemistry due to its sensitivity to overcharge and over-discharge conditions. The varying degradation rates between cells in a pack necessitate sophisticated balancing algorithms that must continuously adapt to changing cell characteristics throughout the battery lifecycle. Existing passive balancing techniques waste energy as heat, while active balancing solutions add complexity, cost, and potential points of failure.

Safety concerns represent perhaps the most pressing challenge, as NMC batteries contain relatively high cobalt content compared to other lithium-ion chemistries, increasing thermal runaway risks. Current Battery Management Systems (BMS) must implement multiple redundant safety mechanisms to prevent catastrophic failures, adding complexity to system design and increasing costs.

Data analytics and predictive modeling capabilities remain underdeveloped for NMC battery systems. The complex electrochemical behaviors of these batteries, influenced by numerous interdependent factors including temperature, charge/discharge rates, and aging mechanisms, create significant challenges for developing accurate predictive models. Current systems typically rely on simplified models that fail to capture the full complexity of battery behavior across diverse operating conditions.

Fast charging protocols present particular difficulties for NMC batteries, as aggressive charging regimes can accelerate degradation through lithium plating, structural changes to the cathode, and electrolyte decomposition. Developing charging protocols that balance speed with longevity requires sophisticated control algorithms that few current systems successfully implement.

Integration challenges with diverse applications further complicate NMC battery management, as systems designed for electric vehicles may not translate effectively to stationary storage applications, necessitating application-specific optimization that increases development costs and time-to-market.

Current Benchmark Solutions for NMC Battery Management

01 Battery Management System Architecture for NMC Batteries

Advanced architecture designs for battery management systems specifically optimized for NMC (Nickel Manganese Cobalt) batteries. These systems incorporate specialized hardware and software components to monitor and control battery parameters such as voltage, current, and temperature. The architecture typically includes multiple control modules, sensors, and communication interfaces that work together to ensure optimal battery performance and safety.- Battery Management System Architecture for NMC Batteries: Advanced architecture designs for battery management systems specifically optimized for NMC (Nickel Manganese Cobalt) batteries. These systems incorporate specialized hardware and software components to monitor and control battery parameters such as voltage, current, temperature, and state of charge. The architecture typically includes sensors, control units, communication interfaces, and safety mechanisms designed to maximize the performance and lifespan of NMC battery systems while ensuring safe operation.

- Thermal Management Techniques for NMC Battery Systems: Innovative thermal management solutions specifically designed for NMC battery systems to maintain optimal operating temperatures. These techniques include active and passive cooling systems, heat dissipation methods, and temperature monitoring algorithms. Effective thermal management is crucial for NMC batteries as it directly impacts performance, efficiency, safety, and longevity by preventing overheating and ensuring uniform temperature distribution across battery cells.

- State of Charge Estimation Algorithms for NMC Batteries: Advanced algorithms for accurate estimation of State of Charge (SoC) in NMC battery systems. These algorithms utilize various methods including coulomb counting, voltage measurement, impedance tracking, and machine learning approaches to determine the remaining capacity of the battery. Precise SoC estimation is essential for optimizing battery usage, preventing over-discharge or overcharge, and providing reliable information to users about remaining battery life.

- Benchmarking Methodologies for NMC Battery Management Systems: Standardized testing and evaluation frameworks for comparing the performance of different NMC battery management systems. These methodologies include performance metrics, testing protocols, and evaluation criteria that enable objective assessment of system efficiency, accuracy, response time, and reliability. Benchmarking helps in identifying best practices, establishing industry standards, and guiding improvements in battery management system design for NMC batteries.

- Predictive Maintenance and Diagnostics for NMC Battery Systems: Advanced diagnostic tools and predictive maintenance techniques for NMC battery systems that can identify potential issues before they cause system failure. These solutions utilize data analytics, machine learning algorithms, and real-time monitoring to assess battery health, predict remaining useful life, and recommend maintenance actions. Predictive maintenance helps extend battery lifespan, reduce downtime, and optimize the total cost of ownership for NMC battery systems.

02 Thermal Management Techniques for NMC Battery Systems

Innovative thermal management solutions designed specifically for NMC battery systems to maintain optimal operating temperatures. These techniques include active cooling systems, passive heat dissipation methods, and intelligent thermal control algorithms. Effective thermal management is crucial for extending battery life, improving performance, and preventing thermal runaway in NMC batteries, which are known to be sensitive to temperature fluctuations.Expand Specific Solutions03 State of Charge Estimation and Monitoring for NMC Batteries

Advanced algorithms and methodologies for accurately estimating and monitoring the state of charge in NMC battery systems. These approaches utilize various parameters including voltage curves, current integration, impedance measurements, and machine learning techniques to provide precise real-time information about battery capacity. Accurate state of charge estimation is essential for optimizing battery usage, preventing over-discharge, and providing reliable range information in electric vehicles.Expand Specific Solutions04 Predictive Analytics and Diagnostics for NMC Battery Systems

Implementation of predictive analytics and diagnostic tools specifically designed for NMC battery systems. These solutions utilize artificial intelligence, machine learning algorithms, and historical data analysis to predict battery degradation, identify potential failures before they occur, and optimize maintenance schedules. The diagnostic capabilities include detection of cell imbalances, internal resistance changes, and early warning signs of capacity fade.Expand Specific Solutions05 Energy Optimization Strategies for NMC Battery Systems

Comprehensive energy optimization strategies for NMC battery systems that maximize efficiency and extend battery life. These strategies include intelligent charge/discharge control, load balancing between cells, adaptive power management based on usage patterns, and energy recovery systems. The optimization techniques are designed to address the specific characteristics of NMC chemistry, including its voltage profile, cycle life limitations, and temperature sensitivity.Expand Specific Solutions

Industry Leaders in NMC Battery Technology

The NMC Battery Energy Management Systems market is currently in a growth phase, with increasing adoption across electric vehicles and energy storage applications. The market size is expanding rapidly, driven by the global shift towards electrification and renewable energy integration. Technologically, the sector shows varying maturity levels, with established players like Huawei Digital Power, LG Energy Solution, Samsung SDI, and CATL leading innovation in advanced battery management algorithms. Companies like BattGenie and Brill Power represent emerging players focusing on specialized software solutions for battery optimization. Traditional energy companies such as Sinopec and China Three Gorges are diversifying into this space, while automotive suppliers like ElringKlinger are developing integrated systems. The competitive landscape features both vertical integration from battery manufacturers and specialized BMS solution providers competing on efficiency, safety, and battery longevity metrics.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has engineered a comprehensive Battery Management System for NMC batteries that focuses on maximizing energy efficiency while ensuring safety and longevity. Their system incorporates high-precision voltage and current sensing technologies with accuracy rates of ±0.1% to enable precise state-of-charge and state-of-health estimations. The BMS features adaptive charging algorithms that automatically adjust parameters based on battery condition and environmental factors. LG's solution includes a sophisticated thermal management subsystem that maintains optimal operating temperatures between 15-35°C through active cooling and heating elements. Their BMS employs a hierarchical architecture with master and slave controllers to efficiently manage large-scale battery arrays in applications ranging from electric vehicles to grid-scale storage. The system also features wireless connectivity for remote diagnostics and over-the-air updates to continuously improve performance metrics.

Strengths: Exceptional accuracy in state-of-charge estimation specifically calibrated for NMC chemistry; robust thermal management system that addresses NMC's sensitivity to temperature extremes. Weaknesses: Higher component costs due to premium sensing hardware; more complex implementation requiring specialized expertise.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a next-generation Battery Management System specifically designed for their NMC battery technology. The system employs a distributed architecture with dedicated microcontrollers monitoring individual cell modules, feeding data to a central processing unit for comprehensive analysis. Their BMS features proprietary algorithms that can detect subtle electrochemical changes within NMC cells to predict potential issues before they manifest as performance problems. Samsung's solution incorporates dynamic power allocation technology that optimizes discharge patterns based on real-time demand and battery condition. The system includes an advanced thermal management component that uses predictive modeling to anticipate temperature fluctuations and proactively adjust cooling parameters. Their BMS also features integrated cybersecurity protocols to protect against unauthorized access or manipulation of battery parameters, which is particularly important for grid-connected applications using NMC technology.

Strengths: Superior early detection capabilities for potential cell degradation issues specific to NMC chemistry; excellent integration with broader energy management ecosystems. Weaknesses: Proprietary nature limits compatibility with third-party battery systems; higher initial implementation costs compared to generic BMS solutions.

Key Patents in NMC Battery Management Systems

Lithium ion batteries, electronic devices, and methods

PatentActiveUS20190207246A1

Innovation

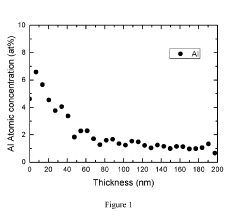

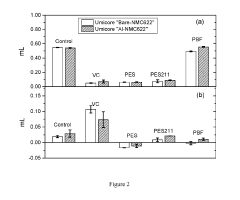

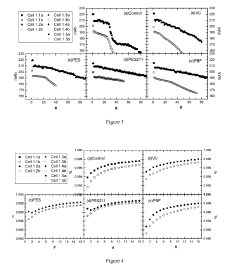

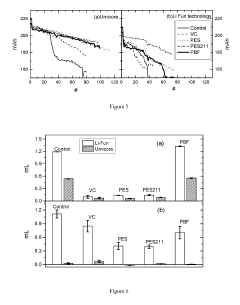

- A rechargeable lithium ion battery design featuring a positive electrode with surface-modified lithium nickel manganese cobalt oxide particles coated with Al2O3 and a nonaqueous liquid electrolyte containing specific additives, such as prop-1-ene-1,3-sultone, tris(trimethylsilyl)phosphite, and methylene methanedisulfonate, to enhance stability and reduce gas generation.

Lithium rich nickel manganese cobalt oxide (LR-NMC)

PatentWO2016106321A1

Innovation

- Development of lithium-rich nickel manganese cobalt oxide (LR-NMC) materials with specific chemical compositions and manufacturing methods that include varying ratios of nickel, manganese, and cobalt, and the use of lithium-containing salts to stabilize lithium within the crystal lattice, resulting in enhanced energy density and cycle lifetimes.

Safety Standards and Compliance Requirements

The safety standards and compliance requirements for NMC (Nickel Manganese Cobalt) battery energy management systems have evolved significantly in response to the growing adoption of these battery technologies across various industries. International standards such as IEC 62133, UL 1642, and UN 38.3 establish baseline requirements for lithium-ion batteries, with specific provisions applicable to NMC chemistry. These standards address critical safety aspects including thermal runaway prevention, overcharge protection, and short circuit mitigation.

For automotive applications, ISO 26262 and UN ECE R100 provide comprehensive frameworks for functional safety and electrical safety requirements respectively. The automotive industry has particularly stringent requirements due to the high energy density of NMC batteries and potential catastrophic consequences of failure. Battery management systems must comply with these standards through rigorous validation testing and documentation.

Energy storage system deployments utilizing NMC batteries must adhere to UL 9540 and NFPA 855, which outline installation requirements and fire protection measures. These standards have been updated in recent years to address specific thermal propagation concerns associated with NMC chemistry, requiring more sophisticated thermal management strategies within the BMS architecture.

Regional variations in compliance requirements present significant challenges for global manufacturers. The European Union's Battery Directive 2006/66/EC and its upcoming revision emphasize sustainability aspects alongside safety, while China's GB/T standards impose additional testing protocols. This regulatory fragmentation necessitates adaptable BMS designs that can accommodate multiple certification pathways.

Certification processes for NMC battery management systems typically involve third-party testing and validation. These processes evaluate thermal management capabilities, cell balancing algorithms, state-of-charge estimation accuracy, and fault detection mechanisms. The testing protocols have become increasingly comprehensive, often requiring accelerated aging tests and abuse condition simulations to verify long-term safety performance.

Emerging standards are beginning to address cybersecurity concerns for connected battery management systems. ISO/SAE 21434 establishes requirements for automotive cybersecurity engineering, with implications for BMS designs that feature remote monitoring and over-the-air update capabilities. As NMC battery systems become more integrated with smart grid infrastructure, compliance with IEC 62443 for industrial automation and control systems security is becoming increasingly relevant.

For automotive applications, ISO 26262 and UN ECE R100 provide comprehensive frameworks for functional safety and electrical safety requirements respectively. The automotive industry has particularly stringent requirements due to the high energy density of NMC batteries and potential catastrophic consequences of failure. Battery management systems must comply with these standards through rigorous validation testing and documentation.

Energy storage system deployments utilizing NMC batteries must adhere to UL 9540 and NFPA 855, which outline installation requirements and fire protection measures. These standards have been updated in recent years to address specific thermal propagation concerns associated with NMC chemistry, requiring more sophisticated thermal management strategies within the BMS architecture.

Regional variations in compliance requirements present significant challenges for global manufacturers. The European Union's Battery Directive 2006/66/EC and its upcoming revision emphasize sustainability aspects alongside safety, while China's GB/T standards impose additional testing protocols. This regulatory fragmentation necessitates adaptable BMS designs that can accommodate multiple certification pathways.

Certification processes for NMC battery management systems typically involve third-party testing and validation. These processes evaluate thermal management capabilities, cell balancing algorithms, state-of-charge estimation accuracy, and fault detection mechanisms. The testing protocols have become increasingly comprehensive, often requiring accelerated aging tests and abuse condition simulations to verify long-term safety performance.

Emerging standards are beginning to address cybersecurity concerns for connected battery management systems. ISO/SAE 21434 establishes requirements for automotive cybersecurity engineering, with implications for BMS designs that feature remote monitoring and over-the-air update capabilities. As NMC battery systems become more integrated with smart grid infrastructure, compliance with IEC 62443 for industrial automation and control systems security is becoming increasingly relevant.

Thermal Management Strategies for NMC Batteries

Thermal management is a critical aspect of NMC (Nickel Manganese Cobalt) battery systems that directly impacts performance, safety, and longevity. Current benchmark systems employ multiple strategies to maintain optimal temperature ranges between 15-35°C during operation. Active cooling systems utilizing liquid coolants have demonstrated superior efficiency in high-power applications, with recent data showing temperature gradient reductions of up to 70% compared to passive systems.

Phase change materials (PCMs) represent an emerging thermal management approach, offering advantages in weight reduction and simplified system architecture. Testing across various NMC chemistries indicates that paraffin-based PCMs with graphite enhancement can absorb 200-300 J/g of thermal energy during phase transition, effectively preventing thermal runaway conditions during rapid charge/discharge cycles.

Air cooling remains prevalent in cost-sensitive applications, with advanced designs incorporating computational fluid dynamics optimization to achieve 30-40% improved heat dissipation compared to conventional systems. Industry benchmarks show that forced air cooling with intelligent fan control algorithms can maintain temperature variations below 5°C across battery packs during normal operation.

Cell-to-cell thermal balancing has emerged as a differentiation point among premium energy management systems. Leading solutions implement distributed temperature sensing with resolution of 0.1°C and response times under 100ms, enabling preemptive thermal management before hotspots develop. This approach has demonstrated a 15-20% extension in cycle life during accelerated aging tests.

Thermal insulation strategies vary significantly between automotive and stationary storage applications. Benchmark systems for electric vehicles typically employ composite materials with thermal conductivity below 0.03 W/m·K while maintaining mechanical integrity under vibration conditions. Stationary systems prioritize fire-resistant materials with self-extinguishing properties to meet UL94 V-0 standards.

Integration of thermal management with battery management systems (BMS) represents the current frontier in NMC battery optimization. Advanced systems utilize machine learning algorithms to predict thermal behavior based on usage patterns, environmental conditions, and battery age. These predictive models enable dynamic adjustment of charging protocols and power limits, reducing peak temperatures by up to 25% during fast charging operations while minimizing capacity degradation.

Phase change materials (PCMs) represent an emerging thermal management approach, offering advantages in weight reduction and simplified system architecture. Testing across various NMC chemistries indicates that paraffin-based PCMs with graphite enhancement can absorb 200-300 J/g of thermal energy during phase transition, effectively preventing thermal runaway conditions during rapid charge/discharge cycles.

Air cooling remains prevalent in cost-sensitive applications, with advanced designs incorporating computational fluid dynamics optimization to achieve 30-40% improved heat dissipation compared to conventional systems. Industry benchmarks show that forced air cooling with intelligent fan control algorithms can maintain temperature variations below 5°C across battery packs during normal operation.

Cell-to-cell thermal balancing has emerged as a differentiation point among premium energy management systems. Leading solutions implement distributed temperature sensing with resolution of 0.1°C and response times under 100ms, enabling preemptive thermal management before hotspots develop. This approach has demonstrated a 15-20% extension in cycle life during accelerated aging tests.

Thermal insulation strategies vary significantly between automotive and stationary storage applications. Benchmark systems for electric vehicles typically employ composite materials with thermal conductivity below 0.03 W/m·K while maintaining mechanical integrity under vibration conditions. Stationary systems prioritize fire-resistant materials with self-extinguishing properties to meet UL94 V-0 standards.

Integration of thermal management with battery management systems (BMS) represents the current frontier in NMC battery optimization. Advanced systems utilize machine learning algorithms to predict thermal behavior based on usage patterns, environmental conditions, and battery age. These predictive models enable dynamic adjustment of charging protocols and power limits, reducing peak temperatures by up to 25% during fast charging operations while minimizing capacity degradation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!