Benchmark NMC Battery Power Dynamics in High-Demand Uses

AUG 27, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Evolution and Performance Objectives

Lithium-ion batteries with Nickel Manganese Cobalt (NMC) cathodes have emerged as a dominant technology in high-performance energy storage applications. The evolution of NMC battery technology has been marked by continuous improvements in energy density, power capability, and cycle life since its commercial introduction in the early 2000s. Initially developed as an alternative to LiCoO2 cathodes to reduce cobalt content while maintaining performance, NMC chemistry has undergone several generational advancements.

The first generation NMC111 (equal parts nickel, manganese, and cobalt) provided a balanced approach to stability and energy density. Subsequent iterations have progressively increased nickel content while reducing cobalt, leading to NMC532, NMC622, and most recently NMC811 compositions. This evolution reflects the industry's pursuit of higher energy density and lower material costs, as nickel provides higher specific capacity while expensive and ethically problematic cobalt is minimized.

In high-demand use scenarios, power dynamics represent a critical performance metric for NMC batteries. These dynamics encompass the battery's ability to deliver and accept high current rates without significant degradation or safety concerns. The performance objectives for modern NMC batteries in power-intensive applications include achieving discharge rates of 3-5C continuously and pulse discharge rates exceeding 10C while maintaining thermal stability and acceptable cycle life.

Current benchmarking efforts focus on several key performance indicators: maximum sustainable discharge and charge rates, power density (W/kg and W/L), internal resistance evolution during cycling, thermal behavior under high loads, and capacity retention after repeated high-power cycling. Industry standards increasingly demand NMC batteries that can deliver at least 1000 W/kg at 80% depth of discharge while maintaining temperature increases below 10°C during continuous high-power operation.

The automotive sector has been particularly influential in driving NMC battery power performance requirements. Electric vehicles require batteries capable of both high-power discharge for acceleration and high-power charging for fast-charging capabilities. The benchmark targets for next-generation NMC batteries include 15-minute charging to 80% capacity without significant degradation and the ability to support multiple daily fast-charging sessions throughout the battery's service life.

Looking forward, the technical roadmap for NMC battery evolution includes several ambitious performance objectives: increasing energy density to beyond 300 Wh/kg at the cell level while maintaining high power capability, extending cycle life to 2000+ cycles at 80% depth of discharge under high-power conditions, and improving low-temperature power delivery to maintain at least 70% of room temperature performance at -20°C. These objectives will require innovations in electrode design, electrolyte formulation, and thermal management systems.

The first generation NMC111 (equal parts nickel, manganese, and cobalt) provided a balanced approach to stability and energy density. Subsequent iterations have progressively increased nickel content while reducing cobalt, leading to NMC532, NMC622, and most recently NMC811 compositions. This evolution reflects the industry's pursuit of higher energy density and lower material costs, as nickel provides higher specific capacity while expensive and ethically problematic cobalt is minimized.

In high-demand use scenarios, power dynamics represent a critical performance metric for NMC batteries. These dynamics encompass the battery's ability to deliver and accept high current rates without significant degradation or safety concerns. The performance objectives for modern NMC batteries in power-intensive applications include achieving discharge rates of 3-5C continuously and pulse discharge rates exceeding 10C while maintaining thermal stability and acceptable cycle life.

Current benchmarking efforts focus on several key performance indicators: maximum sustainable discharge and charge rates, power density (W/kg and W/L), internal resistance evolution during cycling, thermal behavior under high loads, and capacity retention after repeated high-power cycling. Industry standards increasingly demand NMC batteries that can deliver at least 1000 W/kg at 80% depth of discharge while maintaining temperature increases below 10°C during continuous high-power operation.

The automotive sector has been particularly influential in driving NMC battery power performance requirements. Electric vehicles require batteries capable of both high-power discharge for acceleration and high-power charging for fast-charging capabilities. The benchmark targets for next-generation NMC batteries include 15-minute charging to 80% capacity without significant degradation and the ability to support multiple daily fast-charging sessions throughout the battery's service life.

Looking forward, the technical roadmap for NMC battery evolution includes several ambitious performance objectives: increasing energy density to beyond 300 Wh/kg at the cell level while maintaining high power capability, extending cycle life to 2000+ cycles at 80% depth of discharge under high-power conditions, and improving low-temperature power delivery to maintain at least 70% of room temperature performance at -20°C. These objectives will require innovations in electrode design, electrolyte formulation, and thermal management systems.

Market Analysis for High-Demand Battery Applications

The high-demand battery application market has experienced substantial growth in recent years, primarily driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronic devices. The global market for high-performance batteries reached $112 billion in 2022 and is projected to grow at a CAGR of 18.7% through 2030, with NMC (Nickel Manganese Cobalt) batteries capturing approximately 40% of this market.

Electric vehicles represent the largest application segment for high-demand NMC batteries, accounting for 63% of total market share. This dominance stems from the automotive industry's aggressive shift toward electrification, with major manufacturers committing to partial or complete transitions to electric fleets within the next decade. Consumer demand for longer range, faster charging, and improved performance in EVs has placed significant pressure on battery manufacturers to enhance power dynamics and energy density.

The stationary energy storage sector constitutes the second-largest market segment at 21%, driven by grid stabilization needs and the integration of intermittent renewable energy sources. Utility companies increasingly deploy large-scale battery systems to manage peak demand, provide frequency regulation, and ensure grid reliability. This application requires batteries with exceptional cycle life and consistent power delivery under variable load conditions.

Consumer electronics and power tools represent 12% of the high-demand battery market, with manufacturers seeking batteries capable of delivering high discharge rates for performance-intensive applications while maintaining safety and reliability. The remaining 4% encompasses emerging applications including electric marine vessels, aviation, and specialized industrial equipment.

Regional analysis reveals Asia-Pacific as the dominant market (52%), led by China's massive EV production ecosystem and battery manufacturing capacity. North America (24%) and Europe (19%) follow, with both regions investing heavily in domestic battery production to reduce supply chain dependencies. Latin America and Middle East/Africa regions currently represent smaller shares but show accelerated growth rates due to emerging EV markets and renewable energy initiatives.

Market research indicates that consumers and industrial users prioritize five key performance attributes in high-demand applications: power density (ability to deliver high current), thermal management during rapid charge/discharge cycles, cycle life under high-stress conditions, fast-charging capability, and safety during extreme usage scenarios. NMC chemistry has gained prominence specifically because it offers a balanced profile across these attributes, though challenges remain in optimizing power dynamics without compromising longevity.

Industry forecasts suggest the high-demand battery market will continue its robust growth trajectory, with particular expansion in electric commercial vehicles, grid-scale storage, and high-performance portable applications. The competitive landscape features established battery manufacturers increasingly partnering with end-use industries to develop application-specific solutions that address the unique power dynamic requirements of each use case.

Electric vehicles represent the largest application segment for high-demand NMC batteries, accounting for 63% of total market share. This dominance stems from the automotive industry's aggressive shift toward electrification, with major manufacturers committing to partial or complete transitions to electric fleets within the next decade. Consumer demand for longer range, faster charging, and improved performance in EVs has placed significant pressure on battery manufacturers to enhance power dynamics and energy density.

The stationary energy storage sector constitutes the second-largest market segment at 21%, driven by grid stabilization needs and the integration of intermittent renewable energy sources. Utility companies increasingly deploy large-scale battery systems to manage peak demand, provide frequency regulation, and ensure grid reliability. This application requires batteries with exceptional cycle life and consistent power delivery under variable load conditions.

Consumer electronics and power tools represent 12% of the high-demand battery market, with manufacturers seeking batteries capable of delivering high discharge rates for performance-intensive applications while maintaining safety and reliability. The remaining 4% encompasses emerging applications including electric marine vessels, aviation, and specialized industrial equipment.

Regional analysis reveals Asia-Pacific as the dominant market (52%), led by China's massive EV production ecosystem and battery manufacturing capacity. North America (24%) and Europe (19%) follow, with both regions investing heavily in domestic battery production to reduce supply chain dependencies. Latin America and Middle East/Africa regions currently represent smaller shares but show accelerated growth rates due to emerging EV markets and renewable energy initiatives.

Market research indicates that consumers and industrial users prioritize five key performance attributes in high-demand applications: power density (ability to deliver high current), thermal management during rapid charge/discharge cycles, cycle life under high-stress conditions, fast-charging capability, and safety during extreme usage scenarios. NMC chemistry has gained prominence specifically because it offers a balanced profile across these attributes, though challenges remain in optimizing power dynamics without compromising longevity.

Industry forecasts suggest the high-demand battery market will continue its robust growth trajectory, with particular expansion in electric commercial vehicles, grid-scale storage, and high-performance portable applications. The competitive landscape features established battery manufacturers increasingly partnering with end-use industries to develop application-specific solutions that address the unique power dynamic requirements of each use case.

Current Limitations and Technical Challenges in NMC Batteries

Despite significant advancements in NMC (Nickel Manganese Cobalt) battery technology, several critical limitations and technical challenges persist, particularly in high-demand applications. The primary constraint remains energy density, which currently plateaus at 250-300 Wh/kg for commercial NMC batteries. This ceiling significantly restricts the operational range of electric vehicles and the runtime of portable electronics under intensive usage scenarios.

Thermal management represents another substantial challenge. During high-power discharge events, NMC batteries generate considerable heat that can trigger thermal runaway if not properly dissipated. Current cooling systems add substantial weight and complexity to battery packs, reducing overall system efficiency and increasing costs. The thermal coefficient of NMC materials further complicates this issue, as performance characteristics vary significantly across temperature ranges.

Cycle life degradation under high-power conditions presents a persistent obstacle. Repeated rapid charging and high-current discharges accelerate capacity fade through various degradation mechanisms. Research indicates that NMC cathodes experience structural instability when subjected to deep discharge cycles at high currents, leading to microcracks, particle isolation, and eventual capacity loss. This degradation accelerates exponentially when discharge rates exceed 3C.

Rate capability limitations become particularly evident in high-demand applications. As discharge rates increase beyond 2C, NMC batteries exhibit significant voltage sag and reduced energy delivery efficiency. This performance drop stems from kinetic limitations in lithium-ion transport through the electrode materials and electrolyte interfaces. The resulting impedance rise further exacerbates heat generation, creating a negative feedback loop.

Safety concerns remain paramount, especially in high-power applications. The combination of high energy density and flammable liquid electrolytes creates inherent risks. While modern battery management systems mitigate many hazards, fundamental material properties of NMC cathodes—particularly those with higher nickel content—make them susceptible to oxygen release during thermal events or mechanical damage.

Manufacturing consistency presents another significant challenge. Variations in particle morphology, coating uniformity, and electrode calendering can create substantial performance differences between cells, even within the same production batch. These inconsistencies become more pronounced under high-power conditions, where minor material defects can lead to localized hotspots and accelerated degradation.

Cost factors continue to constrain widespread adoption, with raw material price volatility—particularly for cobalt and nickel—creating uncertainty in production economics. While manufacturers have reduced cobalt content in newer NMC formulations (moving from NMC 111 to NMC 811), this transition introduces new stability challenges that must be addressed through additional engineering solutions, further complicating the cost-performance equation.

Thermal management represents another substantial challenge. During high-power discharge events, NMC batteries generate considerable heat that can trigger thermal runaway if not properly dissipated. Current cooling systems add substantial weight and complexity to battery packs, reducing overall system efficiency and increasing costs. The thermal coefficient of NMC materials further complicates this issue, as performance characteristics vary significantly across temperature ranges.

Cycle life degradation under high-power conditions presents a persistent obstacle. Repeated rapid charging and high-current discharges accelerate capacity fade through various degradation mechanisms. Research indicates that NMC cathodes experience structural instability when subjected to deep discharge cycles at high currents, leading to microcracks, particle isolation, and eventual capacity loss. This degradation accelerates exponentially when discharge rates exceed 3C.

Rate capability limitations become particularly evident in high-demand applications. As discharge rates increase beyond 2C, NMC batteries exhibit significant voltage sag and reduced energy delivery efficiency. This performance drop stems from kinetic limitations in lithium-ion transport through the electrode materials and electrolyte interfaces. The resulting impedance rise further exacerbates heat generation, creating a negative feedback loop.

Safety concerns remain paramount, especially in high-power applications. The combination of high energy density and flammable liquid electrolytes creates inherent risks. While modern battery management systems mitigate many hazards, fundamental material properties of NMC cathodes—particularly those with higher nickel content—make them susceptible to oxygen release during thermal events or mechanical damage.

Manufacturing consistency presents another significant challenge. Variations in particle morphology, coating uniformity, and electrode calendering can create substantial performance differences between cells, even within the same production batch. These inconsistencies become more pronounced under high-power conditions, where minor material defects can lead to localized hotspots and accelerated degradation.

Cost factors continue to constrain widespread adoption, with raw material price volatility—particularly for cobalt and nickel—creating uncertainty in production economics. While manufacturers have reduced cobalt content in newer NMC formulations (moving from NMC 111 to NMC 811), this transition introduces new stability challenges that must be addressed through additional engineering solutions, further complicating the cost-performance equation.

Benchmark Methodologies for NMC Battery Power Dynamics

01 NMC Battery Composition and Structure

Nickel Manganese Cobalt (NMC) batteries have specific compositions and structures that affect their power dynamics. The ratio of nickel, manganese, and cobalt in the cathode material significantly influences the battery's performance characteristics. Various structural designs and material compositions are employed to optimize energy density, power output, and thermal stability. These innovations in composition and structure directly impact the battery's overall power dynamics and operational efficiency.- NMC cathode material composition and structure: Nickel-Manganese-Cobalt (NMC) cathode materials are critical components in lithium-ion batteries that significantly influence power dynamics. The specific composition ratios of nickel, manganese, and cobalt affect energy density, power output, and thermal stability. Various structural modifications, such as core-shell structures or gradient compositions, can be implemented to optimize the balance between high energy density and stable power delivery. These compositional and structural innovations help address challenges related to capacity retention and power performance during cycling.

- Battery management systems for NMC power optimization: Advanced battery management systems (BMS) are essential for optimizing the power dynamics of NMC batteries. These systems monitor and control various parameters including temperature, state of charge, and current flow to maximize power output while preventing degradation. Sophisticated algorithms can predict battery behavior under different load conditions, enabling dynamic power adjustment. BMS technologies also implement protective measures against overcharging and over-discharging, which are particularly important for maintaining the power capabilities of NMC batteries throughout their lifecycle.

- Thermal management techniques for NMC power stability: Thermal management is crucial for maintaining stable power output in NMC batteries, which can experience significant heat generation during high-power operations. Various cooling strategies, including liquid cooling systems, phase change materials, and heat dissipation structures, help regulate temperature distribution within battery packs. Effective thermal management prevents localized hotspots that can lead to accelerated degradation and power fade. These techniques enable NMC batteries to deliver consistent power performance even under demanding conditions such as fast charging or high-rate discharge.

- Electrode design for enhanced power delivery: Innovative electrode designs significantly impact the power dynamics of NMC batteries. Approaches include optimizing electrode thickness, porosity, and particle size distribution to facilitate faster ion transport and reduce internal resistance. Advanced conductive networks incorporating carbon nanotubes, graphene, or other conductive additives enhance electron transfer throughout the electrode. Structured electrodes with gradient porosity or hierarchical architectures can balance high energy density with improved power capabilities. These design strategies enable NMC batteries to achieve superior rate capability and power performance.

- Electrolyte formulations for power performance: Specialized electrolyte formulations play a critical role in determining the power characteristics of NMC batteries. Advanced electrolytes incorporating functional additives can form stable solid-electrolyte interphase layers that facilitate rapid lithium-ion transport while protecting electrode surfaces. High-conductivity electrolytes reduce internal resistance, enabling higher power output. Temperature-responsive electrolyte systems maintain performance across wider operating ranges. These electrolyte innovations help overcome power limitations in NMC batteries, particularly at low temperatures or during high-current operations, while simultaneously contributing to longer cycle life.

02 Thermal Management Systems for NMC Batteries

Effective thermal management is crucial for maintaining optimal NMC battery power dynamics. Advanced cooling systems help prevent thermal runaway and maintain battery performance under various load conditions. These systems include liquid cooling circuits, phase change materials, and heat dissipation structures that regulate temperature distribution across battery cells. Proper thermal management extends battery life, improves safety, and ensures consistent power delivery during high-demand operations.Expand Specific Solutions03 Power Control and Management Algorithms

Sophisticated algorithms and control systems are developed to optimize NMC battery power dynamics. These systems monitor and regulate charge/discharge rates, voltage levels, and current flow to maximize efficiency and battery lifespan. Advanced battery management systems (BMS) employ predictive modeling and real-time adjustments to balance power demands with battery health considerations. These control mechanisms are essential for maintaining stable power output while preventing conditions that could lead to degradation or safety issues.Expand Specific Solutions04 Performance Enhancement Techniques

Various techniques are employed to enhance the power dynamics of NMC batteries. These include doping the cathode material with additional elements, applying specialized coatings to electrode surfaces, and implementing novel electrolyte formulations. Surface modification technologies improve the interface between electrodes and electrolytes, reducing resistance and enhancing ion transport. These enhancements result in improved power density, faster charging capabilities, and better overall battery performance under dynamic load conditions.Expand Specific Solutions05 Degradation Mechanisms and Lifetime Extension

Understanding and mitigating degradation mechanisms is vital for maintaining NMC battery power dynamics over time. Research focuses on identifying factors that lead to capacity fade and power loss, such as structural changes in electrode materials, electrolyte decomposition, and lithium plating. Advanced diagnostic tools monitor battery health and predict potential failures. Various strategies are implemented to extend battery lifetime, including optimized charging protocols, improved cell balancing techniques, and materials that resist degradation under cycling stress.Expand Specific Solutions

Leading Manufacturers and Research Institutions in NMC Battery Field

The NMC battery power dynamics market is currently in a growth phase, with increasing demand driven by electric vehicle adoption and energy storage applications. The market size is projected to expand significantly, reaching multi-billion dollar valuation by 2030. In terms of technical maturity, NMC battery technology has evolved from early-stage development to commercial implementation, with key players demonstrating varying levels of advancement. Samsung SDI, LG Energy Solution, and Panasonic lead in high-performance NMC battery production, while automotive manufacturers like Toyota, Volkswagen, and BMW are integrating these systems into their vehicles. Research institutions like Argonne National Laboratory and emerging players such as QuantumScape are pushing boundaries with next-generation NMC formulations that address power density and thermal stability challenges in high-demand applications.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has pioneered high-nickel content NMC battery technology (NMC 811 and beyond) specifically engineered for high-demand applications. Their benchmark methodology for power dynamics employs sophisticated electrochemical impedance spectroscopy (EIS) to characterize internal resistance changes under varying load conditions. Samsung's PRiMX platform integrates multi-layer safety designs with specialized electrolyte additives that maintain performance stability even during extreme power demands. Their testing protocols include pulse power characterization tests that measure instantaneous power capability across different states of charge (10-90%) and temperatures (-10°C to 45°C). The company has developed proprietary grain boundary engineering techniques that strengthen cathode structural integrity during high C-rate operations, reducing capacity fade mechanisms. Samsung's benchmark testing includes real-world simulation profiles derived from electric vehicle racing conditions, providing practical performance metrics beyond standard laboratory tests. Their cells demonstrate exceptional power retention after 1000+ high-power cycles, maintaining over 80% of initial discharge capability.

Strengths: Industry-leading power-to-weight ratio for NMC chemistry; excellent thermal stability during high-discharge events; superior manufacturing consistency resulting in minimal cell-to-cell variation. Weaknesses: Premium pricing positions their solutions above market average; requires sophisticated cooling systems for sustained high-power applications; slightly lower energy density compared to their latest energy-optimized NMC variants.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed a comprehensive NMC battery benchmarking system focused on power dynamics in high-demand applications, particularly for automotive and industrial uses. Their methodology incorporates multi-dimensional stress testing that evaluates performance across variable discharge rates (0.5C to 15C), temperature gradients (-30°C to 60°C), and state-of-charge windows. Panasonic's proprietary electrode manufacturing process creates optimized microstructures that facilitate rapid lithium-ion diffusion while minimizing mechanical degradation during high-current operations. Their benchmark testing includes hybrid pulse power characterization (HPPC) protocols that measure dynamic power capability under conditions mimicking real-world acceleration and regenerative braking scenarios. The company employs advanced in-situ diagnostic tools including acoustic emission monitoring and thermal imaging to identify performance limitations during extreme power demands. Panasonic's NMC formulations incorporate gradient concentration cathodes with higher nickel content in the bulk and stabilized surface structures to balance power delivery with longevity. Their benchmark data demonstrates that their latest NMC cells can deliver 80% of maximum power even at 20% state of charge, a critical metric for high-demand applications.

Strengths: Exceptional manufacturing consistency resulting in highly predictable performance characteristics; superior low-temperature power delivery compared to competitors; robust mechanical design withstands physical stresses during high-power cycling. Weaknesses: Higher initial production costs compared to standard NMC formulations; requires more sophisticated thermal management systems; slightly lower volumetric energy density compared to some competitors' highest-density offerings.

Critical Patents and Research Breakthroughs in NMC Chemistry

Lithium rich nickel manganese cobalt oxide (LR-NMC)

PatentWO2016106321A1

Innovation

- Development of lithium-rich nickel manganese cobalt oxide (LR-NMC) materials with specific chemical compositions and manufacturing methods that include varying ratios of nickel, manganese, and cobalt, and the use of lithium-containing salts to stabilize lithium within the crystal lattice, resulting in enhanced energy density and cycle lifetimes.

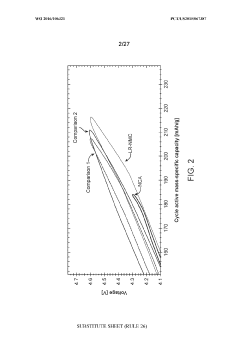

Method for restoration performances of aged nickel-rich NMC cathode material for lithium-ion secondary battery

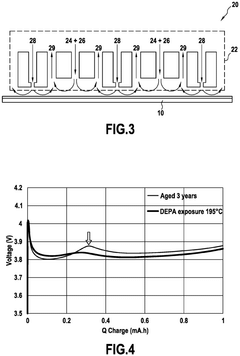

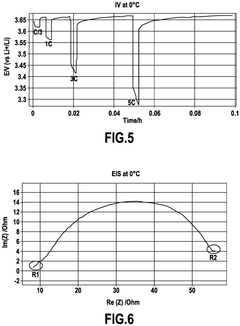

PatentPendingEP4550454A1

Innovation

- A method involving the formation of a cathode with aged nickel-rich NMC material, a binder, and carbon black, followed by exposure to diethyl phosphoramidate at temperatures above 160°C to create a lithium phosphate protective layer, thereby reducing the overpotential peak.

Thermal Management Solutions for High-Demand Battery Applications

Thermal management represents a critical challenge in high-demand battery applications, particularly for NMC (Nickel Manganese Cobalt) batteries which experience significant thermal stress during rapid charging and discharging cycles. Effective thermal management solutions are essential for maintaining optimal performance, extending battery lifespan, and ensuring safety in applications requiring high power output.

Advanced cooling systems have emerged as the primary approach to thermal management in high-demand NMC battery applications. Liquid cooling technologies, utilizing ethylene glycol or specialized dielectric fluids, have demonstrated superior heat dissipation capabilities compared to traditional air cooling methods. Recent benchmark studies indicate that liquid-cooled NMC battery systems can maintain temperature gradients within 3-5°C across the battery pack, even under sustained high-power discharge rates of 3C or greater.

Phase change materials (PCMs) represent another promising thermal management solution, particularly for applications with intermittent high-power demands. These materials absorb excess heat during intensive operation through the latent heat of phase transition. Experimental data shows that PCM-based systems can reduce peak temperatures by up to 15°C during high-demand discharge cycles, though they present challenges in terms of system weight and volume.

Active thermal management systems incorporating predictive algorithms have shown significant advantages in preemptively managing thermal loads. These systems utilize machine learning models trained on battery performance data to anticipate thermal behavior under various operating conditions. Implementation of such systems has demonstrated up to 30% improvement in power availability during high-demand scenarios by optimizing thermal conditions before critical operations.

Cell-level thermal management innovations include advanced electrode coatings and electrolyte additives designed to reduce internal resistance and minimize heat generation. Benchmark testing reveals that these modifications can reduce heat generation by 10-20% during high-power operations, providing complementary benefits to external cooling systems.

Integration of thermal management with battery management systems (BMS) represents the most comprehensive approach for high-demand applications. These integrated systems continuously monitor cell temperatures and adjust power delivery parameters to prevent thermal runaway while maximizing available power. Real-world testing in electric vehicle racing applications demonstrates that integrated thermal-BMS solutions can sustain 25% higher power outputs compared to systems with separate thermal management.

For extreme high-demand applications, hybrid cooling approaches combining multiple technologies have shown the most promising results. These systems typically integrate liquid cooling with PCM buffers and advanced thermal interface materials to manage both sustained and peak thermal loads effectively.

Advanced cooling systems have emerged as the primary approach to thermal management in high-demand NMC battery applications. Liquid cooling technologies, utilizing ethylene glycol or specialized dielectric fluids, have demonstrated superior heat dissipation capabilities compared to traditional air cooling methods. Recent benchmark studies indicate that liquid-cooled NMC battery systems can maintain temperature gradients within 3-5°C across the battery pack, even under sustained high-power discharge rates of 3C or greater.

Phase change materials (PCMs) represent another promising thermal management solution, particularly for applications with intermittent high-power demands. These materials absorb excess heat during intensive operation through the latent heat of phase transition. Experimental data shows that PCM-based systems can reduce peak temperatures by up to 15°C during high-demand discharge cycles, though they present challenges in terms of system weight and volume.

Active thermal management systems incorporating predictive algorithms have shown significant advantages in preemptively managing thermal loads. These systems utilize machine learning models trained on battery performance data to anticipate thermal behavior under various operating conditions. Implementation of such systems has demonstrated up to 30% improvement in power availability during high-demand scenarios by optimizing thermal conditions before critical operations.

Cell-level thermal management innovations include advanced electrode coatings and electrolyte additives designed to reduce internal resistance and minimize heat generation. Benchmark testing reveals that these modifications can reduce heat generation by 10-20% during high-power operations, providing complementary benefits to external cooling systems.

Integration of thermal management with battery management systems (BMS) represents the most comprehensive approach for high-demand applications. These integrated systems continuously monitor cell temperatures and adjust power delivery parameters to prevent thermal runaway while maximizing available power. Real-world testing in electric vehicle racing applications demonstrates that integrated thermal-BMS solutions can sustain 25% higher power outputs compared to systems with separate thermal management.

For extreme high-demand applications, hybrid cooling approaches combining multiple technologies have shown the most promising results. These systems typically integrate liquid cooling with PCM buffers and advanced thermal interface materials to manage both sustained and peak thermal loads effectively.

Sustainability and Recycling Considerations for NMC Battery Technology

The sustainability of NMC (Nickel Manganese Cobalt) battery technology has become increasingly critical as high-demand applications proliferate across electric vehicles, grid storage, and portable electronics sectors. The environmental footprint of these batteries extends beyond their operational phase to encompass raw material extraction, manufacturing processes, and end-of-life management.

Current recycling rates for NMC batteries remain suboptimal, with global recovery averaging below 5% for lithium and under 50% for cobalt and nickel. This presents significant challenges as demand for these critical materials continues to surge, with projections indicating a potential 500% increase in lithium demand by 2030. The environmental impact of inadequate recycling infrastructure manifests in increased mining activities, which generate substantial carbon emissions and ecological disruption.

Several recycling methodologies have emerged to address these challenges. Hydrometallurgical processes offer high recovery rates (up to 95% for cobalt and nickel) but involve chemical-intensive procedures with potential environmental hazards. Pyrometallurgical approaches provide robust processing capabilities but consume significant energy and typically recover fewer elements. Direct recycling methods, while promising for preserving cathode structures, remain largely experimental and face scalability challenges.

Life cycle assessment (LCA) studies indicate that effective recycling can reduce the carbon footprint of NMC batteries by 25-30% compared to virgin material production. This becomes particularly relevant when benchmarking power dynamics in high-demand applications, as extended battery lifespans through second-life applications can further enhance sustainability metrics before final recycling.

Industry leaders have begun implementing closed-loop systems, with companies like Umicore and Redwood Materials establishing integrated recycling facilities capable of processing thousands of tons annually. These initiatives demonstrate commercial viability while highlighting the need for standardized battery designs that facilitate easier disassembly and material recovery.

Regulatory frameworks are evolving globally to address these challenges. The European Union's Battery Directive mandates minimum recycled content and collection rates, while similar legislation emerges in North America and Asia. These regulations increasingly incorporate extended producer responsibility principles, shifting end-of-life management burdens upstream to manufacturers and incentivizing design-for-recycling approaches.

Future sustainability improvements will likely emerge from advances in battery chemistry that reduce dependence on critical materials while maintaining performance characteristics necessary for high-demand applications. Research into phosphate-based alternatives and silicon-composite anodes shows promise for reducing environmental impact while potentially enhancing power dynamics under demanding operational conditions.

Current recycling rates for NMC batteries remain suboptimal, with global recovery averaging below 5% for lithium and under 50% for cobalt and nickel. This presents significant challenges as demand for these critical materials continues to surge, with projections indicating a potential 500% increase in lithium demand by 2030. The environmental impact of inadequate recycling infrastructure manifests in increased mining activities, which generate substantial carbon emissions and ecological disruption.

Several recycling methodologies have emerged to address these challenges. Hydrometallurgical processes offer high recovery rates (up to 95% for cobalt and nickel) but involve chemical-intensive procedures with potential environmental hazards. Pyrometallurgical approaches provide robust processing capabilities but consume significant energy and typically recover fewer elements. Direct recycling methods, while promising for preserving cathode structures, remain largely experimental and face scalability challenges.

Life cycle assessment (LCA) studies indicate that effective recycling can reduce the carbon footprint of NMC batteries by 25-30% compared to virgin material production. This becomes particularly relevant when benchmarking power dynamics in high-demand applications, as extended battery lifespans through second-life applications can further enhance sustainability metrics before final recycling.

Industry leaders have begun implementing closed-loop systems, with companies like Umicore and Redwood Materials establishing integrated recycling facilities capable of processing thousands of tons annually. These initiatives demonstrate commercial viability while highlighting the need for standardized battery designs that facilitate easier disassembly and material recovery.

Regulatory frameworks are evolving globally to address these challenges. The European Union's Battery Directive mandates minimum recycled content and collection rates, while similar legislation emerges in North America and Asia. These regulations increasingly incorporate extended producer responsibility principles, shifting end-of-life management burdens upstream to manufacturers and incentivizing design-for-recycling approaches.

Future sustainability improvements will likely emerge from advances in battery chemistry that reduce dependence on critical materials while maintaining performance characteristics necessary for high-demand applications. Research into phosphate-based alternatives and silicon-composite anodes shows promise for reducing environmental impact while potentially enhancing power dynamics under demanding operational conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!