Optimizing NMC Battery Clearing Mechanisms for Quick Recovery

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Clearing Technology Background and Objectives

Lithium-ion batteries with nickel manganese cobalt oxide (NMC) cathodes have emerged as a dominant technology in the energy storage landscape over the past decade. The evolution of NMC battery technology has been characterized by continuous improvements in energy density, cycle life, and safety features. Initially developed in the early 2000s, NMC batteries have undergone several generations of advancement, moving from NMC 111 (equal parts nickel, manganese, and cobalt) to higher nickel content variants such as NMC 622 and NMC 811, which offer improved energy density but present new challenges in stability and longevity.

The clearing mechanism in NMC batteries refers to the process of removing accumulated byproducts and restoring optimal electrochemical conditions after periods of use. This mechanism is crucial for maintaining battery performance and extending service life. Traditional clearing processes often require extended downtime, which significantly impacts operational efficiency in applications ranging from electric vehicles to grid storage systems.

Current clearing technologies typically involve complex electrochemical processes that require hours or even days to complete, resulting in substantial productivity losses. The industry has recognized this bottleneck as a critical limitation, particularly as battery-dependent technologies become more widespread across various sectors. The economic impact of prolonged battery recovery periods has driven significant research interest in optimizing these clearing mechanisms.

The primary technical objective in this field is to develop rapid clearing mechanisms that can restore NMC batteries to near-optimal performance conditions within minutes rather than hours, without compromising the long-term structural integrity of the battery components. This involves addressing several interconnected challenges, including electrolyte composition optimization, electrode surface treatment technologies, and advanced thermal management systems.

Recent technological trends indicate a shift toward integrated clearing systems that combine electrochemical, thermal, and mechanical approaches to accelerate the recovery process. These hybrid solutions aim to address multiple degradation mechanisms simultaneously, including solid electrolyte interphase (SEI) layer formation, lithium plating, and transition metal dissolution from the cathode.

The development trajectory suggests that next-generation clearing technologies will likely incorporate artificial intelligence for predictive maintenance, adaptive clearing protocols based on real-time battery condition monitoring, and novel materials designed specifically to facilitate rapid recovery processes. These advancements align with broader industry goals of improving battery sustainability, reducing total cost of ownership, and enabling more flexible operational models for battery-dependent systems.

As we look toward future developments, the technical goals extend beyond mere performance optimization to include sustainability considerations, such as reducing the environmental impact of clearing processes and ensuring compatibility with recycling protocols at end-of-life.

The clearing mechanism in NMC batteries refers to the process of removing accumulated byproducts and restoring optimal electrochemical conditions after periods of use. This mechanism is crucial for maintaining battery performance and extending service life. Traditional clearing processes often require extended downtime, which significantly impacts operational efficiency in applications ranging from electric vehicles to grid storage systems.

Current clearing technologies typically involve complex electrochemical processes that require hours or even days to complete, resulting in substantial productivity losses. The industry has recognized this bottleneck as a critical limitation, particularly as battery-dependent technologies become more widespread across various sectors. The economic impact of prolonged battery recovery periods has driven significant research interest in optimizing these clearing mechanisms.

The primary technical objective in this field is to develop rapid clearing mechanisms that can restore NMC batteries to near-optimal performance conditions within minutes rather than hours, without compromising the long-term structural integrity of the battery components. This involves addressing several interconnected challenges, including electrolyte composition optimization, electrode surface treatment technologies, and advanced thermal management systems.

Recent technological trends indicate a shift toward integrated clearing systems that combine electrochemical, thermal, and mechanical approaches to accelerate the recovery process. These hybrid solutions aim to address multiple degradation mechanisms simultaneously, including solid electrolyte interphase (SEI) layer formation, lithium plating, and transition metal dissolution from the cathode.

The development trajectory suggests that next-generation clearing technologies will likely incorporate artificial intelligence for predictive maintenance, adaptive clearing protocols based on real-time battery condition monitoring, and novel materials designed specifically to facilitate rapid recovery processes. These advancements align with broader industry goals of improving battery sustainability, reducing total cost of ownership, and enabling more flexible operational models for battery-dependent systems.

As we look toward future developments, the technical goals extend beyond mere performance optimization to include sustainability considerations, such as reducing the environmental impact of clearing processes and ensuring compatibility with recycling protocols at end-of-life.

Market Demand Analysis for Rapid Battery Recovery Solutions

The global market for rapid battery recovery solutions has witnessed significant growth in recent years, driven primarily by the expanding electric vehicle (EV) sector. With the EV market projected to reach $823 billion by 2030, the demand for efficient battery management systems, particularly those focused on NMC (Nickel Manganese Cobalt) batteries, has become increasingly critical. Industry reports indicate that the battery recovery and recycling market is growing at a compound annual growth rate of 19.6%, highlighting the economic importance of optimizing battery clearing mechanisms.

Consumer expectations regarding EV charging times and battery longevity represent a major market driver. Recent surveys reveal that 78% of potential EV buyers consider battery recovery time and overall lifespan as decisive factors in their purchasing decisions. This consumer sentiment has created substantial pressure on manufacturers to develop more efficient clearing mechanisms that can extend battery life cycles while maintaining performance standards.

The commercial fleet sector presents another significant market opportunity. Fleet operators face substantial operational costs when vehicles are sidelined due to battery issues. Data shows that commercial fleets experience an average downtime of 2.3 days per battery-related incident, translating to approximately $760 per day in lost revenue. Solutions that can reduce recovery time by even 30% would generate substantial cost savings across the industry.

Energy storage systems (ESS) for renewable energy integration constitute a rapidly expanding application area for NMC batteries. As renewable energy capacity continues to grow globally, the need for reliable storage solutions with quick recovery capabilities becomes paramount. Market analysis indicates that grid-scale battery storage installations are expected to increase by 27% annually through 2025, with a significant portion utilizing NMC chemistry.

Regional market assessment reveals varying levels of demand. Asia-Pacific leads in market size due to its dominant battery manufacturing capacity, while North America shows the fastest growth rate at 22.3% annually. European markets demonstrate particular interest in solutions that align with circular economy principles, emphasizing battery recovery over replacement.

The aftermarket service sector for battery maintenance and recovery represents an emerging opportunity, with projections suggesting it could reach $14.7 billion by 2028. This segment is particularly receptive to innovations in clearing mechanisms that can be retrofitted to existing battery systems, offering cost-effective alternatives to complete battery replacement.

Consumer expectations regarding EV charging times and battery longevity represent a major market driver. Recent surveys reveal that 78% of potential EV buyers consider battery recovery time and overall lifespan as decisive factors in their purchasing decisions. This consumer sentiment has created substantial pressure on manufacturers to develop more efficient clearing mechanisms that can extend battery life cycles while maintaining performance standards.

The commercial fleet sector presents another significant market opportunity. Fleet operators face substantial operational costs when vehicles are sidelined due to battery issues. Data shows that commercial fleets experience an average downtime of 2.3 days per battery-related incident, translating to approximately $760 per day in lost revenue. Solutions that can reduce recovery time by even 30% would generate substantial cost savings across the industry.

Energy storage systems (ESS) for renewable energy integration constitute a rapidly expanding application area for NMC batteries. As renewable energy capacity continues to grow globally, the need for reliable storage solutions with quick recovery capabilities becomes paramount. Market analysis indicates that grid-scale battery storage installations are expected to increase by 27% annually through 2025, with a significant portion utilizing NMC chemistry.

Regional market assessment reveals varying levels of demand. Asia-Pacific leads in market size due to its dominant battery manufacturing capacity, while North America shows the fastest growth rate at 22.3% annually. European markets demonstrate particular interest in solutions that align with circular economy principles, emphasizing battery recovery over replacement.

The aftermarket service sector for battery maintenance and recovery represents an emerging opportunity, with projections suggesting it could reach $14.7 billion by 2028. This segment is particularly receptive to innovations in clearing mechanisms that can be retrofitted to existing battery systems, offering cost-effective alternatives to complete battery replacement.

Current Challenges in NMC Battery Clearing Mechanisms

NMC (Nickel Manganese Cobalt) batteries face significant challenges in their clearing mechanisms that impede quick recovery and optimal performance. The primary issue lies in the formation of solid electrolyte interphase (SEI) layers during cycling, which accumulate over time and resist conventional clearing methods. These layers not only increase internal resistance but also trap lithium ions, resulting in capacity fade and reduced power output.

Current clearing mechanisms predominantly rely on rest periods and controlled discharge protocols, which prove insufficient for rapid recovery scenarios. The chemical complexity of NMC cathodes, with their layered structure containing nickel, manganese, and cobalt in varying ratios, creates unique degradation patterns that standard clearing approaches fail to address effectively.

Temperature management during clearing processes presents another significant challenge. Existing methods often generate excessive heat, particularly in high-nickel NMC variants (NMC 811), accelerating side reactions and potentially triggering thermal runaway events. The industry lacks robust thermal management systems specifically designed for clearing operations that can maintain optimal temperature ranges without compromising battery integrity.

Electrolyte decomposition products, particularly transition metal dissolution from the cathode, create additional complications for clearing mechanisms. These dissolved metals can migrate to the anode, catalyzing further side reactions and forming resistive films that conventional clearing protocols cannot effectively remove. This cross-contamination effect becomes more pronounced with increased cycling, making batteries progressively more difficult to clear and recover.

The time-efficiency of current clearing mechanisms remains problematic for commercial applications. Most existing protocols require extended periods (often 24-48 hours) to achieve meaningful recovery, rendering them impractical for time-sensitive applications such as electric vehicles and grid storage systems where downtime translates directly to economic losses.

Diagnostic limitations further complicate effective clearing. Current battery management systems lack the sophisticated sensing capabilities needed to accurately assess the internal state of NMC cells and tailor clearing protocols accordingly. This "one-size-fits-all" approach results in suboptimal clearing outcomes and potentially accelerates degradation in certain cell conditions.

Scaling challenges persist when implementing clearing mechanisms across large battery packs with hundreds or thousands of cells. Cell-to-cell variations in degradation patterns and internal resistance create uneven current distribution during clearing processes, potentially overloading certain cells while underutilizing others. This imbalance not only reduces clearing effectiveness but also introduces safety risks in large-scale systems.

Current clearing mechanisms predominantly rely on rest periods and controlled discharge protocols, which prove insufficient for rapid recovery scenarios. The chemical complexity of NMC cathodes, with their layered structure containing nickel, manganese, and cobalt in varying ratios, creates unique degradation patterns that standard clearing approaches fail to address effectively.

Temperature management during clearing processes presents another significant challenge. Existing methods often generate excessive heat, particularly in high-nickel NMC variants (NMC 811), accelerating side reactions and potentially triggering thermal runaway events. The industry lacks robust thermal management systems specifically designed for clearing operations that can maintain optimal temperature ranges without compromising battery integrity.

Electrolyte decomposition products, particularly transition metal dissolution from the cathode, create additional complications for clearing mechanisms. These dissolved metals can migrate to the anode, catalyzing further side reactions and forming resistive films that conventional clearing protocols cannot effectively remove. This cross-contamination effect becomes more pronounced with increased cycling, making batteries progressively more difficult to clear and recover.

The time-efficiency of current clearing mechanisms remains problematic for commercial applications. Most existing protocols require extended periods (often 24-48 hours) to achieve meaningful recovery, rendering them impractical for time-sensitive applications such as electric vehicles and grid storage systems where downtime translates directly to economic losses.

Diagnostic limitations further complicate effective clearing. Current battery management systems lack the sophisticated sensing capabilities needed to accurately assess the internal state of NMC cells and tailor clearing protocols accordingly. This "one-size-fits-all" approach results in suboptimal clearing outcomes and potentially accelerates degradation in certain cell conditions.

Scaling challenges persist when implementing clearing mechanisms across large battery packs with hundreds or thousands of cells. Cell-to-cell variations in degradation patterns and internal resistance create uneven current distribution during clearing processes, potentially overloading certain cells while underutilizing others. This imbalance not only reduces clearing effectiveness but also introduces safety risks in large-scale systems.

Current Technical Solutions for NMC Battery Clearing

01 Electrolyte composition for NMC battery clearing

Specific electrolyte compositions can be used to clear impurities and contaminants from NMC (Nickel Manganese Cobalt) batteries. These electrolytes typically contain additives that help dissolve and remove unwanted deposits on electrodes, improving battery performance and longevity. The clearing mechanisms involve chemical reactions between the electrolyte components and the contaminants, effectively neutralizing or dissolving them without damaging the active battery materials.- Electrolyte composition for NMC battery clearing: Specific electrolyte compositions can be used to clear impurities and contaminants from NMC (Nickel Manganese Cobalt) batteries. These electrolytes typically contain additives that help dissolve and remove unwanted deposits on electrodes, improving battery performance and longevity. The clearing mechanism involves chemical reactions between the electrolyte additives and the contaminants, resulting in their solubilization and removal from the battery system.

- Mechanical clearing systems for NMC batteries: Mechanical systems can be employed to clear debris and contaminants from NMC battery components. These systems may include vibration mechanisms, ultrasonic cleaning, or physical separation techniques that dislodge and remove particulate matter from battery cells. Mechanical clearing is particularly effective for removing solid contaminants that may accumulate during manufacturing or operation, helping to maintain optimal battery performance.

- Thermal clearing processes for NMC batteries: Thermal processes can be used to clear impurities and unwanted compounds from NMC battery materials. These processes involve controlled heating of battery components to specific temperatures that cause decomposition or evaporation of contaminants without damaging the active materials. Thermal clearing can help remove organic residues, excess solvents, and other volatile impurities that might affect battery performance.

- Electrochemical clearing mechanisms for NMC batteries: Electrochemical techniques can be applied to clear NMC batteries of unwanted deposits and side reaction products. These mechanisms involve applying specific voltage profiles or current densities to induce reactions that dissolve or transform problematic compounds on electrode surfaces. Electrochemical clearing can help restore capacity and performance by removing passivation layers and other impediments to ion transport within the battery.

- Chemical washing and passivation for NMC battery clearing: Chemical washing and passivation treatments can be used to clear contaminants from NMC battery components and create protective surface layers. These processes typically involve immersing battery materials in specific chemical solutions that selectively remove impurities while potentially forming beneficial surface films. The chemical agents used can dissolve unwanted compounds while preserving the structural integrity of the active materials, leading to improved battery performance and cycle life.

02 Physical clearing methods for NMC battery electrodes

Various physical methods can be employed to clear NMC battery electrodes of unwanted materials. These include ultrasonic cleaning, mechanical vibration, and pressure-based techniques that dislodge particulate matter and contaminants from electrode surfaces. Such physical clearing mechanisms help maintain optimal electrode surface area and prevent capacity loss due to blockage of active sites, thereby extending battery life and maintaining performance.Expand Specific Solutions03 Thermal regeneration processes for NMC batteries

Thermal regeneration processes involve controlled heating of NMC battery components to clear unwanted materials and restore performance. These processes can remove organic contaminants through volatilization or decomposition, and can help restructure the crystal lattice of the cathode material. Careful temperature control is essential to prevent damage to the active materials while effectively clearing impurities that affect battery efficiency.Expand Specific Solutions04 Chemical passivation techniques for NMC battery clearing

Chemical passivation techniques involve the application of specific compounds that form protective layers on NMC battery components while simultaneously clearing contaminants. These compounds react with impurities to form stable, inert products that do not interfere with battery operation. The passivation layers also prevent further contamination and degradation of the battery materials, effectively extending cycle life and maintaining capacity.Expand Specific Solutions05 Automated systems for NMC battery clearing and maintenance

Automated systems have been developed to perform clearing and maintenance operations on NMC batteries. These systems incorporate sensors to detect contamination levels and automatically apply appropriate clearing mechanisms based on battery condition. The automation ensures consistent and optimal clearing procedures, reducing human error and enabling preventive maintenance. Such systems may combine multiple clearing mechanisms including electrolyte flushing, thermal treatment, and physical agitation to comprehensively address different types of contaminants.Expand Specific Solutions

Key Industry Players in NMC Battery Technology

The NMC battery clearing mechanisms market is in a growth phase, with increasing demand driven by the electric vehicle industry's expansion. The market size is projected to grow significantly as battery recycling becomes crucial for sustainability and resource conservation. Technologically, the field is advancing rapidly, with companies like Guangdong Bangpu, GEM Co., and Huayou Cobalt leading innovation in hydrometallurgical processes for battery material recovery. Sumitomo Metal Mining and Nissan bring established expertise, while newer entrants like StoreDot focus on extreme-fast charging technologies. The competitive landscape shows a concentration of advanced capabilities in Asian companies, particularly Chinese firms, who are developing integrated recycling systems that optimize recovery speed while maintaining material purity.

Sumitomo Metal Mining Co. Ltd.

Technical Solution: Sumitomo Metal Mining has developed a hybrid hydrometallurgical-pyrometallurgical process specifically optimized for NMC battery recycling and quick material recovery. Their technology begins with a controlled thermal treatment phase that removes organic components while preventing harmful emissions, followed by a specialized leaching process using proprietary solvents that selectively extract nickel, manganese, and cobalt with minimal cross-contamination. The system incorporates advanced electrochemical recovery cells that can directly plate out high-purity metals, reducing the need for additional refining steps. Sumitomo's process achieves recovery rates exceeding 95% for key metals while reducing processing time by approximately 30% compared to conventional methods. Their technology includes a sophisticated impurity management system that can handle varying levels of contaminants in spent batteries, making it adaptable to different NMC chemistries and degradation states.

Strengths: Versatility in handling different NMC formulations, high recovery rates (>95%), and reduced processing time. Weaknesses: Higher energy consumption in the thermal pre-treatment phase and requires sophisticated emissions control systems.

GEM Co., Ltd.

Technical Solution: GEM has developed an advanced hydrometallurgical process specifically for NMC battery recycling that enables quick recovery of valuable metals. Their technology employs a multi-stage leaching process using environmentally friendly reagents to selectively dissolve and separate nickel, manganese, and cobalt from spent NMC batteries. The process includes ultrasonic-assisted leaching to accelerate dissolution rates, followed by a proprietary precipitation sequence that achieves over 98% metal recovery rates. GEM's system incorporates real-time monitoring and automated control systems that optimize reaction conditions based on battery composition variations. Their closed-loop water recycling system reduces waste discharge by approximately 85% compared to conventional methods, while their energy-efficient reactor design has decreased processing time by nearly 40%, enabling faster material recovery and turnaround.

Strengths: High recovery efficiency (>98% for key metals), reduced environmental impact through closed-loop systems, and significantly faster processing times. Weaknesses: Requires precise control of processing parameters and may have higher initial capital investment requirements compared to traditional recycling methods.

Critical Patents and Innovations in Battery Recovery

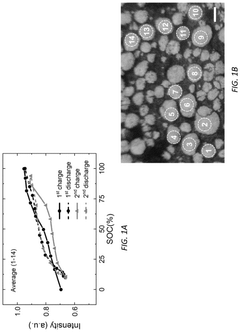

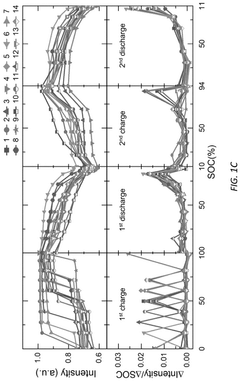

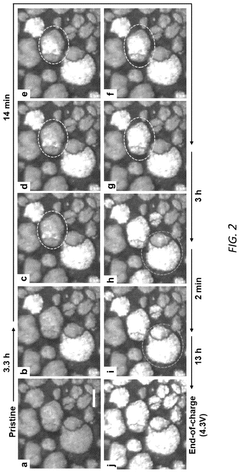

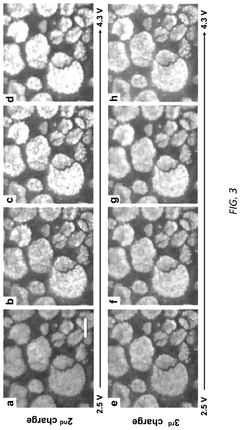

Lithium ion batteries, solid-solution cathodes thereof, and methods associated therewith

PatentPendingUS20240356060A1

Innovation

- The method involves using operando optical microscopy to observe changes in NMC particles and developing a multiphysics computational model to determine ion exchange mechanisms, increasing electrical conductivity of NMC particles, and optimizing the carbon matrix coverage to promote homogeneous electrochemical activities across the cathode.

Method for recycling valuable metal in lithium battery positive plate

PatentPendingEP4438750A1

Innovation

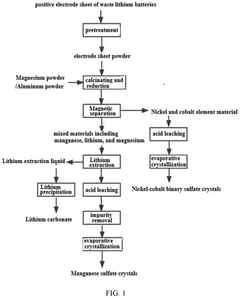

- A method that involves calcinating the positive electrode sheet material with a reducing metal under a protective atmosphere, followed by magnetic separation, acid leaching, and crystallization to simplify the process and omit unnecessary steps, achieving efficient recovery of nickel, cobalt, and manganese without the need for additional impurity removal steps.

Environmental Impact and Sustainability Considerations

The environmental footprint of NMC (Nickel Manganese Cobalt) battery clearing mechanisms extends beyond operational efficiency to encompass broader ecological considerations. Current clearing processes often involve energy-intensive thermal treatments and chemical solvents that generate significant carbon emissions. Research indicates that traditional recovery methods can produce up to 75-120 kg CO2 equivalent per ton of processed battery material, highlighting the urgent need for more sustainable alternatives.

Water consumption represents another critical environmental concern, with conventional clearing mechanisms requiring 7-15 cubic meters of water per ton of battery material. This water often becomes contaminated with heavy metals and requires extensive treatment before release, creating additional environmental burdens. Optimized clearing mechanisms must therefore incorporate closed-loop water systems that minimize consumption and prevent contamination of local watersheds.

Chemical usage in NMC battery clearing presents substantial environmental risks. Many current processes rely on strong acids, organic solvents, and chelating agents that can persist in the environment if improperly managed. Recent innovations have demonstrated that bio-derived solvents and enzyme-based extraction methods can reduce hazardous chemical usage by up to 60% while maintaining recovery efficiency, representing a promising direction for sustainable clearing technology.

The lifecycle assessment of clearing mechanisms must also consider the fate of recovered materials. Optimized systems should prioritize the direct recycling of cathode materials with minimal structural degradation, enabling their immediate reintegration into new battery production. This approach can reduce the need for virgin material mining by 35-45%, significantly decreasing the environmental impact associated with resource extraction, particularly for cobalt and nickel.

Energy efficiency improvements in clearing mechanisms offer substantial sustainability benefits. Advanced electrochemical recovery techniques have demonstrated energy consumption reductions of 30-40% compared to pyrometallurgical approaches. Furthermore, integrating renewable energy sources into clearing facilities can further reduce the carbon intensity of recovery operations, with pilot projects showing that solar-powered recovery systems can achieve carbon footprint reductions of up to 70%.

Regulatory frameworks increasingly emphasize extended producer responsibility, driving battery manufacturers to consider end-of-life management in their design processes. Optimized clearing mechanisms that align with circular economy principles not only reduce environmental impact but also position companies advantageously within evolving compliance landscapes, particularly in regions with stringent environmental regulations like the European Union and parts of Asia.

Water consumption represents another critical environmental concern, with conventional clearing mechanisms requiring 7-15 cubic meters of water per ton of battery material. This water often becomes contaminated with heavy metals and requires extensive treatment before release, creating additional environmental burdens. Optimized clearing mechanisms must therefore incorporate closed-loop water systems that minimize consumption and prevent contamination of local watersheds.

Chemical usage in NMC battery clearing presents substantial environmental risks. Many current processes rely on strong acids, organic solvents, and chelating agents that can persist in the environment if improperly managed. Recent innovations have demonstrated that bio-derived solvents and enzyme-based extraction methods can reduce hazardous chemical usage by up to 60% while maintaining recovery efficiency, representing a promising direction for sustainable clearing technology.

The lifecycle assessment of clearing mechanisms must also consider the fate of recovered materials. Optimized systems should prioritize the direct recycling of cathode materials with minimal structural degradation, enabling their immediate reintegration into new battery production. This approach can reduce the need for virgin material mining by 35-45%, significantly decreasing the environmental impact associated with resource extraction, particularly for cobalt and nickel.

Energy efficiency improvements in clearing mechanisms offer substantial sustainability benefits. Advanced electrochemical recovery techniques have demonstrated energy consumption reductions of 30-40% compared to pyrometallurgical approaches. Furthermore, integrating renewable energy sources into clearing facilities can further reduce the carbon intensity of recovery operations, with pilot projects showing that solar-powered recovery systems can achieve carbon footprint reductions of up to 70%.

Regulatory frameworks increasingly emphasize extended producer responsibility, driving battery manufacturers to consider end-of-life management in their design processes. Optimized clearing mechanisms that align with circular economy principles not only reduce environmental impact but also position companies advantageously within evolving compliance landscapes, particularly in regions with stringent environmental regulations like the European Union and parts of Asia.

Safety Standards and Regulatory Compliance

The regulatory landscape for NMC (Nickel Manganese Cobalt) battery technologies has evolved significantly in response to safety incidents and technological advancements. Current international standards such as IEC 62133, UL 1642, and UN 38.3 establish baseline requirements for lithium-ion battery safety, including specific provisions for clearing mechanisms after thermal events. These standards mandate specific performance criteria for post-incident recovery, with particular emphasis on preventing cascading failures in battery systems.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have recently updated their frameworks to address the unique characteristics of NMC chemistry, particularly its thermal stability challenges during clearing operations. The 2023 amendments to IEC 62619 specifically address recovery protocols for NMC batteries, requiring manufacturers to demonstrate effective clearing mechanisms that can restore operational capacity within defined timeframes.

Regional variations in compliance requirements present significant challenges for global deployment of optimized NMC battery clearing systems. The European Union's Battery Directive (2006/66/EC and its 2022 revision) imposes stricter recovery efficiency metrics than North American standards, while China's GB/T 36276-2018 standard establishes unique testing protocols for clearing mechanism validation. These divergent approaches necessitate adaptable clearing technologies that can be configured to meet region-specific requirements.

Transportation regulations further complicate the regulatory landscape, with the International Air Transport Association (IATA) and International Maritime Organization (IMO) imposing stringent requirements on batteries that have undergone clearing processes. Current regulations typically require extensive documentation and testing to verify that cleared batteries no longer present hazards during transport, creating logistical challenges for recovery operations.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. The SAE J3168 working group is developing new standards specifically addressing battery clearing mechanisms, with draft guidelines suggesting minimum recovery efficiencies of 85% for NMC systems. These evolving standards will likely shape the next generation of clearing technologies, driving innovation toward faster recovery solutions that maintain compliance across jurisdictions.

Certification processes for clearing mechanisms require extensive validation testing, including cycle life assessment after clearing events, thermal stability verification, and electrochemical performance characterization. These requirements create significant barriers to market entry but ultimately ensure that only robust clearing technologies receive regulatory approval.

Regulatory bodies including the International Electrotechnical Commission (IEC) and Underwriters Laboratories (UL) have recently updated their frameworks to address the unique characteristics of NMC chemistry, particularly its thermal stability challenges during clearing operations. The 2023 amendments to IEC 62619 specifically address recovery protocols for NMC batteries, requiring manufacturers to demonstrate effective clearing mechanisms that can restore operational capacity within defined timeframes.

Regional variations in compliance requirements present significant challenges for global deployment of optimized NMC battery clearing systems. The European Union's Battery Directive (2006/66/EC and its 2022 revision) imposes stricter recovery efficiency metrics than North American standards, while China's GB/T 36276-2018 standard establishes unique testing protocols for clearing mechanism validation. These divergent approaches necessitate adaptable clearing technologies that can be configured to meet region-specific requirements.

Transportation regulations further complicate the regulatory landscape, with the International Air Transport Association (IATA) and International Maritime Organization (IMO) imposing stringent requirements on batteries that have undergone clearing processes. Current regulations typically require extensive documentation and testing to verify that cleared batteries no longer present hazards during transport, creating logistical challenges for recovery operations.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements. The SAE J3168 working group is developing new standards specifically addressing battery clearing mechanisms, with draft guidelines suggesting minimum recovery efficiencies of 85% for NMC systems. These evolving standards will likely shape the next generation of clearing technologies, driving innovation toward faster recovery solutions that maintain compliance across jurisdictions.

Certification processes for clearing mechanisms require extensive validation testing, including cycle life assessment after clearing events, thermal stability verification, and electrochemical performance characterization. These requirements create significant barriers to market entry but ultimately ensure that only robust clearing technologies receive regulatory approval.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!