Measure NMC Battery's Material Erosion Using Industry Protocols

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Erosion Measurement Background and Objectives

Lithium-ion batteries with nickel-manganese-cobalt (NMC) cathodes have emerged as a dominant technology in electric vehicles and energy storage systems due to their high energy density, good cycle life, and relatively lower cost compared to other lithium-ion chemistries. The evolution of NMC battery technology has progressed from early formulations like NMC 111 (equal parts nickel, manganese, and cobalt) to more nickel-rich compositions such as NMC 622 and NMC 811, driven by the need for higher energy density and reduced cobalt content.

Material erosion in NMC batteries represents a critical degradation mechanism that directly impacts battery performance, safety, and longevity. This erosion primarily manifests as the dissolution of transition metal ions from the cathode material into the electrolyte during cycling, particularly at elevated temperatures and high states of charge. The dissolved metal ions can subsequently deposit on the anode surface, leading to increased impedance, capacity fade, and potential safety concerns.

The measurement and characterization of material erosion in NMC batteries have historically relied on post-mortem analysis techniques, which provide limited insights into the dynamic nature of the erosion process. Recent advancements in in-situ and operando characterization methods have enabled more comprehensive understanding of erosion mechanisms under realistic operating conditions, but standardization remains a significant challenge in the industry.

This technical research report aims to evaluate current industry protocols for measuring NMC battery material erosion, identify their limitations, and explore emerging methodologies that offer improved accuracy and reliability. The objective is to establish a comprehensive framework for quantifying and predicting material erosion in NMC batteries across different formulations, operating conditions, and application scenarios.

Additionally, this report seeks to correlate material erosion measurements with battery performance metrics, enabling more accurate lifetime predictions and informing the development of mitigation strategies. By standardizing erosion measurement protocols, battery manufacturers can better optimize cell design, material selection, and operating parameters to minimize degradation and extend battery life.

The technical goals of this research include: (1) evaluating the effectiveness of current industry protocols for measuring NMC material erosion; (2) identifying key parameters and environmental factors that accelerate erosion; (3) establishing correlations between measurable erosion indicators and battery performance degradation; and (4) proposing standardized testing methodologies that can be widely adopted across the industry for consistent quality control and performance validation.

Material erosion in NMC batteries represents a critical degradation mechanism that directly impacts battery performance, safety, and longevity. This erosion primarily manifests as the dissolution of transition metal ions from the cathode material into the electrolyte during cycling, particularly at elevated temperatures and high states of charge. The dissolved metal ions can subsequently deposit on the anode surface, leading to increased impedance, capacity fade, and potential safety concerns.

The measurement and characterization of material erosion in NMC batteries have historically relied on post-mortem analysis techniques, which provide limited insights into the dynamic nature of the erosion process. Recent advancements in in-situ and operando characterization methods have enabled more comprehensive understanding of erosion mechanisms under realistic operating conditions, but standardization remains a significant challenge in the industry.

This technical research report aims to evaluate current industry protocols for measuring NMC battery material erosion, identify their limitations, and explore emerging methodologies that offer improved accuracy and reliability. The objective is to establish a comprehensive framework for quantifying and predicting material erosion in NMC batteries across different formulations, operating conditions, and application scenarios.

Additionally, this report seeks to correlate material erosion measurements with battery performance metrics, enabling more accurate lifetime predictions and informing the development of mitigation strategies. By standardizing erosion measurement protocols, battery manufacturers can better optimize cell design, material selection, and operating parameters to minimize degradation and extend battery life.

The technical goals of this research include: (1) evaluating the effectiveness of current industry protocols for measuring NMC material erosion; (2) identifying key parameters and environmental factors that accelerate erosion; (3) establishing correlations between measurable erosion indicators and battery performance degradation; and (4) proposing standardized testing methodologies that can be widely adopted across the industry for consistent quality control and performance validation.

Market Demand Analysis for Advanced Battery Testing Methods

The global battery testing market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicle (EV) production and renewable energy storage systems. Market research indicates that the battery testing equipment market is projected to reach $6.5 billion by 2027, with a compound annual growth rate of 14.2% from 2022. This significant growth trajectory underscores the increasing demand for advanced battery testing methodologies, particularly for NMC (Nickel Manganese Cobalt) batteries which have become the dominant chemistry in the EV sector.

Material erosion testing represents a critical segment within this market, as manufacturers seek to extend battery lifespans and improve safety profiles. Industry surveys reveal that over 78% of battery manufacturers consider material erosion as one of the top three factors affecting long-term battery performance and safety. This concern has intensified as EV warranties typically extend to 8-10 years, requiring batteries to maintain performance integrity over extended periods.

The automotive sector remains the largest consumer of advanced battery testing solutions, accounting for approximately 42% of the total market demand. Major automotive manufacturers have increased their R&D budgets for battery testing by an average of 23% annually since 2020, highlighting the strategic importance of this technology. Tesla, Volkswagen Group, and BYD have established dedicated battery research facilities with substantial investments in testing equipment.

Energy storage system (ESS) applications represent the fastest-growing segment for battery testing solutions, with a projected growth rate of 18.7% annually. This is largely attributed to the increasing deployment of grid-scale storage systems and the critical need for reliability in these applications. Utility companies and renewable energy developers are increasingly demanding standardized testing protocols that can accurately predict material erosion under various operational conditions.

Consumer electronics manufacturers constitute another significant market segment, particularly as devices become more power-intensive while maintaining slim profiles. This sector demands miniaturized testing equipment that can accurately simulate real-world usage patterns and detect early signs of material degradation.

Geographically, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea, where major battery manufacturing facilities are concentrated. North America and Europe follow with 28% and 22% market shares respectively, with both regions showing accelerated growth as they establish domestic battery production capabilities to reduce dependency on Asian suppliers.

The market is also witnessing increased demand for testing solutions that comply with emerging international standards such as IEC 62660 and ISO 12405, which are becoming mandatory requirements for battery certification in many jurisdictions. This regulatory-driven demand creates additional market opportunities for advanced testing methodologies that can accurately measure material erosion according to these standardized protocols.

Material erosion testing represents a critical segment within this market, as manufacturers seek to extend battery lifespans and improve safety profiles. Industry surveys reveal that over 78% of battery manufacturers consider material erosion as one of the top three factors affecting long-term battery performance and safety. This concern has intensified as EV warranties typically extend to 8-10 years, requiring batteries to maintain performance integrity over extended periods.

The automotive sector remains the largest consumer of advanced battery testing solutions, accounting for approximately 42% of the total market demand. Major automotive manufacturers have increased their R&D budgets for battery testing by an average of 23% annually since 2020, highlighting the strategic importance of this technology. Tesla, Volkswagen Group, and BYD have established dedicated battery research facilities with substantial investments in testing equipment.

Energy storage system (ESS) applications represent the fastest-growing segment for battery testing solutions, with a projected growth rate of 18.7% annually. This is largely attributed to the increasing deployment of grid-scale storage systems and the critical need for reliability in these applications. Utility companies and renewable energy developers are increasingly demanding standardized testing protocols that can accurately predict material erosion under various operational conditions.

Consumer electronics manufacturers constitute another significant market segment, particularly as devices become more power-intensive while maintaining slim profiles. This sector demands miniaturized testing equipment that can accurately simulate real-world usage patterns and detect early signs of material degradation.

Geographically, Asia-Pacific dominates the market with approximately 45% share, led by China, Japan, and South Korea, where major battery manufacturing facilities are concentrated. North America and Europe follow with 28% and 22% market shares respectively, with both regions showing accelerated growth as they establish domestic battery production capabilities to reduce dependency on Asian suppliers.

The market is also witnessing increased demand for testing solutions that comply with emerging international standards such as IEC 62660 and ISO 12405, which are becoming mandatory requirements for battery certification in many jurisdictions. This regulatory-driven demand creates additional market opportunities for advanced testing methodologies that can accurately measure material erosion according to these standardized protocols.

Current Challenges in NMC Material Erosion Assessment

Despite significant advancements in NMC (Nickel Manganese Cobalt) battery technology, the assessment of material erosion remains a critical challenge for industry researchers and manufacturers. Current protocols for measuring erosion in NMC cathode materials suffer from several limitations that impede accurate evaluation and standardization across the industry.

One of the primary challenges is the lack of universally accepted testing methodologies. Different manufacturers and research institutions employ varied protocols, making cross-comparison of results difficult and often unreliable. This inconsistency creates barriers to establishing industry benchmarks and hinders collaborative efforts to address material degradation issues.

The time-dependent nature of erosion processes presents another significant obstacle. Accelerated testing methods, while efficient for rapid assessment, often fail to accurately replicate real-world degradation patterns that occur over extended periods. This disconnect between laboratory results and actual field performance creates uncertainty in predicting battery longevity and reliability.

Environmental variability further complicates erosion assessment. NMC materials respond differently to temperature fluctuations, humidity levels, and charging conditions. Current protocols struggle to account for these variables comprehensively, resulting in testing conditions that may not reflect the diverse operating environments batteries encounter during their lifecycle.

The microscopic scale of erosion phenomena introduces measurement precision challenges. Existing analytical techniques have limitations in detecting and quantifying subtle material changes, particularly in early degradation stages. This sensitivity gap means potential failure mechanisms may go undetected until they manifest as significant performance issues.

Interdependency between different degradation mechanisms creates additional complexity. Material erosion often occurs simultaneously with other processes such as SEI layer formation, lithium plating, and structural transformations. Current protocols typically isolate these phenomena rather than addressing their combined effects, leading to incomplete understanding of degradation pathways.

Data interpretation presents yet another hurdle. The correlation between measured erosion parameters and actual battery performance metrics remains imperfectly understood. Researchers struggle to translate laboratory measurements into meaningful predictions about capacity retention, power capability, and safety characteristics over a battery's operational lifetime.

Cost and time constraints also limit comprehensive erosion studies. Thorough assessment requires expensive analytical equipment and extended testing periods, creating practical barriers for many industry participants, particularly smaller manufacturers and research groups seeking to innovate in this space.

One of the primary challenges is the lack of universally accepted testing methodologies. Different manufacturers and research institutions employ varied protocols, making cross-comparison of results difficult and often unreliable. This inconsistency creates barriers to establishing industry benchmarks and hinders collaborative efforts to address material degradation issues.

The time-dependent nature of erosion processes presents another significant obstacle. Accelerated testing methods, while efficient for rapid assessment, often fail to accurately replicate real-world degradation patterns that occur over extended periods. This disconnect between laboratory results and actual field performance creates uncertainty in predicting battery longevity and reliability.

Environmental variability further complicates erosion assessment. NMC materials respond differently to temperature fluctuations, humidity levels, and charging conditions. Current protocols struggle to account for these variables comprehensively, resulting in testing conditions that may not reflect the diverse operating environments batteries encounter during their lifecycle.

The microscopic scale of erosion phenomena introduces measurement precision challenges. Existing analytical techniques have limitations in detecting and quantifying subtle material changes, particularly in early degradation stages. This sensitivity gap means potential failure mechanisms may go undetected until they manifest as significant performance issues.

Interdependency between different degradation mechanisms creates additional complexity. Material erosion often occurs simultaneously with other processes such as SEI layer formation, lithium plating, and structural transformations. Current protocols typically isolate these phenomena rather than addressing their combined effects, leading to incomplete understanding of degradation pathways.

Data interpretation presents yet another hurdle. The correlation between measured erosion parameters and actual battery performance metrics remains imperfectly understood. Researchers struggle to translate laboratory measurements into meaningful predictions about capacity retention, power capability, and safety characteristics over a battery's operational lifetime.

Cost and time constraints also limit comprehensive erosion studies. Thorough assessment requires expensive analytical equipment and extended testing periods, creating practical barriers for many industry participants, particularly smaller manufacturers and research groups seeking to innovate in this space.

Standard Industry Protocols for NMC Erosion Measurement

01 Protective coatings to prevent NMC material erosion

Various protective coating technologies can be applied to NMC (Nickel Manganese Cobalt) battery materials to prevent erosion during cycling. These coatings create a barrier that protects the active material from direct contact with the electrolyte, reducing dissolution and structural degradation. Common coating materials include metal oxides, phosphates, and polymeric substances that enhance the chemical stability of the cathode material while maintaining good ionic conductivity.- Protective coatings to prevent NMC material erosion: Various protective coating technologies can be applied to NMC battery materials to prevent erosion during cycling. These coatings create a barrier between the active material and the electrolyte, reducing direct contact and subsequent degradation. Coating materials may include metal oxides, polymers, or composite materials that maintain structural integrity while allowing lithium-ion transport. These protective layers significantly extend battery life by minimizing material dissolution and structural deterioration.

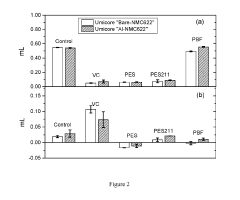

- Electrolyte additives for stabilizing NMC interfaces: Specialized electrolyte additives can be incorporated to form stable interfaces on NMC cathode materials, preventing erosion during battery operation. These additives work by creating protective solid electrolyte interphase (SEI) layers that inhibit unwanted side reactions while maintaining efficient ion transport. The additives can include fluorinated compounds, boron-based materials, or other functional molecules that selectively bind to vulnerable sites on the NMC surface, thereby reducing material dissolution and structural degradation.

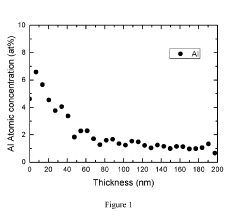

- Doping strategies to enhance NMC structural stability: Introducing dopant elements into the NMC crystal structure can significantly improve its resistance to erosion and degradation. Dopants such as aluminum, magnesium, zirconium, or titanium can stabilize the crystal lattice, particularly during high-voltage operation when transition metal dissolution is most severe. These dopants occupy specific sites within the structure, strengthening metal-oxygen bonds and reducing the likelihood of structural collapse during cycling. This approach enhances the material's chemical stability against electrolyte attack and mechanical integrity during repeated lithiation/delithiation.

- Advanced synthesis methods for erosion-resistant NMC: Novel synthesis techniques can produce NMC materials with inherently higher resistance to erosion. These methods include co-precipitation processes with precise control of reaction parameters, sol-gel approaches with specialized precursors, or hydrothermal/solvothermal techniques that yield optimized particle morphologies. By controlling particle size, crystallinity, surface facets, and grain boundaries, these advanced synthesis routes create NMC materials with reduced surface reactivity and improved structural integrity during electrochemical cycling.

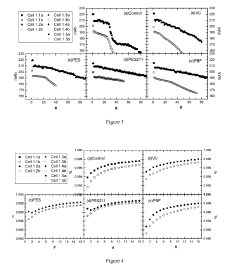

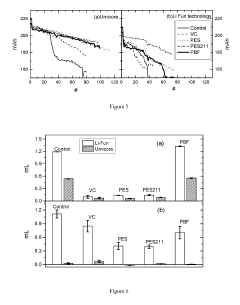

- Diagnostic and monitoring techniques for NMC erosion: Advanced analytical methods can be employed to detect and monitor NMC material erosion during battery operation. These techniques include electrochemical impedance spectroscopy, in-situ X-ray diffraction, transmission electron microscopy, and inductively coupled plasma analysis of electrolytes. By identifying early signs of material degradation, these diagnostic approaches enable the development of more effective mitigation strategies. Real-time monitoring systems can also be integrated into battery management systems to adapt charging protocols based on detected erosion patterns.

02 Electrolyte additives for mitigating NMC erosion

Specialized electrolyte additives can be incorporated into battery systems to form stable interfaces on NMC cathode surfaces, thereby reducing material erosion. These additives work by creating protective films that prevent direct contact between the cathode material and aggressive electrolyte components. The additives can include fluorinated compounds, boron-based substances, and other functional molecules that selectively react at the electrode surface to form passivation layers.Expand Specific Solutions03 Structural modifications of NMC materials to enhance stability

The crystal structure and composition of NMC materials can be modified to enhance their resistance to erosion. Techniques include doping with stabilizing elements, controlling the nickel-manganese-cobalt ratio, and engineering grain boundaries. These modifications aim to reduce lattice strain during cycling, minimize transition metal dissolution, and maintain structural integrity even under harsh operating conditions.Expand Specific Solutions04 Advanced testing methods for evaluating NMC erosion

Specialized analytical techniques have been developed to evaluate and quantify the erosion of NMC battery materials. These methods include electrochemical impedance spectroscopy, in-situ electron microscopy, and accelerated aging protocols that can predict long-term material degradation. By understanding the mechanisms and progression of erosion, researchers can develop more effective mitigation strategies and improve battery durability.Expand Specific Solutions05 Manufacturing processes to minimize NMC material erosion

Optimized manufacturing processes can significantly reduce the susceptibility of NMC materials to erosion. These include controlled synthesis conditions, precise thermal treatment protocols, and specialized particle engineering techniques. By carefully managing parameters such as calcination temperature, particle size distribution, and surface area, manufacturers can produce NMC materials with enhanced structural stability and resistance to degradation mechanisms.Expand Specific Solutions

Key Industry Players in Battery Testing and Standardization

The NMC battery material erosion measurement market is in a growth phase, with increasing demand driven by electric vehicle and energy storage applications. The market is characterized by a mix of established players and emerging innovators across multiple regions. Key competitors include LG Energy Solution, a global leader in battery manufacturing, alongside research-focused entities like University of Houston and Xi'an Jiaotong University advancing measurement protocols. Traditional industrial giants such as Sinopec, Toyota, and Hyundai are investing in this technology to support their electrification strategies. The technology is approaching maturity in standardized testing methods, though innovation continues in specialized measurement techniques, with companies like Bruker BioSpin and Dynexus Technology developing advanced diagnostic tools for more precise erosion analysis.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive protocol for measuring NMC cathode material erosion that combines accelerated life testing with advanced analytical techniques. Their approach utilizes differential voltage analysis (DVA) during cycling to identify capacity fade mechanisms related specifically to cathode degradation. The protocol incorporates precise coulombic efficiency measurements at various temperatures (10-60°C) and C-rates (0.5C-3C) to isolate erosion effects from other degradation pathways. For post-mortem analysis, LG employs scanning electron microscopy (SEM) with energy-dispersive X-ray spectroscopy (EDX) to quantify elemental dissolution, particularly focusing on transition metal migration to the anode. Their methodology also includes inductively coupled plasma mass spectrometry (ICP-MS) of harvested electrodes to measure precise quantities of dissolved metals in the electrolyte, providing quantitative erosion metrics that correlate with electrochemical performance decline.

Strengths: Comprehensive approach combining in-situ electrochemical measurements with post-mortem analytical techniques provides both real-time and detailed compositional data. Their established correlation between measured transition metal dissolution and capacity fade enables predictive modeling of battery lifetime. Weaknesses: Post-mortem techniques are destructive and cannot be used for continuous monitoring. The protocol requires expensive analytical equipment and specialized laboratory facilities.

Toyota Motor Corp.

Technical Solution: Toyota Motor Corporation has developed a sophisticated protocol for measuring NMC battery material erosion that focuses on long-term durability under real-world automotive conditions. Their approach combines standardized cycling protocols with advanced in-situ monitoring techniques. Toyota's methodology employs reference electrode measurements during extended cycling to isolate cathode degradation from overall cell performance decline. The company has pioneered the use of operando X-ray absorption spectroscopy (XAS) to monitor transition metal oxidation states during cycling, providing insights into chemical changes associated with material dissolution. Their protocol includes specialized electrolyte analysis techniques that can detect sub-ppm levels of dissolved transition metals using inductively coupled plasma optical emission spectroscopy (ICP-OES). Toyota has also developed accelerated testing protocols that correlate with real-world degradation patterns observed in their hybrid and electric vehicle fleets, allowing for more accurate prediction of cathode erosion rates under various driving conditions and environmental factors.

Strengths: Protocols are validated against extensive real-world vehicle data, ensuring relevance to actual automotive applications. Their multi-scale approach connects atomic-level material changes to vehicle-level performance impacts. Weaknesses: Some techniques require specialized synchrotron facilities for operando measurements, limiting widespread implementation. The proprietary nature of some testing protocols limits standardization across the industry.

Critical Technologies in Battery Material Degradation Analysis

Lithium ion batteries, electronic devices, and methods

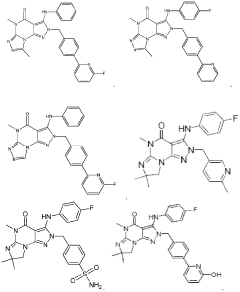

PatentActiveUS20190207246A1

Innovation

- A rechargeable lithium ion battery design featuring a positive electrode with surface-modified lithium nickel manganese cobalt oxide particles coated with Al2O3 and a nonaqueous liquid electrolyte containing specific additives, such as prop-1-ene-1,3-sultone, tris(trimethylsilyl)phosphite, and methylene methanedisulfonate, to enhance stability and reduce gas generation.

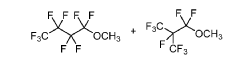

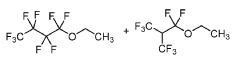

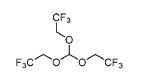

High efficiency electrolytes for high voltage battery systems

PatentWO2020131175A1

Innovation

- Development of electrolytes comprising a lithium-containing active salt, an ether-based solvent, and a diluent, specifically lithium bis(fluorosulfonyl)imide (LiFSI) with DME and TTE, which form localized solvent-cation-anion aggregates, reducing free solvent molecules and enhancing stability, allowing batteries to operate at voltages of 4.4 V or higher with high coulombic efficiency.

Safety and Environmental Implications of NMC Battery Testing

The testing of NMC (Nickel Manganese Cobalt) batteries carries significant safety and environmental implications that must be carefully considered during material erosion measurements. These lithium-ion batteries contain potentially hazardous materials that can pose risks during testing procedures, particularly when evaluating degradation mechanisms.

Safety protocols for NMC battery testing must address thermal runaway risks, which can occur when testing conditions exceed safe operating parameters. Industry standards typically require testing facilities to implement robust ventilation systems, fire suppression equipment, and personal protective equipment for technicians. The release of toxic gases, including hydrogen fluoride and carbon monoxide, represents a serious hazard during thermal events that may occur during accelerated erosion testing.

Environmental considerations extend beyond immediate laboratory safety to the broader ecological impact of testing procedures. The leaching of heavy metals, particularly nickel and cobalt, from eroded battery materials presents significant environmental concerns. These metals can contaminate water systems and soil if not properly contained during and after testing. Industry protocols therefore mandate appropriate waste management procedures, including specialized disposal methods for test samples and contaminated equipment.

Regulatory frameworks governing NMC battery testing vary globally but generally include provisions from organizations such as the International Electrotechnical Commission (IEC) and ASTM International. These standards establish minimum requirements for environmental protection during testing, including containment measures for potentially harmful emissions and leachates. Compliance with these regulations is essential not only for legal operation but also for responsible environmental stewardship.

The life cycle assessment perspective must also be considered when evaluating material erosion. Testing protocols increasingly incorporate methodologies that account for the environmental footprint of the entire testing process, from sample preparation to waste disposal. This holistic approach helps quantify the true environmental cost of battery development and optimization efforts.

Worker exposure to potentially carcinogenic compounds during erosion testing represents another critical safety consideration. Nickel compounds, in particular, are classified as human carcinogens, necessitating strict exposure limits and monitoring protocols. Industry best practices include regular air quality assessments and biological monitoring for technicians regularly involved in NMC battery testing.

Emerging research suggests that nano-scale particles released during erosion testing may pose unique health and environmental risks not fully addressed by current protocols. These particles can remain airborne for extended periods and potentially penetrate protective equipment, highlighting the need for continued evolution of safety standards as measurement technologies advance.

Safety protocols for NMC battery testing must address thermal runaway risks, which can occur when testing conditions exceed safe operating parameters. Industry standards typically require testing facilities to implement robust ventilation systems, fire suppression equipment, and personal protective equipment for technicians. The release of toxic gases, including hydrogen fluoride and carbon monoxide, represents a serious hazard during thermal events that may occur during accelerated erosion testing.

Environmental considerations extend beyond immediate laboratory safety to the broader ecological impact of testing procedures. The leaching of heavy metals, particularly nickel and cobalt, from eroded battery materials presents significant environmental concerns. These metals can contaminate water systems and soil if not properly contained during and after testing. Industry protocols therefore mandate appropriate waste management procedures, including specialized disposal methods for test samples and contaminated equipment.

Regulatory frameworks governing NMC battery testing vary globally but generally include provisions from organizations such as the International Electrotechnical Commission (IEC) and ASTM International. These standards establish minimum requirements for environmental protection during testing, including containment measures for potentially harmful emissions and leachates. Compliance with these regulations is essential not only for legal operation but also for responsible environmental stewardship.

The life cycle assessment perspective must also be considered when evaluating material erosion. Testing protocols increasingly incorporate methodologies that account for the environmental footprint of the entire testing process, from sample preparation to waste disposal. This holistic approach helps quantify the true environmental cost of battery development and optimization efforts.

Worker exposure to potentially carcinogenic compounds during erosion testing represents another critical safety consideration. Nickel compounds, in particular, are classified as human carcinogens, necessitating strict exposure limits and monitoring protocols. Industry best practices include regular air quality assessments and biological monitoring for technicians regularly involved in NMC battery testing.

Emerging research suggests that nano-scale particles released during erosion testing may pose unique health and environmental risks not fully addressed by current protocols. These particles can remain airborne for extended periods and potentially penetrate protective equipment, highlighting the need for continued evolution of safety standards as measurement technologies advance.

Regulatory Compliance for Battery Material Evaluation

Regulatory compliance frameworks for battery material evaluation have evolved significantly in response to the growing importance of lithium-ion batteries in various industries. For NMC (Nickel Manganese Cobalt) battery material erosion measurement, adherence to established protocols is essential not only for quality assurance but also for meeting legal requirements across global markets.

The International Electrotechnical Commission (IEC) has developed several standards specifically addressing battery testing methodologies, with IEC 62660 series being particularly relevant for material degradation assessment in lithium-ion batteries. These standards outline specific procedures for measuring electrode material changes during cycling, including protocols for sample preparation, measurement conditions, and data analysis.

In the United States, the Department of Energy's Battery500 Consortium has established standardized testing protocols that manufacturers must follow when evaluating material stability in high-energy density batteries. These protocols specifically address NMC cathode material erosion measurements through techniques such as post-mortem analysis and in-situ monitoring methods.

The European Union, through its Battery Directive (2006/66/EC) and the more recent European Battery Regulation proposal, mandates specific requirements for battery durability testing. These regulations increasingly focus on material degradation as a key performance indicator, requiring manufacturers to document erosion rates using standardized measurement techniques.

In Asia, particularly in Japan and South Korea, industry associations like the Battery Association of Japan (BAJ) have developed their own testing standards that complement international protocols. These standards often include more stringent requirements for measuring transition metal dissolution from NMC cathodes, reflecting the region's leadership in battery manufacturing.

Compliance with these regulatory frameworks requires sophisticated analytical techniques. X-ray diffraction (XRD), scanning electron microscopy (SEM), and inductively coupled plasma mass spectrometry (ICP-MS) are commonly specified in these protocols for quantifying material erosion. The specific sample preparation methods, measurement parameters, and reporting formats are typically detailed in the regulatory documents.

For companies developing or manufacturing NMC batteries, maintaining a comprehensive regulatory compliance program is essential. This includes regular testing according to prescribed protocols, documentation of results in standardized formats, and continuous monitoring of evolving regulatory requirements across different markets. Failure to comply with these standards can result in market access restrictions, product recalls, or legal penalties.

The International Electrotechnical Commission (IEC) has developed several standards specifically addressing battery testing methodologies, with IEC 62660 series being particularly relevant for material degradation assessment in lithium-ion batteries. These standards outline specific procedures for measuring electrode material changes during cycling, including protocols for sample preparation, measurement conditions, and data analysis.

In the United States, the Department of Energy's Battery500 Consortium has established standardized testing protocols that manufacturers must follow when evaluating material stability in high-energy density batteries. These protocols specifically address NMC cathode material erosion measurements through techniques such as post-mortem analysis and in-situ monitoring methods.

The European Union, through its Battery Directive (2006/66/EC) and the more recent European Battery Regulation proposal, mandates specific requirements for battery durability testing. These regulations increasingly focus on material degradation as a key performance indicator, requiring manufacturers to document erosion rates using standardized measurement techniques.

In Asia, particularly in Japan and South Korea, industry associations like the Battery Association of Japan (BAJ) have developed their own testing standards that complement international protocols. These standards often include more stringent requirements for measuring transition metal dissolution from NMC cathodes, reflecting the region's leadership in battery manufacturing.

Compliance with these regulatory frameworks requires sophisticated analytical techniques. X-ray diffraction (XRD), scanning electron microscopy (SEM), and inductively coupled plasma mass spectrometry (ICP-MS) are commonly specified in these protocols for quantifying material erosion. The specific sample preparation methods, measurement parameters, and reporting formats are typically detailed in the regulatory documents.

For companies developing or manufacturing NMC batteries, maintaining a comprehensive regulatory compliance program is essential. This includes regular testing according to prescribed protocols, documentation of results in standardized formats, and continuous monitoring of evolving regulatory requirements across different markets. Failure to comply with these standards can result in market access restrictions, product recalls, or legal penalties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!