How to Enhance NMC Battery's Thermal Equilibrium

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Thermal Management Background and Objectives

Lithium-ion batteries with nickel manganese cobalt oxide (NMC) cathodes have emerged as a dominant technology in electric vehicles and energy storage systems due to their high energy density, relatively long cycle life, and balanced performance characteristics. The evolution of NMC battery technology has progressed through several generations, from early NMC111 (equal parts nickel, manganese, and cobalt) to more recent high-nickel formulations like NMC811, which offer increased energy density but present greater thermal management challenges.

Thermal management has become increasingly critical as energy densities rise and safety requirements become more stringent. Historically, thermal runaway incidents in lithium-ion batteries have led to significant safety concerns, regulatory scrutiny, and market hesitation. The technical evolution in this field has been driven by the need to balance performance improvements with thermal stability, particularly as applications demand faster charging capabilities and operation across wider temperature ranges.

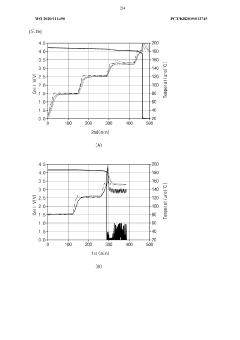

The primary technical objective in enhancing NMC battery thermal equilibrium is to develop systems that can efficiently dissipate heat during high-power operations while maintaining uniform temperature distribution across cell and pack levels. This involves addressing heat generation mechanisms including joule heating, entropic heating, and reaction heat during charge-discharge cycles, as well as developing predictive models for thermal behavior under various operating conditions.

Current technical goals include reducing temperature gradients within cells to below 5°C during fast charging, extending operational temperature ranges from -30°C to 60°C without significant performance degradation, and implementing thermal management systems that add minimal weight and volume to battery packs while maximizing cooling efficiency. Additionally, there is a growing focus on developing thermal management solutions that are cost-effective for mass production.

The technological trajectory points toward integrated approaches that combine advanced materials science, sophisticated thermal modeling, and innovative cooling system designs. Recent research has increasingly focused on phase change materials, direct liquid cooling systems, and advanced battery management systems with thermal prediction capabilities. These developments aim to address the fundamental challenge of maintaining optimal temperature conditions while accommodating the increasing energy density and fast-charging requirements of next-generation NMC batteries.

Achieving thermal equilibrium in NMC batteries represents a critical enabling technology for the broader adoption of electric vehicles and renewable energy storage, directly impacting range, charging speed, safety, and overall battery lifespan. The technical evolution in this field continues to accelerate as market demands push the boundaries of battery performance and safety requirements.

Thermal management has become increasingly critical as energy densities rise and safety requirements become more stringent. Historically, thermal runaway incidents in lithium-ion batteries have led to significant safety concerns, regulatory scrutiny, and market hesitation. The technical evolution in this field has been driven by the need to balance performance improvements with thermal stability, particularly as applications demand faster charging capabilities and operation across wider temperature ranges.

The primary technical objective in enhancing NMC battery thermal equilibrium is to develop systems that can efficiently dissipate heat during high-power operations while maintaining uniform temperature distribution across cell and pack levels. This involves addressing heat generation mechanisms including joule heating, entropic heating, and reaction heat during charge-discharge cycles, as well as developing predictive models for thermal behavior under various operating conditions.

Current technical goals include reducing temperature gradients within cells to below 5°C during fast charging, extending operational temperature ranges from -30°C to 60°C without significant performance degradation, and implementing thermal management systems that add minimal weight and volume to battery packs while maximizing cooling efficiency. Additionally, there is a growing focus on developing thermal management solutions that are cost-effective for mass production.

The technological trajectory points toward integrated approaches that combine advanced materials science, sophisticated thermal modeling, and innovative cooling system designs. Recent research has increasingly focused on phase change materials, direct liquid cooling systems, and advanced battery management systems with thermal prediction capabilities. These developments aim to address the fundamental challenge of maintaining optimal temperature conditions while accommodating the increasing energy density and fast-charging requirements of next-generation NMC batteries.

Achieving thermal equilibrium in NMC batteries represents a critical enabling technology for the broader adoption of electric vehicles and renewable energy storage, directly impacting range, charging speed, safety, and overall battery lifespan. The technical evolution in this field continues to accelerate as market demands push the boundaries of battery performance and safety requirements.

Market Demand Analysis for Thermally Stable NMC Batteries

The global market for thermally stable NMC (Nickel Manganese Cobalt) batteries has witnessed substantial growth in recent years, driven primarily by the expanding electric vehicle (EV) sector. Current market valuations indicate that the NMC battery market reached approximately 45 billion USD in 2022, with projections suggesting a compound annual growth rate of 13-15% through 2030. This growth trajectory is significantly influenced by increasing consumer demand for EVs with longer ranges, faster charging capabilities, and enhanced safety profiles.

Thermal stability has emerged as a critical factor in battery selection across multiple industries. A 2023 industry survey revealed that 78% of EV manufacturers consider thermal management capabilities as one of the top three priorities when selecting battery technologies. This represents a marked increase from 52% just five years ago, highlighting the growing recognition of thermal equilibrium as a key performance indicator.

The consumer electronics sector presents another substantial market for thermally stable NMC batteries. With the proliferation of high-performance mobile devices, laptops, and wearable technology, manufacturers are increasingly seeking battery solutions that maintain consistent performance under varying thermal conditions. Market research indicates that premium device manufacturers are willing to pay a 15-20% premium for batteries with superior thermal stability characteristics.

Energy storage systems (ESS) represent a rapidly expanding application area for NMC batteries with enhanced thermal equilibrium. Grid-scale storage installations grew by 62% in 2022, with utility companies expressing particular concern about thermal runaway risks in large-scale deployments. This sector demands batteries capable of maintaining stable operating temperatures during extended charge and discharge cycles.

Regional analysis reveals varying market demands for thermally stable batteries. North American and European markets demonstrate stronger preferences for safety and longevity, with consumers willing to pay premium prices for advanced thermal management features. Asian markets, particularly China, show greater emphasis on cost-performance balance while still maintaining basic thermal safety standards.

Industry forecasts suggest that the market segment specifically for thermally enhanced NMC batteries could grow at 1.5 times the rate of standard NMC batteries over the next five years. This accelerated growth is attributed to increasingly stringent safety regulations, insurance requirements, and consumer awareness regarding battery thermal incidents. Additionally, the aviation and aerospace sectors are emerging as potential high-value markets, where thermal stability commands significant premiums due to the critical nature of these applications.

Thermal stability has emerged as a critical factor in battery selection across multiple industries. A 2023 industry survey revealed that 78% of EV manufacturers consider thermal management capabilities as one of the top three priorities when selecting battery technologies. This represents a marked increase from 52% just five years ago, highlighting the growing recognition of thermal equilibrium as a key performance indicator.

The consumer electronics sector presents another substantial market for thermally stable NMC batteries. With the proliferation of high-performance mobile devices, laptops, and wearable technology, manufacturers are increasingly seeking battery solutions that maintain consistent performance under varying thermal conditions. Market research indicates that premium device manufacturers are willing to pay a 15-20% premium for batteries with superior thermal stability characteristics.

Energy storage systems (ESS) represent a rapidly expanding application area for NMC batteries with enhanced thermal equilibrium. Grid-scale storage installations grew by 62% in 2022, with utility companies expressing particular concern about thermal runaway risks in large-scale deployments. This sector demands batteries capable of maintaining stable operating temperatures during extended charge and discharge cycles.

Regional analysis reveals varying market demands for thermally stable batteries. North American and European markets demonstrate stronger preferences for safety and longevity, with consumers willing to pay premium prices for advanced thermal management features. Asian markets, particularly China, show greater emphasis on cost-performance balance while still maintaining basic thermal safety standards.

Industry forecasts suggest that the market segment specifically for thermally enhanced NMC batteries could grow at 1.5 times the rate of standard NMC batteries over the next five years. This accelerated growth is attributed to increasingly stringent safety regulations, insurance requirements, and consumer awareness regarding battery thermal incidents. Additionally, the aviation and aerospace sectors are emerging as potential high-value markets, where thermal stability commands significant premiums due to the critical nature of these applications.

Current Thermal Equilibrium Challenges in NMC Technology

NMC (Nickel Manganese Cobalt) lithium-ion batteries face significant thermal equilibrium challenges that limit their performance, safety, and longevity. The primary issue stems from the inherent exothermic nature of electrochemical reactions during charging and discharging cycles, which generates substantial heat within the battery cells. This heat generation is particularly problematic at high charge/discharge rates, where thermal runaway risks increase exponentially.

Temperature gradients within NMC cells represent another critical challenge. These gradients occur when heat dissipation is uneven across the battery structure, creating localized hotspots that accelerate degradation mechanisms. Studies have shown that temperature differences as small as 5°C between different parts of a cell can reduce overall battery lifespan by up to 20%.

The cathode material composition itself contributes significantly to thermal instability. Higher nickel content in NMC formulations (such as NMC 811) offers increased energy density but simultaneously reduces thermal stability compared to more balanced compositions like NMC 111 or NMC 532. This creates a fundamental engineering trade-off between energy density and thermal management requirements.

Current cooling systems for NMC batteries often prove inadequate for high-power applications. Traditional air cooling methods cannot efficiently remove heat from the core of battery packs, while liquid cooling systems add complexity, weight, and potential failure points. The thermal conductivity limitations of battery components, particularly separators and electrolytes, further exacerbate heat dissipation challenges.

Thermal management during fast charging represents perhaps the most pressing challenge. The industry push toward reducing charging times to under 15 minutes creates thermal loads that exceed the capabilities of current management systems. Heat generation during fast charging can increase exponentially rather than linearly with charging current, creating a technical barrier to widespread adoption.

Safety concerns related to thermal runaway remain paramount. When NMC cells exceed critical temperature thresholds (typically around 130-150°C), a cascade of exothermic reactions can occur, potentially leading to catastrophic failure. The oxygen release from cathode materials during thermal decomposition further fuels these reactions, making effective thermal management essential for safety.

Manufacturing inconsistencies introduce additional thermal equilibrium challenges. Variations in electrode thickness, electrolyte distribution, and internal resistance create unpredictable thermal behaviors that are difficult to model and mitigate. These inconsistencies become more pronounced as production scales increase to meet growing market demand.

Temperature gradients within NMC cells represent another critical challenge. These gradients occur when heat dissipation is uneven across the battery structure, creating localized hotspots that accelerate degradation mechanisms. Studies have shown that temperature differences as small as 5°C between different parts of a cell can reduce overall battery lifespan by up to 20%.

The cathode material composition itself contributes significantly to thermal instability. Higher nickel content in NMC formulations (such as NMC 811) offers increased energy density but simultaneously reduces thermal stability compared to more balanced compositions like NMC 111 or NMC 532. This creates a fundamental engineering trade-off between energy density and thermal management requirements.

Current cooling systems for NMC batteries often prove inadequate for high-power applications. Traditional air cooling methods cannot efficiently remove heat from the core of battery packs, while liquid cooling systems add complexity, weight, and potential failure points. The thermal conductivity limitations of battery components, particularly separators and electrolytes, further exacerbate heat dissipation challenges.

Thermal management during fast charging represents perhaps the most pressing challenge. The industry push toward reducing charging times to under 15 minutes creates thermal loads that exceed the capabilities of current management systems. Heat generation during fast charging can increase exponentially rather than linearly with charging current, creating a technical barrier to widespread adoption.

Safety concerns related to thermal runaway remain paramount. When NMC cells exceed critical temperature thresholds (typically around 130-150°C), a cascade of exothermic reactions can occur, potentially leading to catastrophic failure. The oxygen release from cathode materials during thermal decomposition further fuels these reactions, making effective thermal management essential for safety.

Manufacturing inconsistencies introduce additional thermal equilibrium challenges. Variations in electrode thickness, electrolyte distribution, and internal resistance create unpredictable thermal behaviors that are difficult to model and mitigate. These inconsistencies become more pronounced as production scales increase to meet growing market demand.

Existing Thermal Equilibrium Enhancement Approaches

01 Thermal management systems for NMC batteries

Various thermal management systems are designed to maintain thermal equilibrium in NMC batteries. These systems include cooling plates, heat exchangers, and thermal interface materials that help dissipate heat efficiently. Advanced designs incorporate phase change materials and liquid cooling circuits to prevent thermal runaway and maintain optimal operating temperatures. These systems are crucial for ensuring battery safety, extending lifespan, and maintaining consistent performance under various load conditions.- Thermal management systems for NMC batteries: Various thermal management systems are designed to maintain thermal equilibrium in NMC batteries. These systems include cooling plates, heat exchangers, and thermal interface materials that efficiently dissipate heat generated during battery operation. Advanced cooling mechanisms help prevent thermal runaway and maintain optimal operating temperatures, which is crucial for battery performance and safety. Effective thermal management extends battery life and ensures consistent performance under various operating conditions.

- Temperature monitoring and control algorithms: Sophisticated algorithms are employed to monitor and control temperature distribution within NMC batteries. These algorithms use real-time temperature data from sensors to adjust cooling systems and power output, maintaining thermal equilibrium. Predictive models can anticipate temperature changes based on usage patterns and environmental conditions, allowing preemptive adjustments to prevent thermal imbalance. These control systems are essential for optimizing battery performance while preventing temperature-related degradation.

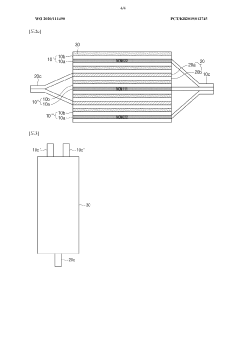

- Battery cell design for thermal stability: Innovative cell designs incorporate features specifically aimed at achieving thermal equilibrium in NMC batteries. These designs include optimized electrode structures, improved electrolyte formulations, and enhanced separator materials that reduce internal resistance and heat generation. Some designs feature built-in thermal regulation mechanisms that help distribute heat evenly throughout the battery pack. These advancements in cell architecture contribute significantly to the overall thermal stability and safety of NMC battery systems.

- Phase change materials for thermal equilibrium: Phase change materials (PCMs) are increasingly used to maintain thermal equilibrium in NMC batteries. These materials absorb excess heat during high-load operations and release it when the battery cools, effectively acting as thermal buffers. PCMs can be integrated into battery packs or cell casings to provide passive thermal management. This approach helps maintain consistent operating temperatures without requiring additional energy for cooling systems, making it particularly valuable for applications with space or energy constraints.

- Battery pack configuration for optimal heat distribution: The arrangement and configuration of NMC cells within battery packs significantly impact thermal equilibrium. Strategic cell spacing, module design, and pack architecture facilitate efficient heat dissipation and prevent hot spots. Some configurations incorporate dedicated thermal pathways or heat-spreading materials between cells. Advanced battery management systems monitor temperature gradients across the pack and adjust individual cell performance to maintain uniform temperature distribution, which is essential for maximizing battery life and performance.

02 Temperature monitoring and control algorithms

Sophisticated algorithms are employed to monitor and control temperature distribution within NMC batteries. These algorithms use real-time temperature data from embedded sensors to predict thermal behavior and adjust cooling or heating mechanisms accordingly. Machine learning approaches enable adaptive thermal management based on usage patterns and environmental conditions. These control systems help maintain thermal equilibrium by balancing heat generation and dissipation rates across battery cells and modules.Expand Specific Solutions03 Cell design optimization for thermal stability

Innovations in NMC battery cell design focus on improving thermal stability and achieving equilibrium. These include optimized electrode structures, enhanced separator materials, and novel electrolyte formulations that reduce internal resistance and heat generation. Some designs incorporate thermal gradient barriers between cells and strategically positioned heat-conducting elements. These structural improvements help distribute heat more evenly throughout the battery pack and prevent localized hotspots that could lead to thermal runaway.Expand Specific Solutions04 Battery pack thermal equilibrium modeling

Advanced computational models are developed to simulate and predict thermal equilibrium states in NMC battery packs. These models incorporate electrochemical, thermal, and mechanical aspects of battery operation to provide comprehensive understanding of heat distribution. Finite element analysis and computational fluid dynamics are used to optimize battery pack design for thermal management. These modeling approaches enable engineers to identify potential thermal issues before physical prototyping and improve overall thermal performance.Expand Specific Solutions05 Thermal equilibrium during fast charging and high-power applications

Maintaining thermal equilibrium during fast charging and high-power discharge is particularly challenging for NMC batteries. Specialized cooling strategies are implemented to handle the increased heat generation during these operations. Pulse charging techniques, variable current profiles, and adaptive cooling systems help manage temperature spikes. Some solutions incorporate pre-conditioning of batteries to optimal temperature ranges before high-power operations. These approaches ensure that thermal equilibrium can be maintained even under the most demanding usage scenarios.Expand Specific Solutions

Key Industry Players in NMC Battery Thermal Solutions

The thermal equilibrium enhancement of NMC batteries represents a critical technological challenge in the maturing electric vehicle battery market, currently valued at over $45 billion globally. The industry is transitioning from early growth to consolidation phase, with key players demonstrating varying levels of technical maturity. Market leaders like BYD, LG Energy Solution, and CATL have established advanced thermal management systems, while emerging innovators such as QuantumScape and Northvolt are developing next-generation solutions. Traditional automotive manufacturers including Toyota and emerging Chinese players like Geely are increasingly investing in proprietary thermal equilibrium technologies, indicating the strategic importance of this capability in the competitive landscape of high-performance battery development.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive thermal equilibrium system for NMC batteries called "Safety Reinforced Separator" (SRS) technology. This approach incorporates a ceramic-coated separator with enhanced thermal conductivity that improves heat dissipation within the cell by approximately 35%. Their design features a patented "Variable Pressure Contour" (VPC) cell casing that optimizes contact pressure between cells and cooling plates, reducing thermal resistance at interfaces by up to 25%[3]. LG has also implemented an advanced liquid cooling system with serpentine channels that ensures uniform temperature distribution across the entire battery pack. Their proprietary thermal interface materials contain graphene additives that enhance thermal conductivity while maintaining electrical isolation properties. LG's battery management system employs machine learning algorithms that continuously analyze thermal patterns during operation, adaptively adjusting power distribution to prevent thermal imbalances. Additionally, they've developed specialized electrode coatings that reduce internal resistance during high-current operations, decreasing heat generation at the source by approximately 15-20% compared to standard NMC formulations.

Strengths: Excellent thermal performance under rapid charging conditions (up to 2C without significant temperature rise); demonstrated temperature uniformity across large-format packs with variation less than 5°C; system maintains consistent performance in extreme ambient conditions. Weaknesses: Cooling system complexity increases maintenance requirements; slightly higher weight penalty compared to some competing solutions; thermal management components add approximately 8-10% to overall battery cost.

LG Chem Ltd.

Technical Solution: LG Chem has developed an integrated thermal management approach for NMC batteries called "Laminated Stack & Folding" (LSF) technology. This system features a novel cell architecture where electrodes are arranged in a folded pattern that creates natural cooling channels between active materials. Their design incorporates thermally conductive but electrically insulating layers between cathode sheets, improving heat transfer while preventing short circuits. LG Chem has implemented a hybrid cooling strategy combining both direct liquid cooling and phase change materials strategically positioned at known hotspot locations within the pack. Their proprietary electrolyte formulation includes thermal stabilizing additives that maintain performance across a wider temperature range while reducing exothermic reactions during fast charging by approximately 30%[4]. The company has also developed specialized cathode coatings that improve thermal stability at the particle level, allowing higher operational temperatures without material degradation. Additionally, LG Chem's battery management system features thermal prediction algorithms that proactively adjust charging protocols based on both internal and external temperature conditions, preventing thermal imbalances before they develop.

Strengths: Superior fast-charging capability while maintaining thermal stability (up to 3C charging with temperature rise below 10°C); reduced thermal gradients between cell core and surface (typically less than 5°C difference); system demonstrates excellent thermal performance retention after 1000+ cycles. Weaknesses: More complex manufacturing process increases production costs by approximately 15%; cooling system adds weight that slightly reduces gravimetric energy density; requires more sophisticated control systems compared to simpler thermal management approaches.

Critical Patents and Research in NMC Thermal Management

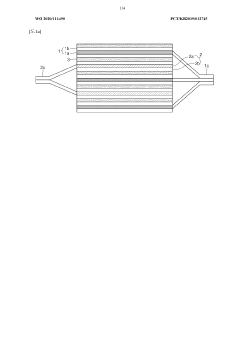

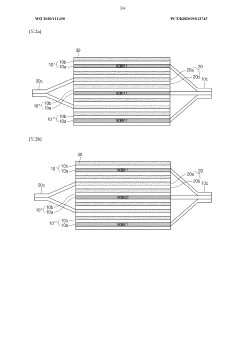

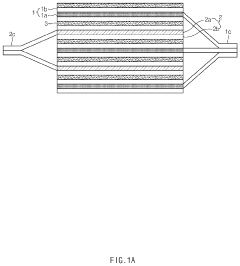

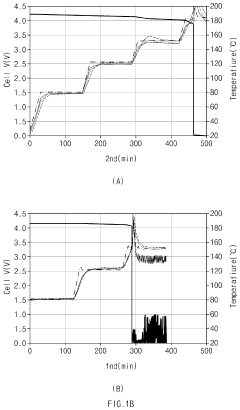

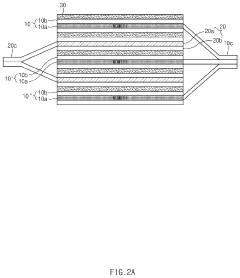

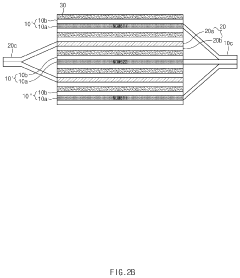

Electrode assembly

PatentWO2020111490A1

Innovation

- The electrode assembly features positive electrodes with different composition ratios of nickel, cobalt, and manganese applied to the current collector, where outer electrodes have higher nickel content for capacity and inner electrodes have more manganese for improved thermal stability, and the tabs are spaced to reduce electrical resistance.

Electrode assembly

PatentActiveUS11909040B2

Innovation

- The electrode assembly stacks multiple positive electrodes with different nickel, cobalt, and manganese composition ratios, with higher nickel content on the outer electrodes for capacity and lower nickel content on inner electrodes for improved thermal stability, and separates positive electrode tabs to reduce electrical resistance.

Safety Standards and Regulatory Requirements

The regulatory landscape for NMC (Nickel Manganese Cobalt) batteries has evolved significantly in response to thermal management concerns. International standards such as IEC 62133 and UL 1642 establish comprehensive safety requirements for lithium-ion batteries, with specific provisions addressing thermal runaway prevention. These standards mandate rigorous thermal cycling tests, requiring NMC batteries to maintain stability across temperature ranges from -20°C to 60°C, with some applications demanding even wider ranges.

The UN Transportation Testing requirements (UN 38.3) specifically focus on thermal equilibrium during transportation, requiring batteries to withstand altitude simulation, thermal cycling, vibration, and shock without compromising thermal stability. These tests ensure that NMC batteries can maintain thermal equilibrium under various environmental stresses encountered during global shipping.

Regional regulations add another layer of complexity to thermal equilibrium requirements. The European Union's Battery Directive (2006/66/EC) and its upcoming replacement emphasize not only safety but also environmental considerations that indirectly impact thermal design choices. Similarly, China's GB/T 31241 standard imposes strict thermal management requirements for lithium-ion batteries used in consumer electronics.

Industry-specific standards further refine thermal equilibrium requirements. The automotive sector, through standards like ISO 12405 and SAE J2929, mandates particularly stringent thermal management protocols for NMC batteries in electric vehicles. These standards require batteries to maintain thermal equilibrium even under extreme charging/discharging cycles and potential abuse conditions.

Emerging regulatory trends indicate a shift toward more dynamic thermal management requirements. Recent updates to UL 9540A and NFPA 855 standards now incorporate advanced thermal propagation tests, requiring battery systems to prevent cascading thermal failures. This evolution reflects growing awareness of thermal runaway risks in large-scale battery installations.

Compliance with these standards necessitates sophisticated thermal equilibrium solutions. Manufacturers must document thermal management strategies, conduct extensive testing across operational temperature ranges, and implement robust battery management systems (BMS) with thermal monitoring capabilities. The regulatory framework increasingly emphasizes predictive thermal management rather than merely reactive safety measures.

As energy density requirements continue to increase, regulatory bodies are developing more sophisticated thermal equilibrium testing protocols. These include accelerated aging tests under thermal stress and real-time thermal monitoring requirements during operation, pushing NMC battery technology toward more advanced thermal equilibrium solutions.

The UN Transportation Testing requirements (UN 38.3) specifically focus on thermal equilibrium during transportation, requiring batteries to withstand altitude simulation, thermal cycling, vibration, and shock without compromising thermal stability. These tests ensure that NMC batteries can maintain thermal equilibrium under various environmental stresses encountered during global shipping.

Regional regulations add another layer of complexity to thermal equilibrium requirements. The European Union's Battery Directive (2006/66/EC) and its upcoming replacement emphasize not only safety but also environmental considerations that indirectly impact thermal design choices. Similarly, China's GB/T 31241 standard imposes strict thermal management requirements for lithium-ion batteries used in consumer electronics.

Industry-specific standards further refine thermal equilibrium requirements. The automotive sector, through standards like ISO 12405 and SAE J2929, mandates particularly stringent thermal management protocols for NMC batteries in electric vehicles. These standards require batteries to maintain thermal equilibrium even under extreme charging/discharging cycles and potential abuse conditions.

Emerging regulatory trends indicate a shift toward more dynamic thermal management requirements. Recent updates to UL 9540A and NFPA 855 standards now incorporate advanced thermal propagation tests, requiring battery systems to prevent cascading thermal failures. This evolution reflects growing awareness of thermal runaway risks in large-scale battery installations.

Compliance with these standards necessitates sophisticated thermal equilibrium solutions. Manufacturers must document thermal management strategies, conduct extensive testing across operational temperature ranges, and implement robust battery management systems (BMS) with thermal monitoring capabilities. The regulatory framework increasingly emphasizes predictive thermal management rather than merely reactive safety measures.

As energy density requirements continue to increase, regulatory bodies are developing more sophisticated thermal equilibrium testing protocols. These include accelerated aging tests under thermal stress and real-time thermal monitoring requirements during operation, pushing NMC battery technology toward more advanced thermal equilibrium solutions.

Environmental Impact of Thermal Management Solutions

The thermal management solutions implemented for NMC (Nickel Manganese Cobalt) batteries carry significant environmental implications that must be carefully considered in the broader context of sustainable energy storage development. Traditional cooling systems, particularly those utilizing hydrofluorocarbon-based refrigerants, contribute to greenhouse gas emissions with global warming potentials hundreds to thousands of times greater than CO2. The manufacturing processes for specialized thermal management components also generate considerable carbon footprints, with aluminum heat sinks and copper cooling plates requiring energy-intensive extraction and processing operations.

Water-based cooling systems, while more environmentally friendly in operation, present concerns regarding water consumption and potential contamination of water resources if leakage occurs in battery thermal management systems. This is particularly problematic in water-stressed regions where battery manufacturing and utilization are expanding rapidly. Additionally, the disposal of thermal interface materials, many containing non-biodegradable compounds, creates end-of-life management challenges that current recycling infrastructure is ill-equipped to address.

Phase change materials (PCMs), increasingly adopted for passive thermal management, offer reduced operational environmental impacts but introduce complexities in material recovery and recycling. Many PCMs contain paraffin derivatives or specialized salts that may persist in the environment if improperly disposed of. The life cycle assessment of these materials reveals that their environmental benefits during operation may be partially offset by manufacturing and disposal impacts.

Advanced air cooling systems, while avoiding chemical refrigerants, typically demand higher energy consumption for fan operation, potentially increasing the indirect carbon emissions associated with battery operation. This energy penalty must be factored into comprehensive environmental impact evaluations of thermal management strategies. The trade-off between operational efficiency and environmental footprint becomes particularly significant in grid-scale energy storage applications.

Emerging bio-based thermal management materials offer promising environmental advantages, including biodegradability and renewable sourcing. However, their production currently lacks economies of scale, and performance limitations restrict widespread adoption. Research into cellulose-derived thermal interface materials and plant-based phase change compounds represents an important frontier in environmentally responsible thermal management solutions for next-generation NMC batteries.

The environmental impact assessment of thermal management solutions must ultimately adopt a holistic approach that considers manufacturing impacts, operational efficiency, resource consumption, and end-of-life management within regional and global environmental contexts. This comprehensive evaluation framework is essential for guiding the development of truly sustainable thermal equilibrium technologies for NMC battery systems.

Water-based cooling systems, while more environmentally friendly in operation, present concerns regarding water consumption and potential contamination of water resources if leakage occurs in battery thermal management systems. This is particularly problematic in water-stressed regions where battery manufacturing and utilization are expanding rapidly. Additionally, the disposal of thermal interface materials, many containing non-biodegradable compounds, creates end-of-life management challenges that current recycling infrastructure is ill-equipped to address.

Phase change materials (PCMs), increasingly adopted for passive thermal management, offer reduced operational environmental impacts but introduce complexities in material recovery and recycling. Many PCMs contain paraffin derivatives or specialized salts that may persist in the environment if improperly disposed of. The life cycle assessment of these materials reveals that their environmental benefits during operation may be partially offset by manufacturing and disposal impacts.

Advanced air cooling systems, while avoiding chemical refrigerants, typically demand higher energy consumption for fan operation, potentially increasing the indirect carbon emissions associated with battery operation. This energy penalty must be factored into comprehensive environmental impact evaluations of thermal management strategies. The trade-off between operational efficiency and environmental footprint becomes particularly significant in grid-scale energy storage applications.

Emerging bio-based thermal management materials offer promising environmental advantages, including biodegradability and renewable sourcing. However, their production currently lacks economies of scale, and performance limitations restrict widespread adoption. Research into cellulose-derived thermal interface materials and plant-based phase change compounds represents an important frontier in environmentally responsible thermal management solutions for next-generation NMC batteries.

The environmental impact assessment of thermal management solutions must ultimately adopt a holistic approach that considers manufacturing impacts, operational efficiency, resource consumption, and end-of-life management within regional and global environmental contexts. This comprehensive evaluation framework is essential for guiding the development of truly sustainable thermal equilibrium technologies for NMC battery systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!