How to Test Mechanical Integrity of NMC Battery Pack Designs

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Pack Mechanical Testing Background and Objectives

Lithium-ion batteries with nickel manganese cobalt oxide (NMC) cathodes have emerged as a dominant technology in electric vehicles and energy storage systems due to their high energy density, good thermal stability, and relatively long cycle life. The mechanical integrity of NMC battery packs is critical to ensure safety, reliability, and performance throughout their operational lifetime. Testing methodologies for mechanical integrity have evolved significantly over the past decade, from basic crush tests to sophisticated multi-axial stress simulations and real-time monitoring systems.

The evolution of NMC battery technology has been marked by continuous improvements in energy density, with current commercial cells achieving 250-300 Wh/kg compared to approximately 150 Wh/kg a decade ago. This increase in energy density has been accompanied by new challenges in mechanical design and testing, as higher energy densities often correlate with increased sensitivity to mechanical damage and potential thermal runaway events.

Regulatory frameworks have significantly influenced the development of mechanical testing protocols. Standards such as UN 38.3, SAE J2464, and IEC 62660 have established baseline requirements for transportation, abuse tolerance, and performance testing. These standards continue to evolve as understanding of failure mechanisms improves and as new applications for NMC battery packs emerge across industries.

The primary objective of mechanical integrity testing for NMC battery packs is to validate designs against multiple failure modes, including vibration fatigue, shock impact, crush resistance, puncture resistance, and thermal expansion stresses. Testing must account for both normal operating conditions and extreme scenarios such as vehicle crashes or seismic events for stationary storage systems.

Another critical objective is to develop testing methodologies that can accurately predict battery pack behavior throughout its entire lifecycle. This includes understanding how mechanical properties change with aging, cycling, and temperature variations. Current research indicates that cell swelling during cycling can create internal stresses within packs that weren't present during initial testing, highlighting the need for dynamic testing approaches.

Advanced computational modeling has become an essential complement to physical testing, allowing for rapid iteration of designs before prototype fabrication. The integration of finite element analysis (FEA) with electrochemical models represents the cutting edge of pre-physical testing validation, though significant challenges remain in accurately modeling the complex multi-physics interactions within battery systems.

The ultimate goal of mechanical integrity testing is to establish a comprehensive framework that balances safety, performance, cost, and manufacturability. This requires a holistic approach that considers not only the battery cells themselves but also interconnects, thermal management systems, enclosures, and mounting structures as an integrated system under mechanical stress.

The evolution of NMC battery technology has been marked by continuous improvements in energy density, with current commercial cells achieving 250-300 Wh/kg compared to approximately 150 Wh/kg a decade ago. This increase in energy density has been accompanied by new challenges in mechanical design and testing, as higher energy densities often correlate with increased sensitivity to mechanical damage and potential thermal runaway events.

Regulatory frameworks have significantly influenced the development of mechanical testing protocols. Standards such as UN 38.3, SAE J2464, and IEC 62660 have established baseline requirements for transportation, abuse tolerance, and performance testing. These standards continue to evolve as understanding of failure mechanisms improves and as new applications for NMC battery packs emerge across industries.

The primary objective of mechanical integrity testing for NMC battery packs is to validate designs against multiple failure modes, including vibration fatigue, shock impact, crush resistance, puncture resistance, and thermal expansion stresses. Testing must account for both normal operating conditions and extreme scenarios such as vehicle crashes or seismic events for stationary storage systems.

Another critical objective is to develop testing methodologies that can accurately predict battery pack behavior throughout its entire lifecycle. This includes understanding how mechanical properties change with aging, cycling, and temperature variations. Current research indicates that cell swelling during cycling can create internal stresses within packs that weren't present during initial testing, highlighting the need for dynamic testing approaches.

Advanced computational modeling has become an essential complement to physical testing, allowing for rapid iteration of designs before prototype fabrication. The integration of finite element analysis (FEA) with electrochemical models represents the cutting edge of pre-physical testing validation, though significant challenges remain in accurately modeling the complex multi-physics interactions within battery systems.

The ultimate goal of mechanical integrity testing is to establish a comprehensive framework that balances safety, performance, cost, and manufacturability. This requires a holistic approach that considers not only the battery cells themselves but also interconnects, thermal management systems, enclosures, and mounting structures as an integrated system under mechanical stress.

Market Requirements for Battery Pack Mechanical Integrity

The global market for battery pack mechanical integrity testing is experiencing significant growth, driven primarily by the rapid expansion of electric vehicle (EV) adoption worldwide. Industry forecasts indicate that the EV battery testing equipment market is expected to grow at a compound annual growth rate of 17.5% through 2030, reflecting the increasing demand for reliable battery safety verification systems.

Automotive manufacturers and battery suppliers are facing stringent regulatory requirements regarding battery safety, particularly following several high-profile thermal runaway incidents. The UN ECE R100, GB/T 31467, and IEC 62660 standards have established comprehensive mechanical testing protocols that manufacturers must adhere to, creating substantial market demand for advanced testing solutions specifically designed for NMC (Nickel Manganese Cobalt) battery packs.

Consumer expectations regarding battery safety have reached unprecedented levels, with surveys indicating that over 85% of potential EV buyers consider battery safety ratings as a critical factor in their purchasing decisions. This consumer sentiment is driving OEMs to implement more rigorous testing regimes beyond minimum regulatory requirements, expanding the market for premium testing solutions that can provide comprehensive mechanical integrity verification.

The insurance industry has emerged as another significant market driver, with many insurers now requiring detailed battery pack testing documentation before providing coverage for EV fleets. This has created additional demand for standardized testing protocols and certification processes that can be recognized across multiple markets and jurisdictions.

From a geographical perspective, the Asia-Pacific region currently represents the largest market for battery pack testing equipment, accounting for approximately 45% of global demand. This regional dominance is attributed to the concentration of battery manufacturing facilities in China, South Korea, and Japan. However, North America and Europe are experiencing the fastest growth rates as domestic battery production capacity expands in these regions.

The market increasingly demands testing solutions that can simulate real-world conditions more accurately, including multi-axis vibration testing, thermal cycling during mechanical stress, and advanced impact testing that replicates complex crash scenarios. Additionally, there is growing interest in non-destructive testing methods that can be integrated into production lines, allowing for 100% inspection without sacrificing manufacturing throughput.

Cost considerations remain significant, with manufacturers seeking testing solutions that balance comprehensive safety verification with economic viability. The market shows particular interest in modular testing platforms that can be scaled according to production volume and adapted to different battery pack designs without requiring complete system replacement.

Automotive manufacturers and battery suppliers are facing stringent regulatory requirements regarding battery safety, particularly following several high-profile thermal runaway incidents. The UN ECE R100, GB/T 31467, and IEC 62660 standards have established comprehensive mechanical testing protocols that manufacturers must adhere to, creating substantial market demand for advanced testing solutions specifically designed for NMC (Nickel Manganese Cobalt) battery packs.

Consumer expectations regarding battery safety have reached unprecedented levels, with surveys indicating that over 85% of potential EV buyers consider battery safety ratings as a critical factor in their purchasing decisions. This consumer sentiment is driving OEMs to implement more rigorous testing regimes beyond minimum regulatory requirements, expanding the market for premium testing solutions that can provide comprehensive mechanical integrity verification.

The insurance industry has emerged as another significant market driver, with many insurers now requiring detailed battery pack testing documentation before providing coverage for EV fleets. This has created additional demand for standardized testing protocols and certification processes that can be recognized across multiple markets and jurisdictions.

From a geographical perspective, the Asia-Pacific region currently represents the largest market for battery pack testing equipment, accounting for approximately 45% of global demand. This regional dominance is attributed to the concentration of battery manufacturing facilities in China, South Korea, and Japan. However, North America and Europe are experiencing the fastest growth rates as domestic battery production capacity expands in these regions.

The market increasingly demands testing solutions that can simulate real-world conditions more accurately, including multi-axis vibration testing, thermal cycling during mechanical stress, and advanced impact testing that replicates complex crash scenarios. Additionally, there is growing interest in non-destructive testing methods that can be integrated into production lines, allowing for 100% inspection without sacrificing manufacturing throughput.

Cost considerations remain significant, with manufacturers seeking testing solutions that balance comprehensive safety verification with economic viability. The market shows particular interest in modular testing platforms that can be scaled according to production volume and adapted to different battery pack designs without requiring complete system replacement.

Current Testing Methodologies and Technical Barriers

The mechanical integrity testing of NMC (Nickel Manganese Cobalt) battery packs currently employs several established methodologies, each with specific applications and limitations. Vibration testing represents one of the most common approaches, typically conducted on electrodynamic shakers that simulate real-world conditions according to standards like UN38.3, SAE J2380, and IEC 62660. These tests evaluate how battery packs respond to various frequency profiles and acceleration levels, but often struggle to accurately replicate complex multi-axial vibrations encountered in actual usage scenarios.

Shock testing, another critical methodology, assesses battery pack resilience against sudden impacts through half-sine, sawtooth, or square wave pulses. While effective for evaluating catastrophic failure resistance, current shock testing equipment frequently lacks the capability to simulate combined loading conditions that batteries experience during real accidents, creating a significant gap between test results and real-world performance.

Crush and penetration testing methodologies evaluate structural integrity under extreme mechanical deformation. These tests typically involve applying controlled force until a predetermined displacement or until failure occurs. A major technical barrier in this domain is the difficulty in standardizing test procedures across different battery geometries and chemistries, leading to inconsistent safety evaluations across the industry.

Thermal-mechanical combined testing represents an emerging but underdeveloped methodology. Current approaches often test thermal and mechanical properties separately, failing to capture the critical interactions between thermal expansion, mechanical stress, and structural integrity. This separation creates significant blind spots in safety assessment, particularly for NMC batteries which are known for their thermal sensitivity.

Computational simulation methods, including Finite Element Analysis (FEA), are increasingly utilized but face substantial challenges in accurately modeling the complex multi-physics interactions within battery packs. Material models often inadequately represent the anisotropic and non-linear behaviors of battery components, while validation data remains limited due to the proprietary nature of battery designs and the destructive nature of mechanical testing.

Scale-related barriers present another significant challenge, as testing methodologies developed for cell-level assessment often fail to capture system-level behaviors when applied to complete battery packs. The interactions between cells, cooling systems, and structural components create emergent behaviors that current testing protocols struggle to evaluate comprehensively.

Accelerated aging effects on mechanical properties represent perhaps the most significant technical barrier in current testing methodologies. Most mechanical integrity tests are performed on new battery packs, neglecting the significant changes in material properties and structural integrity that occur throughout a battery's operational lifetime.

Shock testing, another critical methodology, assesses battery pack resilience against sudden impacts through half-sine, sawtooth, or square wave pulses. While effective for evaluating catastrophic failure resistance, current shock testing equipment frequently lacks the capability to simulate combined loading conditions that batteries experience during real accidents, creating a significant gap between test results and real-world performance.

Crush and penetration testing methodologies evaluate structural integrity under extreme mechanical deformation. These tests typically involve applying controlled force until a predetermined displacement or until failure occurs. A major technical barrier in this domain is the difficulty in standardizing test procedures across different battery geometries and chemistries, leading to inconsistent safety evaluations across the industry.

Thermal-mechanical combined testing represents an emerging but underdeveloped methodology. Current approaches often test thermal and mechanical properties separately, failing to capture the critical interactions between thermal expansion, mechanical stress, and structural integrity. This separation creates significant blind spots in safety assessment, particularly for NMC batteries which are known for their thermal sensitivity.

Computational simulation methods, including Finite Element Analysis (FEA), are increasingly utilized but face substantial challenges in accurately modeling the complex multi-physics interactions within battery packs. Material models often inadequately represent the anisotropic and non-linear behaviors of battery components, while validation data remains limited due to the proprietary nature of battery designs and the destructive nature of mechanical testing.

Scale-related barriers present another significant challenge, as testing methodologies developed for cell-level assessment often fail to capture system-level behaviors when applied to complete battery packs. The interactions between cells, cooling systems, and structural components create emergent behaviors that current testing protocols struggle to evaluate comprehensively.

Accelerated aging effects on mechanical properties represent perhaps the most significant technical barrier in current testing methodologies. Most mechanical integrity tests are performed on new battery packs, neglecting the significant changes in material properties and structural integrity that occur throughout a battery's operational lifetime.

State-of-the-Art Mechanical Integrity Testing Solutions

01 Structural design for mechanical integrity of NMC battery packs

The mechanical integrity of NMC battery packs can be enhanced through specific structural designs that protect against physical damage. These designs include reinforced casings, shock-absorbing materials, and specialized housing structures that distribute mechanical stress. Such structural elements help maintain the integrity of the battery pack during impact, vibration, and other mechanical stresses, preventing internal short circuits and ensuring operational safety.- Structural design for mechanical integrity: Battery packs with NMC (Nickel Manganese Cobalt) cathodes require specific structural designs to maintain mechanical integrity. These designs include reinforced housing, shock-absorbing materials, and strategic cell arrangement to distribute mechanical stress. The structural elements protect against external impacts, vibration, and thermal expansion, ensuring the battery pack remains intact during normal operation and in case of accidents.

- Thermal management systems for structural stability: Effective thermal management systems are crucial for maintaining the mechanical integrity of NMC battery packs. These systems include cooling channels, heat sinks, and thermal interface materials that prevent overheating and thermal runaway. By controlling temperature distribution, these systems minimize thermal stress on battery components, preventing warping, expansion, and other mechanical failures that could compromise the pack's structural integrity.

- Cell interconnection and mounting techniques: Advanced interconnection and mounting techniques are essential for NMC battery pack mechanical integrity. These include flexible bus bars, vibration-resistant cell holders, and specialized welding methods for electrical connections. These techniques accommodate the natural expansion and contraction of cells during charge-discharge cycles while maintaining electrical connectivity and structural stability, even under mechanical stress conditions.

- Protective encapsulation and sealing methods: Protective encapsulation and sealing methods enhance the mechanical integrity of NMC battery packs by isolating cells from environmental factors. These methods include conformal coatings, potting compounds, and specialized gaskets that prevent moisture ingress, chemical contamination, and physical damage. The encapsulation materials are selected for their ability to absorb shock, resist temperature fluctuations, and maintain structural integrity over the battery's operational lifetime.

- Monitoring and safety systems for mechanical integrity: Advanced monitoring and safety systems are implemented to maintain and verify the mechanical integrity of NMC battery packs. These include pressure sensors, strain gauges, and accelerometers that detect mechanical deformation or stress. The systems can trigger protective measures such as current limitation or pack disconnection when mechanical integrity is compromised, preventing cascading failures and enhancing overall safety and reliability.

02 Thermal management systems for NMC battery pack stability

Effective thermal management systems are crucial for maintaining the mechanical integrity of NMC battery packs. These systems include cooling channels, heat dissipation structures, and temperature regulation mechanisms that prevent thermal runaway and associated mechanical failures. By controlling temperature distribution within the battery pack, these systems reduce thermal expansion stress and prevent degradation of mechanical components, thereby extending battery life and enhancing safety.Expand Specific Solutions03 Cell arrangement and connection methods for improved mechanical strength

The arrangement and connection methods of individual NMC cells within a battery pack significantly impact its mechanical integrity. Innovative cell configurations, secure fastening techniques, and robust electrical connections help distribute mechanical loads evenly throughout the pack. These design approaches minimize stress concentration points and prevent cell movement during vibration or impact, thereby reducing the risk of internal damage and maintaining the structural integrity of the entire battery system.Expand Specific Solutions04 Protective coatings and materials for enhanced durability

Specialized protective coatings and materials can significantly enhance the mechanical integrity of NMC battery packs. These include corrosion-resistant layers, impact-absorbing composites, and flexible yet durable encapsulation materials that protect battery components from environmental factors and physical stress. The application of these materials helps prevent mechanical degradation over time, enhances resistance to vibration and impact, and extends the operational lifespan of the battery pack.Expand Specific Solutions05 Monitoring and safety systems for mechanical integrity maintenance

Advanced monitoring and safety systems play a crucial role in maintaining the mechanical integrity of NMC battery packs. These systems include sensors that detect mechanical stress, deformation, or damage, coupled with protective circuits that can isolate affected cells or shut down the battery when mechanical integrity is compromised. Real-time monitoring allows for early detection of potential mechanical failures, preventing catastrophic damage and enhancing overall battery pack safety and reliability.Expand Specific Solutions

Leading Battery Testing Equipment Manufacturers and Labs

The mechanical integrity testing of NMC battery packs is currently in a growth phase, with the market expanding rapidly due to increasing electric vehicle adoption and energy storage applications. The global market size for battery testing equipment is projected to reach significant scale as major players invest in advanced testing technologies. Leading companies like LG Energy Solution, Samsung SDI, and BYD have developed sophisticated mechanical integrity testing protocols, while automotive manufacturers such as GM and traditional engineering firms like Robert Bosch GmbH are advancing testing methodologies. Chinese manufacturers including CALB Group and Tianjin Lishen are rapidly gaining market share by implementing comprehensive testing frameworks. The technology is approaching maturity with standardized testing procedures emerging, though innovation continues in non-destructive testing methods and real-time monitoring systems.

Robert Bosch GmbH

Technical Solution: Bosch has developed a systematic approach to mechanical integrity testing for NMC battery packs that integrates both physical testing and advanced simulation methodologies. Their testing protocol begins with component-level characterization of materials and subassemblies before progressing to full pack testing. Bosch employs modal analysis techniques to identify natural frequencies and vibration modes of battery structures, using these insights to optimize test parameters. Their methodology includes hardware-in-the-loop simulation where physical battery components are integrated with virtual models to evaluate mechanical responses under complex loading scenarios. Bosch has developed specialized test equipment for evaluating connector and busbar reliability under vibration and thermal cycling, as these connection points are often critical failure locations. Their approach incorporates accelerated aging protocols that combine mechanical stress with charge-discharge cycling to evaluate how mechanical integrity changes throughout battery lifetime. Bosch also conducts extensive crash testing with high-speed cameras and sensor arrays to capture detailed deformation patterns during impact events.

Strengths: Integrated simulation and physical testing approach reduces development time; component-level characterization enables targeted design improvements; hardware-in-the-loop testing bridges gap between simulation and real-world performance. Weaknesses: Complex testing methodology requires specialized expertise; integration of multiple testing approaches increases program complexity and coordination requirements.

LG Chem Ltd.

Technical Solution: LG Chem has developed a comprehensive mechanical integrity testing protocol for NMC battery packs that combines multiple testing methodologies. Their approach includes multi-level testing from cell to module to pack level, utilizing vibration testing with six degrees of freedom simulation to replicate real-world conditions. They employ advanced computational methods including finite element analysis (FEA) to predict mechanical failures before physical testing. Their protocol includes crush tests, drop tests, and penetration tests with specialized equipment that can apply precise forces while monitoring electrical performance in real-time. LG Chem also utilizes thermal-mechanical coupled testing to evaluate how thermal expansion affects mechanical integrity during charge-discharge cycles. Their testing facilities incorporate high-speed imaging and acoustic emission monitoring to detect micro-cracks and internal structural changes before catastrophic failure occurs.

Strengths: Comprehensive multi-level testing approach provides thorough validation; advanced simulation capabilities reduce physical testing costs; real-time monitoring during tests enables early detection of potential failures. Weaknesses: Complex testing protocols require significant investment in specialized equipment; time-intensive testing process may slow time-to-market for new designs.

Critical Patents in Battery Pack Mechanical Testing

Lithium ion batteries, electronic devices, and methods

PatentActiveUS20190207246A1

Innovation

- A rechargeable lithium ion battery design featuring a positive electrode with surface-modified lithium nickel manganese cobalt oxide particles coated with Al2O3 and a nonaqueous liquid electrolyte containing specific additives, such as prop-1-ene-1,3-sultone, tris(trimethylsilyl)phosphite, and methylene methanedisulfonate, to enhance stability and reduce gas generation.

Method for restoration performances of aged nickel-rich NMC cathode material for lithium-ion secondary battery

PatentPendingEP4550454A1

Innovation

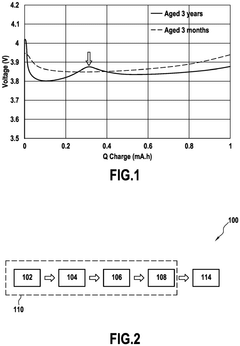

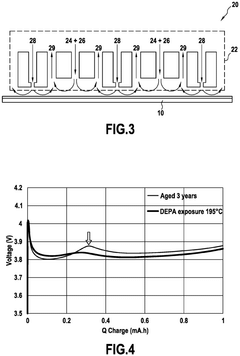

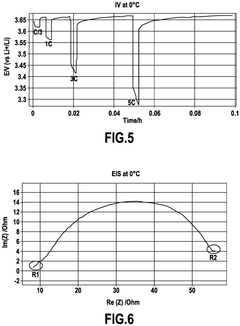

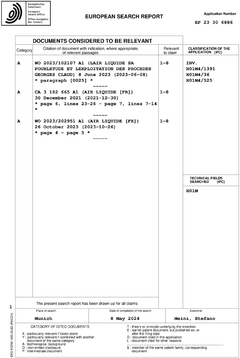

- A method involving the formation of a cathode with aged nickel-rich NMC material, a binder, and carbon black, followed by exposure to diethyl phosphoramidate at temperatures above 160°C to create a lithium phosphate protective layer, thereby reducing the overpotential peak.

Safety Regulations and Compliance Requirements

The mechanical integrity testing of NMC (Nickel Manganese Cobalt) battery packs must adhere to a comprehensive framework of safety regulations and compliance requirements established by various international and regional authorities. These standards are designed to ensure that battery packs can withstand mechanical stresses without compromising safety or performance.

UN 38.3 Transportation Testing serves as a foundational requirement for lithium-ion batteries, mandating mechanical tests including altitude simulation, thermal cycling, vibration, shock, external short circuit, impact/crush, overcharge, and forced discharge. Any battery pack design must pass these tests before being transported internationally, making them a critical baseline for mechanical integrity validation.

Regional certifications add another layer of compliance requirements. In North America, UL 2580 for electric vehicle batteries and UL 1642 for lithium cells establish specific mechanical abuse test protocols. The European Union enforces ECE R100 for vehicle batteries, while China implements GB/T 31485 standards. These regional variations necessitate tailored testing approaches for manufacturers targeting global markets.

Automotive-specific standards impose particularly rigorous mechanical integrity requirements. ISO 12405 details mechanical shock and vibration testing procedures specifically for lithium-ion traction battery packs. SAE J2464 provides comprehensive mechanical abuse test procedures, including crush, drop, penetration, and roll-over simulations that directly evaluate structural integrity under extreme conditions.

Industry-specific requirements further complicate the compliance landscape. Consumer electronics follow IEC 62133 standards, while grid storage applications must adhere to UL 9540A for thermal runaway propagation resistance. These standards often include mechanical integrity components tailored to the specific use environment.

Emerging regulations are increasingly focusing on mechanical safety during end-of-life handling and recycling. The EU Battery Directive and similar regulations in other regions mandate design considerations for safe disassembly and material recovery, adding another dimension to mechanical integrity requirements.

Testing laboratories must maintain appropriate accreditations (ISO/IEC 17025) to perform regulatory compliance testing, and documentation requirements are extensive. Test reports must include detailed information on test conditions, procedures, observations, and results with appropriate measurement uncertainties. This documentation becomes part of the technical file required for market access in most jurisdictions.

UN 38.3 Transportation Testing serves as a foundational requirement for lithium-ion batteries, mandating mechanical tests including altitude simulation, thermal cycling, vibration, shock, external short circuit, impact/crush, overcharge, and forced discharge. Any battery pack design must pass these tests before being transported internationally, making them a critical baseline for mechanical integrity validation.

Regional certifications add another layer of compliance requirements. In North America, UL 2580 for electric vehicle batteries and UL 1642 for lithium cells establish specific mechanical abuse test protocols. The European Union enforces ECE R100 for vehicle batteries, while China implements GB/T 31485 standards. These regional variations necessitate tailored testing approaches for manufacturers targeting global markets.

Automotive-specific standards impose particularly rigorous mechanical integrity requirements. ISO 12405 details mechanical shock and vibration testing procedures specifically for lithium-ion traction battery packs. SAE J2464 provides comprehensive mechanical abuse test procedures, including crush, drop, penetration, and roll-over simulations that directly evaluate structural integrity under extreme conditions.

Industry-specific requirements further complicate the compliance landscape. Consumer electronics follow IEC 62133 standards, while grid storage applications must adhere to UL 9540A for thermal runaway propagation resistance. These standards often include mechanical integrity components tailored to the specific use environment.

Emerging regulations are increasingly focusing on mechanical safety during end-of-life handling and recycling. The EU Battery Directive and similar regulations in other regions mandate design considerations for safe disassembly and material recovery, adding another dimension to mechanical integrity requirements.

Testing laboratories must maintain appropriate accreditations (ISO/IEC 17025) to perform regulatory compliance testing, and documentation requirements are extensive. Test reports must include detailed information on test conditions, procedures, observations, and results with appropriate measurement uncertainties. This documentation becomes part of the technical file required for market access in most jurisdictions.

Thermal-Mechanical Coupled Testing Approaches

Thermal-mechanical coupled testing represents a critical advancement in evaluating NMC battery pack designs, addressing the complex interplay between thermal and mechanical stresses that occur during operation. These testing methodologies simulate real-world conditions where temperature fluctuations and mechanical loads simultaneously affect battery integrity. The approach typically involves specialized equipment capable of applying controlled mechanical forces while simultaneously managing thermal conditions, ranging from extreme cold (-40°C) to elevated temperatures (60°C and beyond).

A comprehensive thermal-mechanical coupled testing protocol generally incorporates three key testing dimensions: thermal cycling under mechanical constraint, vibration testing at controlled temperatures, and impact/crush testing with thermal monitoring. These tests reveal failure modes that might remain undetected in isolated thermal or mechanical tests, providing crucial data on how thermal expansion and contraction interact with mechanical stresses to potentially compromise cell and pack integrity.

Advanced testing facilities employ environmental chambers equipped with servo-hydraulic or electrodynamic shaker systems that can apply precise mechanical loads while maintaining temperature control. High-precision sensors monitor multiple parameters simultaneously, including strain, displacement, temperature distribution, and electrical performance metrics. This multi-parameter monitoring enables researchers to identify correlations between thermal gradients and mechanical failure points.

Recent innovations in this field include the development of non-destructive evaluation techniques that can be applied during thermal-mechanical testing. These include acoustic emission monitoring, digital image correlation for real-time deformation mapping, and thermographic imaging to identify hotspots that may indicate incipient failure. Such techniques allow for the detection of internal structural changes before catastrophic failure occurs.

The data collected from thermal-mechanical coupled tests provides essential inputs for computational models, enabling more accurate prediction of battery pack behavior under complex operating conditions. This creates a valuable feedback loop where experimental results inform model refinement, and improved models guide the design of more targeted experimental protocols. The ultimate goal is to develop battery packs that maintain mechanical integrity across the full spectrum of thermal and mechanical stresses encountered throughout their operational lifetime.

For NMC battery packs specifically, thermal-mechanical coupled testing has revealed unique challenges related to the material's thermal expansion characteristics and mechanical properties at different states of charge. Testing protocols must therefore be tailored to address these specific material behaviors, with particular attention to the interfaces between cells and structural components where differential expansion can create significant stress concentrations.

A comprehensive thermal-mechanical coupled testing protocol generally incorporates three key testing dimensions: thermal cycling under mechanical constraint, vibration testing at controlled temperatures, and impact/crush testing with thermal monitoring. These tests reveal failure modes that might remain undetected in isolated thermal or mechanical tests, providing crucial data on how thermal expansion and contraction interact with mechanical stresses to potentially compromise cell and pack integrity.

Advanced testing facilities employ environmental chambers equipped with servo-hydraulic or electrodynamic shaker systems that can apply precise mechanical loads while maintaining temperature control. High-precision sensors monitor multiple parameters simultaneously, including strain, displacement, temperature distribution, and electrical performance metrics. This multi-parameter monitoring enables researchers to identify correlations between thermal gradients and mechanical failure points.

Recent innovations in this field include the development of non-destructive evaluation techniques that can be applied during thermal-mechanical testing. These include acoustic emission monitoring, digital image correlation for real-time deformation mapping, and thermographic imaging to identify hotspots that may indicate incipient failure. Such techniques allow for the detection of internal structural changes before catastrophic failure occurs.

The data collected from thermal-mechanical coupled tests provides essential inputs for computational models, enabling more accurate prediction of battery pack behavior under complex operating conditions. This creates a valuable feedback loop where experimental results inform model refinement, and improved models guide the design of more targeted experimental protocols. The ultimate goal is to develop battery packs that maintain mechanical integrity across the full spectrum of thermal and mechanical stresses encountered throughout their operational lifetime.

For NMC battery packs specifically, thermal-mechanical coupled testing has revealed unique challenges related to the material's thermal expansion characteristics and mechanical properties at different states of charge. Testing protocols must therefore be tailored to address these specific material behaviors, with particular attention to the interfaces between cells and structural components where differential expansion can create significant stress concentrations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!