Benchmark NMC Battery Thermal Management for Optimal Performance

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Thermal Management Background and Objectives

Lithium-ion batteries with nickel manganese cobalt oxide (NMC) cathodes have emerged as a dominant technology in electric vehicles and energy storage systems due to their high energy density, good cycle life, and relatively lower cost compared to other lithium-ion chemistries. The evolution of NMC battery technology has progressed from early NMC111 (equal parts nickel, manganese, and cobalt) to more nickel-rich compositions like NMC622 and NMC811, which offer higher energy density but present greater thermal management challenges.

Thermal management has become increasingly critical as NMC batteries have evolved toward higher energy densities and faster charging capabilities. Historical data shows that inadequate thermal control has been a primary factor in battery degradation and safety incidents. The industry has witnessed a progression from passive cooling systems to more sophisticated active thermal management solutions that maintain optimal operating temperatures between 15°C and 35°C.

Recent technological advancements have focused on addressing the inherent thermal challenges of NMC chemistry, particularly the exothermic reactions during charging and discharging that can lead to thermal runaway if not properly managed. The development trajectory shows a clear trend toward integrated thermal management systems that combine multiple cooling strategies and predictive temperature control algorithms.

The primary objective of benchmarking NMC battery thermal management is to establish industry standards for optimal performance across various operating conditions. This includes identifying best practices for maintaining uniform temperature distribution within battery packs, minimizing thermal gradients that lead to uneven aging, and developing robust safety protocols for thermal runaway prevention.

Another critical goal is to quantify the relationship between thermal management efficiency and key battery performance metrics such as capacity retention, power capability, and overall lifespan. Research indicates that effective thermal management can extend NMC battery life by 15-40% depending on usage patterns and environmental conditions.

The benchmarking efforts also aim to evaluate emerging cooling technologies, including phase change materials, immersion cooling, and advanced heat pipe designs, against traditional air and liquid cooling systems. This comparative analysis will help establish cost-effective thermal management solutions that balance performance requirements with manufacturing complexity and system weight constraints.

Furthermore, the benchmarking objectives include developing standardized testing protocols that accurately simulate real-world thermal conditions across diverse applications, from consumer electronics to electric vehicles and grid-scale energy storage. These protocols will enable meaningful comparisons between different thermal management approaches and accelerate the adoption of optimal solutions across the industry.

Thermal management has become increasingly critical as NMC batteries have evolved toward higher energy densities and faster charging capabilities. Historical data shows that inadequate thermal control has been a primary factor in battery degradation and safety incidents. The industry has witnessed a progression from passive cooling systems to more sophisticated active thermal management solutions that maintain optimal operating temperatures between 15°C and 35°C.

Recent technological advancements have focused on addressing the inherent thermal challenges of NMC chemistry, particularly the exothermic reactions during charging and discharging that can lead to thermal runaway if not properly managed. The development trajectory shows a clear trend toward integrated thermal management systems that combine multiple cooling strategies and predictive temperature control algorithms.

The primary objective of benchmarking NMC battery thermal management is to establish industry standards for optimal performance across various operating conditions. This includes identifying best practices for maintaining uniform temperature distribution within battery packs, minimizing thermal gradients that lead to uneven aging, and developing robust safety protocols for thermal runaway prevention.

Another critical goal is to quantify the relationship between thermal management efficiency and key battery performance metrics such as capacity retention, power capability, and overall lifespan. Research indicates that effective thermal management can extend NMC battery life by 15-40% depending on usage patterns and environmental conditions.

The benchmarking efforts also aim to evaluate emerging cooling technologies, including phase change materials, immersion cooling, and advanced heat pipe designs, against traditional air and liquid cooling systems. This comparative analysis will help establish cost-effective thermal management solutions that balance performance requirements with manufacturing complexity and system weight constraints.

Furthermore, the benchmarking objectives include developing standardized testing protocols that accurately simulate real-world thermal conditions across diverse applications, from consumer electronics to electric vehicles and grid-scale energy storage. These protocols will enable meaningful comparisons between different thermal management approaches and accelerate the adoption of optimal solutions across the industry.

Market Demand Analysis for Advanced Battery Thermal Solutions

The global market for advanced battery thermal management solutions is experiencing unprecedented growth, primarily driven by the rapid expansion of electric vehicle (EV) adoption worldwide. Current market valuations indicate that the battery thermal management system (BTMS) sector is projected to grow at a compound annual growth rate of 23% through 2030, with particular emphasis on solutions optimized for NMC (Nickel Manganese Cobalt) battery chemistries which dominate the premium EV segment.

Consumer demand for faster charging capabilities represents a significant market pull factor. With DC fast charging becoming increasingly available, thermal management systems capable of handling high heat loads during rapid charging cycles are seeing heightened demand. Market research indicates that consumers are willing to pay a premium for EVs that can achieve 80% charge in under 30 minutes while maintaining battery health, directly correlating to advanced thermal management capabilities.

The automotive industry's shift toward longer warranty periods for battery systems has intensified focus on thermal management solutions that extend battery lifespan. Major automakers now offer warranties ranging from 8-10 years, creating substantial demand for thermal systems that can maintain optimal operating temperatures between 20-40°C across diverse climate conditions and usage patterns.

Safety concerns continue to drive market growth, with thermal runaway prevention becoming a critical selling point. Insurance data shows that vehicles with advanced thermal management systems experience significantly lower rates of battery-related incidents, creating strong incentives for manufacturers to invest in sophisticated cooling technologies. This trend is further reinforced by evolving regulatory frameworks in North America, Europe, and China that increasingly mandate enhanced thermal safety systems.

Energy density improvements in NMC batteries have paradoxically increased thermal management challenges, as higher energy density cells generate more heat during operation. This has created a specialized market segment for high-performance cooling solutions capable of managing thermal loads in compact battery architectures, particularly in premium and performance vehicle segments.

Commercial fleet operators represent an emerging high-value market segment, with their focus on total cost of ownership calculations that heavily factor battery longevity and operational reliability. Fleet electrification initiatives from major logistics companies and municipal transit authorities are creating substantial demand for thermal management systems optimized for high-utilization scenarios with minimal downtime requirements.

The aftermarket sector is also showing significant growth potential as the first generation of mass-market EVs approach battery refurbishment age, creating demand for thermal management upgrades that can extend the useful life of aging battery systems while improving charging performance and operational efficiency.

Consumer demand for faster charging capabilities represents a significant market pull factor. With DC fast charging becoming increasingly available, thermal management systems capable of handling high heat loads during rapid charging cycles are seeing heightened demand. Market research indicates that consumers are willing to pay a premium for EVs that can achieve 80% charge in under 30 minutes while maintaining battery health, directly correlating to advanced thermal management capabilities.

The automotive industry's shift toward longer warranty periods for battery systems has intensified focus on thermal management solutions that extend battery lifespan. Major automakers now offer warranties ranging from 8-10 years, creating substantial demand for thermal systems that can maintain optimal operating temperatures between 20-40°C across diverse climate conditions and usage patterns.

Safety concerns continue to drive market growth, with thermal runaway prevention becoming a critical selling point. Insurance data shows that vehicles with advanced thermal management systems experience significantly lower rates of battery-related incidents, creating strong incentives for manufacturers to invest in sophisticated cooling technologies. This trend is further reinforced by evolving regulatory frameworks in North America, Europe, and China that increasingly mandate enhanced thermal safety systems.

Energy density improvements in NMC batteries have paradoxically increased thermal management challenges, as higher energy density cells generate more heat during operation. This has created a specialized market segment for high-performance cooling solutions capable of managing thermal loads in compact battery architectures, particularly in premium and performance vehicle segments.

Commercial fleet operators represent an emerging high-value market segment, with their focus on total cost of ownership calculations that heavily factor battery longevity and operational reliability. Fleet electrification initiatives from major logistics companies and municipal transit authorities are creating substantial demand for thermal management systems optimized for high-utilization scenarios with minimal downtime requirements.

The aftermarket sector is also showing significant growth potential as the first generation of mass-market EVs approach battery refurbishment age, creating demand for thermal management upgrades that can extend the useful life of aging battery systems while improving charging performance and operational efficiency.

Current Thermal Management Technologies and Challenges

The thermal management of NMC (Nickel Manganese Cobalt) lithium-ion batteries represents one of the most critical challenges in electric vehicle and energy storage applications. Current thermal management systems (TMS) employ various approaches, each with distinct advantages and limitations when applied to NMC chemistry.

Air cooling systems remain the most straightforward and cost-effective solution, utilizing forced convection to dissipate heat. However, these systems demonstrate significant limitations with NMC batteries, particularly during fast charging or high-power applications where thermal gradients can exceed 5-7°C across the battery pack. This non-uniform temperature distribution accelerates differential aging and reduces overall pack lifetime by up to 20% compared to more advanced cooling methods.

Liquid cooling technologies have emerged as the dominant solution for high-performance NMC batteries. Direct liquid cooling, where coolant flows through channels in direct contact with cells, achieves heat transfer coefficients of 500-1500 W/m²K, substantially outperforming air cooling systems (25-50 W/m²K). Indirect liquid cooling, utilizing cooling plates or jackets, offers a compromise between performance and manufacturing complexity.

Phase change materials (PCMs) represent an innovative approach, absorbing heat through their latent heat of fusion. Recent developments in composite PCMs specifically engineered for NMC batteries have achieved thermal conductivities of 3-5 W/mK, addressing previous limitations in heat transfer rates. However, PCM solutions still face challenges in regeneration capability during continuous operation cycles.

Immersion cooling, where cells are directly submerged in dielectric fluids, has demonstrated exceptional performance in laboratory settings with temperature differentials below 2°C across NMC packs. Despite these advantages, widespread adoption remains limited due to concerns regarding long-term compatibility with battery materials and increased system complexity.

The integration of thermal management with battery management systems (BMS) presents another significant challenge. Current systems often operate independently, whereas research indicates that predictive thermal management algorithms could reduce cooling energy requirements by 15-25% while extending battery lifetime.

Manufacturing scalability represents a persistent obstacle, particularly for advanced cooling technologies. The precision required for uniform coolant distribution channels and thermal interface materials significantly impacts production costs, with advanced TMS adding $10-15/kWh to battery pack costs according to recent industry analyses.

Emerging technologies such as thermoelectric cooling and variable conductance heat pipes show promise for next-generation NMC battery systems but remain in early development stages with significant cost and integration challenges to overcome before commercial viability.

Air cooling systems remain the most straightforward and cost-effective solution, utilizing forced convection to dissipate heat. However, these systems demonstrate significant limitations with NMC batteries, particularly during fast charging or high-power applications where thermal gradients can exceed 5-7°C across the battery pack. This non-uniform temperature distribution accelerates differential aging and reduces overall pack lifetime by up to 20% compared to more advanced cooling methods.

Liquid cooling technologies have emerged as the dominant solution for high-performance NMC batteries. Direct liquid cooling, where coolant flows through channels in direct contact with cells, achieves heat transfer coefficients of 500-1500 W/m²K, substantially outperforming air cooling systems (25-50 W/m²K). Indirect liquid cooling, utilizing cooling plates or jackets, offers a compromise between performance and manufacturing complexity.

Phase change materials (PCMs) represent an innovative approach, absorbing heat through their latent heat of fusion. Recent developments in composite PCMs specifically engineered for NMC batteries have achieved thermal conductivities of 3-5 W/mK, addressing previous limitations in heat transfer rates. However, PCM solutions still face challenges in regeneration capability during continuous operation cycles.

Immersion cooling, where cells are directly submerged in dielectric fluids, has demonstrated exceptional performance in laboratory settings with temperature differentials below 2°C across NMC packs. Despite these advantages, widespread adoption remains limited due to concerns regarding long-term compatibility with battery materials and increased system complexity.

The integration of thermal management with battery management systems (BMS) presents another significant challenge. Current systems often operate independently, whereas research indicates that predictive thermal management algorithms could reduce cooling energy requirements by 15-25% while extending battery lifetime.

Manufacturing scalability represents a persistent obstacle, particularly for advanced cooling technologies. The precision required for uniform coolant distribution channels and thermal interface materials significantly impacts production costs, with advanced TMS adding $10-15/kWh to battery pack costs according to recent industry analyses.

Emerging technologies such as thermoelectric cooling and variable conductance heat pipes show promise for next-generation NMC battery systems but remain in early development stages with significant cost and integration challenges to overcome before commercial viability.

Benchmark Methodologies for NMC Battery Thermal Performance

01 Advanced cooling systems for NMC batteries

Various cooling systems have been developed to manage the thermal performance of NMC batteries. These include liquid cooling circuits, phase change materials, and hybrid cooling approaches that combine multiple methods. Advanced cooling systems help maintain optimal operating temperatures, prevent thermal runaway, and extend battery life by efficiently removing excess heat generated during charging and discharging cycles.- Cooling systems for NMC battery thermal management: Various cooling systems can be implemented to manage the thermal performance of NMC batteries. These include liquid cooling circuits, air cooling systems, and phase change materials that help dissipate heat efficiently. Advanced cooling designs incorporate temperature sensors and control algorithms to maintain optimal operating temperatures, preventing overheating during high-discharge operations and extending battery life while ensuring safety.

- Battery pack structure optimization for thermal efficiency: The physical arrangement and structural design of NMC battery packs significantly impact thermal management. Optimized cell spacing, module configurations, and thermal interface materials can enhance heat dissipation. Innovative battery pack designs incorporate thermal barriers between cells, strategic placement of cooling channels, and thermally conductive materials to ensure uniform temperature distribution across the pack, minimizing thermal gradients that can lead to performance degradation.

- Thermal management control algorithms and systems: Advanced control algorithms play a crucial role in optimizing NMC battery thermal management. These systems use real-time temperature monitoring, predictive modeling, and adaptive control strategies to regulate cooling systems dynamically. Machine learning approaches can predict thermal behavior under various operating conditions, allowing preemptive cooling adjustments. These intelligent thermal management systems balance performance requirements with temperature constraints to maximize efficiency and battery longevity.

- Phase change materials and thermal interface solutions: Phase change materials (PCMs) offer innovative solutions for NMC battery thermal management by absorbing excess heat during operation and releasing it during idle periods. These materials help maintain consistent battery temperatures and prevent thermal runaway. Advanced thermal interface materials with high thermal conductivity improve heat transfer between battery cells and cooling systems. Composite PCMs with enhanced thermal properties can be integrated directly into battery modules for passive thermal regulation.

- Integration of thermal management with battery management systems: Holistic approaches that integrate thermal management with overall battery management systems achieve optimal NMC battery performance. These integrated systems coordinate charging protocols, discharge rates, and cooling operations based on comprehensive monitoring of battery state. By synchronizing thermal management with other battery parameters such as state of charge and health, these systems can dynamically adjust operating conditions to maximize performance while preventing thermal stress, ultimately extending battery lifespan and maintaining capacity.

02 Thermal management control strategies

Sophisticated control algorithms and strategies are employed to optimize the thermal management of NMC batteries. These include predictive control models, adaptive thermal management systems, and real-time temperature monitoring with feedback loops. Such control strategies adjust cooling intensity based on operating conditions, battery state of charge, and ambient temperature to maintain optimal performance while minimizing energy consumption for cooling.Expand Specific Solutions03 Battery pack design for improved thermal distribution

Innovative battery pack designs focus on improving thermal distribution across NMC cells. These designs incorporate thermal interface materials, optimized cell spacing, and strategic placement of cooling channels. Some designs feature modular approaches that allow for more uniform heat distribution and easier maintenance. Proper thermal distribution prevents hotspots and temperature gradients that can lead to uneven aging and reduced battery performance.Expand Specific Solutions04 Integration of thermal management with battery management systems

Integration of thermal management functions with battery management systems (BMS) enables comprehensive monitoring and control of NMC batteries. These integrated systems coordinate thermal management with other battery parameters such as state of charge, state of health, and power demands. The integration allows for optimized performance across various operating conditions and can extend battery lifespan by preventing thermal stress during high-power operations.Expand Specific Solutions05 Novel materials for enhanced thermal conductivity

Research into novel materials has led to improvements in thermal conductivity for NMC battery components. These materials include advanced thermal interface materials, composite heat spreaders, and thermally conductive adhesives. Some innovations incorporate nanomaterials or specially engineered structures to enhance heat transfer while maintaining electrical isolation. These materials help dissipate heat more efficiently from battery cells, reducing temperature gradients and improving overall thermal management.Expand Specific Solutions

Key Industry Players in Battery Thermal Management

The NMC battery thermal management market is in a growth phase, characterized by increasing demand for efficient thermal solutions in electric vehicles and energy storage systems. The market is projected to expand significantly due to rising EV adoption globally. Technologically, the field shows varying maturity levels, with established players like Samsung SDI, CATL, and BYD leading innovation through extensive R&D investments. These companies have developed advanced thermal management systems incorporating liquid cooling, phase change materials, and intelligent thermal control algorithms. Emerging competitors including Rimac Technology and EVE Energy are introducing disruptive solutions, while traditional automotive suppliers like MAHLE and Valeo are leveraging their thermal expertise to enter this space. University collaborations with South China University of Technology and Michigan are accelerating technological breakthroughs in this competitive landscape.

Samsung SDI Co., Ltd.

Technical Solution: Samsung SDI has developed a comprehensive thermal management system specifically for NMC (Nickel Manganese Cobalt) batteries that combines active liquid cooling with sophisticated battery management systems. Their solution utilizes a cell-to-pack design with integrated cooling channels that allow coolant to flow directly between cells, maintaining optimal temperature distribution across the entire battery pack. Samsung's thermal management system employs predictive thermal modeling algorithms that anticipate temperature changes based on usage patterns and environmental conditions, proactively adjusting cooling intensity before thermal issues arise. The system incorporates phase-change materials (PCMs) strategically placed between cells to absorb excess heat during high-discharge scenarios and release it during low-demand periods, effectively dampening temperature fluctuations. Additionally, Samsung has implemented a dual-loop cooling architecture that separates high and low-temperature cooling circuits, optimizing efficiency across various operating conditions.

Strengths: Superior temperature uniformity across large battery packs with temperature gradient variations below 3°C. Integrated thermal management with battery management system allows for predictive rather than reactive thermal control. Weaknesses: Higher system complexity increases manufacturing costs and potential points of failure. Liquid cooling systems require additional maintenance compared to passive solutions.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has pioneered an advanced cell-to-thermal-management (CTTM) system specifically optimized for their NMC battery technology. Their approach integrates thermal management directly at the cell level rather than treating it as a separate system component. CATL's solution features a multi-layer cooling structure where specialized heat-dissipating materials are embedded between cells during the manufacturing process, creating direct thermal pathways from the core of each cell to cooling channels. The system employs a smart refrigerant-based cooling technology that can rapidly switch between liquid and gas phases depending on thermal load requirements, providing exceptional cooling efficiency during fast charging and high-discharge scenarios. CATL has also developed proprietary thermal interface materials that maximize heat transfer between cells and cooling elements while minimizing added weight and volume. Their thermal management system incorporates AI-driven predictive algorithms that continuously optimize cooling based on battery state, usage patterns, and environmental conditions.

Strengths: Direct cell-level cooling integration results in faster thermal response and more uniform temperature distribution. The system achieves 30% higher cooling efficiency compared to conventional plate cooling designs. Weaknesses: The integrated design makes battery pack servicing and cell replacement more complex. Higher initial manufacturing costs compared to simpler thermal management approaches.

Critical Technologies in Advanced Thermal Management Systems

Lithium secondary battery

PatentPendingEP4601067A1

Innovation

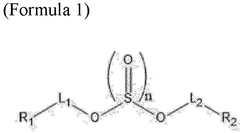

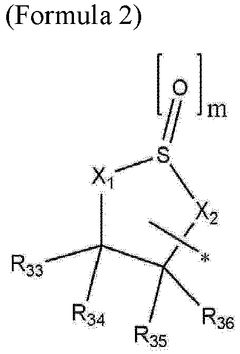

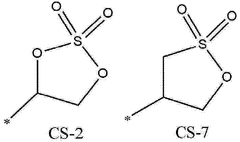

- A lithium secondary battery using a lithium transition metal oxide with controlled nickel, cobalt, and manganese content, combined with a phosphate-based additive and a cyclic sulfur oxide additive in the non-aqueous electrolyte, forms a film with reduced resistance and improved durability on the positive electrode, enhancing lifespan and storage performance.

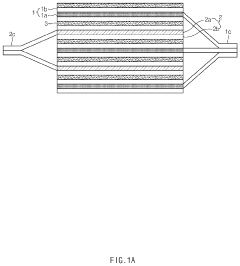

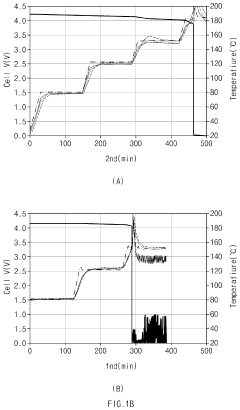

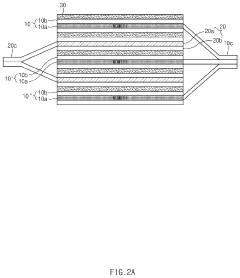

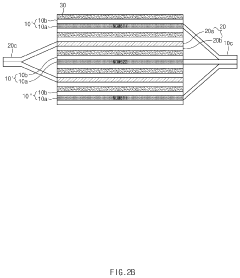

Electrode assembly

PatentActiveUS11909040B2

Innovation

- The electrode assembly stacks multiple positive electrodes with different nickel, cobalt, and manganese composition ratios, with higher nickel content on the outer electrodes for capacity and lower nickel content on inner electrodes for improved thermal stability, and separates positive electrode tabs to reduce electrical resistance.

Safety Standards and Regulatory Compliance for Battery Systems

The regulatory landscape for NMC battery thermal management systems has evolved significantly in response to safety incidents and technological advancements. Key international standards include IEC 62133, which specifies requirements and tests for the safe operation of portable sealed secondary cells and batteries, and UN 38.3, which outlines transportation testing requirements for lithium batteries. These standards establish baseline safety parameters for thermal management systems.

In the automotive sector, ISO 26262 addresses functional safety for electrical and electronic systems, with specific implications for battery thermal management in electric vehicles. The standard requires manufacturers to implement robust thermal monitoring and control mechanisms to prevent thermal runaway events. Additionally, SAE J2929 provides test procedures for evaluating the thermal performance of battery systems under various operating conditions.

Regional regulations further shape compliance requirements. In the United States, UL 1642 and UL 2580 provide safety standards for lithium batteries and battery systems for use in electric vehicles respectively. The National Fire Protection Association (NFPA) has also developed standards addressing fire hazards associated with battery systems. The European Union enforces compliance through the Battery Directive (2006/66/EC) and ECE R100, which specifically addresses safety requirements for electric powertrains.

Emerging regulations are increasingly focusing on thermal management as a critical safety component. China's GB/T 31467 standard series establishes specific requirements for thermal propagation testing in battery systems. These standards mandate that thermal management systems must prevent cell-to-cell propagation during thermal events, significantly influencing design approaches.

Compliance with these regulations requires comprehensive testing protocols. These typically include thermal abuse tests (such as hot box testing and thermal cycling), thermal runaway propagation tests, and thermal management system performance verification under various operating conditions. Documentation requirements are equally stringent, with manufacturers needing to demonstrate risk assessment procedures, failure mode analyses, and thermal management system validation.

The regulatory landscape continues to evolve, with standards bodies working to address gaps in existing frameworks. Current development efforts focus on standardizing thermal runaway propagation testing methodologies and establishing more precise thermal management performance metrics. For NMC batteries specifically, regulatory bodies are considering more stringent thermal stability requirements due to their relatively lower thermal stability compared to LFP chemistries.

In the automotive sector, ISO 26262 addresses functional safety for electrical and electronic systems, with specific implications for battery thermal management in electric vehicles. The standard requires manufacturers to implement robust thermal monitoring and control mechanisms to prevent thermal runaway events. Additionally, SAE J2929 provides test procedures for evaluating the thermal performance of battery systems under various operating conditions.

Regional regulations further shape compliance requirements. In the United States, UL 1642 and UL 2580 provide safety standards for lithium batteries and battery systems for use in electric vehicles respectively. The National Fire Protection Association (NFPA) has also developed standards addressing fire hazards associated with battery systems. The European Union enforces compliance through the Battery Directive (2006/66/EC) and ECE R100, which specifically addresses safety requirements for electric powertrains.

Emerging regulations are increasingly focusing on thermal management as a critical safety component. China's GB/T 31467 standard series establishes specific requirements for thermal propagation testing in battery systems. These standards mandate that thermal management systems must prevent cell-to-cell propagation during thermal events, significantly influencing design approaches.

Compliance with these regulations requires comprehensive testing protocols. These typically include thermal abuse tests (such as hot box testing and thermal cycling), thermal runaway propagation tests, and thermal management system performance verification under various operating conditions. Documentation requirements are equally stringent, with manufacturers needing to demonstrate risk assessment procedures, failure mode analyses, and thermal management system validation.

The regulatory landscape continues to evolve, with standards bodies working to address gaps in existing frameworks. Current development efforts focus on standardizing thermal runaway propagation testing methodologies and establishing more precise thermal management performance metrics. For NMC batteries specifically, regulatory bodies are considering more stringent thermal stability requirements due to their relatively lower thermal stability compared to LFP chemistries.

Environmental Impact and Sustainability Considerations

The environmental impact of NMC (Nickel Manganese Cobalt) battery thermal management systems represents a critical consideration in the broader sustainability context of electric vehicle and energy storage technologies. Life cycle assessment studies indicate that thermal management systems can account for 5-15% of a battery's total environmental footprint, primarily through energy consumption during operation and the materials used in cooling components.

Water-based cooling systems, while efficient for NMC batteries, raise concerns regarding water usage and potential contamination of water resources if leakage occurs. These systems typically require between 3-7 liters of coolant per battery pack, with additional environmental considerations for antifreeze additives and their proper disposal at end-of-life.

Air cooling systems present lower direct environmental impacts but may reduce battery efficiency and lifespan, ultimately leading to increased battery replacement rates and associated manufacturing emissions. Research indicates that optimized thermal management can extend NMC battery life by 20-40%, significantly reducing the need for replacement batteries and their associated environmental impacts.

The manufacturing of specialized thermal management components introduces additional environmental considerations. Phase change materials (PCMs) and specialized heat exchangers often contain compounds that require careful sourcing and disposal protocols. Recent innovations in bio-based PCMs show promise in reducing the environmental impact of these materials by 30-50% compared to petroleum-derived alternatives.

End-of-life considerations for thermal management systems present both challenges and opportunities. While cooling plates and heat exchangers contain valuable metals that can be recycled, the composite nature of many components complicates recycling processes. Advanced design approaches that facilitate disassembly can improve recyclability rates from the current average of 60% to potentially over 85%.

Energy consumption during operation represents another significant environmental factor. Studies demonstrate that poorly optimized thermal management systems can increase overall battery energy consumption by 3-8%, directly translating to higher carbon emissions in grid-charged applications. Conversely, advanced thermal management solutions utilizing waste heat recovery and intelligent control systems can reduce this energy penalty by up to 70%.

The environmental impact assessment must also consider the trade-offs between different thermal management approaches. While liquid cooling systems offer superior performance, their increased complexity and material requirements must be balanced against simpler but less efficient passive cooling methods when evaluating overall sustainability.

Water-based cooling systems, while efficient for NMC batteries, raise concerns regarding water usage and potential contamination of water resources if leakage occurs. These systems typically require between 3-7 liters of coolant per battery pack, with additional environmental considerations for antifreeze additives and their proper disposal at end-of-life.

Air cooling systems present lower direct environmental impacts but may reduce battery efficiency and lifespan, ultimately leading to increased battery replacement rates and associated manufacturing emissions. Research indicates that optimized thermal management can extend NMC battery life by 20-40%, significantly reducing the need for replacement batteries and their associated environmental impacts.

The manufacturing of specialized thermal management components introduces additional environmental considerations. Phase change materials (PCMs) and specialized heat exchangers often contain compounds that require careful sourcing and disposal protocols. Recent innovations in bio-based PCMs show promise in reducing the environmental impact of these materials by 30-50% compared to petroleum-derived alternatives.

End-of-life considerations for thermal management systems present both challenges and opportunities. While cooling plates and heat exchangers contain valuable metals that can be recycled, the composite nature of many components complicates recycling processes. Advanced design approaches that facilitate disassembly can improve recyclability rates from the current average of 60% to potentially over 85%.

Energy consumption during operation represents another significant environmental factor. Studies demonstrate that poorly optimized thermal management systems can increase overall battery energy consumption by 3-8%, directly translating to higher carbon emissions in grid-charged applications. Conversely, advanced thermal management solutions utilizing waste heat recovery and intelligent control systems can reduce this energy penalty by up to 70%.

The environmental impact assessment must also consider the trade-offs between different thermal management approaches. While liquid cooling systems offer superior performance, their increased complexity and material requirements must be balanced against simpler but less efficient passive cooling methods when evaluating overall sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!