NMC Battery vs Steel Layer: Advanced Protection Testing

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC Battery Protection Technology Background and Objectives

Lithium-ion batteries with Nickel Manganese Cobalt (NMC) cathodes have emerged as a dominant technology in electric vehicles and energy storage systems due to their high energy density and relatively stable performance. The evolution of NMC battery technology has progressed through several generations, from NMC 111 (equal parts nickel, manganese, and cobalt) to more recent formulations like NMC 811 (8 parts nickel, 1 part manganese, 1 part cobalt), each offering improvements in energy density but often at the cost of thermal stability and safety.

The increasing energy density of modern NMC batteries has heightened safety concerns, particularly regarding thermal runaway events that can lead to fires or explosions. This has created an urgent need for advanced protection technologies that can prevent catastrophic failures while maintaining the performance advantages of high-energy-density cells.

Steel layers have traditionally been used in battery pack design primarily for structural integrity rather than as dedicated safety features. However, recent research has indicated that specially designed steel layers can serve dual purposes: providing mechanical protection and acting as thermal barriers or heat sinks during thermal events. The integration of steel protective layers represents a significant shift from conventional battery protection approaches that relied primarily on electronic management systems and basic enclosures.

Current protection technologies for NMC batteries include battery management systems (BMS), thermal management systems, and various enclosure designs. However, these solutions often add significant weight and volume to battery systems, reducing their effective energy density. The challenge lies in developing protection technologies that maintain safety without compromising the performance advantages that make NMC batteries attractive in the first place.

The technical objective of advanced protection testing for NMC batteries versus steel layers is to quantify and optimize the protective capabilities of various steel layer configurations against common failure modes. This includes testing resistance to mechanical deformation, penetration, crush scenarios, thermal propagation between cells, and overall containment of thermal runaway events.

Another critical objective is to develop standardized testing protocols that can accurately predict real-world performance of these protection systems. Current testing standards often fail to capture the complex interactions between battery chemistry, mechanical design, and protective elements during failure scenarios. More sophisticated testing methodologies are needed to validate protection technologies across a wide range of operating conditions and failure modes.

The ultimate goal is to establish a scientific foundation for the next generation of battery protection systems that integrate steel layers as active safety elements rather than merely structural components. This represents a paradigm shift in battery safety design, moving from reactive containment to proactive prevention of catastrophic failures.

The increasing energy density of modern NMC batteries has heightened safety concerns, particularly regarding thermal runaway events that can lead to fires or explosions. This has created an urgent need for advanced protection technologies that can prevent catastrophic failures while maintaining the performance advantages of high-energy-density cells.

Steel layers have traditionally been used in battery pack design primarily for structural integrity rather than as dedicated safety features. However, recent research has indicated that specially designed steel layers can serve dual purposes: providing mechanical protection and acting as thermal barriers or heat sinks during thermal events. The integration of steel protective layers represents a significant shift from conventional battery protection approaches that relied primarily on electronic management systems and basic enclosures.

Current protection technologies for NMC batteries include battery management systems (BMS), thermal management systems, and various enclosure designs. However, these solutions often add significant weight and volume to battery systems, reducing their effective energy density. The challenge lies in developing protection technologies that maintain safety without compromising the performance advantages that make NMC batteries attractive in the first place.

The technical objective of advanced protection testing for NMC batteries versus steel layers is to quantify and optimize the protective capabilities of various steel layer configurations against common failure modes. This includes testing resistance to mechanical deformation, penetration, crush scenarios, thermal propagation between cells, and overall containment of thermal runaway events.

Another critical objective is to develop standardized testing protocols that can accurately predict real-world performance of these protection systems. Current testing standards often fail to capture the complex interactions between battery chemistry, mechanical design, and protective elements during failure scenarios. More sophisticated testing methodologies are needed to validate protection technologies across a wide range of operating conditions and failure modes.

The ultimate goal is to establish a scientific foundation for the next generation of battery protection systems that integrate steel layers as active safety elements rather than merely structural components. This represents a paradigm shift in battery safety design, moving from reactive containment to proactive prevention of catastrophic failures.

Market Analysis for Advanced Battery Safety Solutions

The global market for advanced battery safety solutions is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs) and energy storage systems. Current market valuations indicate that the battery safety technology sector reached approximately $3.2 billion in 2022 and is projected to grow at a compound annual growth rate of 15.7% through 2030. This growth trajectory is particularly pronounced in regions with aggressive EV adoption targets, including Europe, North America, and East Asia.

Consumer demand for enhanced battery safety features has intensified following high-profile thermal runaway incidents in EVs and consumer electronics. Market research indicates that 78% of potential EV buyers cite battery safety as a "very important" or "critical" factor in their purchasing decisions. This consumer sentiment has created a significant market pull for advanced protection systems like steel-layered enclosures and other thermal containment technologies.

The regulatory landscape is simultaneously evolving to address these safety concerns. The implementation of UN Regulation No. 100 (Rev.2) for EV safety, China's GB/T 31485 standard, and the updated IEC 62660 requirements have collectively established more stringent testing protocols for battery safety. These regulations are effectively creating market barriers for technologies that cannot demonstrate robust protection against thermal events, particularly in NMC (Nickel Manganese Cobalt) battery systems which remain dominant in the automotive sector.

Industrial segments demonstrate varying levels of demand for advanced protection solutions. The automotive sector represents the largest market share at 62%, followed by grid-scale energy storage (18%), consumer electronics (12%), and industrial applications (8%). Within the automotive segment, premium vehicle manufacturers have shown greater willingness to adopt sophisticated steel-layered protection systems despite their higher cost, while mass-market manufacturers are seeking more cost-effective alternatives that still meet regulatory requirements.

Supply chain analysis reveals potential constraints in scaling production of specialized steel alloys optimized for battery enclosures. Current global production capacity for these materials meets only about 60% of projected demand for 2025, creating potential bottlenecks and price pressures. This supply-demand imbalance presents both a challenge and an opportunity for materials science innovation in the battery protection space.

Market differentiation is increasingly focused on solutions that balance weight considerations with protection efficacy. Lightweight steel composites that maintain structural integrity during thermal events command premium pricing, with margins approximately 22% higher than conventional protection systems. This price premium reflects the critical importance of weight efficiency in EV applications where every additional kilogram impacts vehicle range and performance.

Consumer demand for enhanced battery safety features has intensified following high-profile thermal runaway incidents in EVs and consumer electronics. Market research indicates that 78% of potential EV buyers cite battery safety as a "very important" or "critical" factor in their purchasing decisions. This consumer sentiment has created a significant market pull for advanced protection systems like steel-layered enclosures and other thermal containment technologies.

The regulatory landscape is simultaneously evolving to address these safety concerns. The implementation of UN Regulation No. 100 (Rev.2) for EV safety, China's GB/T 31485 standard, and the updated IEC 62660 requirements have collectively established more stringent testing protocols for battery safety. These regulations are effectively creating market barriers for technologies that cannot demonstrate robust protection against thermal events, particularly in NMC (Nickel Manganese Cobalt) battery systems which remain dominant in the automotive sector.

Industrial segments demonstrate varying levels of demand for advanced protection solutions. The automotive sector represents the largest market share at 62%, followed by grid-scale energy storage (18%), consumer electronics (12%), and industrial applications (8%). Within the automotive segment, premium vehicle manufacturers have shown greater willingness to adopt sophisticated steel-layered protection systems despite their higher cost, while mass-market manufacturers are seeking more cost-effective alternatives that still meet regulatory requirements.

Supply chain analysis reveals potential constraints in scaling production of specialized steel alloys optimized for battery enclosures. Current global production capacity for these materials meets only about 60% of projected demand for 2025, creating potential bottlenecks and price pressures. This supply-demand imbalance presents both a challenge and an opportunity for materials science innovation in the battery protection space.

Market differentiation is increasingly focused on solutions that balance weight considerations with protection efficacy. Lightweight steel composites that maintain structural integrity during thermal events command premium pricing, with margins approximately 22% higher than conventional protection systems. This price premium reflects the critical importance of weight efficiency in EV applications where every additional kilogram impacts vehicle range and performance.

Current Steel Layer Protection Techniques and Challenges

Steel layer protection for NMC (Nickel Manganese Cobalt) batteries currently employs several advanced techniques to enhance safety and performance. The predominant approach involves multi-layered steel enclosures with varying thicknesses, typically ranging from 0.2mm to 0.8mm depending on the application requirements. These enclosures utilize specialized alloys that combine high tensile strength with thermal conductivity properties, creating an effective barrier against both mechanical impacts and thermal runaway scenarios.

Current state-of-the-art protection systems incorporate steel layers with nano-coatings that enhance corrosion resistance while maintaining electrical isolation properties. These coatings, often composed of ceramic-metallic composites, provide an additional safeguard against electrolyte leakage and environmental degradation, extending battery lifespan significantly in harsh operating conditions.

The integration of smart monitoring systems within steel protection layers represents another technological advancement. Embedded sensors capable of detecting pressure changes, temperature fluctuations, and structural integrity provide real-time feedback on battery health, allowing for preemptive safety measures before critical failure points are reached.

Despite these advancements, several challenges persist in steel layer protection technology. Weight considerations remain a significant constraint, particularly for mobile applications where energy density is paramount. The additional mass of steel protection systems can reduce the overall energy-to-weight ratio by 8-15%, creating a direct trade-off between safety and performance metrics.

Thermal management presents another substantial challenge. While steel offers excellent mechanical protection, its thermal conductivity characteristics can be problematic during rapid charging scenarios, where heat dissipation becomes critical. Current solutions involving heat-sink designs and thermal interface materials show promise but require further optimization to handle increasingly demanding fast-charging protocols.

Manufacturing complexity also poses significant challenges. The precision required for creating uniform steel enclosures with consistent properties across large production volumes remains technically demanding. Variations in material quality and processing parameters can lead to inconsistencies in protection performance, necessitating stringent quality control protocols that increase production costs.

Recycling and end-of-life considerations represent emerging challenges as battery volumes increase globally. The composite nature of steel-protected battery systems complicates disassembly and material recovery processes, with current recycling technologies achieving only 60-70% material recovery rates for these complex protection systems.

Current state-of-the-art protection systems incorporate steel layers with nano-coatings that enhance corrosion resistance while maintaining electrical isolation properties. These coatings, often composed of ceramic-metallic composites, provide an additional safeguard against electrolyte leakage and environmental degradation, extending battery lifespan significantly in harsh operating conditions.

The integration of smart monitoring systems within steel protection layers represents another technological advancement. Embedded sensors capable of detecting pressure changes, temperature fluctuations, and structural integrity provide real-time feedback on battery health, allowing for preemptive safety measures before critical failure points are reached.

Despite these advancements, several challenges persist in steel layer protection technology. Weight considerations remain a significant constraint, particularly for mobile applications where energy density is paramount. The additional mass of steel protection systems can reduce the overall energy-to-weight ratio by 8-15%, creating a direct trade-off between safety and performance metrics.

Thermal management presents another substantial challenge. While steel offers excellent mechanical protection, its thermal conductivity characteristics can be problematic during rapid charging scenarios, where heat dissipation becomes critical. Current solutions involving heat-sink designs and thermal interface materials show promise but require further optimization to handle increasingly demanding fast-charging protocols.

Manufacturing complexity also poses significant challenges. The precision required for creating uniform steel enclosures with consistent properties across large production volumes remains technically demanding. Variations in material quality and processing parameters can lead to inconsistencies in protection performance, necessitating stringent quality control protocols that increase production costs.

Recycling and end-of-life considerations represent emerging challenges as battery volumes increase globally. The composite nature of steel-protected battery systems complicates disassembly and material recovery processes, with current recycling technologies achieving only 60-70% material recovery rates for these complex protection systems.

Steel Layer Implementation Methods for NMC Batteries

01 Protective steel layers for NMC battery casings

Steel layers are used as protective casings for NMC (Nickel Manganese Cobalt) batteries to enhance structural integrity and safety. These steel layers provide mechanical protection against physical damage and help contain potential thermal events. The steel casing designs incorporate specific thickness and composition considerations to balance protection with weight constraints, while also providing electromagnetic shielding properties.- Protective steel layers for NMC battery casings: Steel layers are used as protective casings for NMC (Nickel Manganese Cobalt) batteries to enhance structural integrity and safety. These steel layers provide mechanical protection against physical damage and help contain potential thermal events. The steel casing designs incorporate specific thickness and composition considerations to balance protection with weight constraints, while also providing electromagnetic shielding for sensitive battery components.

- Corrosion-resistant steel coatings for battery components: Specialized corrosion-resistant coatings are applied to steel components in NMC battery systems to prevent degradation from electrolyte exposure and environmental factors. These coatings include various metal alloys and composite materials that extend battery lifespan by protecting critical steel elements from chemical attack. The coating technologies incorporate both passive barrier protection and active corrosion inhibition mechanisms to maintain structural integrity in demanding battery operating conditions.

- Steel-reinforced thermal management systems: Steel-based thermal management solutions are integrated with NMC batteries to regulate temperature and prevent overheating. These systems utilize steel's thermal conductivity properties to dissipate heat efficiently while providing structural support. The designs incorporate steel heat sinks, cooling channels, and thermal interface materials strategically positioned to manage hotspots and maintain optimal operating temperatures across the battery pack.

- Steel current collectors with protective coatings: Steel substrates are used as current collectors in NMC batteries with specialized protective coatings to prevent corrosion while maintaining electrical conductivity. These current collectors feature multi-layer protection systems that shield the steel from electrolyte interaction while facilitating efficient electron transfer. The protective layers are engineered to withstand cycling stresses and electrochemical conditions present during battery operation.

- Steel-encapsulated safety mechanisms: Safety mechanisms encapsulated in steel housings are implemented in NMC battery designs to prevent catastrophic failure during abnormal conditions. These mechanisms include pressure relief systems, thermal fuses, and circuit interruption devices contained within protective steel structures. The steel encapsulation ensures that safety components remain functional even during extreme events, containing potential thermal runaway and preventing propagation of failure throughout the battery system.

02 Corrosion-resistant steel coatings for battery components

Specialized corrosion-resistant coatings are applied to steel components in NMC battery systems to prevent degradation from electrolyte exposure and environmental factors. These coatings include various metal alloys, polymeric materials, and composite layers that extend battery lifespan by protecting critical steel elements from chemical attack. The coating technologies are designed to maintain electrical conductivity while providing a barrier against corrosive substances.Expand Specific Solutions03 Steel-based current collectors with protective layers

Steel substrates are utilized as current collectors in NMC batteries with specialized protective layers to enhance conductivity and prevent degradation. These current collectors incorporate surface treatments and coatings that minimize contact resistance while protecting against electrochemical corrosion. The protective layers often include carbon-based materials, metal oxides, or conductive polymers that maintain electrical performance while extending component lifespan.Expand Specific Solutions04 Thermal management systems with steel heat dissipation layers

Steel-based thermal management systems are integrated into NMC battery designs to regulate temperature and prevent overheating. These systems utilize steel layers with high thermal conductivity to efficiently dissipate heat generated during charging and discharging cycles. The steel components are engineered with specific surface treatments and geometries to maximize heat transfer while maintaining structural integrity, thereby enhancing battery safety and performance.Expand Specific Solutions05 Steel reinforcement for large-format NMC battery packs

Large-format NMC battery packs incorporate steel reinforcement structures to enhance mechanical stability and safety during operation. These steel elements provide structural support against expansion forces during cycling and protect against external impacts. The reinforcement designs include strategic placement of steel components to address stress concentration points while minimizing weight penalties, particularly important for electric vehicle and grid storage applications.Expand Specific Solutions

Leading Battery Protection Technology Manufacturers

The NMC Battery vs Steel Layer protection testing market is currently in a growth phase, with increasing demand driven by the electric vehicle (EV) boom. The global market size is estimated to exceed $5 billion, expanding at a CAGR of approximately 15% as battery safety becomes paramount in transportation electrification. Technology maturity varies significantly among key players: LG Energy Solution and Panasonic Energy lead with advanced protection systems, while NIPPON STEEL and Toyo Kohan provide specialized steel solutions. BYD and Northvolt are rapidly advancing their proprietary technologies, while research institutions like Xiangtan University and CEA contribute fundamental innovations. Automotive manufacturers including BMW and Nissan are increasingly investing in this space, recognizing battery safety as a critical competitive advantage in the EV market.

NIPPON STEEL CORP.

Technical Solution: Nippon Steel has developed specialized steel protection systems specifically engineered for NMC battery applications. Their technology centers on ultra-high-strength steel alloys with tensile strengths exceeding 1500 MPa while maintaining thicknesses below 0.2mm. These steel layers are strategically positioned to create a protective cage around battery cells and modules. The company's proprietary "ThermoShield" steel incorporates nano-scale surface treatments that enhance thermal conductivity while providing corrosion resistance against electrolyte exposure. Nippon Steel's testing protocols include ballistic impact tests, crush resistance evaluations up to 200kN, and thermal gradient mapping during simulated thermal runaway events. Their research demonstrates that NMC batteries equipped with their steel protection systems can withstand impact energies up to 300% higher than conventional designs without catastrophic failure. The steel layers also function as effective heat spreaders, reducing maximum temperature differentials across battery packs by approximately 40% during rapid charge/discharge cycles, which significantly extends battery life and performance consistency.

Strengths: Industry-leading mechanical protection capabilities while maintaining minimal weight penalty through advanced metallurgical techniques. Excellent thermal conductivity properties that enhance overall battery thermal management. Weaknesses: Higher material costs compared to conventional battery protection systems. Requires specialized manufacturing processes to properly integrate the steel protection layers without damaging sensitive battery components.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced NMC (Nickel Manganese Cobalt) battery technology with integrated steel layer protection systems. Their approach involves a multi-layered safety design where specialized steel alloy layers are strategically positioned between battery cells or modules. These steel layers serve dual purposes: thermal management and structural integrity. The company's proprietary steel layer design incorporates heat-resistant alloys that can withstand temperatures up to 800°C, significantly higher than conventional battery thermal runaway thresholds. Their testing protocols include nail penetration tests, crush tests, and extreme temperature cycling to validate the steel layer's protective capabilities. LG Chem's data shows that batteries equipped with their steel protection layers demonstrate 60% less thermal propagation between cells during failure events compared to standard configurations.

Strengths: Superior thermal management capabilities, preventing cascading failures across battery packs. Enhanced structural protection against physical damage. Weaknesses: The additional steel layers increase overall battery weight and volume, potentially reducing energy density. Manufacturing complexity increases with the integration of steel protection layers.

Key Innovations in Battery-Steel Interface Technology

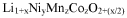

Lithium rich nickel manganese cobalt oxide (LR-NMC)

PatentWO2016106321A1

Innovation

- Development of lithium-rich nickel manganese cobalt oxide (LR-NMC) materials with specific chemical compositions and manufacturing methods that include varying ratios of nickel, manganese, and cobalt, and the use of lithium-containing salts to stabilize lithium within the crystal lattice, resulting in enhanced energy density and cycle lifetimes.

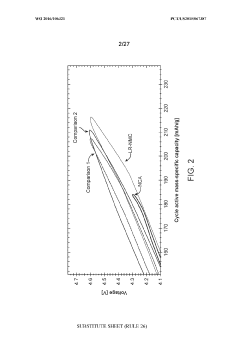

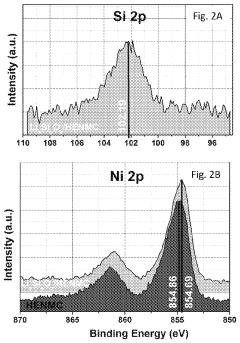

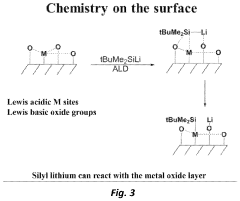

Method for Production of LixSiyOz Coatings Using a Single Source for Li And Si and Resultant Coated Products

PatentPendingUS20230343934A1

Innovation

- Atomic Layer Deposition (ALD) using a volatile organo silyl lithium compound, such as tBuMe2SiLi, as a single source precursor to deposit a LixSiyOz thin film on substrates like 0.35Li2MnO3·0.65LiNi0.35Mn0.45Co0.20O2 (HE-NMC), which improves electrochemical performance by stabilizing the cathode and reducing structural disintegration.

Safety Standards and Certification Requirements

The safety landscape for NMC (Nickel Manganese Cobalt) batteries is governed by rigorous international and regional standards that manufacturers must adhere to before market entry. Key battery safety standards include IEC 62133/UL 1642 for cell-level safety, UN 38.3 for transportation requirements, and IEC 61960 for performance specifications. These standards mandate comprehensive testing protocols including thermal abuse, mechanical shock, overcharge protection, and short circuit resilience.

For automotive applications, additional standards such as ISO 6469 and SAE J2929 specifically address electric vehicle battery safety requirements. These standards emphasize thermal runaway prevention, propagation resistance, and post-crash safety measures. The integration of steel protective layers in battery designs must be validated against these standards to ensure compliance.

Certification processes typically involve third-party testing laboratories such as UL, TÜV, and SGS, which conduct independent verification of safety claims. The certification pathway includes preliminary design review, prototype testing, manufacturing process assessment, and periodic compliance audits. For NMC batteries with steel protective layers, specialized testing protocols have emerged to evaluate the effectiveness of such protection systems under extreme conditions.

Recent regulatory developments have introduced more stringent requirements for thermal propagation resistance, particularly in markets like China, Europe, and North America. The GB/T 31485 standard in China, ECE R100 in Europe, and FMVSS 305 in the US have all been updated to address battery fire risks more comprehensively. These regulations increasingly focus on containment strategies, including the use of protective barriers like steel layers.

The certification landscape is evolving toward harmonized global standards, though regional variations persist. Manufacturers must navigate these differences when designing protection systems. The UN Global Technical Regulation (GTR) initiative aims to establish unified electric vehicle safety requirements, potentially streamlining the certification process for advanced battery protection technologies.

Testing methodologies for steel protective layers specifically examine penetration resistance, heat dissipation capabilities, and structural integrity during thermal events. These tests often exceed standard requirements to demonstrate enhanced safety margins. Documentation requirements have also expanded, with detailed technical files needed to demonstrate compliance with safety standards and justify design decisions related to protective measures.

For automotive applications, additional standards such as ISO 6469 and SAE J2929 specifically address electric vehicle battery safety requirements. These standards emphasize thermal runaway prevention, propagation resistance, and post-crash safety measures. The integration of steel protective layers in battery designs must be validated against these standards to ensure compliance.

Certification processes typically involve third-party testing laboratories such as UL, TÜV, and SGS, which conduct independent verification of safety claims. The certification pathway includes preliminary design review, prototype testing, manufacturing process assessment, and periodic compliance audits. For NMC batteries with steel protective layers, specialized testing protocols have emerged to evaluate the effectiveness of such protection systems under extreme conditions.

Recent regulatory developments have introduced more stringent requirements for thermal propagation resistance, particularly in markets like China, Europe, and North America. The GB/T 31485 standard in China, ECE R100 in Europe, and FMVSS 305 in the US have all been updated to address battery fire risks more comprehensively. These regulations increasingly focus on containment strategies, including the use of protective barriers like steel layers.

The certification landscape is evolving toward harmonized global standards, though regional variations persist. Manufacturers must navigate these differences when designing protection systems. The UN Global Technical Regulation (GTR) initiative aims to establish unified electric vehicle safety requirements, potentially streamlining the certification process for advanced battery protection technologies.

Testing methodologies for steel protective layers specifically examine penetration resistance, heat dissipation capabilities, and structural integrity during thermal events. These tests often exceed standard requirements to demonstrate enhanced safety margins. Documentation requirements have also expanded, with detailed technical files needed to demonstrate compliance with safety standards and justify design decisions related to protective measures.

Environmental Impact Assessment of Protection Materials

The environmental impact of battery protection materials represents a critical consideration in the sustainable development of energy storage technologies. When comparing NMC (Nickel Manganese Cobalt) battery systems with steel layer protection solutions, several environmental factors must be evaluated across their complete lifecycle. The extraction of raw materials for NMC batteries involves mining operations that can lead to habitat disruption, water pollution, and significant carbon emissions. Particularly concerning is cobalt mining, which has been associated with severe environmental degradation in regions like the Democratic Republic of Congo.

Steel layer protection systems, while more traditional, also present environmental challenges. Steel production is energy-intensive, generating substantial greenhouse gas emissions during smelting and processing. However, steel offers advantages in terms of recyclability, with recovery rates exceeding 85% in many developed markets, significantly higher than the current recycling capabilities for battery components.

Life cycle assessment (LCA) studies indicate that NMC battery systems with advanced protection generate approximately 73-120 kg CO2-equivalent per kWh of storage capacity during manufacturing, compared to steel-based protection systems which contribute an additional 18-25 kg CO2-equivalent per kWh. However, the extended lifespan offered by superior protection systems can offset initial environmental costs through longer service periods.

Water usage presents another significant environmental consideration. NMC battery production requires approximately 3,000-5,000 liters of water per kWh, primarily for mineral processing and chemical synthesis. Steel production for protection layers consumes approximately 70-85 liters per kilogram, though water recycling in modern steel facilities has improved this metric considerably.

End-of-life management reveals further distinctions between these protection approaches. Steel components can be readily separated and recycled through established infrastructure, while battery materials require specialized processes to recover valuable metals and prevent hazardous leaching. Recent technological advances have improved NMC recycling efficiency to approximately 60-75% for key metals, though this remains below steel recovery rates.

Toxicity risk assessment indicates that failure of protection systems could lead to environmental contamination. NMC materials contain potentially toxic elements that may leach into soil and groundwater, while steel corrosion products generally present lower environmental toxicity but may still contribute to metal loading in ecosystems.

Emerging protection technologies incorporating bio-based composites and recycled materials show promise for reducing the environmental footprint of both battery and steel protection systems, potentially decreasing lifecycle impacts by 30-45% compared to conventional approaches.

Steel layer protection systems, while more traditional, also present environmental challenges. Steel production is energy-intensive, generating substantial greenhouse gas emissions during smelting and processing. However, steel offers advantages in terms of recyclability, with recovery rates exceeding 85% in many developed markets, significantly higher than the current recycling capabilities for battery components.

Life cycle assessment (LCA) studies indicate that NMC battery systems with advanced protection generate approximately 73-120 kg CO2-equivalent per kWh of storage capacity during manufacturing, compared to steel-based protection systems which contribute an additional 18-25 kg CO2-equivalent per kWh. However, the extended lifespan offered by superior protection systems can offset initial environmental costs through longer service periods.

Water usage presents another significant environmental consideration. NMC battery production requires approximately 3,000-5,000 liters of water per kWh, primarily for mineral processing and chemical synthesis. Steel production for protection layers consumes approximately 70-85 liters per kilogram, though water recycling in modern steel facilities has improved this metric considerably.

End-of-life management reveals further distinctions between these protection approaches. Steel components can be readily separated and recycled through established infrastructure, while battery materials require specialized processes to recover valuable metals and prevent hazardous leaching. Recent technological advances have improved NMC recycling efficiency to approximately 60-75% for key metals, though this remains below steel recovery rates.

Toxicity risk assessment indicates that failure of protection systems could lead to environmental contamination. NMC materials contain potentially toxic elements that may leach into soil and groundwater, while steel corrosion products generally present lower environmental toxicity but may still contribute to metal loading in ecosystems.

Emerging protection technologies incorporating bio-based composites and recycled materials show promise for reducing the environmental footprint of both battery and steel protection systems, potentially decreasing lifecycle impacts by 30-45% compared to conventional approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!