Compare NMC Battery vs Micro-Si Electron: Interactivity Measures

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC vs Micro-Si Battery Technology Background

Lithium-ion batteries have revolutionized portable electronics and are now pivotal in the electric vehicle revolution. Among various lithium-ion chemistries, Nickel Manganese Cobalt (NMC) batteries have dominated the market due to their balanced performance characteristics. However, as energy density demands increase, silicon-based anodes, particularly micro-silicon electron technology, have emerged as promising alternatives to traditional graphite anodes.

NMC batteries evolved from earlier lithium cobalt oxide (LCO) formulations, offering improved thermal stability and longer cycle life. The typical composition includes lithium nickel manganese cobalt oxide (LiNixMnyCozO2) as the cathode material, with various ratios of nickel, manganese, and cobalt (commonly NMC 111, 532, 622, and 811) determining specific performance characteristics. These batteries utilize graphite anodes, which have been the industry standard for decades.

Micro-silicon electron technology represents a significant departure from conventional battery design. Silicon offers theoretical capacity approximately ten times higher than graphite (3,579 mAh/g versus 372 mAh/g), making it an attractive anode material. However, silicon's substantial volume expansion during lithiation (up to 300%) has historically limited its practical application. Micro-silicon technology addresses this challenge by utilizing silicon particles at the microscale, typically 1-5 micrometers, which helps manage expansion stresses while maintaining high capacity.

The technological evolution of both systems has been driven by automotive industry demands for higher energy density, faster charging capabilities, and improved safety profiles. NMC technology has progressed toward higher nickel content (NMC 811) to increase energy density, while micro-silicon has advanced through various structural engineering approaches to mitigate volume expansion issues.

Recent developments have seen the emergence of hybrid systems that incorporate both technologies, with silicon-graphite composite anodes paired with NMC cathodes. These systems aim to leverage the high capacity of silicon while maintaining the stability advantages of traditional materials.

The interactivity between electrode materials—specifically how lithium ions move between cathode and anode during charge-discharge cycles—represents a critical aspect of battery performance. NMC cathodes interact differently with silicon anodes compared to graphite anodes, affecting charge transfer kinetics, solid-electrolyte interphase (SEI) formation, and overall cycling stability.

Understanding these interaction mechanisms at the molecular and electrochemical levels has become a focal point of research, with advanced characterization techniques such as in-situ X-ray diffraction, transmission electron microscopy, and electrochemical impedance spectroscopy providing unprecedented insights into battery operation under real-world conditions.

NMC batteries evolved from earlier lithium cobalt oxide (LCO) formulations, offering improved thermal stability and longer cycle life. The typical composition includes lithium nickel manganese cobalt oxide (LiNixMnyCozO2) as the cathode material, with various ratios of nickel, manganese, and cobalt (commonly NMC 111, 532, 622, and 811) determining specific performance characteristics. These batteries utilize graphite anodes, which have been the industry standard for decades.

Micro-silicon electron technology represents a significant departure from conventional battery design. Silicon offers theoretical capacity approximately ten times higher than graphite (3,579 mAh/g versus 372 mAh/g), making it an attractive anode material. However, silicon's substantial volume expansion during lithiation (up to 300%) has historically limited its practical application. Micro-silicon technology addresses this challenge by utilizing silicon particles at the microscale, typically 1-5 micrometers, which helps manage expansion stresses while maintaining high capacity.

The technological evolution of both systems has been driven by automotive industry demands for higher energy density, faster charging capabilities, and improved safety profiles. NMC technology has progressed toward higher nickel content (NMC 811) to increase energy density, while micro-silicon has advanced through various structural engineering approaches to mitigate volume expansion issues.

Recent developments have seen the emergence of hybrid systems that incorporate both technologies, with silicon-graphite composite anodes paired with NMC cathodes. These systems aim to leverage the high capacity of silicon while maintaining the stability advantages of traditional materials.

The interactivity between electrode materials—specifically how lithium ions move between cathode and anode during charge-discharge cycles—represents a critical aspect of battery performance. NMC cathodes interact differently with silicon anodes compared to graphite anodes, affecting charge transfer kinetics, solid-electrolyte interphase (SEI) formation, and overall cycling stability.

Understanding these interaction mechanisms at the molecular and electrochemical levels has become a focal point of research, with advanced characterization techniques such as in-situ X-ray diffraction, transmission electron microscopy, and electrochemical impedance spectroscopy providing unprecedented insights into battery operation under real-world conditions.

Market Demand Analysis for Advanced Battery Solutions

The global battery market is experiencing unprecedented growth driven by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current projections indicate the advanced battery market will reach $240 billion by 2027, with a compound annual growth rate exceeding 12%. Within this landscape, NMC (Nickel Manganese Cobalt) batteries have dominated the market, capturing approximately 45% of the EV battery segment due to their balanced performance characteristics.

However, market research reveals a significant shift in consumer and industry demands toward batteries with higher energy density, faster charging capabilities, and improved safety profiles. Range anxiety remains the primary concern for potential EV adopters, with 68% of consumers citing insufficient driving range as their main hesitation. This has created substantial market pull for next-generation battery technologies like micro-silicon electron solutions that promise to deliver up to 40% higher energy density compared to traditional NMC batteries.

The industrial energy storage sector presents another rapidly expanding market segment, projected to grow at 20% annually through 2030. Grid-scale applications require batteries with exceptional cycle life and safety characteristics, areas where both NMC and emerging micro-silicon technologies are competing for market share. Utility companies have expressed willingness to pay premium prices for storage solutions that can demonstrate superior longevity and reduced fire risk.

Consumer electronics manufacturers represent a third critical market segment, with increasing demands for batteries that can support more powerful devices while maintaining slim form factors. The wearable technology market, growing at 15% annually, specifically requires batteries with high energy density in extremely compact designs – a need that micro-silicon electron technology is particularly well-positioned to address.

Regional analysis indicates varying adoption patterns, with Asian markets leading in manufacturing capacity for both technologies, while North American and European markets show stronger consumer demand for products utilizing advanced battery solutions. Government policies are significantly influencing market dynamics, with over 20 countries announcing phase-outs of internal combustion engines between 2025 and 2040, creating guaranteed long-term demand for high-performance battery technologies.

Price sensitivity analysis reveals that while micro-silicon electron technology currently commands a 15-20% price premium over NMC batteries, the performance advantages are increasingly justifying this differential for high-end applications. Industry surveys indicate that 72% of automotive manufacturers are actively exploring silicon-based battery technologies for their next-generation vehicle platforms, signaling strong future demand despite current cost considerations.

However, market research reveals a significant shift in consumer and industry demands toward batteries with higher energy density, faster charging capabilities, and improved safety profiles. Range anxiety remains the primary concern for potential EV adopters, with 68% of consumers citing insufficient driving range as their main hesitation. This has created substantial market pull for next-generation battery technologies like micro-silicon electron solutions that promise to deliver up to 40% higher energy density compared to traditional NMC batteries.

The industrial energy storage sector presents another rapidly expanding market segment, projected to grow at 20% annually through 2030. Grid-scale applications require batteries with exceptional cycle life and safety characteristics, areas where both NMC and emerging micro-silicon technologies are competing for market share. Utility companies have expressed willingness to pay premium prices for storage solutions that can demonstrate superior longevity and reduced fire risk.

Consumer electronics manufacturers represent a third critical market segment, with increasing demands for batteries that can support more powerful devices while maintaining slim form factors. The wearable technology market, growing at 15% annually, specifically requires batteries with high energy density in extremely compact designs – a need that micro-silicon electron technology is particularly well-positioned to address.

Regional analysis indicates varying adoption patterns, with Asian markets leading in manufacturing capacity for both technologies, while North American and European markets show stronger consumer demand for products utilizing advanced battery solutions. Government policies are significantly influencing market dynamics, with over 20 countries announcing phase-outs of internal combustion engines between 2025 and 2040, creating guaranteed long-term demand for high-performance battery technologies.

Price sensitivity analysis reveals that while micro-silicon electron technology currently commands a 15-20% price premium over NMC batteries, the performance advantages are increasingly justifying this differential for high-end applications. Industry surveys indicate that 72% of automotive manufacturers are actively exploring silicon-based battery technologies for their next-generation vehicle platforms, signaling strong future demand despite current cost considerations.

Current Technical Challenges in Battery Interactivity

The current landscape of battery interactivity presents several significant technical challenges that impede the advancement of both NMC (Nickel Manganese Cobalt) batteries and Micro-Si Electron technologies. These challenges primarily revolve around interface stability, electron transport mechanisms, and system integration complexities.

Interface degradation remains a critical issue in NMC batteries, where repeated charge-discharge cycles create mechanical stress at electrode-electrolyte interfaces, leading to capacity fade and reduced cycle life. The formation of solid-electrolyte interphase (SEI) layers, while necessary for battery function, often grows unpredictably and inconsistently across the electrode surface, creating impedance variations that affect overall battery performance.

For Micro-Si Electron technology, volume expansion during lithiation presents a formidable challenge, with silicon particles expanding up to 300% during charging. This expansion-contraction cycle disrupts electron pathways and degrades the conductive network essential for efficient charge transfer. Current mitigation strategies using carbon coating and porous structures show promise but introduce manufacturing complexity and cost concerns.

Thermal management issues affect both technologies differently but equally significantly. NMC batteries suffer from thermal runaway risks at high charge-discharge rates, while Micro-Si systems experience localized heating at silicon-carbon interfaces during rapid charging, creating thermal gradients that accelerate degradation of surrounding materials.

Ion transport kinetics present another major challenge, particularly at the nanoscale interfaces where electrochemical reactions occur. NMC cathodes experience phase transitions during cycling that can block lithium diffusion pathways, while silicon anodes form complex lithium-silicon phases that evolve throughout battery operation, changing the fundamental interaction mechanisms.

Advanced characterization limitations hinder progress in understanding these interactive phenomena. Current in-situ and operando techniques lack sufficient spatial and temporal resolution to capture the dynamic processes occurring at electrode interfaces during actual operation. This knowledge gap impedes the development of targeted solutions for improving interactivity.

Computational modeling challenges further complicate the landscape, as multi-scale phenomena from atomic interactions to macroscopic battery behavior must be integrated into cohesive models. The disparate time scales—from femtosecond electron transfers to years of battery aging—create enormous computational complexity that current simulation frameworks struggle to address comprehensively.

These technical challenges collectively represent significant barriers to optimizing the interactivity measures between electronic and ionic components in both NMC and Micro-Si systems, necessitating innovative approaches that span materials science, electrochemistry, and advanced manufacturing techniques.

Interface degradation remains a critical issue in NMC batteries, where repeated charge-discharge cycles create mechanical stress at electrode-electrolyte interfaces, leading to capacity fade and reduced cycle life. The formation of solid-electrolyte interphase (SEI) layers, while necessary for battery function, often grows unpredictably and inconsistently across the electrode surface, creating impedance variations that affect overall battery performance.

For Micro-Si Electron technology, volume expansion during lithiation presents a formidable challenge, with silicon particles expanding up to 300% during charging. This expansion-contraction cycle disrupts electron pathways and degrades the conductive network essential for efficient charge transfer. Current mitigation strategies using carbon coating and porous structures show promise but introduce manufacturing complexity and cost concerns.

Thermal management issues affect both technologies differently but equally significantly. NMC batteries suffer from thermal runaway risks at high charge-discharge rates, while Micro-Si systems experience localized heating at silicon-carbon interfaces during rapid charging, creating thermal gradients that accelerate degradation of surrounding materials.

Ion transport kinetics present another major challenge, particularly at the nanoscale interfaces where electrochemical reactions occur. NMC cathodes experience phase transitions during cycling that can block lithium diffusion pathways, while silicon anodes form complex lithium-silicon phases that evolve throughout battery operation, changing the fundamental interaction mechanisms.

Advanced characterization limitations hinder progress in understanding these interactive phenomena. Current in-situ and operando techniques lack sufficient spatial and temporal resolution to capture the dynamic processes occurring at electrode interfaces during actual operation. This knowledge gap impedes the development of targeted solutions for improving interactivity.

Computational modeling challenges further complicate the landscape, as multi-scale phenomena from atomic interactions to macroscopic battery behavior must be integrated into cohesive models. The disparate time scales—from femtosecond electron transfers to years of battery aging—create enormous computational complexity that current simulation frameworks struggle to address comprehensively.

These technical challenges collectively represent significant barriers to optimizing the interactivity measures between electronic and ionic components in both NMC and Micro-Si systems, necessitating innovative approaches that span materials science, electrochemistry, and advanced manufacturing techniques.

Comparative Analysis of NMC and Micro-Si Solutions

01 NMC-Silicon composite electrode materials

Composite electrode materials combining NMC (Nickel Manganese Cobalt) cathodes with silicon-based anodes show enhanced electrochemical performance. These composites leverage the high capacity of silicon while mitigating its volume expansion issues through microstructural engineering. The electron interactivity between NMC cathodes and micro-silicon anodes is optimized through specific surface treatments and conductive additives, resulting in improved cycling stability and rate capability in lithium-ion batteries.- NMC-Silicon composite electrode materials: Composite electrode materials combining NMC (Nickel Manganese Cobalt) cathodes with silicon-based anodes show enhanced electrochemical performance. The integration of micro-silicon particles with NMC materials creates synergistic effects that improve battery capacity, cycling stability, and electron transfer rates. These composites leverage the high capacity of silicon while mitigating its volume expansion issues through specialized structural designs and coatings.

- Electron transport mechanisms in silicon-based battery materials: The electron transport mechanisms between micro-silicon particles and other battery components significantly impact overall battery performance. Research focuses on measuring and enhancing electron mobility at interfaces, reducing resistance, and creating conductive pathways. Advanced techniques for quantifying electron interactivity include impedance spectroscopy, conductivity measurements, and in-situ characterization methods that reveal how silicon's electronic properties change during charging and discharging cycles.

- Surface modification techniques for silicon-NMC interfaces: Surface modification of silicon particles and NMC materials improves their electrochemical compatibility and electron transfer properties. Techniques include applying conductive coatings, creating functional groups on surfaces, and developing specialized interface layers. These modifications enhance electron mobility between silicon and NMC components, stabilize the solid-electrolyte interphase, and improve cycling performance by maintaining electrical contact despite volume changes during battery operation.

- Measurement and characterization methods for electron interactivity: Advanced analytical techniques have been developed to measure electron interactivity between NMC cathodes and silicon anodes. These include electrochemical impedance spectroscopy, scanning electron microscopy with conductivity mapping, X-ray photoelectron spectroscopy, and in-situ transmission electron microscopy. These methods provide quantitative data on electron transfer rates, interface resistance, and charge distribution, enabling researchers to optimize material compositions and structures for enhanced battery performance.

- Nanostructured silicon designs for improved electron transfer: Nanostructured silicon designs significantly enhance electron transfer capabilities in NMC battery systems. These include silicon nanowires, porous silicon structures, and silicon-carbon nanocomposites that provide shorter electron diffusion paths and larger contact areas with electrolytes. The micro-to-nano architecture of silicon components allows for better electronic connectivity with NMC materials while accommodating volume changes during lithiation/delithiation, resulting in improved cycling stability and rate capability.

02 Electron transport mechanisms in silicon-based battery materials

The electron transport mechanisms in micro-silicon materials for battery applications involve specialized conductive pathways that facilitate charge transfer. These mechanisms are critical for maintaining electrical connectivity during the significant volume changes that silicon undergoes during lithiation and delithiation cycles. Various approaches to enhance electron transport include carbon coating, conductive polymer integration, and the formation of three-dimensional conductive networks that maintain contact with silicon particles throughout cycling.Expand Specific Solutions03 Interface engineering for NMC-Silicon battery systems

Interface engineering between NMC cathodes and silicon-based anodes is crucial for optimizing electron interactivity and overall battery performance. This involves the development of specialized coatings, electrolyte additives, and interfacial layers that stabilize the solid-electrolyte interface (SEI) while promoting efficient electron transfer. Advanced interface engineering techniques help mitigate parasitic reactions, reduce impedance growth, and enhance the long-term cycling stability of NMC-silicon battery systems.Expand Specific Solutions04 Measurement techniques for electron interactivity in battery materials

Various analytical techniques are employed to measure and characterize electron interactivity between NMC cathodes and micro-silicon anodes. These include electrochemical impedance spectroscopy (EIS), cyclic voltammetry, in-situ transmission electron microscopy, and advanced spectroscopic methods. These measurement techniques provide critical insights into charge transfer kinetics, interfacial resistance, and electronic conductivity, enabling the optimization of battery materials and structures for enhanced performance.Expand Specific Solutions05 Nanostructured silicon materials for enhanced electron transport

Nanostructured silicon materials, including silicon nanowires, nanoparticles, and porous silicon structures, offer enhanced electron transport properties when paired with NMC cathodes. These nanostructures provide shorter diffusion paths for both electrons and lithium ions, increased surface area for reactions, and improved mechanical stability during cycling. The controlled design of silicon nanostructures at the micro and nano scales significantly improves the electrochemical performance and cycle life of NMC-silicon battery systems.Expand Specific Solutions

Key Industry Players in Battery Manufacturing

The NMC Battery vs Micro-Si Electron technology landscape is currently in a growth phase, with the market expanding rapidly due to increasing demand for high-performance energy storage solutions. Major players like CATL, LG Energy Solution, and Panasonic are leading NMC battery development, while companies such as Toyota and QuantumScape are advancing micro-silicon electron technology. The market is characterized by intense competition between established battery manufacturers and emerging technology innovators. Technical maturity varies significantly - NMC technology is more commercially established, while micro-silicon electron technology offers promising performance improvements but faces scalability challenges. This competitive environment is driving substantial R&D investment across both technologies to improve energy density, charging capabilities, and safety profiles.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has developed a sophisticated approach to both NMC battery technology and micro-silicon electron integration. Their NMC formulation utilizes a concentration gradient structure where nickel content is higher in the particle core (up to 90%) and decreases toward the surface, creating inherently more stable cathode materials. For silicon anodes, Panasonic employs a proprietary "silicon-graphene sandwich" structure where silicon nanoparticles are encapsulated between graphene sheets, providing both electrical conductivity and mechanical flexibility to accommodate volume changes. Their micro-silicon technology uses particles in the 2-3 μm range with specialized carbon coatings that form elastic networks around silicon particles. Panasonic's electrolyte system incorporates fluoroethylene carbonate additives at precisely controlled concentrations (3-5%) to form stable SEI layers specifically on silicon surfaces. This integrated approach has yielded commercial cells with energy densities exceeding 700 Wh/L while maintaining cycle life comparable to conventional graphite-based systems.

Strengths: Established mass production capabilities; advanced silicon-graphene composite technology effectively managing volume expansion; superior electrolyte formulations specifically engineered for silicon interfaces. Weaknesses: Higher manufacturing costs compared to standard lithium-ion batteries; requires specialized production equipment; silicon content still limited to approximately 5-10% of total anode material to maintain cycle life.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed advanced NMC (Nickel Manganese Cobalt) battery technology with high energy density of up to 800 Wh/L, significantly higher than conventional lithium-ion batteries. Their NCMA (Nickel Cobalt Manganese Aluminum) cathode technology incorporates over 80% nickel content with reduced cobalt, enhancing energy density while maintaining thermal stability. For micro-silicon anodes, LG has implemented a proprietary silicon-carbon composite anode material that accommodates silicon's volume expansion during cycling. Their silicon-graphite composite anodes achieve specific capacities exceeding 600 mAh/g, compared to traditional graphite's 372 mAh/g. LG's batteries feature advanced electrolyte formulations with fluorinated additives that form stable SEI layers on silicon surfaces, improving cycling performance and reducing capacity fade over extended cycles.

Strengths: Superior energy density with NCMA cathodes; advanced silicon-carbon composite technology minimizing volume expansion issues; established manufacturing infrastructure. Weaknesses: Higher production costs compared to standard graphite anodes; silicon-based anodes still face challenges with long-term cycling stability; requires specialized electrolyte formulations to maintain performance.

Core Patents and Research in Electrode Interactivity

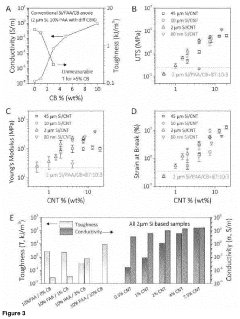

Highly efficient electrodes enabled by segregated networks

PatentPendingUS20230216058A1

Innovation

- The use of a spontaneously formed segregated network of carbon nanotubes or metallic nanowires, which acts as a scaffold to hold particulate active materials in place, eliminating the need for additional binders and conductive additives, thereby enhancing mechanical properties and conductivity, allowing for the production of extremely thick electrodes with high areal capacity.

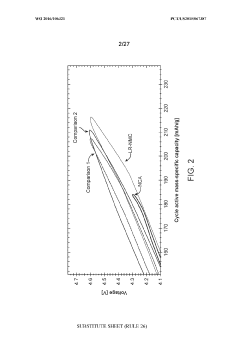

Lithium rich nickel manganese cobalt oxide (LR-NMC)

PatentWO2016106321A1

Innovation

- Development of lithium-rich nickel manganese cobalt oxide (LR-NMC) materials with specific chemical compositions and manufacturing methods that include varying ratios of nickel, manganese, and cobalt, and the use of lithium-containing salts to stabilize lithium within the crystal lattice, resulting in enhanced energy density and cycle lifetimes.

Environmental Impact and Sustainability Assessment

The environmental footprint of battery technologies has become a critical factor in their adoption, particularly as the world shifts towards sustainable energy solutions. When comparing NMC (Nickel Manganese Cobalt) batteries with Micro-Silicon Electron technologies, several key environmental considerations emerge that significantly impact their sustainability profiles.

NMC batteries, while offering high energy density and performance, present substantial environmental challenges throughout their lifecycle. The extraction of nickel, manganese, and particularly cobalt involves intensive mining operations that often result in habitat destruction, water pollution, and significant carbon emissions. Cobalt mining specifically has been associated with severe social and environmental issues, including child labor and toxic waste management problems in countries like the Democratic Republic of Congo.

Manufacturing processes for NMC batteries require considerable energy inputs and generate hazardous waste streams that necessitate specialized treatment. The carbon footprint of NMC production remains high despite efficiency improvements in recent years, with estimates suggesting 60-80 kg CO2 equivalent per kWh of battery capacity produced.

In contrast, Micro-Silicon Electron technology demonstrates promising environmental advantages. Silicon is the second most abundant element in Earth's crust, making its raw material sourcing less environmentally destructive than cobalt or nickel mining. The manufacturing process for silicon-based components typically requires less energy and produces fewer toxic byproducts compared to traditional battery chemistries.

End-of-life considerations further differentiate these technologies. NMC batteries contain valuable but difficult-to-separate materials, with recycling rates currently below 5% globally. The complex mixture of metals and compounds presents technical and economic barriers to efficient recycling. Micro-Silicon Electron components, however, show greater potential for material recovery and reuse, with simpler separation processes and higher theoretical recycling efficiency.

Water usage metrics reveal that NMC battery production consumes approximately 7-15 cubic meters of water per kWh of capacity, primarily in mining and processing operations. Micro-Silicon technology demonstrates approximately 30-40% lower water requirements across its lifecycle, representing a significant sustainability advantage in water-stressed regions.

Carbon footprint analyses indicate that while both technologies contribute to emissions reduction during use phase by enabling renewable energy storage, Micro-Silicon Electron technology may offer 15-25% lower lifecycle greenhouse gas emissions when accounting for production, use, and end-of-life stages. This advantage becomes particularly significant when considering the projected scale of battery deployment in coming decades.

NMC batteries, while offering high energy density and performance, present substantial environmental challenges throughout their lifecycle. The extraction of nickel, manganese, and particularly cobalt involves intensive mining operations that often result in habitat destruction, water pollution, and significant carbon emissions. Cobalt mining specifically has been associated with severe social and environmental issues, including child labor and toxic waste management problems in countries like the Democratic Republic of Congo.

Manufacturing processes for NMC batteries require considerable energy inputs and generate hazardous waste streams that necessitate specialized treatment. The carbon footprint of NMC production remains high despite efficiency improvements in recent years, with estimates suggesting 60-80 kg CO2 equivalent per kWh of battery capacity produced.

In contrast, Micro-Silicon Electron technology demonstrates promising environmental advantages. Silicon is the second most abundant element in Earth's crust, making its raw material sourcing less environmentally destructive than cobalt or nickel mining. The manufacturing process for silicon-based components typically requires less energy and produces fewer toxic byproducts compared to traditional battery chemistries.

End-of-life considerations further differentiate these technologies. NMC batteries contain valuable but difficult-to-separate materials, with recycling rates currently below 5% globally. The complex mixture of metals and compounds presents technical and economic barriers to efficient recycling. Micro-Silicon Electron components, however, show greater potential for material recovery and reuse, with simpler separation processes and higher theoretical recycling efficiency.

Water usage metrics reveal that NMC battery production consumes approximately 7-15 cubic meters of water per kWh of capacity, primarily in mining and processing operations. Micro-Silicon technology demonstrates approximately 30-40% lower water requirements across its lifecycle, representing a significant sustainability advantage in water-stressed regions.

Carbon footprint analyses indicate that while both technologies contribute to emissions reduction during use phase by enabling renewable energy storage, Micro-Silicon Electron technology may offer 15-25% lower lifecycle greenhouse gas emissions when accounting for production, use, and end-of-life stages. This advantage becomes particularly significant when considering the projected scale of battery deployment in coming decades.

Supply Chain Considerations for Battery Materials

The battery material supply chain represents a critical factor in the comparative analysis of NMC (Nickel Manganese Cobalt) batteries versus Micro-Silicon Electron technologies. NMC battery production relies heavily on raw materials with significant geopolitical implications, particularly cobalt, which faces concentration risk with over 70% of global supply originating from the Democratic Republic of Congo. This creates vulnerability to political instability, ethical concerns regarding mining practices, and potential supply disruptions.

Nickel, another key component in NMC batteries, has experienced price volatility and supply constraints as demand increases across multiple industries. The processing capacity for battery-grade nickel is concentrated in China, creating additional supply chain dependencies that manufacturers must navigate.

In contrast, Micro-Silicon Electron technology offers potential advantages from a supply chain perspective. Silicon is the second most abundant element in Earth's crust, with diverse geographical distribution of production facilities across multiple continents. This broader distribution potentially reduces geopolitical risks and supply concentration concerns compared to cobalt and nickel.

However, the processing of silicon into battery-grade micro-silicon requires specialized manufacturing capabilities and significant energy input. Current production capacity remains limited compared to established NMC supply chains, creating near-term scaling challenges despite long-term potential advantages.

Both technologies face challenges regarding sustainable sourcing and environmental impact throughout their supply chains. NMC batteries require energy-intensive mining operations with significant land disturbance, while micro-silicon production demands substantial energy for purification processes. Recycling infrastructure remains more developed for traditional battery chemistries than for newer silicon-based technologies.

Supply chain resilience must also consider manufacturing concentration. NMC battery production capacity is heavily concentrated in East Asia, particularly China, Japan, and South Korea. Micro-silicon technology currently follows similar geographical manufacturing patterns, though diversification efforts are underway in North America and Europe through policy initiatives like the US Inflation Reduction Act and European Battery Alliance.

The transition timeline between technologies presents another critical consideration. NMC supply chains benefit from established supplier networks and economies of scale, while micro-silicon electron technology requires significant investment in new manufacturing capabilities and supplier development, potentially creating short-term cost disadvantages despite long-term promise.

Nickel, another key component in NMC batteries, has experienced price volatility and supply constraints as demand increases across multiple industries. The processing capacity for battery-grade nickel is concentrated in China, creating additional supply chain dependencies that manufacturers must navigate.

In contrast, Micro-Silicon Electron technology offers potential advantages from a supply chain perspective. Silicon is the second most abundant element in Earth's crust, with diverse geographical distribution of production facilities across multiple continents. This broader distribution potentially reduces geopolitical risks and supply concentration concerns compared to cobalt and nickel.

However, the processing of silicon into battery-grade micro-silicon requires specialized manufacturing capabilities and significant energy input. Current production capacity remains limited compared to established NMC supply chains, creating near-term scaling challenges despite long-term potential advantages.

Both technologies face challenges regarding sustainable sourcing and environmental impact throughout their supply chains. NMC batteries require energy-intensive mining operations with significant land disturbance, while micro-silicon production demands substantial energy for purification processes. Recycling infrastructure remains more developed for traditional battery chemistries than for newer silicon-based technologies.

Supply chain resilience must also consider manufacturing concentration. NMC battery production capacity is heavily concentrated in East Asia, particularly China, Japan, and South Korea. Micro-silicon technology currently follows similar geographical manufacturing patterns, though diversification efforts are underway in North America and Europe through policy initiatives like the US Inflation Reduction Act and European Battery Alliance.

The transition timeline between technologies presents another critical consideration. NMC supply chains benefit from established supplier networks and economies of scale, while micro-silicon electron technology requires significant investment in new manufacturing capabilities and supplier development, potentially creating short-term cost disadvantages despite long-term promise.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!