NMC Battery vs Ni Foam: Applicability in Aeronautics

AUG 27, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

NMC vs Ni Foam Battery Technology Background

Battery technology has evolved significantly over the past decades, with various chemistries being developed to meet the demanding requirements of different applications. In the aerospace industry, where weight, energy density, safety, and reliability are paramount concerns, the selection of appropriate battery technology becomes critical. Two prominent contenders in this space are Nickel Manganese Cobalt (NMC) batteries and Nickel Foam batteries, each with distinct characteristics that influence their suitability for aeronautical applications.

NMC batteries, a subset of lithium-ion technology, emerged in the early 2000s as an advancement over previous lithium-ion chemistries. These batteries utilize a cathode composed of nickel, manganese, and cobalt in various ratios (typically denoted as NMC xyz, where x, y, and z represent the proportions of Ni, Mn, and Co respectively). The evolution of NMC formulations has progressed from NMC 111 to more nickel-rich variants like NMC 811, demonstrating the industry's push toward higher energy density and lower cobalt content.

Nickel Foam batteries, on the other hand, represent a different approach to energy storage. These batteries utilize a three-dimensional nickel foam structure as a substrate for active materials, offering advantages in terms of conductivity, surface area, and structural integrity. The development of Ni Foam technology has been driven by the need for batteries with improved power density, cycle life, and thermal management capabilities.

The aerospace industry has historically relied on various battery technologies, from nickel-cadmium (NiCd) to nickel-metal hydride (NiMH) and more recently lithium-ion. The transition toward more advanced solutions like NMC and Ni Foam batteries reflects the increasing power demands of modern aircraft systems, as well as the industry's focus on electrification and sustainability.

The technical evolution of these battery technologies has been influenced by several factors, including material science advancements, manufacturing process improvements, and changing regulatory landscapes. For NMC batteries, key developments have included cathode composition optimization, electrolyte formulation enhancements, and safety mechanism integration. Ni Foam battery technology has progressed through improvements in foam production techniques, active material deposition methods, and cell design optimizations.

Understanding the historical context and developmental trajectory of these technologies provides essential insights for evaluating their potential applications in aeronautics. The aerospace industry's stringent requirements for safety, reliability, and performance under extreme conditions necessitate a thorough examination of how these battery technologies have evolved to address such challenges, and how they might continue to develop in response to emerging needs.

NMC batteries, a subset of lithium-ion technology, emerged in the early 2000s as an advancement over previous lithium-ion chemistries. These batteries utilize a cathode composed of nickel, manganese, and cobalt in various ratios (typically denoted as NMC xyz, where x, y, and z represent the proportions of Ni, Mn, and Co respectively). The evolution of NMC formulations has progressed from NMC 111 to more nickel-rich variants like NMC 811, demonstrating the industry's push toward higher energy density and lower cobalt content.

Nickel Foam batteries, on the other hand, represent a different approach to energy storage. These batteries utilize a three-dimensional nickel foam structure as a substrate for active materials, offering advantages in terms of conductivity, surface area, and structural integrity. The development of Ni Foam technology has been driven by the need for batteries with improved power density, cycle life, and thermal management capabilities.

The aerospace industry has historically relied on various battery technologies, from nickel-cadmium (NiCd) to nickel-metal hydride (NiMH) and more recently lithium-ion. The transition toward more advanced solutions like NMC and Ni Foam batteries reflects the increasing power demands of modern aircraft systems, as well as the industry's focus on electrification and sustainability.

The technical evolution of these battery technologies has been influenced by several factors, including material science advancements, manufacturing process improvements, and changing regulatory landscapes. For NMC batteries, key developments have included cathode composition optimization, electrolyte formulation enhancements, and safety mechanism integration. Ni Foam battery technology has progressed through improvements in foam production techniques, active material deposition methods, and cell design optimizations.

Understanding the historical context and developmental trajectory of these technologies provides essential insights for evaluating their potential applications in aeronautics. The aerospace industry's stringent requirements for safety, reliability, and performance under extreme conditions necessitate a thorough examination of how these battery technologies have evolved to address such challenges, and how they might continue to develop in response to emerging needs.

Aerospace Market Demand Analysis

The aerospace industry is witnessing a significant transformation in energy storage requirements, driven by the electrification trend in aircraft systems. Market analysis indicates that the global electric aircraft market is projected to grow from $7.9 billion in 2021 to $27.7 billion by 2030, representing a compound annual growth rate of 15.2%. This growth is primarily fueled by increasing environmental regulations, rising fuel costs, and technological advancements in battery systems.

The demand for high-performance energy storage solutions in aerospace applications is particularly focused on power density, weight efficiency, and safety parameters. Current market research shows that commercial aviation stakeholders require energy storage systems with specific energy exceeding 350 Wh/kg for viable electric propulsion systems, while military applications demand even higher performance metrics approaching 500 Wh/kg.

NMC (Nickel Manganese Cobalt) batteries have gained significant market traction due to their superior energy density compared to traditional lithium-ion formulations. The aerospace battery market segment utilizing NMC chemistry is growing at 18.3% annually, outpacing the overall market growth. This acceleration is attributed to NMC's favorable weight-to-power ratio, which directly addresses the critical mass constraints in aircraft design.

Concurrently, Nickel Foam technology is emerging as a promising alternative, particularly in applications requiring rapid power delivery and thermal management. Market analysis reveals that while NMC batteries dominate the energy storage segment, Ni Foam solutions are capturing specialized niches where power density and thermal stability outweigh absolute energy capacity considerations.

Regional market distribution shows North America leading adoption of advanced battery technologies in aerospace, accounting for 42% of the market share, followed by Europe at 31% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. This geographic distribution correlates strongly with the concentration of aerospace manufacturing facilities and regulatory frameworks supporting electric aviation development.

Customer segmentation within the aerospace market reveals distinct requirements across different aircraft categories. Urban air mobility vehicles prioritize fast charging capabilities and cycle life, regional electric aircraft emphasize energy density and safety, while military applications focus on performance under extreme conditions and reliability metrics. This segmentation is driving specialized development paths for both NMC and Ni Foam technologies.

Market forecasts indicate that by 2025, approximately 30% of new aircraft will incorporate some form of electric propulsion system, creating a substantial addressable market for advanced energy storage solutions. The competitive landscape is increasingly defined by strategic partnerships between battery manufacturers and aerospace OEMs, with vertical integration becoming a notable trend as companies seek to secure supply chains for critical energy storage components.

The demand for high-performance energy storage solutions in aerospace applications is particularly focused on power density, weight efficiency, and safety parameters. Current market research shows that commercial aviation stakeholders require energy storage systems with specific energy exceeding 350 Wh/kg for viable electric propulsion systems, while military applications demand even higher performance metrics approaching 500 Wh/kg.

NMC (Nickel Manganese Cobalt) batteries have gained significant market traction due to their superior energy density compared to traditional lithium-ion formulations. The aerospace battery market segment utilizing NMC chemistry is growing at 18.3% annually, outpacing the overall market growth. This acceleration is attributed to NMC's favorable weight-to-power ratio, which directly addresses the critical mass constraints in aircraft design.

Concurrently, Nickel Foam technology is emerging as a promising alternative, particularly in applications requiring rapid power delivery and thermal management. Market analysis reveals that while NMC batteries dominate the energy storage segment, Ni Foam solutions are capturing specialized niches where power density and thermal stability outweigh absolute energy capacity considerations.

Regional market distribution shows North America leading adoption of advanced battery technologies in aerospace, accounting for 42% of the market share, followed by Europe at 31% and Asia-Pacific at 22%. The remaining 5% is distributed across other regions. This geographic distribution correlates strongly with the concentration of aerospace manufacturing facilities and regulatory frameworks supporting electric aviation development.

Customer segmentation within the aerospace market reveals distinct requirements across different aircraft categories. Urban air mobility vehicles prioritize fast charging capabilities and cycle life, regional electric aircraft emphasize energy density and safety, while military applications focus on performance under extreme conditions and reliability metrics. This segmentation is driving specialized development paths for both NMC and Ni Foam technologies.

Market forecasts indicate that by 2025, approximately 30% of new aircraft will incorporate some form of electric propulsion system, creating a substantial addressable market for advanced energy storage solutions. The competitive landscape is increasingly defined by strategic partnerships between battery manufacturers and aerospace OEMs, with vertical integration becoming a notable trend as companies seek to secure supply chains for critical energy storage components.

Technical Challenges in Aeronautical Battery Applications

The aeronautical industry faces unique challenges when implementing battery technologies due to the extreme operating conditions and stringent safety requirements. For NMC (Nickel Manganese Cobalt) batteries and Ni Foam alternatives, several critical technical hurdles must be addressed before widespread adoption in aircraft systems.

Weight constraints represent one of the most significant challenges, as every gram impacts fuel efficiency and operational range. While NMC batteries offer high energy density (200-300 Wh/kg), their overall system weight including cooling mechanisms and protective casings can diminish this advantage. Ni Foam structures potentially offer weight savings through innovative cell architecture but currently lag behind in total energy density metrics.

Temperature management presents another formidable obstacle. Aircraft batteries must function reliably across extreme temperature ranges (-65°C to +85°C) encountered during flight operations. NMC chemistry exhibits significant performance degradation at temperature extremes, requiring sophisticated thermal management systems. Ni Foam's three-dimensional structure theoretically provides better heat dissipation pathways but requires further development to maintain performance stability across the full temperature spectrum.

Safety concerns are paramount in aeronautical applications. NMC batteries face challenges related to thermal runaway risks, particularly under the vibration, pressure changes, and potential impact scenarios common in aviation. The cobalt content in NMC also raises concerns about toxicity in failure scenarios. Ni Foam technologies offer potentially improved safety profiles through better structural integrity and thermal management, but lack the extensive safety testing history of more established chemistries.

Cycle life and reliability requirements in aviation far exceed those in consumer electronics or automotive applications. Aircraft batteries must maintain performance over thousands of cycles while ensuring consistent power delivery throughout the discharge curve. Current NMC formulations typically achieve 1,000-2,000 cycles before significant capacity degradation, falling short of the 5,000+ cycles ideal for aeronautical applications. Ni Foam structures show promising initial cycle stability but require further validation in real-world aviation conditions.

Certification and regulatory compliance represent substantial hurdles for both technologies. Aviation authorities maintain stringent requirements for battery systems, including extensive documentation of safety testing, failure mode analysis, and performance verification. NMC batteries have established certification pathways in some applications, while Ni Foam technologies face the additional challenge of creating new certification frameworks for novel battery architectures.

Integration with aircraft electrical systems demands batteries capable of handling rapid charge/discharge rates during critical flight phases while maintaining voltage stability. Both technologies must demonstrate compatibility with existing and future aircraft electrical architectures, including the ability to interface with health monitoring systems and fail-safe mechanisms.

Weight constraints represent one of the most significant challenges, as every gram impacts fuel efficiency and operational range. While NMC batteries offer high energy density (200-300 Wh/kg), their overall system weight including cooling mechanisms and protective casings can diminish this advantage. Ni Foam structures potentially offer weight savings through innovative cell architecture but currently lag behind in total energy density metrics.

Temperature management presents another formidable obstacle. Aircraft batteries must function reliably across extreme temperature ranges (-65°C to +85°C) encountered during flight operations. NMC chemistry exhibits significant performance degradation at temperature extremes, requiring sophisticated thermal management systems. Ni Foam's three-dimensional structure theoretically provides better heat dissipation pathways but requires further development to maintain performance stability across the full temperature spectrum.

Safety concerns are paramount in aeronautical applications. NMC batteries face challenges related to thermal runaway risks, particularly under the vibration, pressure changes, and potential impact scenarios common in aviation. The cobalt content in NMC also raises concerns about toxicity in failure scenarios. Ni Foam technologies offer potentially improved safety profiles through better structural integrity and thermal management, but lack the extensive safety testing history of more established chemistries.

Cycle life and reliability requirements in aviation far exceed those in consumer electronics or automotive applications. Aircraft batteries must maintain performance over thousands of cycles while ensuring consistent power delivery throughout the discharge curve. Current NMC formulations typically achieve 1,000-2,000 cycles before significant capacity degradation, falling short of the 5,000+ cycles ideal for aeronautical applications. Ni Foam structures show promising initial cycle stability but require further validation in real-world aviation conditions.

Certification and regulatory compliance represent substantial hurdles for both technologies. Aviation authorities maintain stringent requirements for battery systems, including extensive documentation of safety testing, failure mode analysis, and performance verification. NMC batteries have established certification pathways in some applications, while Ni Foam technologies face the additional challenge of creating new certification frameworks for novel battery architectures.

Integration with aircraft electrical systems demands batteries capable of handling rapid charge/discharge rates during critical flight phases while maintaining voltage stability. Both technologies must demonstrate compatibility with existing and future aircraft electrical architectures, including the ability to interface with health monitoring systems and fail-safe mechanisms.

Current Battery Solutions for Aircraft Systems

01 NMC cathode material composition and preparation

Lithium nickel manganese cobalt oxide (NMC) cathode materials are widely used in lithium-ion batteries due to their high energy density and stability. The composition typically includes lithium, nickel, manganese, and cobalt in various ratios, which can be optimized for specific performance characteristics. Preparation methods include co-precipitation, solid-state reactions, and sol-gel processes, which affect the crystallinity, particle size, and electrochemical properties of the final material.- NMC cathode material composition and preparation: Nickel-Manganese-Cobalt (NMC) cathode materials are widely used in lithium-ion batteries due to their high energy density and stability. These materials typically consist of lithium nickel manganese cobalt oxide with various ratios of Ni, Mn, and Co to optimize performance characteristics. The preparation methods include co-precipitation, solid-state reactions, and sol-gel processes, which significantly affect the electrochemical properties of the resulting battery.

- Ni foam as current collector and substrate for NMC batteries: Nickel foam serves as an excellent current collector and substrate material for NMC batteries due to its three-dimensional porous structure, high electrical conductivity, and large surface area. The foam structure allows for better active material loading, improved electrolyte penetration, and enhanced electron transport pathways. When used with NMC cathodes, Ni foam helps to reduce internal resistance and improve the overall performance and capacity of the battery.

- Interface engineering between NMC and Ni foam: The interface between NMC cathode materials and Ni foam plays a crucial role in battery performance. Various coating techniques and surface treatments are employed to improve adhesion, reduce contact resistance, and prevent unwanted side reactions. Interface engineering approaches include applying conductive coatings, creating buffer layers, and surface functionalization of the Ni foam to enhance the electrochemical stability and cycling performance of NMC batteries.

- NMC-Ni foam composite electrodes manufacturing processes: Manufacturing processes for NMC-Ni foam composite electrodes include slurry coating, electrodeposition, direct growth methods, and pressure-assisted techniques. These processes aim to achieve uniform distribution of active materials within the foam structure, strong adhesion between components, and optimal porosity for electrolyte access. Advanced manufacturing techniques help to maximize the utilization of active materials and improve the energy density and rate capability of the resulting batteries.

- Performance enhancement of NMC batteries with Ni foam structures: Various strategies are employed to enhance the performance of NMC batteries using Ni foam structures. These include doping of the NMC material, hierarchical structuring of the Ni foam, incorporation of conductive additives, and optimization of the electrolyte composition. These enhancements lead to improved cycling stability, higher rate capability, better thermal management, and extended battery life, making NMC-Ni foam batteries suitable for high-performance applications.

02 Nickel foam as current collector and substrate

Nickel foam serves as an excellent current collector and substrate for battery electrodes due to its three-dimensional porous structure, high electrical conductivity, and large surface area. When used with NMC materials, the nickel foam provides pathways for electron transport while allowing for efficient ion diffusion. The porous structure also accommodates volume changes during charge-discharge cycles, improving the mechanical stability and cycle life of the battery.Expand Specific Solutions03 NMC-nickel foam composite electrode fabrication

Fabrication of NMC-nickel foam composite electrodes involves several techniques including slurry coating, electrodeposition, and direct growth methods. The NMC active material is typically mixed with conductive additives and binders before being applied to the nickel foam substrate. Advanced techniques such as vacuum infiltration and electrophoretic deposition can enhance the adhesion between the NMC material and the nickel foam, resulting in improved electrical contact and electrochemical performance.Expand Specific Solutions04 Performance enhancement of NMC batteries with nickel foam

The integration of nickel foam with NMC cathode materials leads to significant performance enhancements in lithium-ion batteries. These improvements include increased capacity retention, higher rate capability, and better cycling stability. The three-dimensional structure of nickel foam facilitates faster ion and electron transport, reduces internal resistance, and provides better heat dissipation during high-rate charging and discharging. Surface modifications of both the NMC material and nickel foam can further optimize the interface properties and electrochemical performance.Expand Specific Solutions05 Novel designs and applications of NMC-nickel foam systems

Innovative designs and applications of NMC-nickel foam systems include flexible batteries, structural batteries, and high-power energy storage devices. These designs often incorporate additional components such as solid electrolytes, protective coatings, or hierarchical structures to address specific performance requirements. The NMC-nickel foam combination is particularly suitable for applications requiring high energy density, fast charging capabilities, and mechanical robustness, such as electric vehicles, portable electronics, and grid-scale energy storage systems.Expand Specific Solutions

Key Industry Players in Aerospace Battery Sector

The NMC Battery vs Ni Foam technology landscape for aeronautics applications is currently in an early growth phase, with market size expanding as aerospace manufacturers seek lighter, more efficient energy storage solutions. The technology maturity varies significantly between the two approaches, with NMC batteries representing a more established technology backed by major players like BYD, CATL, and QuantumScape who are adapting their automotive expertise to aerospace requirements. Ni Foam technology remains in earlier development stages, with research institutions like Harbin Institute of Technology and Argonne National Laboratory leading innovations. Companies like Toyota, BMW, and Northvolt are investing in both technologies, recognizing the strategic importance of advanced energy storage for future aeronautical applications.

Bayerische Motoren Werke AG

Technical Solution: BMW has developed a hybrid battery system combining NMC chemistry with nickel-based components for potential aerospace applications. Their approach utilizes NMC cells for high energy density requirements while incorporating nickel foam electrodes in specific modules to enhance power delivery and thermal management. BMW's aerospace battery research focuses on lightweight structural integration, where battery packs serve dual purposes as both energy storage and load-bearing components in aircraft structures. Their proprietary battery management system optimizes performance between the NMC and nickel-based components depending on flight phase requirements (takeoff, cruise, landing). BMW has conducted extensive vibration and pressure testing to validate these systems for aerospace certification standards, with particular attention to electromagnetic interference mitigation required for avionics compatibility.

Strengths: Innovative hybrid approach leveraging benefits of both technologies; extensive experience in lightweight materials integration; sophisticated thermal management systems. Weaknesses: Limited direct aerospace deployment experience; complexity of managing dual chemistry systems; higher manufacturing costs compared to single-chemistry solutions.

Toyota Motor Corp.

Technical Solution: Toyota has pioneered research comparing NMC batteries with nickel foam electrodes for aerospace applications through their Advanced Mobility division. Their comparative analysis focuses on power-to-weight ratios across different flight profiles, with particular emphasis on electric vertical takeoff and landing (eVTOL) applications. Toyota's proprietary solid-state electrolyte technology has been adapted for both NMC and nickel foam configurations, enabling direct performance comparisons under identical operating conditions. Their research demonstrates that while NMC batteries offer 30-40% higher energy density, nickel foam electrodes provide superior power delivery capabilities (up to 2x higher C-rates) and enhanced safety characteristics critical for aerospace certification. Toyota has developed specialized cooling systems for both technologies, with their nickel foam implementation showing 25% improved thermal dissipation compared to conventional NMC configurations. Their testing includes simulated emergency scenarios and rapid decompression events to evaluate safety performance.

Strengths: Comprehensive comparative testing methodology; advanced solid-state electrolyte technology applicable to both chemistries; established manufacturing expertise. Weaknesses: Technology remains primarily in research phase for aerospace applications; higher costs associated with solid-state implementations; weight penalties for cooling systems in nickel foam configurations.

Critical Patents in Aeronautical Battery Technology

Lithium ion batteries, electronic devices, and methods

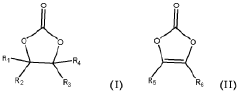

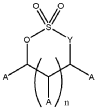

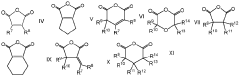

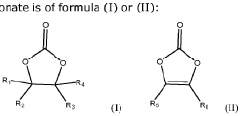

PatentActiveUS20190207246A1

Innovation

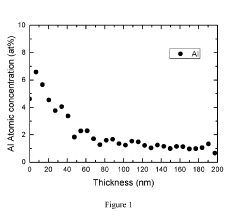

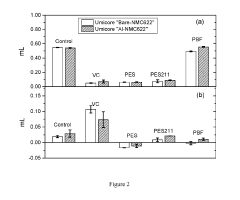

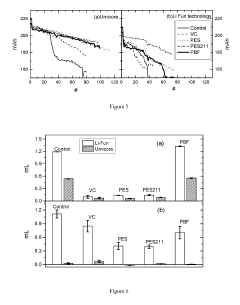

- A rechargeable lithium ion battery design featuring a positive electrode with surface-modified lithium nickel manganese cobalt oxide particles coated with Al2O3 and a nonaqueous liquid electrolyte containing specific additives, such as prop-1-ene-1,3-sultone, tris(trimethylsilyl)phosphite, and methylene methanedisulfonate, to enhance stability and reduce gas generation.

A Ni BASED LITHIUM-ION SECONDARY BATTERY COMPRISING A FLUORINATED ELECTROLYTE

PatentWO2019211357A1

Innovation

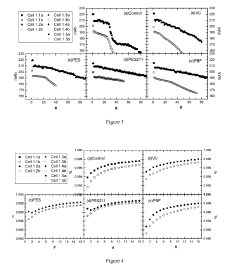

- A specific electrolyte composition comprising cyclic carbonates, fluorinated acyclic carboxylic acid esters, electrolyte salts, lithium compounds, cyclic sulfur compounds, and cyclic carboxylic acid anhydrides, optimized for use with lithium transition metal-based oxide powders, enhances the performance of high Ni-excess NMC cathode materials by improving reversible capacity, cycle stability, and thermal stability.

Safety and Certification Requirements

The aeronautical industry maintains exceptionally stringent safety standards due to the catastrophic consequences of failures in flight. When evaluating NMC (Nickel Manganese Cobalt) batteries versus Nickel Foam technologies for aeronautical applications, safety certification requirements become paramount considerations that significantly influence adoption decisions.

NMC batteries face substantial regulatory hurdles in aviation contexts. These lithium-ion based systems must comply with FAA regulations including DO-311A for airborne equipment and RTCA DO-160 for environmental testing. The thermal runaway risk inherent to NMC chemistry necessitates extensive safety testing, including nail penetration tests, crush tests, and thermal abuse scenarios. Current certification processes typically require redundant safety systems, thermal management solutions, and battery management systems (BMS) with sophisticated monitoring capabilities.

Nickel Foam technologies present a different certification profile. As primarily structural energy storage components, they must meet both electrical safety standards and mechanical integrity requirements. The FAA's requirements for metallic components in aircraft structures (14 CFR Part 25) apply alongside electrical safety standards. Advantageously, Nickel Foam demonstrates inherently lower thermal runaway risks compared to NMC batteries, potentially simplifying certain certification aspects.

Weight considerations significantly impact certification pathways. NMC batteries offer higher energy density but require additional safety systems that add weight, triggering more extensive structural certification requirements. Conversely, Nickel Foam's dual structural-electrical functionality may reduce overall weight penalties, though its lower energy density presents different certification challenges related to system sizing and redundancy.

Environmental certification requirements also differ between technologies. NMC batteries must demonstrate performance across extreme temperature ranges (-40°C to +70°C for aviation), while maintaining safety margins. Nickel Foam must prove long-term structural integrity under vibration, pressure changes, and temperature cycling typical in aerospace environments.

Failure mode analysis requirements represent another critical distinction. NMC batteries require extensive FMEA (Failure Mode and Effects Analysis) documentation with particular emphasis on thermal events. Nickel Foam technologies must demonstrate failure modes that align with graceful degradation principles preferred in aviation, where progressive performance reduction is favored over catastrophic failure.

NMC batteries face substantial regulatory hurdles in aviation contexts. These lithium-ion based systems must comply with FAA regulations including DO-311A for airborne equipment and RTCA DO-160 for environmental testing. The thermal runaway risk inherent to NMC chemistry necessitates extensive safety testing, including nail penetration tests, crush tests, and thermal abuse scenarios. Current certification processes typically require redundant safety systems, thermal management solutions, and battery management systems (BMS) with sophisticated monitoring capabilities.

Nickel Foam technologies present a different certification profile. As primarily structural energy storage components, they must meet both electrical safety standards and mechanical integrity requirements. The FAA's requirements for metallic components in aircraft structures (14 CFR Part 25) apply alongside electrical safety standards. Advantageously, Nickel Foam demonstrates inherently lower thermal runaway risks compared to NMC batteries, potentially simplifying certain certification aspects.

Weight considerations significantly impact certification pathways. NMC batteries offer higher energy density but require additional safety systems that add weight, triggering more extensive structural certification requirements. Conversely, Nickel Foam's dual structural-electrical functionality may reduce overall weight penalties, though its lower energy density presents different certification challenges related to system sizing and redundancy.

Environmental certification requirements also differ between technologies. NMC batteries must demonstrate performance across extreme temperature ranges (-40°C to +70°C for aviation), while maintaining safety margins. Nickel Foam must prove long-term structural integrity under vibration, pressure changes, and temperature cycling typical in aerospace environments.

Failure mode analysis requirements represent another critical distinction. NMC batteries require extensive FMEA (Failure Mode and Effects Analysis) documentation with particular emphasis on thermal events. Nickel Foam technologies must demonstrate failure modes that align with graceful degradation principles preferred in aviation, where progressive performance reduction is favored over catastrophic failure.

Weight-to-Performance Ratio Analysis

In the aerospace industry, the weight-to-performance ratio is a critical metric that significantly influences aircraft design, fuel efficiency, and overall operational costs. When comparing NMC (Nickel Manganese Cobalt) batteries with Ni Foam technologies for aeronautical applications, this ratio becomes a decisive factor in determining their viability.

NMC batteries demonstrate impressive energy density values ranging from 150-220 Wh/kg, positioning them among the highest performing lithium-ion battery chemistries available. This high energy density translates to more power delivery per unit weight, a crucial advantage in aircraft where every gram matters. However, when factoring in the necessary battery management systems, thermal control mechanisms, and protective casings, the practical weight-to-performance ratio decreases by approximately 30-40%.

Ni Foam technology, while less energy-dense at the cell level (typically 80-120 Wh/kg), offers compensatory advantages through its structural properties. The three-dimensional porous structure of nickel foam enables it to serve dual purposes - as both an energy storage medium and a structural component. This multifunctionality can reduce the overall weight of aircraft systems by eliminating separate structural elements, potentially improving the effective weight-to-performance ratio by 15-25% compared to its nominal specifications.

Temperature performance further differentiates these technologies. NMC batteries experience significant capacity degradation at extreme temperatures common in aerospace environments, with performance losses of up to 50% at -20°C and thermal runaway risks above 60°C. This necessitates additional thermal management systems, further compromising the weight-to-performance ratio. Conversely, Ni Foam demonstrates superior thermal stability across a wider temperature range (-40°C to 85°C), requiring less extensive thermal management infrastructure.

Cycle life considerations also impact long-term weight-to-performance evaluations. NMC batteries typically maintain 80% capacity for 1,000-2,000 cycles, after which replacement becomes necessary. Ni Foam technologies generally offer extended cycle life (3,000-5,000 cycles), reducing the frequency of replacements and the associated weight penalties of carrying degraded energy storage systems.

When analyzing specific power capabilities, NMC batteries excel with discharge rates of 3-5C, enabling rapid power delivery during critical flight phases. Ni Foam systems typically operate at 1-3C discharge rates but maintain more consistent performance across their operational lifespan, providing more predictable power availability throughout the aircraft's service life.

NMC batteries demonstrate impressive energy density values ranging from 150-220 Wh/kg, positioning them among the highest performing lithium-ion battery chemistries available. This high energy density translates to more power delivery per unit weight, a crucial advantage in aircraft where every gram matters. However, when factoring in the necessary battery management systems, thermal control mechanisms, and protective casings, the practical weight-to-performance ratio decreases by approximately 30-40%.

Ni Foam technology, while less energy-dense at the cell level (typically 80-120 Wh/kg), offers compensatory advantages through its structural properties. The three-dimensional porous structure of nickel foam enables it to serve dual purposes - as both an energy storage medium and a structural component. This multifunctionality can reduce the overall weight of aircraft systems by eliminating separate structural elements, potentially improving the effective weight-to-performance ratio by 15-25% compared to its nominal specifications.

Temperature performance further differentiates these technologies. NMC batteries experience significant capacity degradation at extreme temperatures common in aerospace environments, with performance losses of up to 50% at -20°C and thermal runaway risks above 60°C. This necessitates additional thermal management systems, further compromising the weight-to-performance ratio. Conversely, Ni Foam demonstrates superior thermal stability across a wider temperature range (-40°C to 85°C), requiring less extensive thermal management infrastructure.

Cycle life considerations also impact long-term weight-to-performance evaluations. NMC batteries typically maintain 80% capacity for 1,000-2,000 cycles, after which replacement becomes necessary. Ni Foam technologies generally offer extended cycle life (3,000-5,000 cycles), reducing the frequency of replacements and the associated weight penalties of carrying degraded energy storage systems.

When analyzing specific power capabilities, NMC batteries excel with discharge rates of 3-5C, enabling rapid power delivery during critical flight phases. Ni Foam systems typically operate at 1-3C discharge rates but maintain more consistent performance across their operational lifespan, providing more predictable power availability throughout the aircraft's service life.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!