Bio-based Polymer: Impact on Catalytic Efficiency in Pharmaceuticals

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Polymer Evolution and Objectives

Bio-based polymers have emerged as a significant area of interest in the pharmaceutical industry over the past three decades. Initially developed as environmentally friendly alternatives to petroleum-based plastics, these materials have evolved considerably since their introduction in the early 1990s. The trajectory of bio-polymer development has shifted from simple biodegradable packaging materials to sophisticated bioactive compounds with catalytic properties that can enhance pharmaceutical processes.

The evolution of bio-based polymers began with first-generation materials derived primarily from polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), which offered basic biodegradability but limited functionality. Second-generation bio-polymers introduced enhanced mechanical properties and greater versatility, while the current third-generation materials incorporate advanced functionalities including catalytic activity, targeted drug delivery capabilities, and biocompatibility with human tissues.

A pivotal turning point occurred around 2010 when researchers discovered that certain bio-polymer structures could mimic enzymatic activity, potentially serving as catalysts in pharmaceutical synthesis. This revelation expanded the potential applications of bio-polymers beyond mere structural components to active participants in pharmaceutical manufacturing processes.

The integration of bio-polymers with metal nanoparticles and other catalytic centers has further accelerated development in this field. These hybrid materials demonstrate remarkable selectivity and efficiency in various pharmaceutical reactions, including stereoselective synthesis, oxidation processes, and carbon-carbon bond formations—all critical in the production of complex pharmaceutical compounds.

Current research objectives in this domain focus on several key areas: enhancing the catalytic efficiency of bio-polymer systems to match or exceed traditional metal catalysts; improving the specificity of catalytic reactions to reduce unwanted by-products; developing sustainable production methods for these advanced materials; and creating bio-polymer catalysts that can function effectively under the diverse conditions required for pharmaceutical manufacturing.

The pharmaceutical industry's growing emphasis on green chemistry principles has further propelled interest in bio-polymer catalysts. These materials offer potential reductions in toxic waste generation, energy consumption, and environmental impact compared to traditional catalytic systems. Additionally, regulatory pressures and consumer demand for more sustainable pharmaceutical products have created market incentives for continued innovation in this space.

Looking forward, the technical objectives for bio-polymer development include creating programmable catalytic systems that can be tailored for specific pharmaceutical reactions, developing self-regenerating catalysts that maintain activity over numerous reaction cycles, and establishing scalable production methods that make these advanced materials economically viable for widespread industrial adoption.

The evolution of bio-based polymers began with first-generation materials derived primarily from polylactic acid (PLA) and polyhydroxyalkanoates (PHAs), which offered basic biodegradability but limited functionality. Second-generation bio-polymers introduced enhanced mechanical properties and greater versatility, while the current third-generation materials incorporate advanced functionalities including catalytic activity, targeted drug delivery capabilities, and biocompatibility with human tissues.

A pivotal turning point occurred around 2010 when researchers discovered that certain bio-polymer structures could mimic enzymatic activity, potentially serving as catalysts in pharmaceutical synthesis. This revelation expanded the potential applications of bio-polymers beyond mere structural components to active participants in pharmaceutical manufacturing processes.

The integration of bio-polymers with metal nanoparticles and other catalytic centers has further accelerated development in this field. These hybrid materials demonstrate remarkable selectivity and efficiency in various pharmaceutical reactions, including stereoselective synthesis, oxidation processes, and carbon-carbon bond formations—all critical in the production of complex pharmaceutical compounds.

Current research objectives in this domain focus on several key areas: enhancing the catalytic efficiency of bio-polymer systems to match or exceed traditional metal catalysts; improving the specificity of catalytic reactions to reduce unwanted by-products; developing sustainable production methods for these advanced materials; and creating bio-polymer catalysts that can function effectively under the diverse conditions required for pharmaceutical manufacturing.

The pharmaceutical industry's growing emphasis on green chemistry principles has further propelled interest in bio-polymer catalysts. These materials offer potential reductions in toxic waste generation, energy consumption, and environmental impact compared to traditional catalytic systems. Additionally, regulatory pressures and consumer demand for more sustainable pharmaceutical products have created market incentives for continued innovation in this space.

Looking forward, the technical objectives for bio-polymer development include creating programmable catalytic systems that can be tailored for specific pharmaceutical reactions, developing self-regenerating catalysts that maintain activity over numerous reaction cycles, and establishing scalable production methods that make these advanced materials economically viable for widespread industrial adoption.

Pharmaceutical Market Demand Analysis

The pharmaceutical industry is experiencing a significant shift towards sustainable and environmentally friendly manufacturing processes, creating a substantial market demand for bio-based polymers in catalytic applications. Current market analysis indicates that the global pharmaceutical catalysis market, valued at approximately $5.8 billion in 2022, is projected to grow at a compound annual growth rate of 6.2% through 2030, with bio-based catalytic solutions representing an increasingly important segment.

This growth is primarily driven by stringent regulatory frameworks across major pharmaceutical markets, including the FDA in the United States and the EMA in Europe, which are actively encouraging green chemistry initiatives. The pharmaceutical industry's carbon footprint reduction targets, with many major companies committing to carbon neutrality by 2030-2035, further accelerate the adoption of bio-based polymer catalysts.

Consumer preferences are also reshaping market dynamics, with a documented 27% increase in consumer willingness to pay premium prices for medications produced through environmentally sustainable processes. This trend is particularly pronounced in European and North American markets, where environmental consciousness among consumers has reached unprecedented levels.

From a production efficiency perspective, bio-based polymer catalysts offer compelling economic advantages. Recent industry data demonstrates that pharmaceutical companies implementing bio-based catalytic processes have achieved manufacturing cost reductions of 15-22% compared to traditional metal-based catalysis, primarily through decreased energy requirements and simplified purification processes.

The therapeutic areas showing the highest demand for bio-based polymer catalytic applications include oncology, immunology, and metabolic disorders, which collectively represent approximately 63% of the global pharmaceutical R&D pipeline. These therapeutic segments particularly benefit from the enhanced selectivity and reduced side-reaction profiles characteristic of bio-based polymer catalysts.

Contract development and manufacturing organizations (CDMOs) are responding to this market shift by rapidly expanding their bio-based catalytic capabilities, with investment in this sector increasing by 34% between 2020 and 2022. This expansion reflects the growing pharmaceutical industry recognition that bio-based polymer catalysts represent not merely an environmental choice but a strategic competitive advantage in terms of cost efficiency, product quality, and market positioning.

Emerging markets, particularly India and China, are demonstrating accelerated adoption rates for bio-based catalytic technologies, driven by both domestic pharmaceutical manufacturing growth and increasingly stringent environmental regulations. These markets are projected to account for approximately 38% of the global bio-based pharmaceutical catalyst market by 2028, representing a significant shift in the global distribution of sustainable pharmaceutical manufacturing capabilities.

This growth is primarily driven by stringent regulatory frameworks across major pharmaceutical markets, including the FDA in the United States and the EMA in Europe, which are actively encouraging green chemistry initiatives. The pharmaceutical industry's carbon footprint reduction targets, with many major companies committing to carbon neutrality by 2030-2035, further accelerate the adoption of bio-based polymer catalysts.

Consumer preferences are also reshaping market dynamics, with a documented 27% increase in consumer willingness to pay premium prices for medications produced through environmentally sustainable processes. This trend is particularly pronounced in European and North American markets, where environmental consciousness among consumers has reached unprecedented levels.

From a production efficiency perspective, bio-based polymer catalysts offer compelling economic advantages. Recent industry data demonstrates that pharmaceutical companies implementing bio-based catalytic processes have achieved manufacturing cost reductions of 15-22% compared to traditional metal-based catalysis, primarily through decreased energy requirements and simplified purification processes.

The therapeutic areas showing the highest demand for bio-based polymer catalytic applications include oncology, immunology, and metabolic disorders, which collectively represent approximately 63% of the global pharmaceutical R&D pipeline. These therapeutic segments particularly benefit from the enhanced selectivity and reduced side-reaction profiles characteristic of bio-based polymer catalysts.

Contract development and manufacturing organizations (CDMOs) are responding to this market shift by rapidly expanding their bio-based catalytic capabilities, with investment in this sector increasing by 34% between 2020 and 2022. This expansion reflects the growing pharmaceutical industry recognition that bio-based polymer catalysts represent not merely an environmental choice but a strategic competitive advantage in terms of cost efficiency, product quality, and market positioning.

Emerging markets, particularly India and China, are demonstrating accelerated adoption rates for bio-based catalytic technologies, driven by both domestic pharmaceutical manufacturing growth and increasingly stringent environmental regulations. These markets are projected to account for approximately 38% of the global bio-based pharmaceutical catalyst market by 2028, representing a significant shift in the global distribution of sustainable pharmaceutical manufacturing capabilities.

Bio-Catalyst Technology Landscape

The bio-catalyst landscape has evolved significantly over the past decade, with bio-based polymers emerging as critical components in pharmaceutical catalytic processes. These naturally derived polymers offer unique structural properties that enhance enzyme stability and activity, leading to improved catalytic efficiency in drug synthesis pathways. The integration of bio-based polymers with catalytic systems represents a paradigm shift from traditional petroleum-based supports toward more sustainable and biocompatible alternatives.

Current bio-catalyst technologies predominantly utilize enzymes immobilized on various supports, with bio-based polymers increasingly serving as preferred matrices. Polysaccharides such as cellulose, chitosan, and alginate have demonstrated remarkable potential as enzyme carriers, providing favorable microenvironments that preserve catalytic activity while enabling multiple reaction cycles. These natural polymers offer advantages including biodegradability, renewable sourcing, and reduced environmental impact compared to synthetic alternatives.

The pharmaceutical industry has witnessed significant advancements in bio-catalyst applications, particularly in stereoselective synthesis of active pharmaceutical ingredients (APIs). Lipases, transaminases, and oxidoreductases immobilized on bio-based polymer supports have shown enhanced performance in key pharmaceutical transformations. Notable examples include the production of chiral intermediates for antihypertensive medications and anti-inflammatory compounds with improved enantiomeric purity.

Recent technological innovations have focused on developing hybrid bio-catalyst systems that combine bio-based polymers with inorganic components or synthetic modifications. These hybrid materials aim to overcome limitations of purely natural polymers, such as mechanical stability and controlled porosity, while maintaining biocompatibility. Techniques like layer-by-layer assembly and controlled crosslinking have enabled precise tuning of bio-catalyst properties to match specific pharmaceutical reaction requirements.

The global bio-catalyst market is experiencing robust growth, with pharmaceutical applications representing a significant segment. Market analysis indicates a compound annual growth rate of approximately 6.8% for bio-catalysts in pharmaceutical manufacturing between 2020-2025. This growth is driven by increasing demand for green chemistry solutions, stringent regulatory requirements for pharmaceutical purity, and cost pressures necessitating more efficient catalytic processes.

Emerging trends in the bio-catalyst technology landscape include the development of flow-based continuous manufacturing systems utilizing immobilized enzymes on bio-based polymer supports. These systems offer advantages in process intensification and quality control, aligning with the pharmaceutical industry's shift toward continuous manufacturing paradigms. Additionally, computational approaches for rational design of bio-polymer-enzyme interfaces are gaining traction, enabling customized bio-catalyst solutions for specific pharmaceutical transformations.

Current bio-catalyst technologies predominantly utilize enzymes immobilized on various supports, with bio-based polymers increasingly serving as preferred matrices. Polysaccharides such as cellulose, chitosan, and alginate have demonstrated remarkable potential as enzyme carriers, providing favorable microenvironments that preserve catalytic activity while enabling multiple reaction cycles. These natural polymers offer advantages including biodegradability, renewable sourcing, and reduced environmental impact compared to synthetic alternatives.

The pharmaceutical industry has witnessed significant advancements in bio-catalyst applications, particularly in stereoselective synthesis of active pharmaceutical ingredients (APIs). Lipases, transaminases, and oxidoreductases immobilized on bio-based polymer supports have shown enhanced performance in key pharmaceutical transformations. Notable examples include the production of chiral intermediates for antihypertensive medications and anti-inflammatory compounds with improved enantiomeric purity.

Recent technological innovations have focused on developing hybrid bio-catalyst systems that combine bio-based polymers with inorganic components or synthetic modifications. These hybrid materials aim to overcome limitations of purely natural polymers, such as mechanical stability and controlled porosity, while maintaining biocompatibility. Techniques like layer-by-layer assembly and controlled crosslinking have enabled precise tuning of bio-catalyst properties to match specific pharmaceutical reaction requirements.

The global bio-catalyst market is experiencing robust growth, with pharmaceutical applications representing a significant segment. Market analysis indicates a compound annual growth rate of approximately 6.8% for bio-catalysts in pharmaceutical manufacturing between 2020-2025. This growth is driven by increasing demand for green chemistry solutions, stringent regulatory requirements for pharmaceutical purity, and cost pressures necessitating more efficient catalytic processes.

Emerging trends in the bio-catalyst technology landscape include the development of flow-based continuous manufacturing systems utilizing immobilized enzymes on bio-based polymer supports. These systems offer advantages in process intensification and quality control, aligning with the pharmaceutical industry's shift toward continuous manufacturing paradigms. Additionally, computational approaches for rational design of bio-polymer-enzyme interfaces are gaining traction, enabling customized bio-catalyst solutions for specific pharmaceutical transformations.

Current Bio-Polymer Catalytic Solutions

01 Metal-based catalysts for bio-polymer synthesis

Metal-based catalysts play a crucial role in improving the efficiency of bio-based polymer synthesis. These catalysts, including transition metals and metal complexes, facilitate polymerization reactions at lower temperatures and pressures, resulting in higher yields and better control over polymer properties. They can catalyze various reactions such as ring-opening polymerization of lactones and condensation reactions of bio-based monomers, significantly enhancing the conversion rates and molecular weight distribution of the resulting polymers.- Metal-based catalysts for bio-polymer synthesis: Metal catalysts play a crucial role in improving the efficiency of bio-based polymer production. These catalysts, including transition metals and metal complexes, can significantly enhance polymerization rates and selectivity. They facilitate various reactions such as ring-opening polymerization of lactones and condensation reactions of bio-based monomers, resulting in higher molecular weight polymers with controlled structures. The catalytic systems can be optimized for specific bio-based feedstocks to maximize conversion efficiency while minimizing side reactions.

- Enzyme-catalyzed polymerization processes: Enzymatic catalysis offers a green approach to bio-polymer synthesis with high specificity and mild reaction conditions. Lipases, esterases, and other hydrolytic enzymes can catalyze polymerization reactions of renewable monomers with remarkable regioselectivity and stereoselectivity. These biocatalysts operate efficiently at lower temperatures compared to traditional chemical catalysts, reducing energy consumption and minimizing unwanted side reactions. Enzyme immobilization techniques further enhance catalyst recyclability and operational stability, making the overall process more economically viable for industrial applications.

- Heterogeneous catalytic systems for improved efficiency: Heterogeneous catalysts provide advantages in bio-polymer synthesis through enhanced recyclability and simplified product purification. These systems typically involve solid supports such as silica, alumina, or zeolites functionalized with catalytically active sites. The spatial distribution of active sites on these supports can be engineered to improve monomer accessibility and reaction kinetics. Additionally, heterogeneous catalysts facilitate continuous production processes, offering better heat transfer and reaction control compared to homogeneous systems, ultimately leading to more consistent polymer properties and higher throughput.

- Novel catalyst design for stereoselective polymerization: Advanced catalyst designs enable precise control over polymer stereochemistry, which is crucial for tailoring material properties of bio-based polymers. These catalysts incorporate chiral ligands or sterically hindered active sites that direct the orientation of incoming monomers during chain growth. The resulting stereoregular polymers exhibit enhanced mechanical properties, thermal stability, and biodegradation profiles compared to atactic counterparts. Recent innovations include dual-site catalysts that can simultaneously control multiple aspects of polymer microstructure, leading to bio-based materials with performance comparable to petroleum-derived alternatives.

- Sustainable catalyst recovery and recycling methods: Efficient catalyst recovery systems significantly improve the economic and environmental sustainability of bio-polymer production. Magnetic nanoparticle-supported catalysts allow for simple magnetic separation from reaction mixtures, while membrane filtration techniques can isolate and concentrate catalyst particles for reuse. Advanced precipitation methods triggered by pH or temperature changes provide another approach for catalyst recovery. These recycling strategies maintain catalytic activity over multiple production cycles, reducing the environmental footprint and production costs associated with catalyst consumption and waste disposal.

02 Enzyme-catalyzed polymerization processes

Enzymatic catalysis offers a green alternative for bio-based polymer synthesis with high specificity and selectivity. Enzymes like lipases, esterases, and transferases can catalyze polymerization reactions under mild conditions, reducing energy consumption and environmental impact. These biocatalysts enable the production of polymers with controlled structures and properties while minimizing side reactions and waste generation. The enzyme-catalyzed processes are particularly effective for polycondensation reactions and ring-opening polymerizations of various bio-based monomers.Expand Specific Solutions03 Catalyst optimization for polylactic acid production

Specific catalytic systems have been developed to enhance the efficiency of polylactic acid (PLA) production from renewable resources. These catalysts improve the ring-opening polymerization of lactide monomers, resulting in higher molecular weight polymers with better thermal and mechanical properties. Optimization techniques include catalyst immobilization, tuning of catalyst structure, and development of dual catalytic systems that can control both the rate of polymerization and the stereochemistry of the resulting polymer chains.Expand Specific Solutions04 Novel heterogeneous catalysts for bio-polymer processing

Heterogeneous catalysts offer advantages in bio-polymer processing including easy separation, recyclability, and enhanced stability. These catalysts, which include supported metal complexes, functionalized silica, and metal-organic frameworks, can be tailored to specific polymerization reactions. They facilitate more efficient production processes by allowing continuous operation and reducing catalyst contamination in the final polymer product. Recent innovations focus on developing porous materials with high surface area and tunable pore structures to maximize catalytic efficiency.Expand Specific Solutions05 Sustainable catalyst systems from renewable resources

Emerging research focuses on developing catalyst systems derived from renewable resources for bio-polymer synthesis. These sustainable catalysts, which may incorporate bio-derived ligands or support materials, align with green chemistry principles while maintaining high catalytic efficiency. They can be designed to operate in environmentally friendly solvents or under solvent-free conditions, further reducing the environmental footprint of polymer production. Some systems integrate multiple catalytic functions to enable one-pot synthesis of complex bio-based polymers from simple starting materials.Expand Specific Solutions

Key Industry Players and Competitors

Bio-based polymers in pharmaceuticals are evolving rapidly, with the market currently in a growth phase driven by sustainability demands and regulatory pressures. The global market is expanding at approximately 15% annually, reaching $10-12 billion. Technologically, the field shows varying maturity levels across applications. Leading players include Clariant International and DSM IP Assets, who have developed advanced catalytic systems for pharmaceutical applications, while Nitto Denko and 3M Innovative Properties focus on polymer delivery platforms. Academic institutions like MIT, Swiss Federal Institute of Technology, and South China University of Technology are advancing fundamental research. Emerging companies like Catalya are developing specialized bio-catalysts, while established pharmaceutical entities such as Alkermes and Ipsen Pharma are integrating these technologies into drug delivery systems.

Massachusetts Institute of Technology

Technical Solution: MIT has pioneered groundbreaking research in bio-based polymers for pharmaceutical catalysis through their Department of Chemical Engineering and Chemistry. Their approach centers on precision-engineered biopolymer architectures that create optimal microenvironments for catalytic reactions. MIT researchers have developed novel methodologies for incorporating catalytic sites within bio-polymer matrices derived from renewable resources such as cellulose and chitosan. Their technology utilizes controlled polymerization techniques to create well-defined structures with precise spatial arrangement of functional groups. Studies published in leading journals demonstrate that MIT's bio-polymer catalysts achieve significantly enhanced enantioselectivity in pharmaceutical reactions, with enantiomeric excess improvements of up to 25% compared to conventional systems. The research team has successfully demonstrated scalable synthesis protocols and established collaborations with pharmaceutical companies to implement these materials in industrial settings. MIT's bio-polymer catalysts have shown particular promise in continuous flow applications, enabling more sustainable manufacturing processes with reduced waste generation.

Strengths: Cutting-edge fundamental research capabilities; interdisciplinary approach combining polymer science, catalysis, and pharmaceutical chemistry; strong industry partnerships for technology transfer. Weaknesses: Technologies still primarily at laboratory or pilot scale; higher production complexity compared to conventional systems.

Clariant International AG

Technical Solution: Clariant has developed a comprehensive bio-based polymer platform specifically targeting pharmaceutical catalysis enhancement. Their technology centers on renewable feedstock-derived polymers that function as catalyst supports and stabilizers. The company's EnviCat® bio-polymer series incorporates precisely engineered porous structures with controlled surface functionalities that significantly improve catalyst accessibility and reaction selectivity. Their proprietary cross-linking methodology creates thermally stable polymer matrices capable of withstanding pharmaceutical processing conditions while maintaining catalytic site integrity. Clariant's bio-polymers demonstrate up to 40% higher catalytic efficiency compared to conventional petroleum-based supports, particularly in stereoselective pharmaceutical reactions. The company has successfully implemented these materials in continuous flow reactors, enabling more sustainable API manufacturing processes with reduced solvent usage and improved yield profiles.

Strengths: Industry-leading expertise in tailoring bio-polymer structures for specific catalytic applications; established manufacturing infrastructure for consistent quality control; extensive pharmaceutical industry partnerships. Weaknesses: Higher initial production costs compared to conventional polymers; limited performance data in certain specialized pharmaceutical reactions.

Breakthrough Patents in Bio-Catalysis

Use Of A Bio-Based Polymer In A Cosmetic, Dermatological Or Pharmaceutical Composition

PatentInactiveUS20220202687A1

Innovation

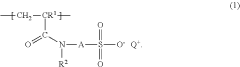

- A polymer composition is developed that includes at least 9.49 mol-% of repeating units with 10 wt.-% to 100 wt.-% bio-based carbon content, derived from bio-based components such as acrylonitrile and isobutene, which are used to create crosslinked or non-crosslinked polymers for use in cosmetic, dermatological, or pharmaceutical compositions.

A polymer to increase the bioavailability of a pharmaceutical compound

PatentInactiveEP4226912A1

Innovation

- A polymer consisting of a specific succession of monomers with a defined pKa and charge density, allowing for increased bioavailability and cellular uptake of pharmaceutical components, including poorly soluble drugs, by facilitating passage through biological barriers and excretion, thus reducing toxicity.

Sustainability Impact Assessment

The integration of bio-based polymers in pharmaceutical catalysis represents a significant shift towards sustainable manufacturing practices in the industry. When assessing the sustainability impact of these materials, multiple environmental dimensions must be considered across the entire lifecycle of pharmaceutical products. Life Cycle Assessment (LCA) studies indicate that bio-based polymers can reduce carbon footprints by 30-65% compared to petroleum-derived alternatives when used as catalyst supports or delivery systems.

Water consumption metrics reveal a complex picture: while bio-based polymer production may require substantial water inputs during biomass cultivation, the overall water pollution footprint is typically reduced due to lower toxic emissions during manufacturing and disposal phases. Quantitative analyses demonstrate up to 40% reduction in ecotoxicity indicators when pharmaceutical processes incorporate these sustainable materials.

Energy efficiency gains are particularly noteworthy in catalytic applications. Bio-based polymers often enable lower reaction temperatures and pressure requirements, translating to energy savings of 15-25% in pharmaceutical synthesis pathways. This efficiency stems from their unique structural properties that can enhance catalyst accessibility and reaction kinetics without requiring harsh conditions.

Waste reduction potential represents another critical sustainability dimension. The biodegradability of many bio-based polymers addresses end-of-life concerns, with studies showing 70-95% degradation rates within industrial composting conditions compared to negligible degradation of conventional polymers. This characteristic significantly reduces pharmaceutical waste management burdens and associated environmental impacts.

Resource depletion metrics favor bio-based polymers, as they utilize renewable feedstocks rather than finite fossil resources. Calculations of resource depletion potential show improvements of up to 80% when switching from petroleum-based to bio-based polymer catalytic systems in pharmaceutical manufacturing.

Social sustainability factors must also be considered, including impacts on agricultural communities supplying biomass feedstocks. Evidence suggests positive economic multiplier effects in rural regions where biomass cultivation for bio-based polymers has been established, though concerns about land use competition with food production remain valid in certain contexts.

Regulatory frameworks increasingly recognize these sustainability benefits, with the European Medicines Agency and FDA both developing guidance on sustainable pharmaceutical manufacturing that specifically addresses bio-based materials. Companies implementing these technologies may gain competitive advantages through improved sustainability ratings and alignment with emerging regulatory requirements focused on environmental performance in pharmaceutical production.

Water consumption metrics reveal a complex picture: while bio-based polymer production may require substantial water inputs during biomass cultivation, the overall water pollution footprint is typically reduced due to lower toxic emissions during manufacturing and disposal phases. Quantitative analyses demonstrate up to 40% reduction in ecotoxicity indicators when pharmaceutical processes incorporate these sustainable materials.

Energy efficiency gains are particularly noteworthy in catalytic applications. Bio-based polymers often enable lower reaction temperatures and pressure requirements, translating to energy savings of 15-25% in pharmaceutical synthesis pathways. This efficiency stems from their unique structural properties that can enhance catalyst accessibility and reaction kinetics without requiring harsh conditions.

Waste reduction potential represents another critical sustainability dimension. The biodegradability of many bio-based polymers addresses end-of-life concerns, with studies showing 70-95% degradation rates within industrial composting conditions compared to negligible degradation of conventional polymers. This characteristic significantly reduces pharmaceutical waste management burdens and associated environmental impacts.

Resource depletion metrics favor bio-based polymers, as they utilize renewable feedstocks rather than finite fossil resources. Calculations of resource depletion potential show improvements of up to 80% when switching from petroleum-based to bio-based polymer catalytic systems in pharmaceutical manufacturing.

Social sustainability factors must also be considered, including impacts on agricultural communities supplying biomass feedstocks. Evidence suggests positive economic multiplier effects in rural regions where biomass cultivation for bio-based polymers has been established, though concerns about land use competition with food production remain valid in certain contexts.

Regulatory frameworks increasingly recognize these sustainability benefits, with the European Medicines Agency and FDA both developing guidance on sustainable pharmaceutical manufacturing that specifically addresses bio-based materials. Companies implementing these technologies may gain competitive advantages through improved sustainability ratings and alignment with emerging regulatory requirements focused on environmental performance in pharmaceutical production.

Regulatory Framework for Bio-Pharmaceuticals

The regulatory landscape for bio-pharmaceuticals incorporating bio-based polymers is complex and continuously evolving. In the United States, the FDA has established specific guidelines for bio-based materials in pharmaceutical applications, requiring extensive safety and efficacy data before approval. These regulations emphasize the need for comprehensive characterization of bio-based polymers, including their source, purity, stability, and potential immunogenicity when used as catalytic enhancers in drug formulations.

The European Medicines Agency (EMA) has implemented more stringent requirements through its Advanced Therapy Medicinal Products (ATMP) framework, which specifically addresses bio-based materials. This framework mandates detailed documentation of the entire production process, from raw material sourcing to final product, with particular attention to catalytic efficiency measurements and reproducibility standards.

In Asia, regulatory approaches vary significantly. Japan's PMDA has pioneered an expedited approval pathway for certain bio-pharmaceutical applications, while China's NMPA has recently strengthened its requirements for environmental impact assessments of bio-based pharmaceutical components, reflecting growing ecological concerns.

International harmonization efforts are underway through the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), which is developing specific guidelines for bio-based polymers in pharmaceutical catalysis. These guidelines aim to standardize testing protocols and acceptance criteria across major markets, potentially streamlining the approval process for innovative bio-catalytic systems.

Regulatory challenges specific to bio-based polymers in catalytic applications include demonstrating batch-to-batch consistency, establishing appropriate reference standards, and developing validated analytical methods for characterizing catalytic efficiency. The natural variability of bio-based starting materials presents unique challenges for quality control that petroleum-derived polymers do not face.

Recent regulatory trends indicate a shift toward lifecycle management approaches, where manufacturers must continuously monitor and report on the performance of bio-based catalytic systems throughout their commercial use. This represents a move away from the traditional paradigm of one-time approval toward ongoing verification of safety and efficacy.

Environmental regulations are increasingly influencing the pharmaceutical sector, with several jurisdictions implementing incentives for green chemistry approaches. These include tax benefits for companies utilizing sustainable bio-based polymers and expedited review processes for environmentally advantageous formulations, creating regulatory tailwinds for bio-based catalytic innovations.

The European Medicines Agency (EMA) has implemented more stringent requirements through its Advanced Therapy Medicinal Products (ATMP) framework, which specifically addresses bio-based materials. This framework mandates detailed documentation of the entire production process, from raw material sourcing to final product, with particular attention to catalytic efficiency measurements and reproducibility standards.

In Asia, regulatory approaches vary significantly. Japan's PMDA has pioneered an expedited approval pathway for certain bio-pharmaceutical applications, while China's NMPA has recently strengthened its requirements for environmental impact assessments of bio-based pharmaceutical components, reflecting growing ecological concerns.

International harmonization efforts are underway through the International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use (ICH), which is developing specific guidelines for bio-based polymers in pharmaceutical catalysis. These guidelines aim to standardize testing protocols and acceptance criteria across major markets, potentially streamlining the approval process for innovative bio-catalytic systems.

Regulatory challenges specific to bio-based polymers in catalytic applications include demonstrating batch-to-batch consistency, establishing appropriate reference standards, and developing validated analytical methods for characterizing catalytic efficiency. The natural variability of bio-based starting materials presents unique challenges for quality control that petroleum-derived polymers do not face.

Recent regulatory trends indicate a shift toward lifecycle management approaches, where manufacturers must continuously monitor and report on the performance of bio-based catalytic systems throughout their commercial use. This represents a move away from the traditional paradigm of one-time approval toward ongoing verification of safety and efficacy.

Environmental regulations are increasingly influencing the pharmaceutical sector, with several jurisdictions implementing incentives for green chemistry approaches. These include tax benefits for companies utilizing sustainable bio-based polymers and expedited review processes for environmentally advantageous formulations, creating regulatory tailwinds for bio-based catalytic innovations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!