Effect of Bio-based Polymer on Reducing Microplastic Pollution

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Polymer Technology Background and Objectives

Microplastic pollution has emerged as one of the most pressing environmental challenges of the 21st century, with an estimated 8 million metric tons of plastic waste entering our oceans annually. The persistence of conventional petroleum-based plastics in the environment, often taking hundreds of years to degrade, has led to a global crisis affecting marine ecosystems, wildlife, and potentially human health. This growing concern has catalyzed research into alternative materials that can provide similar functionality while minimizing environmental impact.

Bio-based polymers represent a promising solution to this challenge, having evolved significantly since their initial development in the early 20th century. These polymers, derived from renewable biomass sources such as plants, algae, and microorganisms, offer biodegradable alternatives to traditional plastics. The technological evolution in this field has accelerated dramatically over the past two decades, driven by advances in biotechnology, material science, and growing environmental consciousness.

The development trajectory of bio-polymers has progressed from simple starch-based materials to sophisticated engineered polymers with tailored properties. Early bio-polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) have been joined by newer innovations including cellulose-based polymers, chitin derivatives, and protein-based materials. Each generation has brought improvements in mechanical properties, processability, and biodegradation rates.

The primary objective of bio-polymer technology in addressing microplastic pollution is multifaceted. First, it aims to develop materials that maintain the functional benefits of conventional plastics while ensuring complete biodegradation in natural environments within acceptable timeframes. Second, it seeks to establish scalable and economically viable production methods that can compete with petroleum-based alternatives. Third, it strives to create bio-polymers that degrade into non-toxic components, eliminating the persistent microplastic particles that conventional plastics generate.

Current technological goals include enhancing the mechanical properties of bio-polymers to match or exceed those of conventional plastics, particularly in terms of durability, flexibility, and barrier properties. Additionally, researchers are working to optimize biodegradation rates for different applications and environments, ensuring materials degrade rapidly enough to prevent accumulation but slowly enough to maintain functionality during their intended use period.

The future trajectory of bio-polymer technology is expected to focus on developing "smart" biodegradable materials with programmable degradation triggers, expanding feedstock options beyond food crops to utilize agricultural waste and industrial byproducts, and creating hybrid materials that combine the benefits of different bio-polymer types. These advancements aim to position bio-based polymers as a viable, sustainable solution to the growing crisis of microplastic pollution in our global ecosystems.

Bio-based polymers represent a promising solution to this challenge, having evolved significantly since their initial development in the early 20th century. These polymers, derived from renewable biomass sources such as plants, algae, and microorganisms, offer biodegradable alternatives to traditional plastics. The technological evolution in this field has accelerated dramatically over the past two decades, driven by advances in biotechnology, material science, and growing environmental consciousness.

The development trajectory of bio-polymers has progressed from simple starch-based materials to sophisticated engineered polymers with tailored properties. Early bio-polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) have been joined by newer innovations including cellulose-based polymers, chitin derivatives, and protein-based materials. Each generation has brought improvements in mechanical properties, processability, and biodegradation rates.

The primary objective of bio-polymer technology in addressing microplastic pollution is multifaceted. First, it aims to develop materials that maintain the functional benefits of conventional plastics while ensuring complete biodegradation in natural environments within acceptable timeframes. Second, it seeks to establish scalable and economically viable production methods that can compete with petroleum-based alternatives. Third, it strives to create bio-polymers that degrade into non-toxic components, eliminating the persistent microplastic particles that conventional plastics generate.

Current technological goals include enhancing the mechanical properties of bio-polymers to match or exceed those of conventional plastics, particularly in terms of durability, flexibility, and barrier properties. Additionally, researchers are working to optimize biodegradation rates for different applications and environments, ensuring materials degrade rapidly enough to prevent accumulation but slowly enough to maintain functionality during their intended use period.

The future trajectory of bio-polymer technology is expected to focus on developing "smart" biodegradable materials with programmable degradation triggers, expanding feedstock options beyond food crops to utilize agricultural waste and industrial byproducts, and creating hybrid materials that combine the benefits of different bio-polymer types. These advancements aim to position bio-based polymers as a viable, sustainable solution to the growing crisis of microplastic pollution in our global ecosystems.

Market Demand for Microplastic Pollution Solutions

The global market for microplastic pollution solutions has witnessed significant growth in recent years, driven by increasing awareness of the detrimental effects of microplastics on ecosystems and human health. According to recent market research, the global microplastic filtration and remediation market was valued at approximately 1.5 billion USD in 2022 and is projected to grow at a compound annual growth rate of 6.8% through 2030.

Consumer demand for sustainable products has become a major market driver, with surveys indicating that over 70% of consumers across North America, Europe, and Asia-Pacific regions express willingness to pay premium prices for products that demonstrably reduce environmental impact. This consumer sentiment has created substantial market pull for bio-based polymer alternatives that can replace conventional plastics while offering comparable performance characteristics.

Regulatory frameworks worldwide are increasingly targeting microplastic pollution, creating market opportunities for compliant solutions. The European Union's ban on intentionally added microplastics, scheduled for full implementation by 2027, represents a regulatory catalyst expected to accelerate market adoption of bio-based alternatives. Similar regulatory trends are emerging in North America, Australia, and parts of Asia, expanding the global market potential.

Industrial sectors including packaging, textiles, cosmetics, and agriculture represent the largest potential markets for bio-based polymer solutions. The packaging industry alone accounts for approximately 40% of the current demand, with biodegradable food packaging solutions experiencing annual growth rates exceeding 12% in developed markets.

Marine and freshwater remediation technologies addressing existing microplastic pollution constitute an emerging market segment with significant growth potential. Government-funded cleanup initiatives and corporate sustainability commitments are driving investment in this sector, with annual spending on remediation technologies increasing by approximately 15% year-over-year since 2020.

The healthcare sector presents another substantial market opportunity, with growing concerns about microplastic contamination in medical products and pharmaceutical packaging. Hospitals and healthcare systems in developed economies are increasingly adopting procurement policies that favor biodegradable alternatives, creating a specialized high-value market segment.

Market analysis indicates that while price sensitivity remains a challenge, particularly in developing economies, the total addressable market for bio-based polymer solutions to microplastic pollution is expanding rapidly. Industry forecasts suggest that bio-based polymers could capture up to 25% of the conventional plastic market by 2035, representing a potential market value exceeding 50 billion USD annually.

Consumer demand for sustainable products has become a major market driver, with surveys indicating that over 70% of consumers across North America, Europe, and Asia-Pacific regions express willingness to pay premium prices for products that demonstrably reduce environmental impact. This consumer sentiment has created substantial market pull for bio-based polymer alternatives that can replace conventional plastics while offering comparable performance characteristics.

Regulatory frameworks worldwide are increasingly targeting microplastic pollution, creating market opportunities for compliant solutions. The European Union's ban on intentionally added microplastics, scheduled for full implementation by 2027, represents a regulatory catalyst expected to accelerate market adoption of bio-based alternatives. Similar regulatory trends are emerging in North America, Australia, and parts of Asia, expanding the global market potential.

Industrial sectors including packaging, textiles, cosmetics, and agriculture represent the largest potential markets for bio-based polymer solutions. The packaging industry alone accounts for approximately 40% of the current demand, with biodegradable food packaging solutions experiencing annual growth rates exceeding 12% in developed markets.

Marine and freshwater remediation technologies addressing existing microplastic pollution constitute an emerging market segment with significant growth potential. Government-funded cleanup initiatives and corporate sustainability commitments are driving investment in this sector, with annual spending on remediation technologies increasing by approximately 15% year-over-year since 2020.

The healthcare sector presents another substantial market opportunity, with growing concerns about microplastic contamination in medical products and pharmaceutical packaging. Hospitals and healthcare systems in developed economies are increasingly adopting procurement policies that favor biodegradable alternatives, creating a specialized high-value market segment.

Market analysis indicates that while price sensitivity remains a challenge, particularly in developing economies, the total addressable market for bio-based polymer solutions to microplastic pollution is expanding rapidly. Industry forecasts suggest that bio-based polymers could capture up to 25% of the conventional plastic market by 2035, representing a potential market value exceeding 50 billion USD annually.

Current State and Challenges in Bio-based Polymers

Bio-based polymers have emerged as a promising solution to address the growing concern of microplastic pollution. Currently, these polymers are derived from renewable biomass sources such as cellulose, starch, proteins, and various plant oils. The global market for bio-based polymers has shown significant growth, reaching approximately 2.11 million tonnes in 2020, with projections suggesting a compound annual growth rate of 19% through 2026.

Despite this progress, bio-based polymers currently represent only about 1% of the total polymer production worldwide. This limited market penetration stems from several technical and economic challenges. Production costs remain significantly higher than conventional petroleum-based plastics, with bio-based alternatives typically costing 2-4 times more. This price differential creates substantial barriers to widespread adoption, particularly in price-sensitive markets and applications.

From a technical perspective, many bio-based polymers still exhibit inferior mechanical properties compared to their petroleum-based counterparts. Issues such as lower tensile strength, reduced thermal stability, and higher moisture sensitivity limit their application in demanding environments. For instance, PLA (polylactic acid), one of the most commercially successful bio-based polymers, has a glass transition temperature of approximately 60°C, restricting its use in high-temperature applications.

Biodegradability, while often considered an advantage, presents its own set of challenges. The degradation rates of bio-based polymers vary significantly depending on environmental conditions. In marine environments, where microplastic pollution is particularly problematic, many bio-based polymers degrade much slower than in industrial composting facilities. This discrepancy creates confusion regarding end-of-life management and potential environmental benefits.

Scalability remains another significant hurdle. Current production infrastructure for bio-based polymers lacks the economies of scale achieved by the conventional plastics industry over decades of development. Additionally, the agricultural feedstocks used for bio-based polymers raise concerns about land use competition with food production, potential deforestation, and water usage.

Regulatory frameworks worldwide are inconsistent regarding standards for biodegradability and compostability, creating market fragmentation and confusion among consumers and manufacturers. The absence of harmonized global standards impedes investment and technological development in the sector.

Research efforts are increasingly focused on addressing these challenges through various approaches, including the development of novel polymer blends, enhancement of material properties through additives and reinforcements, and exploration of non-food biomass sources such as agricultural waste and algae. Significant progress has been made in improving the heat resistance of PLA through stereocomplexation techniques and enhancing the water resistance of starch-based polymers through various chemical modifications.

Despite this progress, bio-based polymers currently represent only about 1% of the total polymer production worldwide. This limited market penetration stems from several technical and economic challenges. Production costs remain significantly higher than conventional petroleum-based plastics, with bio-based alternatives typically costing 2-4 times more. This price differential creates substantial barriers to widespread adoption, particularly in price-sensitive markets and applications.

From a technical perspective, many bio-based polymers still exhibit inferior mechanical properties compared to their petroleum-based counterparts. Issues such as lower tensile strength, reduced thermal stability, and higher moisture sensitivity limit their application in demanding environments. For instance, PLA (polylactic acid), one of the most commercially successful bio-based polymers, has a glass transition temperature of approximately 60°C, restricting its use in high-temperature applications.

Biodegradability, while often considered an advantage, presents its own set of challenges. The degradation rates of bio-based polymers vary significantly depending on environmental conditions. In marine environments, where microplastic pollution is particularly problematic, many bio-based polymers degrade much slower than in industrial composting facilities. This discrepancy creates confusion regarding end-of-life management and potential environmental benefits.

Scalability remains another significant hurdle. Current production infrastructure for bio-based polymers lacks the economies of scale achieved by the conventional plastics industry over decades of development. Additionally, the agricultural feedstocks used for bio-based polymers raise concerns about land use competition with food production, potential deforestation, and water usage.

Regulatory frameworks worldwide are inconsistent regarding standards for biodegradability and compostability, creating market fragmentation and confusion among consumers and manufacturers. The absence of harmonized global standards impedes investment and technological development in the sector.

Research efforts are increasingly focused on addressing these challenges through various approaches, including the development of novel polymer blends, enhancement of material properties through additives and reinforcements, and exploration of non-food biomass sources such as agricultural waste and algae. Significant progress has been made in improving the heat resistance of PLA through stereocomplexation techniques and enhancing the water resistance of starch-based polymers through various chemical modifications.

Current Bio-Polymer Solutions for Microplastic Reduction

01 Biodegradable polymers as alternatives to conventional plastics

Biodegradable polymers derived from renewable resources are being developed as alternatives to conventional plastics to reduce microplastic pollution. These bio-based polymers can naturally decompose in the environment, minimizing long-term ecological impact. The development focuses on materials that maintain functional properties while ensuring complete biodegradation under various environmental conditions.- Biodegradable polymers as alternatives to conventional plastics: Biodegradable polymers derived from renewable resources are being developed as alternatives to conventional plastics to reduce microplastic pollution. These bio-based polymers can naturally decompose in the environment, minimizing long-term ecological impact. The development focuses on materials that maintain functional properties while ensuring complete biodegradation under various environmental conditions.

- Microplastic detection and filtration systems: Advanced systems for detecting and filtering microplastics from water bodies are being developed to address existing pollution. These technologies include specialized membranes, filtration devices, and monitoring systems that can identify and remove polymer microparticles from various aquatic environments, helping to mitigate the spread of microplastic pollution before it enters food chains or remote ecosystems.

- Polymer modification for enhanced biodegradability: Chemical and structural modifications of polymers are being implemented to enhance their biodegradability while maintaining desired material properties. These modifications include incorporating biodegradable linkages, using bio-based additives, and developing composite structures that facilitate microbial breakdown. Such approaches help reduce the persistence of microplastics in the environment.

- Microplastic remediation and waste management solutions: Innovative remediation technologies and waste management solutions are being developed to address existing microplastic pollution. These include biological treatment systems using specialized microorganisms, advanced waste sorting technologies, and integrated approaches for collecting and processing plastic waste before it degrades into microplastics in the environment.

- Environmental impact assessment of bio-based polymers: Methods and systems for assessing the environmental impact of bio-based polymers throughout their lifecycle are being developed. These include standardized testing protocols to evaluate biodegradation rates in different environments, ecotoxicity assessments, and comprehensive lifecycle analyses that compare bio-based alternatives with conventional plastics to ensure genuine environmental benefits.

02 Microplastic detection and filtration systems

Advanced systems for detecting and filtering microplastics from water bodies and wastewater streams are being developed. These technologies employ various mechanisms including membrane filtration, adsorption, and separation techniques specifically designed to capture polymer microparticles of different sizes. Such systems help prevent microplastic pollution from reaching oceans and other natural environments.Expand Specific Solutions03 Polymer modification for enhanced biodegradability

Chemical and structural modifications of polymers are being implemented to enhance their biodegradability while maintaining desired physical properties. These modifications include incorporating biodegradable linkages, using bio-based additives, and developing composite structures that facilitate microbial degradation. Such approaches help reduce the persistence of microplastics in the environment.Expand Specific Solutions04 Microplastic remediation technologies

Novel remediation technologies are being developed to address existing microplastic pollution in various environmental compartments. These include bioremediation approaches using microorganisms capable of degrading polymer materials, enzymatic treatments that break down specific polymer types, and combined physical-biological systems designed for environmental restoration of contaminated areas.Expand Specific Solutions05 Circular economy approaches for polymer waste management

Circular economy strategies are being implemented to manage polymer waste and prevent microplastic pollution. These approaches include developing closed-loop recycling systems, designing polymers for easier recycling, implementing waste collection infrastructures, and creating economic incentives for proper disposal. Such holistic approaches aim to minimize the release of microplastics into the environment.Expand Specific Solutions

Key Industry Players in Bio-based Materials

The bio-based polymer market for microplastic pollution reduction is in its growth phase, with increasing regulatory pressure and consumer awareness driving adoption. The market is projected to expand significantly as companies seek sustainable alternatives to conventional plastics. Leading players like Novamont SpA and Teysha Technologies have developed proprietary biodegradable polymer technologies, while established chemical companies such as Henkel, PTT Global Chemical, and Arkema are investing in bio-based solutions. Academic institutions including University of California and Texas A&M are advancing fundamental research. The technology landscape shows varying maturity levels, with some companies (Algenesis, Sulapac) offering commercial products while others focus on R&D. The competitive environment is characterized by partnerships between research institutions and industry players to accelerate commercialization of these environmentally beneficial materials.

Novamont SpA

Technical Solution: Novamont has developed the MATER-BI family of bioplastics, which are biodegradable and compostable materials derived from starches, cellulose, and vegetable oils. Their technology involves creating polymers that maintain functionality comparable to conventional plastics while ensuring complete biodegradation in natural environments. The company's approach includes a proprietary process for creating biopolyesters combined with thermoplastic starch, resulting in materials that decompose into water, CO2, and biomass without leaving persistent microplastic residues. Their third-generation bioplastics incorporate higher percentages of renewable resources (up to 60%) and demonstrate improved mechanical properties and processability. Novamont has also pioneered the development of biodegradable mulch films for agriculture that eliminate the need for removal and disposal, reducing soil contamination with microplastics.

Strengths: Fully biodegradable in multiple environments (soil, marine, compost) with certification for home and industrial composting. Established commercial production with scalable technology. Weaknesses: Higher production costs compared to conventional plastics, potentially limiting widespread adoption. Some applications still require blending with non-renewable components to achieve desired performance characteristics.

Teysha Technologies Ltd.

Technical Solution: Teysha Technologies has developed a patented platform for creating tunable, biodegradable polycarbonate materials derived from natural feedstocks. Their innovative "plug-and-play" technology allows for the creation of polymers with customizable properties by combining various natural monomers and co-monomers. The resulting materials can be engineered to degrade completely within specific timeframes and environmental conditions, from weeks to years depending on the application requirements. Their approach utilizes natural sugars, amino acids, and other biological building blocks to create polymers that maintain functionality during use but break down into benign components at end-of-life. The technology enables the creation of materials with varying rigidity, flexibility, and thermal properties while ensuring complete biodegradation without persistent microplastic formation. Teysha's polymers can be processed using conventional plastic manufacturing equipment, facilitating industry adoption.

Strengths: Highly customizable degradation rates and mechanical properties to suit specific applications. Complete biodegradation without microplastic residue. Utilizes renewable, natural feedstocks. Weaknesses: Relatively new technology with limited commercial-scale production history. May face regulatory hurdles as a novel material entering established markets. Potentially higher production costs during early scaling phases.

Core Innovations in Biodegradable Polymer Research

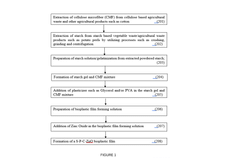

Starch-based bioplastic film reinforced with cellulose microfibres, zinc oxide, and method thereof

PatentPendingIN202311050736A

Innovation

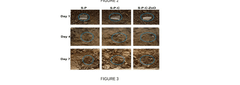

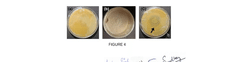

- A bioplastic film composed of cellulose microfibers, Polyvinyl Alcohol (PVA), Glycerol, and Zinc Oxide (ZnO) is developed, using agricultural waste as raw materials, which enhances biodegradability, mechanical strength, and antimicrobial properties, particularly against E. coli bacteria.

Environmental Impact Assessment Methodologies

Assessing the environmental impact of bio-based polymers in reducing microplastic pollution requires robust methodological frameworks that can accurately quantify benefits and potential drawbacks. Life Cycle Assessment (LCA) stands as the primary methodology, offering a comprehensive evaluation of environmental impacts throughout a product's entire lifecycle - from raw material extraction through production, use, and disposal. For bio-based polymers, LCA methodologies must be adapted to account for agricultural inputs, land use changes, and biodegradation processes that differ significantly from conventional plastics.

Material Flow Analysis (MFA) complements LCA by tracking the pathways of polymers through environmental systems. This methodology is particularly valuable for understanding how bio-based polymers move through waste streams and natural environments, providing insights into their fate and potential accumulation points. Recent advancements in MFA techniques have improved our ability to model the degradation rates of bio-based polymers in various environmental compartments.

Risk Assessment frameworks specifically designed for microplastics have emerged as critical tools. These methodologies evaluate exposure pathways, persistence, and potential ecological and human health impacts. For bio-based polymers, these assessments must consider unique degradation products and their toxicological profiles, which often differ from those of conventional plastics.

Environmental monitoring protocols represent another crucial methodology category. These include standardized sampling techniques for detecting bio-based polymer fragments in various environmental matrices (water, soil, sediment), analytical methods for polymer identification, and quantification approaches. Advanced spectroscopic techniques such as FTIR and Raman spectroscopy have been adapted to distinguish bio-based polymers from conventional plastics in environmental samples.

Ecosystem impact studies employ field and laboratory methodologies to assess how organisms interact with bio-based polymers. These include standardized ecotoxicity tests, bioaccumulation studies, and ecosystem-level assessments that examine community-level effects. Such methodologies are essential for understanding whether bio-based polymers truly represent a reduced environmental threat compared to conventional plastics.

Economic valuation methodologies complete the assessment framework by quantifying the environmental costs and benefits of transitioning to bio-based polymers. These include ecosystem service valuation techniques, cost-benefit analyses, and environmental damage cost assessments that help translate environmental impacts into economic terms for policy and business decision-making.

Material Flow Analysis (MFA) complements LCA by tracking the pathways of polymers through environmental systems. This methodology is particularly valuable for understanding how bio-based polymers move through waste streams and natural environments, providing insights into their fate and potential accumulation points. Recent advancements in MFA techniques have improved our ability to model the degradation rates of bio-based polymers in various environmental compartments.

Risk Assessment frameworks specifically designed for microplastics have emerged as critical tools. These methodologies evaluate exposure pathways, persistence, and potential ecological and human health impacts. For bio-based polymers, these assessments must consider unique degradation products and their toxicological profiles, which often differ from those of conventional plastics.

Environmental monitoring protocols represent another crucial methodology category. These include standardized sampling techniques for detecting bio-based polymer fragments in various environmental matrices (water, soil, sediment), analytical methods for polymer identification, and quantification approaches. Advanced spectroscopic techniques such as FTIR and Raman spectroscopy have been adapted to distinguish bio-based polymers from conventional plastics in environmental samples.

Ecosystem impact studies employ field and laboratory methodologies to assess how organisms interact with bio-based polymers. These include standardized ecotoxicity tests, bioaccumulation studies, and ecosystem-level assessments that examine community-level effects. Such methodologies are essential for understanding whether bio-based polymers truly represent a reduced environmental threat compared to conventional plastics.

Economic valuation methodologies complete the assessment framework by quantifying the environmental costs and benefits of transitioning to bio-based polymers. These include ecosystem service valuation techniques, cost-benefit analyses, and environmental damage cost assessments that help translate environmental impacts into economic terms for policy and business decision-making.

Regulatory Framework for Plastic Alternatives

The regulatory landscape for plastic alternatives is rapidly evolving as governments worldwide recognize the urgent need to address microplastic pollution. The European Union leads with its Single-Use Plastics Directive (2019), which not only bans certain single-use plastic items but also establishes a regulatory preference for bio-based alternatives. This directive represents one of the most comprehensive regulatory frameworks, requiring member states to implement measures promoting sustainable alternatives to conventional plastics.

In North America, regulations vary significantly between jurisdictions. The United States lacks comprehensive federal legislation specifically addressing bio-based polymers, though the USDA BioPreferred Program provides certification and procurement preferences for bio-based products. Canada has implemented the Ocean Plastics Charter and is developing a regulatory framework under its Zero Plastic Waste Strategy that includes provisions for bio-based alternatives.

Asian countries demonstrate diverse regulatory approaches. Japan's Biomass Nippon Strategy promotes bio-based materials through financial incentives and research funding. China has introduced its "Plastic Ban" policy, phasing out certain single-use plastics while simultaneously investing in bio-based polymer research and manufacturing capacity. India's Plastic Waste Management Rules include provisions encouraging biodegradable alternatives.

International standards organizations play a crucial role in establishing verification frameworks. ISO 14855 and ASTM D6400 provide standardized testing protocols for biodegradability and compostability claims. These standards help prevent greenwashing and ensure that bio-based polymers deliver genuine environmental benefits. The certification landscape includes labels such as TÜV Austria's "OK Compost" and the Biodegradable Products Institute's certification program.

Emerging regulatory trends include Extended Producer Responsibility (EPR) schemes that incentivize manufacturers to adopt bio-based materials. Carbon pricing mechanisms are increasingly incorporating considerations for bio-based polymers' reduced carbon footprint. Several jurisdictions are implementing plastic taxes with exemptions or reduced rates for verified bio-based alternatives.

Regulatory challenges remain significant. The lack of harmonization across jurisdictions creates compliance complexities for global manufacturers. Scientific uncertainty regarding the long-term environmental impacts of some bio-based polymers has led to regulatory caution. Additionally, enforcement mechanisms for existing regulations often lack sufficient resources and technical capabilities, particularly in developing economies where plastic pollution is most severe.

Future regulatory developments will likely focus on life-cycle assessment requirements, ensuring that bio-based alternatives deliver genuine environmental benefits across their entire life cycle. Harmonization efforts through international agreements may establish global minimum standards for plastic alternatives, creating more predictable regulatory environments for innovation and investment.

In North America, regulations vary significantly between jurisdictions. The United States lacks comprehensive federal legislation specifically addressing bio-based polymers, though the USDA BioPreferred Program provides certification and procurement preferences for bio-based products. Canada has implemented the Ocean Plastics Charter and is developing a regulatory framework under its Zero Plastic Waste Strategy that includes provisions for bio-based alternatives.

Asian countries demonstrate diverse regulatory approaches. Japan's Biomass Nippon Strategy promotes bio-based materials through financial incentives and research funding. China has introduced its "Plastic Ban" policy, phasing out certain single-use plastics while simultaneously investing in bio-based polymer research and manufacturing capacity. India's Plastic Waste Management Rules include provisions encouraging biodegradable alternatives.

International standards organizations play a crucial role in establishing verification frameworks. ISO 14855 and ASTM D6400 provide standardized testing protocols for biodegradability and compostability claims. These standards help prevent greenwashing and ensure that bio-based polymers deliver genuine environmental benefits. The certification landscape includes labels such as TÜV Austria's "OK Compost" and the Biodegradable Products Institute's certification program.

Emerging regulatory trends include Extended Producer Responsibility (EPR) schemes that incentivize manufacturers to adopt bio-based materials. Carbon pricing mechanisms are increasingly incorporating considerations for bio-based polymers' reduced carbon footprint. Several jurisdictions are implementing plastic taxes with exemptions or reduced rates for verified bio-based alternatives.

Regulatory challenges remain significant. The lack of harmonization across jurisdictions creates compliance complexities for global manufacturers. Scientific uncertainty regarding the long-term environmental impacts of some bio-based polymers has led to regulatory caution. Additionally, enforcement mechanisms for existing regulations often lack sufficient resources and technical capabilities, particularly in developing economies where plastic pollution is most severe.

Future regulatory developments will likely focus on life-cycle assessment requirements, ensuring that bio-based alternatives deliver genuine environmental benefits across their entire life cycle. Harmonization efforts through international agreements may establish global minimum standards for plastic alternatives, creating more predictable regulatory environments for innovation and investment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!