R&D Innovations in Bio-based Polymer Coatings Technology

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Polymer Coatings Background and Objectives

Bio-based polymer coatings represent a significant shift in materials science, emerging from the convergence of environmental concerns and technological innovation. These coatings, derived from renewable biological sources such as plant oils, starches, proteins, and cellulose, have evolved considerably over the past two decades. Initially limited to simple applications with modest performance characteristics, bio-based coatings have progressively advanced to compete with petroleum-based alternatives in durability, chemical resistance, and versatility.

The evolution of this technology has been driven by multiple factors, including increasing regulatory pressure on volatile organic compounds (VOCs), growing consumer demand for sustainable products, and corporate sustainability initiatives. Early developments focused primarily on replacing solvent systems with water-based alternatives, while recent innovations have targeted the polymer backbone itself, seeking to substitute petroleum-derived monomers with bio-based counterparts.

A significant technological milestone occurred around 2010 with the commercial introduction of high-performance coatings containing substantial bio-based content. This breakthrough demonstrated that sustainability and performance need not be mutually exclusive, catalyzing accelerated research and development across the industry. The subsequent decade has witnessed exponential growth in patent filings and scientific publications related to bio-based coating technologies.

Current research trajectories indicate several promising directions, including the development of novel bio-based monomers with enhanced functionality, optimization of crosslinking mechanisms for improved durability, and exploration of hybrid systems that combine bio-based components with conventional materials to achieve optimal performance profiles. Additionally, advances in biotechnology and green chemistry have opened new pathways for synthesizing platform chemicals from renewable feedstocks.

The primary technical objectives in this field include achieving 100% bio-based content without compromising performance, developing cost-effective production methods to achieve price parity with conventional coatings, and ensuring consistent quality across varying biomass feedstocks. Secondary objectives focus on enhancing specific properties such as UV resistance, antimicrobial functionality, and self-healing capabilities.

Looking forward, the bio-based polymer coatings sector is poised for transformative growth as technological capabilities align with market demands for sustainable solutions. The convergence of materials science, biotechnology, and chemical engineering is expected to yield increasingly sophisticated coating systems that not only match but potentially exceed the performance of traditional petroleum-based products, while offering significant environmental advantages throughout their lifecycle.

The evolution of this technology has been driven by multiple factors, including increasing regulatory pressure on volatile organic compounds (VOCs), growing consumer demand for sustainable products, and corporate sustainability initiatives. Early developments focused primarily on replacing solvent systems with water-based alternatives, while recent innovations have targeted the polymer backbone itself, seeking to substitute petroleum-derived monomers with bio-based counterparts.

A significant technological milestone occurred around 2010 with the commercial introduction of high-performance coatings containing substantial bio-based content. This breakthrough demonstrated that sustainability and performance need not be mutually exclusive, catalyzing accelerated research and development across the industry. The subsequent decade has witnessed exponential growth in patent filings and scientific publications related to bio-based coating technologies.

Current research trajectories indicate several promising directions, including the development of novel bio-based monomers with enhanced functionality, optimization of crosslinking mechanisms for improved durability, and exploration of hybrid systems that combine bio-based components with conventional materials to achieve optimal performance profiles. Additionally, advances in biotechnology and green chemistry have opened new pathways for synthesizing platform chemicals from renewable feedstocks.

The primary technical objectives in this field include achieving 100% bio-based content without compromising performance, developing cost-effective production methods to achieve price parity with conventional coatings, and ensuring consistent quality across varying biomass feedstocks. Secondary objectives focus on enhancing specific properties such as UV resistance, antimicrobial functionality, and self-healing capabilities.

Looking forward, the bio-based polymer coatings sector is poised for transformative growth as technological capabilities align with market demands for sustainable solutions. The convergence of materials science, biotechnology, and chemical engineering is expected to yield increasingly sophisticated coating systems that not only match but potentially exceed the performance of traditional petroleum-based products, while offering significant environmental advantages throughout their lifecycle.

Market Demand Analysis for Sustainable Coating Solutions

The global market for sustainable coating solutions has witnessed significant growth in recent years, driven by increasing environmental concerns and stringent regulations regarding volatile organic compounds (VOCs) and other harmful chemicals in traditional coatings. Bio-based polymer coatings represent a rapidly expanding segment within this market, with demand projected to grow at a compound annual growth rate of 7.2% through 2030.

Consumer preferences have shifted dramatically toward environmentally friendly products, with surveys indicating that 68% of consumers are willing to pay premium prices for sustainable alternatives. This trend is particularly pronounced in developed markets such as North America and Europe, where regulatory frameworks like the European Green Deal and the U.S. EPA's stricter emissions standards are accelerating the transition toward bio-based solutions.

The construction industry represents the largest end-user segment for sustainable coatings, accounting for approximately 40% of market demand. This is followed by automotive applications (22%), industrial equipment (18%), and consumer goods (12%). Within these sectors, there is growing recognition of the performance benefits that bio-based polymer coatings can offer beyond mere environmental compliance, including enhanced durability, improved chemical resistance, and reduced maintenance requirements.

Supply chain considerations are also driving market demand, as manufacturers seek to reduce their carbon footprint and enhance sustainability credentials throughout their value chains. Major corporations have established ambitious sustainability targets, with many pledging to achieve carbon neutrality by 2030-2050, necessitating the adoption of bio-based materials including coatings.

Regional analysis reveals varying adoption rates and market maturity. Europe leads in market penetration of sustainable coatings, followed by North America, while Asia-Pacific represents the fastest-growing regional market with China and India showing particularly strong growth trajectories. This is attributed to strengthening environmental regulations, rapid industrialization, and increasing consumer awareness in these regions.

Price sensitivity remains a challenge, with bio-based polymer coatings typically commanding a 15-30% premium over conventional alternatives. However, this gap is narrowing as production scales increase and technological advancements improve cost-efficiency. Market forecasts suggest price parity could be achieved in several application segments by 2028, which would significantly accelerate adoption rates.

The COVID-19 pandemic temporarily disrupted market growth but has ultimately accelerated the shift toward sustainable solutions as part of broader economic recovery plans emphasizing green technology and circular economy principles. This has created new opportunities for bio-based polymer coating technologies that align with these priorities.

Consumer preferences have shifted dramatically toward environmentally friendly products, with surveys indicating that 68% of consumers are willing to pay premium prices for sustainable alternatives. This trend is particularly pronounced in developed markets such as North America and Europe, where regulatory frameworks like the European Green Deal and the U.S. EPA's stricter emissions standards are accelerating the transition toward bio-based solutions.

The construction industry represents the largest end-user segment for sustainable coatings, accounting for approximately 40% of market demand. This is followed by automotive applications (22%), industrial equipment (18%), and consumer goods (12%). Within these sectors, there is growing recognition of the performance benefits that bio-based polymer coatings can offer beyond mere environmental compliance, including enhanced durability, improved chemical resistance, and reduced maintenance requirements.

Supply chain considerations are also driving market demand, as manufacturers seek to reduce their carbon footprint and enhance sustainability credentials throughout their value chains. Major corporations have established ambitious sustainability targets, with many pledging to achieve carbon neutrality by 2030-2050, necessitating the adoption of bio-based materials including coatings.

Regional analysis reveals varying adoption rates and market maturity. Europe leads in market penetration of sustainable coatings, followed by North America, while Asia-Pacific represents the fastest-growing regional market with China and India showing particularly strong growth trajectories. This is attributed to strengthening environmental regulations, rapid industrialization, and increasing consumer awareness in these regions.

Price sensitivity remains a challenge, with bio-based polymer coatings typically commanding a 15-30% premium over conventional alternatives. However, this gap is narrowing as production scales increase and technological advancements improve cost-efficiency. Market forecasts suggest price parity could be achieved in several application segments by 2028, which would significantly accelerate adoption rates.

The COVID-19 pandemic temporarily disrupted market growth but has ultimately accelerated the shift toward sustainable solutions as part of broader economic recovery plans emphasizing green technology and circular economy principles. This has created new opportunities for bio-based polymer coating technologies that align with these priorities.

Technical Challenges in Bio-based Polymer Development

Despite significant advancements in bio-based polymer coatings technology, several critical technical challenges continue to impede widespread commercial adoption. The inherent variability of natural feedstocks presents a fundamental obstacle, as biomass sources often exhibit inconsistent chemical compositions depending on growing conditions, harvest timing, and geographic origin. This variability directly impacts polymer quality, making standardization and quality control exceptionally difficult compared to petroleum-based alternatives with more predictable properties.

Performance limitations represent another significant barrier, particularly in durability metrics. Bio-based coatings frequently demonstrate inferior water resistance, UV stability, and chemical resistance compared to conventional synthetic counterparts. These shortcomings restrict their application in demanding environments where long-term protection is essential, such as exterior architectural coatings or marine applications.

Processing challenges further complicate development efforts. Bio-based polymers often exhibit poor solubility in environmentally friendly solvents, creating a technical paradox where supposedly "green" materials require environmentally harmful processing methods. Additionally, many bio-based polymers demonstrate higher viscosity profiles and narrower processing windows, necessitating specialized equipment modifications that increase manufacturing complexity and cost.

Stability issues during storage and application represent another critical challenge. Many bio-based polymers show accelerated degradation through hydrolysis or oxidation mechanisms, resulting in shortened shelf life and inconsistent application properties. This instability necessitates additional stabilizers or preservatives, which may compromise the environmental benefits of the original bio-based formulation.

Scale-up difficulties present perhaps the most significant barrier to commercialization. Laboratory-scale synthesis methods often prove inefficient or economically unfeasible when translated to industrial production volumes. The complex purification requirements for many bio-based intermediates further complicate manufacturing processes, resulting in higher production costs that make market competitiveness difficult to achieve.

Compatibility issues with existing coating systems and substrates create additional technical hurdles. Many bio-based polymers demonstrate poor adhesion to certain substrates or incompatibility with common additives, pigments, and curing systems. This necessitates comprehensive reformulation rather than simple drop-in replacement, extending development timelines and increasing technical complexity.

Regulatory and testing challenges also impede progress, as existing performance standards and testing methodologies were largely developed for petroleum-based systems. These may not adequately capture the unique performance attributes or environmental benefits of bio-based alternatives, creating market entry barriers despite potential real-world performance advantages.

Performance limitations represent another significant barrier, particularly in durability metrics. Bio-based coatings frequently demonstrate inferior water resistance, UV stability, and chemical resistance compared to conventional synthetic counterparts. These shortcomings restrict their application in demanding environments where long-term protection is essential, such as exterior architectural coatings or marine applications.

Processing challenges further complicate development efforts. Bio-based polymers often exhibit poor solubility in environmentally friendly solvents, creating a technical paradox where supposedly "green" materials require environmentally harmful processing methods. Additionally, many bio-based polymers demonstrate higher viscosity profiles and narrower processing windows, necessitating specialized equipment modifications that increase manufacturing complexity and cost.

Stability issues during storage and application represent another critical challenge. Many bio-based polymers show accelerated degradation through hydrolysis or oxidation mechanisms, resulting in shortened shelf life and inconsistent application properties. This instability necessitates additional stabilizers or preservatives, which may compromise the environmental benefits of the original bio-based formulation.

Scale-up difficulties present perhaps the most significant barrier to commercialization. Laboratory-scale synthesis methods often prove inefficient or economically unfeasible when translated to industrial production volumes. The complex purification requirements for many bio-based intermediates further complicate manufacturing processes, resulting in higher production costs that make market competitiveness difficult to achieve.

Compatibility issues with existing coating systems and substrates create additional technical hurdles. Many bio-based polymers demonstrate poor adhesion to certain substrates or incompatibility with common additives, pigments, and curing systems. This necessitates comprehensive reformulation rather than simple drop-in replacement, extending development timelines and increasing technical complexity.

Regulatory and testing challenges also impede progress, as existing performance standards and testing methodologies were largely developed for petroleum-based systems. These may not adequately capture the unique performance attributes or environmental benefits of bio-based alternatives, creating market entry barriers despite potential real-world performance advantages.

Current Bio-based Polymer Coating Solutions

01 Plant-derived polymer coatings

Bio-based polymer coatings derived from plant sources offer sustainable alternatives to petroleum-based products. These coatings utilize renewable resources such as cellulose, lignin, and plant oils to create environmentally friendly protective layers. The formulations typically involve processing plant materials to extract polymeric compounds that can be modified for specific coating applications, providing comparable performance to conventional coatings while reducing environmental impact.- Plant-derived polymer coatings: Bio-based polymer coatings derived from plant sources offer sustainable alternatives to petroleum-based materials. These coatings utilize polymers extracted from renewable plant resources such as cellulose, lignin, and plant oils. They provide comparable performance properties while reducing environmental impact and carbon footprint. These plant-derived polymers can be modified to enhance properties like water resistance, adhesion, and durability for various applications including packaging, construction, and consumer products.

- Biodegradable polymer coating formulations: Biodegradable polymer coatings are formulated to break down naturally in the environment after their useful life. These formulations typically incorporate polymers like polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers that can degrade through biological processes. Additives and plasticizers derived from natural sources enhance the processing properties and performance characteristics while maintaining biodegradability. These coatings address end-of-life concerns for products and packaging by reducing persistent plastic waste.

- Bio-based polymer blends for enhanced coating properties: Blending different bio-based polymers creates coating systems with optimized performance characteristics. These blends combine complementary properties of various bio-polymers to achieve desired flexibility, strength, barrier properties, and adhesion. Compatibilizers and cross-linking agents are often incorporated to improve the miscibility and interaction between different bio-polymers. This approach allows formulators to tailor coatings for specific applications while maximizing the renewable content and minimizing environmental impact.

- Functionalized bio-polymers for specialized coating applications: Chemical modification of bio-based polymers enhances their functionality for specialized coating applications. Techniques such as esterification, etherification, and grafting introduce specific functional groups that improve properties like water resistance, chemical resistance, and adhesion to various substrates. These functionalized bio-polymers can be used in demanding applications such as protective coatings, electronics, and medical devices where specific performance requirements must be met while maintaining sustainability benefits.

- Processing technologies for bio-based polymer coatings: Advanced processing technologies enable the effective application and curing of bio-based polymer coatings. These include water-based dispersion techniques, solvent-free application methods, UV-curing systems, and thermal processing adaptations specifically designed for bio-polymers. These technologies address challenges related to viscosity control, film formation, and curing efficiency of bio-based materials. Innovations in processing equipment and parameters optimize coating performance while minimizing energy consumption and environmental impact during manufacturing.

02 Biodegradable polymer coating compositions

These coating formulations focus on biodegradability as a key feature, allowing the coating to naturally decompose after its useful life. The compositions typically include bio-based polymers combined with biodegradation enhancers and plasticizers that maintain coating performance while ensuring environmental breakdown. Applications range from packaging materials to agricultural films, offering reduced environmental persistence compared to traditional polymer coatings.Expand Specific Solutions03 Bio-based polymer coatings for medical applications

Specialized bio-based polymer coatings designed for medical and healthcare applications provide biocompatibility and specific therapeutic functions. These coatings can be applied to medical devices, implants, and wound care products. The formulations often incorporate antimicrobial properties, controlled drug release capabilities, or tissue-friendly interfaces, combining the benefits of renewable resources with advanced healthcare functionality.Expand Specific Solutions04 Composite bio-based polymer coatings

These innovative coatings combine bio-based polymers with other materials such as nanoparticles, fibers, or inorganic compounds to enhance performance characteristics. The composite structure allows for improved mechanical properties, barrier functions, or special features like self-healing capabilities. By strategically incorporating different components, these coatings achieve superior performance while maintaining a high renewable content.Expand Specific Solutions05 Processing technologies for bio-based polymer coatings

Advanced processing methods specifically developed for bio-based polymer coatings address challenges in application, curing, and performance optimization. These technologies include specialized extrusion techniques, novel curing mechanisms, and surface treatment processes that enhance adhesion and durability. The processing approaches are designed to overcome inherent limitations of bio-based materials while maximizing their environmental benefits in coating applications.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The bio-based polymer coatings technology sector is currently in a growth phase, with increasing market adoption driven by sustainability demands. The global market is expanding at approximately 8-10% annually, reaching an estimated $12 billion. Technologically, the field shows varying maturity levels across applications. Leading research institutions like CNRS, Sorbonne Université, and University of Akron are advancing fundamental science, while commercial players demonstrate different specialization levels. Companies like DSM IP Assets, Clariant International, and Solvay Specialty Polymers lead in industrial applications, with Toyota Motor Corp exploring automotive implementations. Emerging players such as Novomer and Poly-Med focus on innovative niche applications, while established coating manufacturers like Guangdong Carpoly and Shanghai Zhanchen are integrating bio-based solutions into conventional product lines.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed sophisticated bio-based polymer coating technologies through their interdisciplinary research programs. Their scientists have pioneered the use of polysaccharides from marine sources, particularly chitosan and alginate derivatives, to create functional coatings with inherent antimicrobial properties. CNRS's proprietary "GlycoCoat" platform utilizes enzymatic modification of plant-derived polysaccharides to create tailored coating materials with controlled degradation profiles. Their technology incorporates bio-based polyesters synthesized through microbial fermentation processes, achieving high molecular weights and uniform distribution essential for coating performance. CNRS researchers have developed innovative crosslinking mechanisms using natural phenolic compounds that enable ambient-temperature curing while maintaining flexibility. Their bio-based coatings feature enhanced adhesion to various substrates through biomimetic approaches inspired by marine organisms like mussels, incorporating catechol-functionalized polymers derived from renewable resources. Recent innovations include stimuli-responsive coatings that change properties in response to environmental conditions, utilizing conformational changes in bio-based polymers to create smart surfaces for specialized applications.

Strengths: Advanced scientific approach to bio-based materials, excellent antimicrobial properties, innovative crosslinking mechanisms, and sophisticated biomimetic adhesion strategies. Weaknesses: Complex synthesis procedures limiting industrial scalability, higher production costs, and variable performance depending on environmental conditions.

Commonwealth Scientific & Industrial Research Organisation

Technical Solution: CSIRO has developed pioneering bio-based polymer coating technologies utilizing Australia's unique biological resources. Their research has yielded innovative coating systems based on modified cellulose nanocrystals extracted from agricultural waste streams, providing exceptional barrier properties and mechanical strength. CSIRO's proprietary "BioBarrier" technology incorporates lignin derivatives and tannins from eucalyptus species to create hydrophobic coatings with natural UV resistance and antimicrobial properties. Their scientists have engineered controlled polymerization processes that enable precise molecular architecture of bio-based polymers, resulting in coatings with tunable properties for diverse applications. CSIRO has also developed bio-based epoxy systems derived from vegetable oils that demonstrate comparable crosslinking density and adhesion to petroleum-based counterparts. Their recent innovations include self-healing coatings incorporating microencapsulated natural oils that release upon mechanical damage, extending coating lifespans significantly. CSIRO's technology platform extends to marine antifouling coatings based on compounds extracted from Australian marine organisms that prevent biofouling without environmental toxicity.

Strengths: Utilization of unique regional biological resources, excellent barrier properties, natural UV and antimicrobial protection, and environmentally benign formulations. Weaknesses: Limited scalability of some extraction processes, regional dependency on specific biological feedstocks, and higher production costs compared to synthetic alternatives.

Critical Patents and Technical Literature Review

Biodegradable polymer coating composition with excellent softness and solubility and method for preparing coating solution comprising the same

PatentPendingKR1020240040516A

Innovation

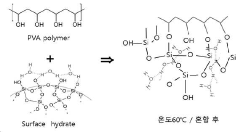

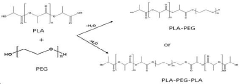

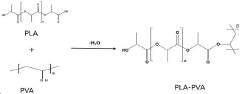

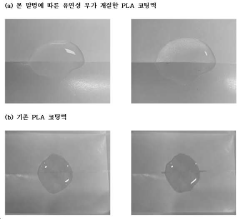

- A biodegradable polymer coating composition is developed by modifying PLA with peroxide to lower surface hardness and molecular weight, using silicate solutions and polyhydric alcohols to enhance softness and solubility, and incorporating colloidal silica and polyvinyl alcohol to improve adhesion and oxygen barrier properties.

Biocompatible controlled release coatings for medical devices and related methods

PatentInactiveEP1656163A1

Innovation

- The development of novel polymer compositions and methods using Hansen solubility parameters to create compatible, non-thrombogenic, and non-inflammatory coatings that maintain elasticity and ductility within specific temperature ranges, ensuring controlled release of bioactive agents by carefully matching polymer glass transition points and solubility parameters with drug properties.

Environmental Impact and Lifecycle Assessment

Bio-based polymer coatings represent a significant advancement in sustainable materials science, with their environmental impact and lifecycle assessment being critical factors in their adoption. These coatings demonstrate substantially reduced carbon footprints compared to petroleum-based alternatives, with recent lifecycle assessments indicating 30-60% lower greenhouse gas emissions depending on feedstock selection and manufacturing processes.

The environmental benefits extend beyond carbon reduction. Bio-based polymer coatings typically require 40-50% less non-renewable energy during production phases. Water consumption patterns vary significantly based on feedstock cultivation requirements, with certain plant-based polymers demanding intensive irrigation while others thrive in low-water conditions, creating regional optimization opportunities for sustainable production.

End-of-life considerations reveal additional environmental advantages. Many bio-based coatings exhibit enhanced biodegradability in appropriate conditions, with decomposition rates 2-5 times faster than conventional petroleum-based counterparts. This characteristic significantly reduces persistent environmental pollution, particularly in marine ecosystems where coating particles often accumulate.

Toxicity profiles of bio-based polymer coatings generally show reduced environmental hazards. Studies indicate 40-70% lower ecotoxicity scores across aquatic and terrestrial assessment models. The absence of certain harmful additives commonly found in conventional coatings, such as phthalates and heavy metal catalysts, contributes to this improved environmental performance.

Comprehensive lifecycle assessments have identified key environmental hotspots requiring further innovation. Agricultural practices for feedstock production remain environmentally intensive, with fertilizer use and land conversion impacts sometimes offsetting downstream benefits. Manufacturing energy requirements, while lower than petroleum alternatives, still represent significant environmental burdens that could be addressed through process optimization and renewable energy integration.

Regulatory frameworks increasingly incorporate lifecycle assessment methodologies specific to bio-based materials. The European Union's Product Environmental Footprint (PEF) guidelines now include specialized impact categories for bio-based products, while North American standards are evolving to better capture land-use change impacts and carbon sequestration benefits unique to these materials.

Future research directions focus on closing assessment gaps, particularly regarding microplastic formation potential from partially bio-based coatings and quantifying ecosystem services provided by sustainable feedstock cultivation systems. Standardized methodologies for calculating biogenic carbon storage in durable coating applications are also under development to better reflect long-term environmental benefits.

The environmental benefits extend beyond carbon reduction. Bio-based polymer coatings typically require 40-50% less non-renewable energy during production phases. Water consumption patterns vary significantly based on feedstock cultivation requirements, with certain plant-based polymers demanding intensive irrigation while others thrive in low-water conditions, creating regional optimization opportunities for sustainable production.

End-of-life considerations reveal additional environmental advantages. Many bio-based coatings exhibit enhanced biodegradability in appropriate conditions, with decomposition rates 2-5 times faster than conventional petroleum-based counterparts. This characteristic significantly reduces persistent environmental pollution, particularly in marine ecosystems where coating particles often accumulate.

Toxicity profiles of bio-based polymer coatings generally show reduced environmental hazards. Studies indicate 40-70% lower ecotoxicity scores across aquatic and terrestrial assessment models. The absence of certain harmful additives commonly found in conventional coatings, such as phthalates and heavy metal catalysts, contributes to this improved environmental performance.

Comprehensive lifecycle assessments have identified key environmental hotspots requiring further innovation. Agricultural practices for feedstock production remain environmentally intensive, with fertilizer use and land conversion impacts sometimes offsetting downstream benefits. Manufacturing energy requirements, while lower than petroleum alternatives, still represent significant environmental burdens that could be addressed through process optimization and renewable energy integration.

Regulatory frameworks increasingly incorporate lifecycle assessment methodologies specific to bio-based materials. The European Union's Product Environmental Footprint (PEF) guidelines now include specialized impact categories for bio-based products, while North American standards are evolving to better capture land-use change impacts and carbon sequestration benefits unique to these materials.

Future research directions focus on closing assessment gaps, particularly regarding microplastic formation potential from partially bio-based coatings and quantifying ecosystem services provided by sustainable feedstock cultivation systems. Standardized methodologies for calculating biogenic carbon storage in durable coating applications are also under development to better reflect long-term environmental benefits.

Regulatory Framework for Bio-based Materials

The regulatory landscape for bio-based materials has evolved significantly in recent years, reflecting growing environmental concerns and sustainability initiatives worldwide. In the European Union, the Renewable Energy Directive (RED II) establishes a comprehensive framework for promoting bio-based products, including polymer coatings, by setting targets for renewable energy use and greenhouse gas emission reductions. This directive is complemented by the EU's Circular Economy Action Plan, which specifically encourages the development and adoption of bio-based alternatives to conventional petroleum-derived materials.

In the United States, the USDA BioPreferred Program mandates federal agencies to increase their purchase of bio-based products, creating a substantial market pull for innovations in bio-based polymer coatings. Additionally, the Environmental Protection Agency's Significant New Use Rules (SNURs) under the Toxic Substances Control Act (TSCA) regulate the introduction of new chemical substances, including bio-based polymers, ensuring their safety before market entry.

Certification schemes play a crucial role in the regulatory framework, with standards such as ASTM D6866 providing methods to determine the bio-based content of materials. The European Committee for Standardization (CEN) has developed EN 16785 for bio-based content certification, while ISO 14021 addresses environmental claims related to bio-based products. These standards provide essential metrics for regulatory compliance and market differentiation.

Volatile Organic Compound (VOC) regulations represent another significant aspect of the regulatory framework affecting bio-based polymer coatings. The EU's VOC Solvents Emissions Directive and the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) impose strict limits on VOC emissions, creating opportunities for water-based and solvent-free bio-based coating technologies.

Emerging regulations are increasingly focusing on end-of-life considerations for bio-based materials. The EU's Single-Use Plastics Directive, while primarily targeting plastics, has implications for coatings and establishes precedents for biodegradability and compostability requirements. Similarly, extended producer responsibility (EPR) schemes are expanding to include coatings and surface treatments, incentivizing designs that facilitate recycling and biodegradation.

Global harmonization of these regulations remains a challenge, with significant variations between regions creating compliance complexities for manufacturers operating in international markets. Industry stakeholders are actively participating in regulatory development through organizations such as the Bio-based Industries Consortium in Europe and the Sustainable Biomaterials Collaborative in North America, working toward more consistent and science-based regulatory approaches.

In the United States, the USDA BioPreferred Program mandates federal agencies to increase their purchase of bio-based products, creating a substantial market pull for innovations in bio-based polymer coatings. Additionally, the Environmental Protection Agency's Significant New Use Rules (SNURs) under the Toxic Substances Control Act (TSCA) regulate the introduction of new chemical substances, including bio-based polymers, ensuring their safety before market entry.

Certification schemes play a crucial role in the regulatory framework, with standards such as ASTM D6866 providing methods to determine the bio-based content of materials. The European Committee for Standardization (CEN) has developed EN 16785 for bio-based content certification, while ISO 14021 addresses environmental claims related to bio-based products. These standards provide essential metrics for regulatory compliance and market differentiation.

Volatile Organic Compound (VOC) regulations represent another significant aspect of the regulatory framework affecting bio-based polymer coatings. The EU's VOC Solvents Emissions Directive and the U.S. EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP) impose strict limits on VOC emissions, creating opportunities for water-based and solvent-free bio-based coating technologies.

Emerging regulations are increasingly focusing on end-of-life considerations for bio-based materials. The EU's Single-Use Plastics Directive, while primarily targeting plastics, has implications for coatings and establishes precedents for biodegradability and compostability requirements. Similarly, extended producer responsibility (EPR) schemes are expanding to include coatings and surface treatments, incentivizing designs that facilitate recycling and biodegradation.

Global harmonization of these regulations remains a challenge, with significant variations between regions creating compliance complexities for manufacturers operating in international markets. Industry stakeholders are actively participating in regulatory development through organizations such as the Bio-based Industries Consortium in Europe and the Sustainable Biomaterials Collaborative in North America, working toward more consistent and science-based regulatory approaches.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!