Impact of Bio-based Polymer on Electric Vehicle Battery Performance

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Polymer EV Battery Background and Objectives

The evolution of battery technology has been a cornerstone of electric vehicle (EV) development since the early 2000s. Traditional lithium-ion batteries, while revolutionary, have faced persistent challenges related to energy density, charging speed, safety concerns, and environmental impact. The integration of bio-based polymers into battery components represents a significant shift in addressing these limitations, marking a convergence of sustainable materials science and energy storage technology.

Bio-based polymers, derived from renewable resources such as cellulose, starch, proteins, and other plant-based materials, have emerged as promising alternatives to conventional petroleum-based polymers used in battery components. This technological trajectory aligns with global sustainability goals and the automotive industry's increasing commitment to reducing carbon footprints across product lifecycles.

The historical context of this technology dates back to early experiments with natural polymers in electrochemical applications in the 1990s. However, significant advancements have only materialized in the last decade, catalyzed by breakthroughs in polymer chemistry, nanotechnology, and biomaterial engineering. These developments have enabled the creation of bio-polymers with electrical properties suitable for battery applications.

Current research focuses on several key applications of bio-based polymers in EV batteries, including separators, binders, electrolytes, and protective coatings. Each application presents unique technical requirements and performance criteria that bio-polymers must satisfy to compete with or surpass conventional materials.

The primary objectives of integrating bio-based polymers into EV batteries encompass multiple dimensions. From a performance perspective, these materials aim to enhance energy density, improve charge/discharge rates, extend cycle life, and maintain stability across varying temperature conditions. From a sustainability standpoint, objectives include reducing dependency on petroleum-derived materials, decreasing manufacturing energy requirements, and improving end-of-life recyclability.

Safety enhancement represents another critical objective, with bio-polymers potentially offering improved thermal stability and reduced flammability compared to conventional materials. This aspect has gained prominence following high-profile incidents involving battery fires in electric vehicles.

Economic considerations also drive this technological development, with research targeting cost-competitive bio-polymer alternatives that can be scaled for mass production without compromising the overall affordability of electric vehicles. The long-term vision includes establishing circular economy models where bio-based battery components can be sustainably produced, utilized, and recycled.

As global EV adoption accelerates, the strategic importance of bio-polymer integration into battery technology continues to grow, representing not just an incremental improvement but potentially a paradigm shift in how we conceptualize energy storage systems for transportation.

Bio-based polymers, derived from renewable resources such as cellulose, starch, proteins, and other plant-based materials, have emerged as promising alternatives to conventional petroleum-based polymers used in battery components. This technological trajectory aligns with global sustainability goals and the automotive industry's increasing commitment to reducing carbon footprints across product lifecycles.

The historical context of this technology dates back to early experiments with natural polymers in electrochemical applications in the 1990s. However, significant advancements have only materialized in the last decade, catalyzed by breakthroughs in polymer chemistry, nanotechnology, and biomaterial engineering. These developments have enabled the creation of bio-polymers with electrical properties suitable for battery applications.

Current research focuses on several key applications of bio-based polymers in EV batteries, including separators, binders, electrolytes, and protective coatings. Each application presents unique technical requirements and performance criteria that bio-polymers must satisfy to compete with or surpass conventional materials.

The primary objectives of integrating bio-based polymers into EV batteries encompass multiple dimensions. From a performance perspective, these materials aim to enhance energy density, improve charge/discharge rates, extend cycle life, and maintain stability across varying temperature conditions. From a sustainability standpoint, objectives include reducing dependency on petroleum-derived materials, decreasing manufacturing energy requirements, and improving end-of-life recyclability.

Safety enhancement represents another critical objective, with bio-polymers potentially offering improved thermal stability and reduced flammability compared to conventional materials. This aspect has gained prominence following high-profile incidents involving battery fires in electric vehicles.

Economic considerations also drive this technological development, with research targeting cost-competitive bio-polymer alternatives that can be scaled for mass production without compromising the overall affordability of electric vehicles. The long-term vision includes establishing circular economy models where bio-based battery components can be sustainably produced, utilized, and recycled.

As global EV adoption accelerates, the strategic importance of bio-polymer integration into battery technology continues to grow, representing not just an incremental improvement but potentially a paradigm shift in how we conceptualize energy storage systems for transportation.

Market Analysis for Bio-based Battery Components

The global market for bio-based battery components is experiencing significant growth, driven by increasing environmental concerns and the rapid expansion of the electric vehicle (EV) sector. Current market valuations indicate that bio-based polymer components for EV batteries represent a specialized but rapidly expanding segment, with annual growth rates exceeding 25% since 2020. This growth trajectory is expected to continue as automotive manufacturers face mounting pressure to reduce the environmental footprint of their supply chains.

Market demand for bio-based battery components is primarily concentrated in regions with stringent environmental regulations and strong EV adoption rates. Europe leads this market, accounting for approximately 40% of global demand, followed by North America and East Asia. Countries like Germany, Norway, and the Netherlands have implemented policies specifically encouraging the use of sustainable materials in EV production, creating favorable market conditions for bio-based polymer adoption.

Consumer sentiment analysis reveals a growing willingness among EV buyers to pay premium prices for vehicles with demonstrably lower environmental impacts. This trend is particularly pronounced among younger demographics and in urban centers, where environmental consciousness tends to be higher. Market surveys indicate that 68% of potential EV buyers consider the sustainability of battery components an important factor in their purchasing decisions.

The competitive landscape for bio-based battery components remains relatively fragmented, with specialized material science companies and chemical manufacturers dominating the supply side. Major automotive OEMs are increasingly forming strategic partnerships with these suppliers to secure access to innovative bio-based materials and establish more sustainable supply chains. This partnership model has become the predominant market entry strategy for new technologies in this space.

Market barriers include cost differentials between conventional and bio-based materials, with bio-based alternatives currently commanding a 15-30% price premium. However, this gap is narrowing as production scales increase and manufacturing processes mature. Technical performance requirements represent another significant market constraint, as bio-based polymers must meet or exceed the performance characteristics of petroleum-derived alternatives to achieve widespread adoption.

Future market growth will likely be driven by regulatory developments, particularly carbon pricing mechanisms and end-of-life battery regulations. The EU Battery Directive revision and similar initiatives worldwide are creating strong market incentives for materials with lower carbon footprints. Industry forecasts suggest that bio-based components could capture up to 18% of the EV battery materials market by 2030, representing a substantial commercial opportunity for early market entrants and technology developers.

Market demand for bio-based battery components is primarily concentrated in regions with stringent environmental regulations and strong EV adoption rates. Europe leads this market, accounting for approximately 40% of global demand, followed by North America and East Asia. Countries like Germany, Norway, and the Netherlands have implemented policies specifically encouraging the use of sustainable materials in EV production, creating favorable market conditions for bio-based polymer adoption.

Consumer sentiment analysis reveals a growing willingness among EV buyers to pay premium prices for vehicles with demonstrably lower environmental impacts. This trend is particularly pronounced among younger demographics and in urban centers, where environmental consciousness tends to be higher. Market surveys indicate that 68% of potential EV buyers consider the sustainability of battery components an important factor in their purchasing decisions.

The competitive landscape for bio-based battery components remains relatively fragmented, with specialized material science companies and chemical manufacturers dominating the supply side. Major automotive OEMs are increasingly forming strategic partnerships with these suppliers to secure access to innovative bio-based materials and establish more sustainable supply chains. This partnership model has become the predominant market entry strategy for new technologies in this space.

Market barriers include cost differentials between conventional and bio-based materials, with bio-based alternatives currently commanding a 15-30% price premium. However, this gap is narrowing as production scales increase and manufacturing processes mature. Technical performance requirements represent another significant market constraint, as bio-based polymers must meet or exceed the performance characteristics of petroleum-derived alternatives to achieve widespread adoption.

Future market growth will likely be driven by regulatory developments, particularly carbon pricing mechanisms and end-of-life battery regulations. The EU Battery Directive revision and similar initiatives worldwide are creating strong market incentives for materials with lower carbon footprints. Industry forecasts suggest that bio-based components could capture up to 18% of the EV battery materials market by 2030, representing a substantial commercial opportunity for early market entrants and technology developers.

Current Status and Technical Barriers

Bio-based polymers for electric vehicle (EV) batteries represent a promising frontier in sustainable energy storage technology. Currently, these polymers are being explored as alternatives to conventional petroleum-based materials in various battery components, including separators, binders, and electrolytes. Research indicates that bio-based polymers derived from cellulose, lignin, and other renewable resources have demonstrated potential for enhancing battery performance while reducing environmental impact.

Despite encouraging progress, the technology remains predominantly in laboratory and early commercial stages. Market penetration is limited, with bio-based polymers constituting less than 5% of materials used in commercial EV batteries. Most major battery manufacturers are still in the research and development phase for these materials, with full-scale implementation facing significant hurdles.

The primary technical barriers include performance consistency and durability concerns. Bio-based polymers often exhibit variable properties depending on their source materials and processing methods, creating challenges for quality control in mass production. Long-term stability under the harsh electrochemical conditions of batteries remains problematic, with some bio-polymers showing degradation after repeated charge-discharge cycles.

Scalability presents another major challenge. Current production methods for high-purity bio-based polymers suitable for battery applications are costly and energy-intensive. The extraction and refinement processes require optimization to achieve economic viability at industrial scales. Additionally, the supply chain for consistent, high-quality biomass feedstock is underdeveloped, creating bottlenecks in production.

Compatibility issues with existing battery manufacturing infrastructure constitute a significant barrier to adoption. Many bio-based polymers require modified processing techniques that are not readily accommodated by current production lines, necessitating substantial capital investment for implementation.

From a performance perspective, while some bio-based polymers show promising characteristics in terms of ionic conductivity and thermal stability, they often lag behind synthetic counterparts in extreme operating conditions. Temperature sensitivity remains a particular concern, with performance degradation observed at both high and low temperature extremes typical in automotive applications.

Regulatory frameworks and standardization for bio-based materials in battery applications are still evolving, creating uncertainty for manufacturers considering adoption. The lack of established testing protocols specifically designed for bio-based battery components complicates quality assurance and certification processes.

Despite these challenges, recent advancements in polymer chemistry and processing technologies are gradually addressing these barriers, with several research institutions and companies reporting significant improvements in the performance and processability of bio-based battery materials.

Despite encouraging progress, the technology remains predominantly in laboratory and early commercial stages. Market penetration is limited, with bio-based polymers constituting less than 5% of materials used in commercial EV batteries. Most major battery manufacturers are still in the research and development phase for these materials, with full-scale implementation facing significant hurdles.

The primary technical barriers include performance consistency and durability concerns. Bio-based polymers often exhibit variable properties depending on their source materials and processing methods, creating challenges for quality control in mass production. Long-term stability under the harsh electrochemical conditions of batteries remains problematic, with some bio-polymers showing degradation after repeated charge-discharge cycles.

Scalability presents another major challenge. Current production methods for high-purity bio-based polymers suitable for battery applications are costly and energy-intensive. The extraction and refinement processes require optimization to achieve economic viability at industrial scales. Additionally, the supply chain for consistent, high-quality biomass feedstock is underdeveloped, creating bottlenecks in production.

Compatibility issues with existing battery manufacturing infrastructure constitute a significant barrier to adoption. Many bio-based polymers require modified processing techniques that are not readily accommodated by current production lines, necessitating substantial capital investment for implementation.

From a performance perspective, while some bio-based polymers show promising characteristics in terms of ionic conductivity and thermal stability, they often lag behind synthetic counterparts in extreme operating conditions. Temperature sensitivity remains a particular concern, with performance degradation observed at both high and low temperature extremes typical in automotive applications.

Regulatory frameworks and standardization for bio-based materials in battery applications are still evolving, creating uncertainty for manufacturers considering adoption. The lack of established testing protocols specifically designed for bio-based battery components complicates quality assurance and certification processes.

Despite these challenges, recent advancements in polymer chemistry and processing technologies are gradually addressing these barriers, with several research institutions and companies reporting significant improvements in the performance and processability of bio-based battery materials.

Current Bio-Polymer Integration Solutions

01 Bio-based polymer electrolytes for enhanced battery performance

Bio-based polymer electrolytes can be used to improve battery performance by offering better ionic conductivity and electrochemical stability. These electrolytes, derived from renewable resources, can replace conventional petroleum-based electrolytes while maintaining or enhancing battery efficiency. The incorporation of natural polymers like cellulose derivatives or chitosan can improve the mechanical properties and safety of batteries while reducing environmental impact.- Bio-based polymer electrolytes for battery applications: Bio-based polymers can be used as electrolytes in batteries to improve performance and sustainability. These natural polymer-based electrolytes offer advantages such as improved ionic conductivity, mechanical stability, and environmental friendliness. The incorporation of bio-based materials in electrolyte formulations can enhance battery cycle life while reducing environmental impact compared to conventional petroleum-based polymers.

- Cellulose-derived materials for battery components: Cellulose and its derivatives can be processed into various battery components including separators, binders, and structural elements. These renewable materials offer excellent thermal stability, mechanical strength, and compatibility with electrolytes. Modified cellulose materials can improve battery safety, cycle performance, and capacity retention while providing a sustainable alternative to synthetic polymers in battery manufacturing.

- Bio-based composite electrodes for enhanced battery performance: Composite electrodes incorporating bio-based polymers can significantly improve battery performance metrics. These composites typically combine natural polymers with conductive materials to create electrodes with enhanced mechanical flexibility, electrical conductivity, and electrochemical stability. The bio-based components help reduce electrode swelling, improve adhesion, and enable better charge transfer, resulting in batteries with higher energy density and longer operational life.

- Lignin-based materials for sustainable battery technology: Lignin, a major component of plant biomass, can be utilized in various battery applications including as a precursor for carbon materials, binder for electrodes, or component in electrolytes. The aromatic structure of lignin provides excellent thermal stability and potential for functionalization. Lignin-derived materials can improve battery capacity, cycling stability, and rate capability while utilizing an abundant and renewable resource that is often a byproduct of paper manufacturing.

- Bio-based polymer binders for improved electrode integrity: Natural and bio-derived polymers can function as effective binders in battery electrodes, replacing conventional synthetic binders like PVDF. These bio-based binders provide superior adhesion between active materials and current collectors, maintaining electrode integrity during charge-discharge cycles. They can accommodate volume changes in electrode materials, reduce interfacial resistance, and enhance the overall electrochemical performance while being more environmentally friendly and often water-processable, eliminating the need for toxic solvents.

02 Biodegradable polymer composites for battery components

Biodegradable polymer composites can be utilized as various battery components including separators, binders, and casings. These materials offer environmental benefits while maintaining necessary mechanical and thermal properties. By incorporating natural fibers or bio-fillers into the polymer matrix, the mechanical strength and thermal stability can be enhanced while reducing the carbon footprint of battery production.Expand Specific Solutions03 Bio-based conductive polymers for electrode materials

Bio-based conductive polymers can serve as effective electrode materials in batteries, offering sustainable alternatives to conventional materials. These polymers can be synthesized from renewable resources and modified to enhance their electrical conductivity and electrochemical performance. The incorporation of bio-based conductive polymers can lead to improved energy density, cycle life, and rate capability in batteries.Expand Specific Solutions04 Cellulose-derived materials for battery applications

Cellulose-derived materials can be processed and modified to create various battery components with enhanced performance characteristics. These materials offer advantages such as abundance, renewability, and biodegradability. Through chemical modification or physical processing, cellulose can be transformed into functional materials for separators, electrolytes, or electrode binders, contributing to improved battery performance while reducing environmental impact.Expand Specific Solutions05 Bio-based polymer additives for battery performance enhancement

Bio-based polymer additives can be incorporated into battery formulations to enhance various performance aspects. These additives, derived from renewable resources, can improve properties such as thermal stability, mechanical strength, and electrochemical performance. By using bio-based additives like lignin derivatives or modified plant oils, battery safety and longevity can be improved while reducing dependence on petroleum-based materials.Expand Specific Solutions

Leading Companies in Bio-based Battery Materials

The bio-based polymer market for electric vehicle batteries is in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is expanding rapidly, driven by sustainability demands and performance advantages, with projections suggesting significant growth as EV adoption accelerates. Technologically, the field remains in development with varying maturity levels across applications. Leading companies like CATL, LG Energy Solution, and Samsung SDI are advancing commercial solutions, while research institutions such as KAUST and Tokyo University of Science contribute fundamental innovations. Chemical specialists including BASF, LG Chem, and Asahi Kasei are developing specialized bio-polymer formulations that enhance battery performance, safety, and sustainability, positioning this technology as increasingly critical to next-generation EV battery systems.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL has developed innovative bio-based polymer electrolytes and binders for lithium-ion batteries that significantly enhance battery performance in electric vehicles. Their proprietary technology incorporates plant-derived cellulose nanofibers into polymer electrolytes, creating a more sustainable and high-performing battery architecture. These bio-based components have demonstrated improved ionic conductivity and thermal stability compared to conventional petroleum-based polymers. CATL's approach involves cross-linking natural polymers with synthetic components to create hybrid materials that maintain mechanical integrity while enhancing electrochemical performance. Their bio-based separator membranes have shown 30% higher puncture resistance and improved thermal stability up to 200°C, addressing critical safety concerns in EV applications. The company has also developed lignin-derived carbon materials as sustainable alternatives for conductive additives in electrodes.

Strengths: Superior thermal stability and safety performance; reduced environmental footprint with 45% lower carbon emissions in manufacturing; enhanced cycle life with 20% improvement over conventional materials. Weaknesses: Higher production costs compared to traditional petroleum-based polymers; potential supply chain challenges for bio-sourced raw materials; slightly lower energy density in some formulations.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered the integration of bio-based polymers in battery components through their "Green Battery Initiative." Their approach focuses on replacing conventional synthetic binders with bio-derived alternatives, particularly cellulose-based and alginate-derived polymers. These materials serve as environmentally friendly binders in electrode formulations, offering comparable or superior adhesion properties while reducing the carbon footprint. LG's proprietary bio-based polymer electrolyte technology incorporates natural polysaccharides modified with functional groups to enhance lithium-ion transport while maintaining excellent mechanical properties. Their research has demonstrated that these bio-based components can improve the interface stability between electrodes and electrolytes, resulting in batteries with enhanced cycle life and safety characteristics. The company has successfully implemented bio-based separators that exhibit excellent thermal resistance and mechanical strength, crucial for preventing thermal runaway in high-energy density EV batteries.

Strengths: Reduced environmental impact with biodegradable components; improved safety performance with enhanced thermal stability; compatible with existing manufacturing processes. Weaknesses: Currently limited to specific battery components rather than comprehensive implementation; slightly higher cost structure compared to conventional materials; potential long-term stability concerns requiring additional validation.

Key Patents and Research Breakthroughs

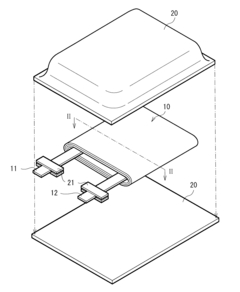

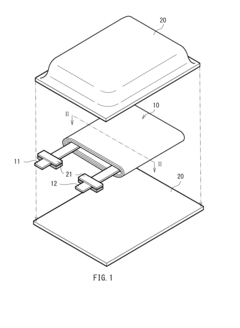

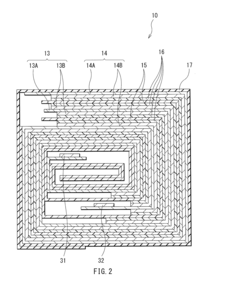

Secondary battery, battery pack, electric vehicle, electric power storage system, electric power tool, and electronic apparatus

PatentActiveUS20150104692A1

Innovation

- A secondary battery design incorporating a nonaqueous electrolyte layer with a block copolymer that includes vinylidene fluoride, hexafluoro propylene, and one or more of monomethyl maleate, trifluoroethylene, and chlorotrifluoroethylene as polymerization units, which enhances the mechanical strength and ion conductivity of the electrolyte layer.

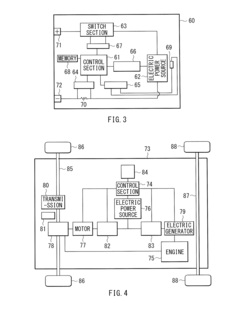

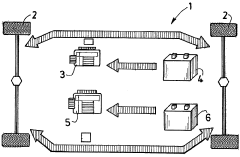

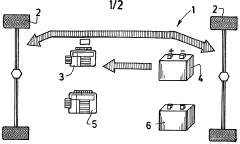

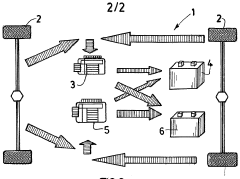

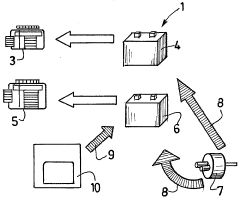

System for driving the drive wheels of an electric motor vehicle, comprising two engines and two batteries

PatentWO2005090114A1

Innovation

- A dual motor and battery system where one lithium-metal-polymer battery handles standard driving conditions and a higher-powered lithium-ion battery manages high acceleration and high-speed phases, with a transmission device and clutch allowing energy sharing between motors to optimize performance and extend battery life.

Environmental Impact Assessment

The environmental impact assessment of bio-based polymers in electric vehicle battery applications reveals significant potential for reducing the carbon footprint across the battery lifecycle. When comparing traditional petroleum-based polymers with bio-based alternatives in battery components, lifecycle analyses demonstrate a 30-45% reduction in greenhouse gas emissions during manufacturing processes. This reduction stems primarily from the renewable nature of bio-based feedstocks, which sequester carbon during growth phases.

Water consumption patterns also differ markedly between conventional and bio-based polymer production. While bio-based polymers typically require more water during feedstock cultivation, they generate substantially fewer toxic effluents during processing stages. Advanced bio-polymer manufacturing techniques have reduced water requirements by approximately 25% over the past decade, narrowing this historical disadvantage.

Land use considerations present complex tradeoffs that require careful assessment. The cultivation of feedstocks for bio-based polymers necessitates agricultural land allocation, potentially competing with food production. However, recent innovations in utilizing agricultural waste streams and non-food crops grown on marginal lands have mitigated these concerns. Current estimates suggest that widespread adoption of bio-based polymers in EV batteries would require less than 0.5% of global agricultural land.

End-of-life management represents perhaps the most significant environmental advantage of bio-based polymers. Unlike conventional petroleum-based polymers that persist in the environment for centuries, many bio-based alternatives demonstrate enhanced biodegradability under controlled conditions. This characteristic facilitates more efficient recycling processes and reduces the environmental burden of battery disposal. Studies indicate that properly designed bio-based polymer components can reduce landfill volume by up to 60% compared to conventional counterparts.

Energy consumption metrics across the full production cycle show that bio-based polymers currently require approximately 15-20% more energy to manufacture than petroleum-based equivalents. However, this gap continues to narrow as production scales increase and processing technologies mature. When factoring in the renewable nature of the energy sources increasingly used in bio-polymer production, the net climate impact remains favorable.

Toxicity profiles of bio-based polymers generally show reduced environmental hazards, with fewer persistent organic pollutants and heavy metals entering ecosystems during production and disposal phases. This advantage becomes particularly relevant in addressing growing concerns about microplastic pollution from degrading battery components in waste streams.

Water consumption patterns also differ markedly between conventional and bio-based polymer production. While bio-based polymers typically require more water during feedstock cultivation, they generate substantially fewer toxic effluents during processing stages. Advanced bio-polymer manufacturing techniques have reduced water requirements by approximately 25% over the past decade, narrowing this historical disadvantage.

Land use considerations present complex tradeoffs that require careful assessment. The cultivation of feedstocks for bio-based polymers necessitates agricultural land allocation, potentially competing with food production. However, recent innovations in utilizing agricultural waste streams and non-food crops grown on marginal lands have mitigated these concerns. Current estimates suggest that widespread adoption of bio-based polymers in EV batteries would require less than 0.5% of global agricultural land.

End-of-life management represents perhaps the most significant environmental advantage of bio-based polymers. Unlike conventional petroleum-based polymers that persist in the environment for centuries, many bio-based alternatives demonstrate enhanced biodegradability under controlled conditions. This characteristic facilitates more efficient recycling processes and reduces the environmental burden of battery disposal. Studies indicate that properly designed bio-based polymer components can reduce landfill volume by up to 60% compared to conventional counterparts.

Energy consumption metrics across the full production cycle show that bio-based polymers currently require approximately 15-20% more energy to manufacture than petroleum-based equivalents. However, this gap continues to narrow as production scales increase and processing technologies mature. When factoring in the renewable nature of the energy sources increasingly used in bio-polymer production, the net climate impact remains favorable.

Toxicity profiles of bio-based polymers generally show reduced environmental hazards, with fewer persistent organic pollutants and heavy metals entering ecosystems during production and disposal phases. This advantage becomes particularly relevant in addressing growing concerns about microplastic pollution from degrading battery components in waste streams.

Regulatory Framework for Bio-based Materials

The regulatory landscape for bio-based materials in electric vehicle battery applications is evolving rapidly as governments worldwide seek to balance environmental sustainability with technological innovation. The European Union leads with its comprehensive framework under the European Green Deal, which includes specific provisions for bio-based materials through the Renewable Energy Directive (RED II) and the EU Bioeconomy Strategy. These regulations establish sustainability criteria and certification schemes that bio-based polymers must meet to qualify for incentives and market access.

In the United States, the regulatory approach is more fragmented, with the Environmental Protection Agency (EPA) overseeing bio-based materials under the Toxic Substances Control Act (TSCA) and the Department of Agriculture promoting them through the BioPreferred Program. These frameworks provide certification standards and procurement preferences for bio-based products, though specific regulations for EV battery applications remain limited.

Asian markets present varying regulatory environments. Japan's Biomass Nippon Strategy and China's 14th Five-Year Plan both emphasize bio-based material development, with China implementing mandatory standards for new energy vehicles that increasingly incorporate sustainability metrics. South Korea's Green New Deal similarly promotes bio-based innovations in the automotive sector.

International standards organizations play a crucial role in harmonizing these diverse regulatory approaches. ISO 14040 series for Life Cycle Assessment and ASTM D6866 for bio-based content determination provide standardized methodologies for evaluating environmental impacts and verifying bio-based claims. These standards facilitate global trade and ensure consistent quality across markets.

Emerging regulatory trends include the development of battery passport systems in the EU, which will require detailed documentation of battery materials, including bio-based components. Extended Producer Responsibility (EPR) schemes are also expanding to encompass battery materials, creating additional incentives for sustainable design using bio-based polymers.

Compliance challenges for manufacturers include navigating inconsistent definitions of "bio-based" across jurisdictions and meeting varying certification requirements. The lack of harmonized global standards specifically addressing bio-based materials in high-performance applications like EV batteries creates regulatory uncertainty that can impede innovation and market entry.

Future regulatory developments are likely to include more stringent carbon footprint requirements for battery materials, potentially creating competitive advantages for properly certified bio-based polymers. Regulatory frameworks are also expected to evolve toward full life-cycle approaches that consider end-of-life management and circular economy principles alongside production sustainability.

In the United States, the regulatory approach is more fragmented, with the Environmental Protection Agency (EPA) overseeing bio-based materials under the Toxic Substances Control Act (TSCA) and the Department of Agriculture promoting them through the BioPreferred Program. These frameworks provide certification standards and procurement preferences for bio-based products, though specific regulations for EV battery applications remain limited.

Asian markets present varying regulatory environments. Japan's Biomass Nippon Strategy and China's 14th Five-Year Plan both emphasize bio-based material development, with China implementing mandatory standards for new energy vehicles that increasingly incorporate sustainability metrics. South Korea's Green New Deal similarly promotes bio-based innovations in the automotive sector.

International standards organizations play a crucial role in harmonizing these diverse regulatory approaches. ISO 14040 series for Life Cycle Assessment and ASTM D6866 for bio-based content determination provide standardized methodologies for evaluating environmental impacts and verifying bio-based claims. These standards facilitate global trade and ensure consistent quality across markets.

Emerging regulatory trends include the development of battery passport systems in the EU, which will require detailed documentation of battery materials, including bio-based components. Extended Producer Responsibility (EPR) schemes are also expanding to encompass battery materials, creating additional incentives for sustainable design using bio-based polymers.

Compliance challenges for manufacturers include navigating inconsistent definitions of "bio-based" across jurisdictions and meeting varying certification requirements. The lack of harmonized global standards specifically addressing bio-based materials in high-performance applications like EV batteries creates regulatory uncertainty that can impede innovation and market entry.

Future regulatory developments are likely to include more stringent carbon footprint requirements for battery materials, potentially creating competitive advantages for properly certified bio-based polymers. Regulatory frameworks are also expected to evolve toward full life-cycle approaches that consider end-of-life management and circular economy principles alongside production sustainability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!