How Bio-based Polymer Supports Sustainable Agriculture Equipment?

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Polymer Agricultural Technology Background and Objectives

Bio-based polymers have emerged as a transformative material class in agricultural equipment manufacturing, representing a significant shift from traditional petroleum-based plastics. The evolution of these materials traces back to the early 20th century, but has gained substantial momentum only in the past two decades as sustainability concerns have intensified across global industries. The agricultural sector, being both a contributor to and victim of environmental degradation, stands to benefit significantly from this technological advancement.

The trajectory of bio-polymer development has accelerated markedly since 2010, with innovations in feedstock diversity, processing techniques, and material performance characteristics. Initially limited to simple applications due to inferior mechanical properties, modern bio-based polymers now rival or exceed conventional plastics in durability, weather resistance, and functional versatility while maintaining their environmental advantages.

Current technological objectives in this field center on developing bio-polymers that specifically address the unique demands of agricultural equipment. These include enhanced UV stability for prolonged outdoor exposure, resistance to agrochemicals, biodegradability timed to specific agricultural cycles, and cost-effectiveness at commercial scale. Additionally, there is growing interest in creating "closed-loop" systems where agricultural waste serves as feedstock for bio-polymers used in equipment that returns to the same agricultural ecosystem.

The integration of nanotechnology with bio-polymers represents another promising frontier, with research focusing on nanocomposites that can dramatically improve mechanical properties while maintaining biodegradability. Smart bio-polymers capable of responding to environmental stimuli (temperature, moisture, pH) are also being explored for precision agriculture applications.

Globally, research trends indicate a convergence toward multi-functional bio-polymers that not only replace conventional materials but add value through inherent properties such as controlled-release capabilities for fertilizers or pest management compounds. The technical goal is to develop materials that contribute actively to agricultural productivity rather than serving as passive structural components.

The ultimate objective of bio-polymer technology in agricultural equipment is to establish a regenerative relationship between material production and agricultural systems. This involves creating equipment components that enhance crop production during their service life and return safely to the soil afterward, potentially even improving soil health through their degradation products.

The trajectory of bio-polymer development has accelerated markedly since 2010, with innovations in feedstock diversity, processing techniques, and material performance characteristics. Initially limited to simple applications due to inferior mechanical properties, modern bio-based polymers now rival or exceed conventional plastics in durability, weather resistance, and functional versatility while maintaining their environmental advantages.

Current technological objectives in this field center on developing bio-polymers that specifically address the unique demands of agricultural equipment. These include enhanced UV stability for prolonged outdoor exposure, resistance to agrochemicals, biodegradability timed to specific agricultural cycles, and cost-effectiveness at commercial scale. Additionally, there is growing interest in creating "closed-loop" systems where agricultural waste serves as feedstock for bio-polymers used in equipment that returns to the same agricultural ecosystem.

The integration of nanotechnology with bio-polymers represents another promising frontier, with research focusing on nanocomposites that can dramatically improve mechanical properties while maintaining biodegradability. Smart bio-polymers capable of responding to environmental stimuli (temperature, moisture, pH) are also being explored for precision agriculture applications.

Globally, research trends indicate a convergence toward multi-functional bio-polymers that not only replace conventional materials but add value through inherent properties such as controlled-release capabilities for fertilizers or pest management compounds. The technical goal is to develop materials that contribute actively to agricultural productivity rather than serving as passive structural components.

The ultimate objective of bio-polymer technology in agricultural equipment is to establish a regenerative relationship between material production and agricultural systems. This involves creating equipment components that enhance crop production during their service life and return safely to the soil afterward, potentially even improving soil health through their degradation products.

Market Demand Analysis for Sustainable Agricultural Equipment

The global market for sustainable agricultural equipment is experiencing significant growth, driven by increasing environmental awareness and the need for more eco-friendly farming practices. Current market analysis indicates that the sustainable agricultural equipment sector is projected to grow at a compound annual growth rate of 8.7% through 2030, with bio-based polymer applications representing one of the fastest-growing segments within this market.

Consumer demand for sustainably produced food continues to rise, creating downstream pressure on agricultural producers to adopt more environmentally responsible practices and equipment. This shift is reflected in purchasing patterns, with over 65% of agricultural equipment buyers now considering sustainability features as important decision factors, compared to just 28% five years ago.

Regulatory frameworks worldwide are increasingly favoring sustainable agricultural practices. The European Union's Farm to Fork Strategy, the United States Department of Agriculture's conservation programs, and similar initiatives in Asia-Pacific regions are creating strong market incentives for equipment manufacturers to incorporate sustainable materials like bio-based polymers into their product designs.

The market for bio-based polymer applications in agricultural equipment is particularly robust in irrigation systems, protective coverings, equipment components, and packaging materials. Biodegradable mulch films made from bio-based polymers have seen a market expansion of nearly 12% annually, addressing farmers' needs for solutions that reduce plastic pollution while maintaining or improving crop yields.

Economic factors are also driving market demand, as fluctuating petroleum prices affect traditional polymer costs, making bio-based alternatives increasingly cost-competitive. Additionally, the total lifecycle cost analysis of bio-based polymer equipment often demonstrates long-term economic advantages despite potentially higher initial investments.

Regional market analysis reveals varying adoption rates, with Europe leading in bio-based polymer agricultural equipment adoption, followed by North America and rapidly growing markets in Asia-Pacific regions, particularly in Japan, South Korea, and China. Developing agricultural economies show strong potential for leapfrogging directly to sustainable technologies, especially where government incentives support such transitions.

Market segmentation indicates that large-scale commercial farming operations currently represent the largest market share for sustainable agricultural equipment, but small and medium-sized farms show the highest growth rate in adoption, particularly when supported by cooperative purchasing arrangements or government subsidies.

Consumer willingness to pay premium prices for sustainably produced agricultural products creates a value chain that ultimately supports investment in sustainable equipment. This market dynamic creates a positive feedback loop where consumer preferences drive farm equipment purchasing decisions, accelerating the transition toward bio-based polymer applications throughout the agricultural sector.

Consumer demand for sustainably produced food continues to rise, creating downstream pressure on agricultural producers to adopt more environmentally responsible practices and equipment. This shift is reflected in purchasing patterns, with over 65% of agricultural equipment buyers now considering sustainability features as important decision factors, compared to just 28% five years ago.

Regulatory frameworks worldwide are increasingly favoring sustainable agricultural practices. The European Union's Farm to Fork Strategy, the United States Department of Agriculture's conservation programs, and similar initiatives in Asia-Pacific regions are creating strong market incentives for equipment manufacturers to incorporate sustainable materials like bio-based polymers into their product designs.

The market for bio-based polymer applications in agricultural equipment is particularly robust in irrigation systems, protective coverings, equipment components, and packaging materials. Biodegradable mulch films made from bio-based polymers have seen a market expansion of nearly 12% annually, addressing farmers' needs for solutions that reduce plastic pollution while maintaining or improving crop yields.

Economic factors are also driving market demand, as fluctuating petroleum prices affect traditional polymer costs, making bio-based alternatives increasingly cost-competitive. Additionally, the total lifecycle cost analysis of bio-based polymer equipment often demonstrates long-term economic advantages despite potentially higher initial investments.

Regional market analysis reveals varying adoption rates, with Europe leading in bio-based polymer agricultural equipment adoption, followed by North America and rapidly growing markets in Asia-Pacific regions, particularly in Japan, South Korea, and China. Developing agricultural economies show strong potential for leapfrogging directly to sustainable technologies, especially where government incentives support such transitions.

Market segmentation indicates that large-scale commercial farming operations currently represent the largest market share for sustainable agricultural equipment, but small and medium-sized farms show the highest growth rate in adoption, particularly when supported by cooperative purchasing arrangements or government subsidies.

Consumer willingness to pay premium prices for sustainably produced agricultural products creates a value chain that ultimately supports investment in sustainable equipment. This market dynamic creates a positive feedback loop where consumer preferences drive farm equipment purchasing decisions, accelerating the transition toward bio-based polymer applications throughout the agricultural sector.

Current Status and Challenges in Bio-based Polymer Development

Bio-based polymers have gained significant traction globally, with current production capacity reaching approximately 2.4 million tonnes annually. However, this represents merely 1% of the conventional plastic market, indicating substantial room for growth. Recent technological advancements have enabled the development of bio-based polymers with properties comparable to petroleum-based counterparts, particularly in terms of durability, flexibility, and weather resistance—critical factors for agricultural equipment applications.

Despite progress, several technical challenges persist in bio-based polymer development. Material performance inconsistency remains a significant hurdle, as natural variations in biomass feedstocks can lead to fluctuations in polymer properties. This inconsistency creates difficulties in maintaining quality standards across production batches, particularly problematic for agricultural equipment requiring precise specifications and reliable performance under harsh field conditions.

Cost competitiveness represents another major challenge. Bio-based polymers typically cost 20-100% more than conventional plastics due to higher raw material costs, complex processing requirements, and smaller production scales. This price premium creates adoption barriers, especially in cost-sensitive agricultural sectors where equipment margins are already tight.

Processing limitations further complicate development efforts. Many bio-based polymers exhibit narrower processing windows compared to conventional plastics, requiring more precise temperature and pressure controls during manufacturing. This complexity increases production costs and limits the range of applicable manufacturing techniques, constraining design possibilities for agricultural equipment components.

Biodegradability control presents a paradoxical challenge. While biodegradability is generally desirable for environmental sustainability, agricultural equipment requires materials with predictable lifespans. Engineers must carefully balance degradation rates with durability requirements, ensuring components maintain structural integrity throughout their intended service life while still offering end-of-life environmental benefits.

Regulatory frameworks worldwide remain fragmented, with inconsistent standards for bio-based content certification, biodegradability claims, and environmental impact assessments. This regulatory uncertainty complicates global market access and increases compliance costs for manufacturers developing bio-based agricultural equipment.

Research infrastructure limitations also impede progress. Compared to the well-established petroleum-based polymer industry, bio-based polymer research suffers from fewer dedicated facilities, limited specialized equipment, and smaller pools of experienced researchers. This infrastructure gap slows innovation cycles and extends development timelines for new agricultural applications.

Despite progress, several technical challenges persist in bio-based polymer development. Material performance inconsistency remains a significant hurdle, as natural variations in biomass feedstocks can lead to fluctuations in polymer properties. This inconsistency creates difficulties in maintaining quality standards across production batches, particularly problematic for agricultural equipment requiring precise specifications and reliable performance under harsh field conditions.

Cost competitiveness represents another major challenge. Bio-based polymers typically cost 20-100% more than conventional plastics due to higher raw material costs, complex processing requirements, and smaller production scales. This price premium creates adoption barriers, especially in cost-sensitive agricultural sectors where equipment margins are already tight.

Processing limitations further complicate development efforts. Many bio-based polymers exhibit narrower processing windows compared to conventional plastics, requiring more precise temperature and pressure controls during manufacturing. This complexity increases production costs and limits the range of applicable manufacturing techniques, constraining design possibilities for agricultural equipment components.

Biodegradability control presents a paradoxical challenge. While biodegradability is generally desirable for environmental sustainability, agricultural equipment requires materials with predictable lifespans. Engineers must carefully balance degradation rates with durability requirements, ensuring components maintain structural integrity throughout their intended service life while still offering end-of-life environmental benefits.

Regulatory frameworks worldwide remain fragmented, with inconsistent standards for bio-based content certification, biodegradability claims, and environmental impact assessments. This regulatory uncertainty complicates global market access and increases compliance costs for manufacturers developing bio-based agricultural equipment.

Research infrastructure limitations also impede progress. Compared to the well-established petroleum-based polymer industry, bio-based polymer research suffers from fewer dedicated facilities, limited specialized equipment, and smaller pools of experienced researchers. This infrastructure gap slows innovation cycles and extends development timelines for new agricultural applications.

Current Bio-Polymer Solutions for Agricultural Applications

01 Bio-based polymers from renewable resources

Bio-based polymers derived from renewable resources such as plant materials offer sustainable alternatives to petroleum-based polymers. These polymers utilize biomass feedstocks like cellulose, starch, and plant oils to create environmentally friendly materials with reduced carbon footprint. The production processes focus on converting these renewable resources into functional polymers with properties comparable to conventional plastics while maintaining biodegradability.- Bio-based polymer production from renewable resources: Bio-based polymers can be produced from renewable resources such as plant materials, agricultural waste, and other biomass. These polymers offer sustainable alternatives to petroleum-based plastics while maintaining comparable physical and chemical properties. The production methods often involve fermentation, enzymatic processes, or chemical modifications of natural polymers to create materials suitable for various industrial applications.

- Biodegradable polymer compositions and applications: Biodegradable polymer compositions are formulated to break down naturally in the environment through microbial action. These compositions often combine bio-based polymers with additives that enhance their biodegradability while maintaining necessary performance characteristics. Applications include packaging materials, agricultural films, medical devices, and consumer products where end-of-life environmental impact is a concern.

- Bio-based polymer blends and composites: Bio-based polymer blends and composites combine different bio-polymers or incorporate natural fibers and fillers to enhance mechanical properties, thermal stability, and processability. These materials can be tailored for specific applications by adjusting the composition and processing conditions. The resulting composites often exhibit improved strength, flexibility, or barrier properties compared to single-component bio-polymers.

- Modified bio-polymers with enhanced properties: Chemical or physical modification of bio-polymers can enhance their properties for specific applications. Techniques include crosslinking, grafting, and functionalization to improve characteristics such as water resistance, thermal stability, mechanical strength, and compatibility with other materials. These modifications expand the range of applications for bio-based polymers in industries where conventional polymers have traditionally dominated.

- Processing technologies for bio-based polymers: Specialized processing technologies have been developed to efficiently convert bio-based polymers into usable products. These include extrusion, injection molding, film blowing, and 3D printing techniques adapted for the unique characteristics of bio-polymers. The processing methods often need to account for different thermal behavior, rheological properties, and moisture sensitivity compared to conventional polymers to achieve optimal product quality and performance.

02 Biodegradable polymer composites and blends

Biodegradable polymer composites and blends combine bio-based polymers with other materials to enhance performance characteristics. These formulations may incorporate natural fibers, minerals, or other biodegradable polymers to improve mechanical properties, thermal stability, or processing characteristics. The resulting materials maintain their environmentally friendly attributes while offering improved functionality for various applications.Expand Specific Solutions03 Processing technologies for bio-based polymers

Specialized processing technologies have been developed for bio-based polymers to address their unique characteristics. These include modified extrusion techniques, specialized molding processes, and surface treatment methods that optimize the performance of bio-based materials. The processing approaches account for differences in thermal behavior, rheology, and crystallization compared to conventional polymers.Expand Specific Solutions04 Bio-based polymer applications in packaging and consumer products

Bio-based polymers are increasingly used in packaging and consumer products as sustainable alternatives to conventional plastics. These applications include food packaging, disposable items, personal care product containers, and household goods. The materials offer benefits such as reduced environmental impact, potential compostability, and marketing advantages for environmentally conscious brands and consumers.Expand Specific Solutions05 Functional bio-based polymers for specialized applications

Functional bio-based polymers are designed for specialized applications requiring specific properties beyond basic structural characteristics. These include bio-based polymers with antimicrobial properties, enhanced barrier characteristics, electrical conductivity, or biomedical compatibility. The materials are engineered through chemical modification, additive incorporation, or processing techniques to achieve targeted performance for applications in healthcare, electronics, and other advanced fields.Expand Specific Solutions

Key Industry Players in Sustainable Agricultural Equipment

The bio-based polymer market for sustainable agriculture equipment is in a growth phase, with increasing market size driven by environmental regulations and consumer demand for eco-friendly solutions. The technology maturity varies across applications, with companies at different development stages. Industry leaders like Procter & Gamble and International Paper are leveraging their scale to commercialize bio-based solutions, while specialized innovators such as AgroSpheres and Teysha Technologies are developing novel delivery systems and tunable polymers. Academic institutions including University of Florida and Delft University of Technology are advancing fundamental research, while companies like PRET Composites and Toray Plastics are focusing on high-performance modified materials. The collaboration between research institutions and industry players is accelerating technology adoption, though cost competitiveness remains a challenge compared to conventional polymers.

Toray Plastics (America), Inc.

Technical Solution: Toray Plastics has developed advanced bio-based polymer solutions for agricultural applications under their Ecodear® product line. Their technology utilizes polylactic acid (PLA) derived from corn and other plant starches, modified with proprietary additives to enhance durability and performance in agricultural environments. For agricultural equipment, Toray has engineered bio-based polymer composites that combine natural fibers with their PLA formulations to create materials with sufficient strength and durability for equipment components, irrigation systems, and storage containers. Their bio-based polymers feature enhanced UV resistance, moisture resistance, and mechanical properties comparable to conventional plastics. Toray has also developed multilayer film technologies that combine bio-based polymers with other materials to achieve specific performance characteristics needed for agricultural applications.

Strengths: Extensive experience in polymer engineering; established manufacturing infrastructure; advanced material science capabilities for creating high-performance bio-based composites. Weaknesses: Higher cost compared to conventional plastics; some formulations still contain partial petroleum-based components; limited biodegradability in certain environmental conditions.

Zhejiang Pret Advanced Materials Co. Ltd.

Technical Solution: Zhejiang Pret has developed specialized bio-based polymer composites reinforced with natural fibers for agricultural equipment applications. Their technology combines plant-derived polymers with agricultural waste fibers (rice husks, wheat straw, bamboo) to create high-strength, lightweight materials suitable for equipment components. Their proprietary processing techniques optimize the interface between natural fibers and bio-polymers, enhancing mechanical properties while maintaining biodegradability. For agricultural equipment, Pret has engineered materials that can withstand outdoor exposure, mechanical stress, and contact with agricultural chemicals. Their bio-composites are processed using conventional equipment like injection molding and extrusion, facilitating adoption by equipment manufacturers. The company has also developed specialized formulations for specific agricultural applications, such as UV-resistant covers for greenhouses and water-resistant components for irrigation systems.

Strengths: Strong expertise in composite materials; established manufacturing capabilities; cost-effective integration of agricultural waste streams into valuable materials. Weaknesses: Variable material properties depending on natural fiber sources; more suitable for non-critical components; limited experience in Western agricultural markets.

Key Technical Innovations in Bio-based Agricultural Materials

A BIO-based coating for agricultural applications.

PatentWO2025136095A1

Innovation

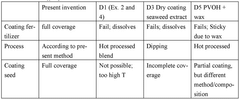

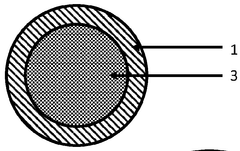

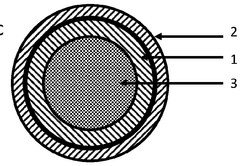

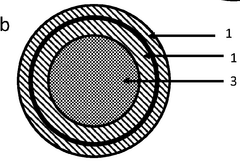

- A bio-based water-soluble coating comprising a protective layer made from 50-98 wt.% biopolymer, 0.1-35 wt.% non-polar binder, and optionally 0-49.9 wt.% plasticizer, applied to agricultural particles such as fertilizers and seeds, providing protection and controlled nutrient release.

Agricultural applicator

PatentWO2024236210A1

Innovation

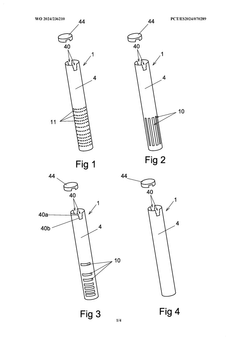

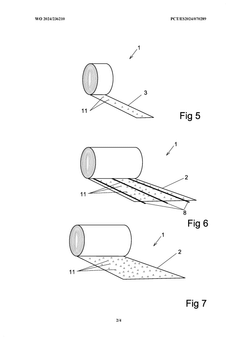

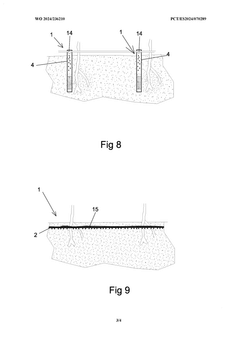

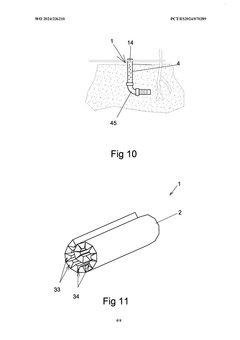

- A biopolymer-based agricultural applicator with a tube-shaped body and exit holes for precise application of water, nutrients, and seeds, featuring adjustable degradability and hygroscopic properties to optimize water use and prevent soil contamination, incorporating organic and mineral fillers for enhanced performance.

Environmental Impact Assessment and Lifecycle Analysis

The environmental impact assessment of bio-based polymers in agricultural equipment reveals significant advantages over conventional petroleum-based plastics. Life cycle analyses demonstrate that bio-based polymers typically reduce greenhouse gas emissions by 30-70% compared to their fossil-based counterparts. This reduction stems primarily from the carbon sequestration during biomass growth and the generally lower energy requirements during manufacturing processes.

When examining the complete lifecycle of agricultural equipment incorporating bio-based polymers, water consumption patterns show notable differences. While bio-based feedstock production may require substantial water inputs, advanced manufacturing techniques have reduced processing water needs by approximately 25% in recent years. The water footprint remains an area requiring careful regional assessment, as impacts vary significantly based on local agricultural practices and water availability.

Soil health benefits emerge as a critical advantage when bio-based agricultural equipment components biodegrade at end-of-life. Studies indicate that properly engineered bio-based polymers can decompose into non-toxic constituents that may actually enhance soil microbial activity. This contrasts sharply with conventional plastics that fragment into microplastics, which persist in agricultural soils for decades and potentially disrupt soil ecosystems.

Land use considerations present complex tradeoffs that must be carefully evaluated. The production of bio-based polymer feedstocks requires agricultural land that could otherwise be used for food production. However, recent innovations in utilizing agricultural waste streams and non-food crops grown on marginal lands have mitigated these concerns. Current estimates suggest that less than 0.02% of global agricultural land would be required to replace conventional plastics in agricultural equipment applications.

Energy efficiency metrics across the full lifecycle reveal that bio-based polymers in agricultural equipment typically consume 20-40% less non-renewable energy than conventional alternatives. This advantage becomes particularly pronounced when considering equipment with extended service lives, as the initial energy investment is amortized over longer periods of sustainable use.

Waste management scenarios demonstrate that end-of-life options for bio-based agricultural equipment components are more environmentally favorable. Composting and biodegradation pathways reduce landfill volumes and associated methane emissions. Furthermore, certain bio-based polymers can be designed for chemical recycling, enabling circular economy approaches that recover valuable chemical building blocks for reuse in new products.

When examining the complete lifecycle of agricultural equipment incorporating bio-based polymers, water consumption patterns show notable differences. While bio-based feedstock production may require substantial water inputs, advanced manufacturing techniques have reduced processing water needs by approximately 25% in recent years. The water footprint remains an area requiring careful regional assessment, as impacts vary significantly based on local agricultural practices and water availability.

Soil health benefits emerge as a critical advantage when bio-based agricultural equipment components biodegrade at end-of-life. Studies indicate that properly engineered bio-based polymers can decompose into non-toxic constituents that may actually enhance soil microbial activity. This contrasts sharply with conventional plastics that fragment into microplastics, which persist in agricultural soils for decades and potentially disrupt soil ecosystems.

Land use considerations present complex tradeoffs that must be carefully evaluated. The production of bio-based polymer feedstocks requires agricultural land that could otherwise be used for food production. However, recent innovations in utilizing agricultural waste streams and non-food crops grown on marginal lands have mitigated these concerns. Current estimates suggest that less than 0.02% of global agricultural land would be required to replace conventional plastics in agricultural equipment applications.

Energy efficiency metrics across the full lifecycle reveal that bio-based polymers in agricultural equipment typically consume 20-40% less non-renewable energy than conventional alternatives. This advantage becomes particularly pronounced when considering equipment with extended service lives, as the initial energy investment is amortized over longer periods of sustainable use.

Waste management scenarios demonstrate that end-of-life options for bio-based agricultural equipment components are more environmentally favorable. Composting and biodegradation pathways reduce landfill volumes and associated methane emissions. Furthermore, certain bio-based polymers can be designed for chemical recycling, enabling circular economy approaches that recover valuable chemical building blocks for reuse in new products.

Regulatory Framework for Bio-based Agricultural Materials

The regulatory landscape governing bio-based agricultural materials has evolved significantly in recent years, reflecting growing global commitment to sustainable practices. In the United States, the USDA BioPreferred Program mandates federal agencies to purchase bio-based products, creating a substantial market pull for sustainable agricultural equipment incorporating bio-based polymers. This program includes certification and labeling systems that help manufacturers demonstrate compliance and gain market recognition.

The European Union has established the most comprehensive framework through its Circular Economy Action Plan and European Green Deal. These initiatives set specific targets for bio-based content in agricultural products and equipment, with the EN 16785 standard providing methodologies for calculating and verifying bio-based content. Additionally, the EU's Single-Use Plastics Directive impacts agricultural films and containers, pushing manufacturers toward bio-based alternatives.

International standards organizations play a crucial role in harmonizing requirements across borders. ISO 14855 and ASTM D6400 provide standardized methods for testing biodegradability and compostability of bio-based polymers used in agricultural applications. These standards ensure that materials claiming environmental benefits can substantiate such claims through verified testing protocols.

Emerging economies are rapidly developing their own regulatory frameworks. China's recent Five-Year Plan emphasizes bio-based materials development, while India has implemented the Plastic Waste Management Rules with specific provisions for agricultural applications, encouraging bio-based alternatives through tax incentives and subsidies.

Carbon accounting regulations increasingly influence material selection in agricultural equipment. The EU's Carbon Border Adjustment Mechanism and similar emerging schemes in other jurisdictions create financial incentives for manufacturers to adopt bio-based polymers with lower carbon footprints. Life Cycle Assessment (LCA) methodologies, as standardized in ISO 14040 and 14044, are becoming mandatory for environmental claims validation.

End-of-life regulations present both challenges and opportunities for bio-based agricultural materials. Extended Producer Responsibility (EPR) schemes in various countries require manufacturers to manage products throughout their lifecycle, including disposal. Bio-based polymers that offer enhanced biodegradability or recyclability provide strategic advantages under these regulatory frameworks, though certification requirements vary significantly by region.

The European Union has established the most comprehensive framework through its Circular Economy Action Plan and European Green Deal. These initiatives set specific targets for bio-based content in agricultural products and equipment, with the EN 16785 standard providing methodologies for calculating and verifying bio-based content. Additionally, the EU's Single-Use Plastics Directive impacts agricultural films and containers, pushing manufacturers toward bio-based alternatives.

International standards organizations play a crucial role in harmonizing requirements across borders. ISO 14855 and ASTM D6400 provide standardized methods for testing biodegradability and compostability of bio-based polymers used in agricultural applications. These standards ensure that materials claiming environmental benefits can substantiate such claims through verified testing protocols.

Emerging economies are rapidly developing their own regulatory frameworks. China's recent Five-Year Plan emphasizes bio-based materials development, while India has implemented the Plastic Waste Management Rules with specific provisions for agricultural applications, encouraging bio-based alternatives through tax incentives and subsidies.

Carbon accounting regulations increasingly influence material selection in agricultural equipment. The EU's Carbon Border Adjustment Mechanism and similar emerging schemes in other jurisdictions create financial incentives for manufacturers to adopt bio-based polymers with lower carbon footprints. Life Cycle Assessment (LCA) methodologies, as standardized in ISO 14040 and 14044, are becoming mandatory for environmental claims validation.

End-of-life regulations present both challenges and opportunities for bio-based agricultural materials. Extended Producer Responsibility (EPR) schemes in various countries require manufacturers to manage products throughout their lifecycle, including disposal. Bio-based polymers that offer enhanced biodegradability or recyclability provide strategic advantages under these regulatory frameworks, though certification requirements vary significantly by region.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!