Study of Bio-based Polymer as an Electrolyte Solution

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Polymer Electrolytes Background and Objectives

The field of bio-based polymer electrolytes has emerged as a promising alternative to conventional petroleum-derived electrolytes, driven by growing environmental concerns and the need for sustainable energy storage solutions. Since the early 2000s, researchers have been exploring natural polymers such as cellulose, chitosan, starch, and various plant-derived materials as potential electrolyte matrices. These materials offer inherent biodegradability, renewability, and in many cases, unique structural properties that can be advantageous for ion transport mechanisms.

The evolution of this technology has progressed from simple blending of natural polymers with conventional electrolyte salts to more sophisticated approaches involving chemical modification of bio-polymers to enhance their electrochemical properties. Recent advancements have focused on improving ionic conductivity, which has historically been a limiting factor for bio-based systems compared to synthetic counterparts.

Current research trends indicate a shift toward hybrid systems that combine bio-based polymers with inorganic components to create composite electrolytes with enhanced mechanical stability and conductivity. Additionally, there is growing interest in developing bio-based gel polymer electrolytes that offer the advantages of both liquid and solid electrolytes while maintaining environmental benefits.

The primary technical objectives in this field include achieving ionic conductivity values comparable to conventional polymer electrolytes (>10^-3 S/cm at ambient temperature), enhancing electrochemical stability windows to accommodate high-voltage battery chemistries, and ensuring long-term stability under various operating conditions. Researchers also aim to develop scalable and cost-effective production methods that can compete with established synthetic polymer electrolyte manufacturing processes.

Another critical goal is to understand and optimize the fundamental ion transport mechanisms in bio-polymer matrices, which often differ significantly from synthetic systems due to their unique hierarchical structures and functional group distributions. This includes investigating the role of crystallinity, cross-linking density, and hydration levels on ionic mobility within these natural polymer networks.

From an application perspective, the technology aims to enable the development of safer, more environmentally friendly energy storage devices, including batteries, supercapacitors, and fuel cells. There is particular interest in applications where biodegradability offers distinct advantages, such as transient electronics, medical devices, and environmental monitoring systems.

The convergence of polymer chemistry, electrochemistry, and materials science in this field presents both challenges and opportunities for creating next-generation electrolyte solutions that align with global sustainability goals while meeting the performance requirements of modern energy storage technologies.

The evolution of this technology has progressed from simple blending of natural polymers with conventional electrolyte salts to more sophisticated approaches involving chemical modification of bio-polymers to enhance their electrochemical properties. Recent advancements have focused on improving ionic conductivity, which has historically been a limiting factor for bio-based systems compared to synthetic counterparts.

Current research trends indicate a shift toward hybrid systems that combine bio-based polymers with inorganic components to create composite electrolytes with enhanced mechanical stability and conductivity. Additionally, there is growing interest in developing bio-based gel polymer electrolytes that offer the advantages of both liquid and solid electrolytes while maintaining environmental benefits.

The primary technical objectives in this field include achieving ionic conductivity values comparable to conventional polymer electrolytes (>10^-3 S/cm at ambient temperature), enhancing electrochemical stability windows to accommodate high-voltage battery chemistries, and ensuring long-term stability under various operating conditions. Researchers also aim to develop scalable and cost-effective production methods that can compete with established synthetic polymer electrolyte manufacturing processes.

Another critical goal is to understand and optimize the fundamental ion transport mechanisms in bio-polymer matrices, which often differ significantly from synthetic systems due to their unique hierarchical structures and functional group distributions. This includes investigating the role of crystallinity, cross-linking density, and hydration levels on ionic mobility within these natural polymer networks.

From an application perspective, the technology aims to enable the development of safer, more environmentally friendly energy storage devices, including batteries, supercapacitors, and fuel cells. There is particular interest in applications where biodegradability offers distinct advantages, such as transient electronics, medical devices, and environmental monitoring systems.

The convergence of polymer chemistry, electrochemistry, and materials science in this field presents both challenges and opportunities for creating next-generation electrolyte solutions that align with global sustainability goals while meeting the performance requirements of modern energy storage technologies.

Market Analysis for Sustainable Battery Technologies

The sustainable battery market is experiencing unprecedented growth, driven by increasing environmental concerns and the global push towards carbon neutrality. Current market valuations indicate that sustainable battery technologies reached approximately $21.4 billion in 2022, with projections suggesting a compound annual growth rate of 18.7% through 2030. Bio-based polymer electrolytes represent an emerging segment within this market, currently accounting for a modest but rapidly growing share estimated at 3.5% of the total sustainable battery materials market.

Consumer electronics continues to dominate application segments, representing 42% of the sustainable battery market, followed by electric vehicles at 38% and grid storage solutions at 15%. The remaining 5% encompasses specialized applications including medical devices and aerospace technologies. Notably, the demand for bio-based polymer electrolytes is growing fastest in the electric vehicle sector, where manufacturers are increasingly prioritizing fully sustainable battery compositions.

Regional analysis reveals Asia-Pacific as the dominant market for sustainable battery technologies, commanding 45% of global market share, with China alone accounting for 28%. North America and Europe follow with 27% and 23% respectively, while emerging markets in Latin America and Africa collectively represent the remaining 5%. European markets demonstrate the strongest preference for bio-based solutions, driven by stringent regulatory frameworks including the European Green Deal and Circular Economy Action Plan.

Key market drivers for bio-based polymer electrolytes include increasing consumer awareness of environmental impacts, corporate sustainability commitments, and government regulations restricting conventional battery materials. The EU Battery Directive revision and similar policies in Japan and South Korea specifically promote bio-based alternatives through incentive programs and research funding. Additionally, supply chain vulnerabilities exposed during recent global disruptions have accelerated interest in locally-sourced bio-based materials.

Market challenges include price sensitivity, with bio-based polymer electrolytes currently commanding a 15-30% premium over conventional alternatives. Performance concerns also persist, particularly regarding cycle life and temperature stability in extreme conditions. However, recent technological breakthroughs have narrowed this performance gap significantly, with several bio-based formulations now achieving 90% of conventional electrolyte performance metrics.

Future market projections indicate bio-based polymer electrolytes could capture up to 12% of the total battery electrolyte market by 2028, representing a potential market value of $5.8 billion. This growth trajectory depends heavily on continued performance improvements and achieving economies of scale in production processes, with price parity expected to be reached by 2026 for certain applications.

Consumer electronics continues to dominate application segments, representing 42% of the sustainable battery market, followed by electric vehicles at 38% and grid storage solutions at 15%. The remaining 5% encompasses specialized applications including medical devices and aerospace technologies. Notably, the demand for bio-based polymer electrolytes is growing fastest in the electric vehicle sector, where manufacturers are increasingly prioritizing fully sustainable battery compositions.

Regional analysis reveals Asia-Pacific as the dominant market for sustainable battery technologies, commanding 45% of global market share, with China alone accounting for 28%. North America and Europe follow with 27% and 23% respectively, while emerging markets in Latin America and Africa collectively represent the remaining 5%. European markets demonstrate the strongest preference for bio-based solutions, driven by stringent regulatory frameworks including the European Green Deal and Circular Economy Action Plan.

Key market drivers for bio-based polymer electrolytes include increasing consumer awareness of environmental impacts, corporate sustainability commitments, and government regulations restricting conventional battery materials. The EU Battery Directive revision and similar policies in Japan and South Korea specifically promote bio-based alternatives through incentive programs and research funding. Additionally, supply chain vulnerabilities exposed during recent global disruptions have accelerated interest in locally-sourced bio-based materials.

Market challenges include price sensitivity, with bio-based polymer electrolytes currently commanding a 15-30% premium over conventional alternatives. Performance concerns also persist, particularly regarding cycle life and temperature stability in extreme conditions. However, recent technological breakthroughs have narrowed this performance gap significantly, with several bio-based formulations now achieving 90% of conventional electrolyte performance metrics.

Future market projections indicate bio-based polymer electrolytes could capture up to 12% of the total battery electrolyte market by 2028, representing a potential market value of $5.8 billion. This growth trajectory depends heavily on continued performance improvements and achieving economies of scale in production processes, with price parity expected to be reached by 2026 for certain applications.

Current Status and Challenges in Bio-based Electrolytes

Bio-based electrolytes have gained significant attention in recent years as sustainable alternatives to conventional petroleum-derived electrolytes. Currently, the global research landscape shows varying levels of development across different bio-based polymer electrolyte systems. Cellulose-derived electrolytes have reached pilot-scale production in several research institutions across North America and Europe, while chitosan-based systems remain predominantly at laboratory scale despite showing promising ionic conductivity properties.

The market for bio-based electrolytes is experiencing rapid growth, with an estimated annual increase of 8.5% in research publications since 2018. Leading research clusters have emerged in Germany, Japan, South Korea, and the United States, with China showing the most accelerated growth in patent filings related to bio-based polymer electrolytes over the past three years.

A significant technical challenge facing bio-based electrolytes is their inherently lower ionic conductivity compared to conventional electrolytes. Most bio-based systems currently achieve conductivities in the range of 10^-5 to 10^-4 S/cm at room temperature, whereas commercial applications typically require at least 10^-3 S/cm. This performance gap represents a major hurdle for widespread adoption in energy storage devices.

Thermal and mechanical stability issues also persist across many bio-based electrolyte formulations. Natural polymers often exhibit degradation at temperatures above 80°C, limiting their application in high-temperature environments. Additionally, many bio-based electrolytes suffer from poor interfacial contact with electrodes, leading to increased internal resistance and reduced device performance.

Manufacturing scalability presents another significant challenge. The extraction and processing of bio-based polymers often involve complex purification steps that are difficult to scale economically. Batch-to-batch variability in natural polymer sources further complicates quality control in industrial settings, creating barriers to mass production.

Regulatory frameworks for bio-based materials in energy storage applications remain underdeveloped in many regions, creating uncertainty for commercial deployment. Safety certification processes designed for conventional electrolytes may not adequately address the unique properties and degradation pathways of bio-based alternatives.

Despite these challenges, recent breakthroughs in chemical modification techniques have shown promise in addressing conductivity limitations. Cross-linking strategies and the incorporation of ionic liquids have demonstrated up to 200% improvements in ionic conductivity while maintaining the biodegradability advantages of bio-based systems. These developments suggest that with continued research investment, the performance gap between bio-based and conventional electrolytes could narrow significantly within the next five years.

The market for bio-based electrolytes is experiencing rapid growth, with an estimated annual increase of 8.5% in research publications since 2018. Leading research clusters have emerged in Germany, Japan, South Korea, and the United States, with China showing the most accelerated growth in patent filings related to bio-based polymer electrolytes over the past three years.

A significant technical challenge facing bio-based electrolytes is their inherently lower ionic conductivity compared to conventional electrolytes. Most bio-based systems currently achieve conductivities in the range of 10^-5 to 10^-4 S/cm at room temperature, whereas commercial applications typically require at least 10^-3 S/cm. This performance gap represents a major hurdle for widespread adoption in energy storage devices.

Thermal and mechanical stability issues also persist across many bio-based electrolyte formulations. Natural polymers often exhibit degradation at temperatures above 80°C, limiting their application in high-temperature environments. Additionally, many bio-based electrolytes suffer from poor interfacial contact with electrodes, leading to increased internal resistance and reduced device performance.

Manufacturing scalability presents another significant challenge. The extraction and processing of bio-based polymers often involve complex purification steps that are difficult to scale economically. Batch-to-batch variability in natural polymer sources further complicates quality control in industrial settings, creating barriers to mass production.

Regulatory frameworks for bio-based materials in energy storage applications remain underdeveloped in many regions, creating uncertainty for commercial deployment. Safety certification processes designed for conventional electrolytes may not adequately address the unique properties and degradation pathways of bio-based alternatives.

Despite these challenges, recent breakthroughs in chemical modification techniques have shown promise in addressing conductivity limitations. Cross-linking strategies and the incorporation of ionic liquids have demonstrated up to 200% improvements in ionic conductivity while maintaining the biodegradability advantages of bio-based systems. These developments suggest that with continued research investment, the performance gap between bio-based and conventional electrolytes could narrow significantly within the next five years.

Current Bio-based Polymer Electrolyte Solutions

01 Bio-based polymer electrolytes for lithium batteries

Bio-based polymers can be used as electrolyte materials in lithium batteries, offering environmentally friendly alternatives to petroleum-based polymers. These materials provide good ionic conductivity while reducing environmental impact. The bio-based polymers can be derived from renewable resources such as cellulose, starch, or other plant-based materials, and can be modified to enhance their electrochemical properties for battery applications.- Bio-based polymer electrolytes from natural sources: Polymer electrolytes derived from renewable natural sources such as cellulose, starch, chitosan, and other plant-based materials can be used to create environmentally friendly electrolyte solutions. These bio-based polymers offer biodegradability and sustainability advantages while maintaining necessary electrochemical properties. The natural polymers can be modified through various chemical processes to enhance their ionic conductivity and mechanical stability for use in energy storage applications.

- Composite polymer electrolytes with bio-based components: Composite electrolyte systems combining bio-based polymers with inorganic fillers or other synthetic polymers can enhance overall performance. These hybrid systems leverage the environmental benefits of bio-based materials while addressing limitations in conductivity or mechanical properties. The composite approach allows for tailoring electrolyte properties through the strategic combination of different materials, resulting in improved electrochemical stability and ion transport capabilities.

- Ionic liquid incorporation in bio-polymer electrolytes: The addition of ionic liquids to bio-based polymer matrices creates high-performance electrolyte solutions with enhanced ionic conductivity. Ionic liquids provide excellent thermal stability and wide electrochemical windows when combined with bio-polymers. This approach maintains the environmental benefits of bio-based materials while significantly improving the electrochemical performance needed for advanced energy storage applications.

- Bio-based gel polymer electrolytes: Gel-type polymer electrolytes using bio-based materials offer improved interfacial contact with electrodes while maintaining good mechanical properties. These gel systems typically contain bio-polymers, plasticizers, and electrolyte salts that form a semi-solid matrix capable of facilitating ion transport. The gel structure provides advantages in terms of leakage prevention and flexibility while utilizing renewable polymer sources as the base material.

- Processing methods for bio-based polymer electrolytes: Various processing techniques can be employed to optimize the performance of bio-based polymer electrolytes, including solution casting, electrospinning, and solvent-free methods. These processing approaches affect the morphology, crystallinity, and ultimately the ionic conductivity of the resulting electrolyte. Advanced processing methods can create nanostructured bio-based electrolytes with enhanced ion transport pathways and improved mechanical properties for battery and other electrochemical applications.

02 Polymer electrolyte solutions with ionic liquids

Incorporating ionic liquids into bio-based polymer electrolyte solutions can significantly improve ionic conductivity and electrochemical stability. These formulations combine the environmental benefits of bio-based polymers with the enhanced performance characteristics of ionic liquids. The resulting electrolyte solutions demonstrate improved thermal stability and wider electrochemical windows, making them suitable for advanced energy storage applications.Expand Specific Solutions03 Cellulose-derived polymer electrolytes

Cellulose and its derivatives can be processed into effective polymer electrolyte solutions. These materials leverage the abundant natural polymer structure of cellulose while incorporating modifications to enhance ionic conductivity. Various chemical treatments can be applied to cellulose to create derivatives with improved solubility and ion transport properties, resulting in sustainable electrolyte solutions for energy storage devices.Expand Specific Solutions04 Composite bio-based electrolytes with inorganic fillers

Adding inorganic fillers to bio-based polymer electrolyte solutions creates composite materials with enhanced mechanical and electrochemical properties. These fillers, such as ceramic nanoparticles or metal oxides, can improve the dimensional stability of the electrolyte while also enhancing ionic conductivity through the creation of additional ion transport pathways. The resulting composite electrolytes combine the sustainability of bio-based polymers with the performance advantages of inorganic materials.Expand Specific Solutions05 Cross-linked bio-polymer electrolyte networks

Cross-linking techniques can be applied to bio-based polymers to create three-dimensional networks with improved mechanical properties and ion transport capabilities. These cross-linked structures maintain dimensional stability while allowing for efficient ion movement through the electrolyte matrix. Various cross-linking agents and methods can be employed to optimize the balance between mechanical strength and ionic conductivity in these sustainable electrolyte solutions.Expand Specific Solutions

Leading Organizations in Bio-based Polymer Electrolyte Research

The bio-based polymer electrolyte solution market is in an early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size is projected to expand significantly due to rising demand for sustainable energy storage solutions, with estimates suggesting a compound annual growth rate of 15-20% over the next five years. Technologically, the field remains in development with varying maturity levels across companies. Industry leaders like LG Energy Solution, Toyota Motor Corp., and JSR Corp. are advancing commercial applications, while research institutions such as Shandong University, KIST, and Tohoku University are driving fundamental innovations. Companies including Ionic Materials, Asahi Kasei, and Sumitomo Chemical are developing proprietary polymer electrolyte technologies, positioning themselves strategically in this evolving landscape that bridges renewable materials with energy storage solutions.

Asahi Kasei Corp.

Technical Solution: Asahi Kasei has developed a sophisticated bio-based polymer electrolyte platform centered around modified cellulose nanofibers (CNF) and bio-derived polyethers. Their approach involves the extraction and chemical modification of cellulose from sustainable plant sources, followed by precise functionalization to enhance ionic conductivity. The company's proprietary technology creates a hierarchical structure where CNFs provide mechanical strength while functionalized side chains facilitate ion transport. These electrolytes achieve conductivities of 0.7-1.0 mS/cm at ambient temperature with excellent thermal stability up to 150°C. A distinguishing feature of Asahi Kasei's technology is their bio-derived crosslinking methodology that creates covalent networks resistant to creep and deformation under battery operating conditions. The company has demonstrated these materials in both lithium-ion and sodium-ion battery prototypes, showing stable cycling performance over 1000 cycles with minimal capacity fade. Their manufacturing process has been optimized to use environmentally friendly solvents and catalysts, further enhancing the sustainability profile of their electrolyte solution.

Strengths: Excellent mechanical properties and dimensional stability; high thermal resistance improving battery safety; versatility across multiple battery chemistries including sodium-ion. Weaknesses: Complex manufacturing process with multiple chemical modification steps; higher raw material costs compared to synthetic polymers; limited low-temperature performance.

Ionic Materials Inc.

Technical Solution: Ionic Materials has developed a revolutionary solid polymer electrolyte platform specifically designed for lithium-ion batteries. Their proprietary technology involves a bio-based polymer matrix that conducts ions at room temperature without the need for liquid components. The polymer electrolyte demonstrates superior ionic conductivity (>1 mS/cm at room temperature) while maintaining excellent mechanical properties. Their approach incorporates renewable biomass-derived monomers that are polymerized using environmentally friendly catalysts. The resulting solid electrolyte enables safer, higher-energy-density batteries by preventing dendrite formation and allowing the use of lithium metal anodes. The company's bio-based polymer electrolytes also show remarkable electrochemical stability windows (>4.5V), making them compatible with high-voltage cathode materials for next-generation energy storage applications.

Strengths: Superior safety profile by eliminating flammable liquid electrolytes; enables lithium metal anodes for higher energy density; environmentally sustainable sourcing of raw materials. Weaknesses: Manufacturing scale-up challenges for solid polymer electrolytes; potential higher production costs compared to conventional liquid electrolytes; may require redesign of existing battery manufacturing processes.

Key Patents and Scientific Breakthroughs in Bio-Electrolytes

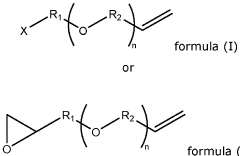

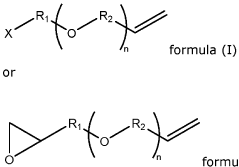

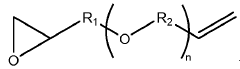

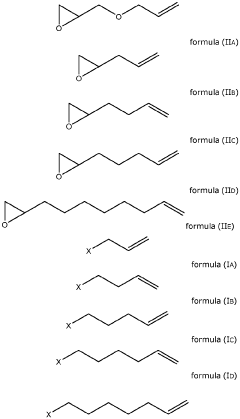

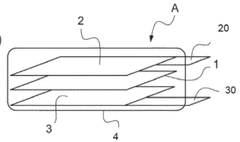

A polymer electrolyte

PatentWO2022136630A1

Innovation

- A polymer electrolyte is developed by reacting a polyether polymer with at least 70% oxyethylene units and a polysiloxane compound, where the polysiloxane is grafted to the polymer through a hydrosilylation reaction, reducing capacity leakage and enhancing ionic conductivity.

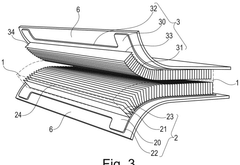

A na-ion bioresorbable and flexible electrochemical micro-battery.

PatentWO2024223772A1

Innovation

- A sodium-ion micro-battery design featuring a flexible encapsulating substrate made of biocompatible and degradable polymers, 3D electrodes with micropillars, and a biocompatible gel polymer electrolyte, using non-toxic materials like magnesium and sodium manganate for enhanced electrochemical performance and bioresorbability.

Environmental Impact and Sustainability Assessment

The environmental impact of bio-based polymers as electrolyte solutions represents a critical dimension in evaluating their viability for widespread adoption. Traditional electrolyte solutions often rely on petroleum-derived polymers and toxic organic solvents, contributing significantly to carbon emissions and environmental degradation throughout their lifecycle. Bio-based alternatives offer substantial environmental advantages, primarily through reduced carbon footprint during production and enhanced biodegradability at end-of-life.

Life Cycle Assessment (LCA) studies indicate that bio-based polymer electrolytes can reduce greenhouse gas emissions by 30-70% compared to conventional petroleum-based counterparts. This reduction stems from the renewable nature of their feedstocks, which sequester carbon during growth phases. However, comprehensive sustainability assessment must consider land use changes, water consumption, and potential competition with food production when agricultural resources are diverted for polymer synthesis.

Water footprint analysis reveals varying impacts depending on the specific bio-polymer source. Cellulose-derived electrolytes typically require less water than those derived from starch or protein sources. Additionally, the processing methods employed significantly influence overall environmental performance, with solvent-free techniques demonstrating superior sustainability profiles compared to traditional solvent-based approaches.

Biodegradability presents another crucial environmental advantage. Studies demonstrate that many bio-based polymer electrolytes can decompose under controlled conditions within 3-12 months, compared to centuries for conventional petroleum-based polymers. This characteristic substantially reduces waste accumulation and microplastic pollution. However, the degradation pathways and potential formation of intermediate compounds require thorough investigation to ensure no harmful substances are released during decomposition.

Toxicity assessments of bio-based polymer electrolytes generally show favorable results compared to conventional systems containing volatile organic compounds. The reduced toxicity profile benefits both environmental systems and human health, particularly in manufacturing environments and during recycling processes. Nevertheless, certain bio-based additives may introduce unexpected ecotoxicological effects that warrant careful screening and regulation.

Resource efficiency metrics indicate that bio-based polymer electrolytes can contribute to circular economy principles through cascading use of biomass and potential for recycling or composting. However, current infrastructure limitations often prevent optimal end-of-life management. Developing appropriate collection and processing systems represents a significant challenge that must be addressed to fully realize the sustainability benefits of these materials.

Policy frameworks increasingly recognize the environmental advantages of bio-based materials, with several jurisdictions implementing incentives for their development and adoption. These include carbon credits, extended producer responsibility schemes, and green procurement policies that can accelerate market penetration of bio-based polymer electrolytes while ensuring their environmental performance meets established standards.

Life Cycle Assessment (LCA) studies indicate that bio-based polymer electrolytes can reduce greenhouse gas emissions by 30-70% compared to conventional petroleum-based counterparts. This reduction stems from the renewable nature of their feedstocks, which sequester carbon during growth phases. However, comprehensive sustainability assessment must consider land use changes, water consumption, and potential competition with food production when agricultural resources are diverted for polymer synthesis.

Water footprint analysis reveals varying impacts depending on the specific bio-polymer source. Cellulose-derived electrolytes typically require less water than those derived from starch or protein sources. Additionally, the processing methods employed significantly influence overall environmental performance, with solvent-free techniques demonstrating superior sustainability profiles compared to traditional solvent-based approaches.

Biodegradability presents another crucial environmental advantage. Studies demonstrate that many bio-based polymer electrolytes can decompose under controlled conditions within 3-12 months, compared to centuries for conventional petroleum-based polymers. This characteristic substantially reduces waste accumulation and microplastic pollution. However, the degradation pathways and potential formation of intermediate compounds require thorough investigation to ensure no harmful substances are released during decomposition.

Toxicity assessments of bio-based polymer electrolytes generally show favorable results compared to conventional systems containing volatile organic compounds. The reduced toxicity profile benefits both environmental systems and human health, particularly in manufacturing environments and during recycling processes. Nevertheless, certain bio-based additives may introduce unexpected ecotoxicological effects that warrant careful screening and regulation.

Resource efficiency metrics indicate that bio-based polymer electrolytes can contribute to circular economy principles through cascading use of biomass and potential for recycling or composting. However, current infrastructure limitations often prevent optimal end-of-life management. Developing appropriate collection and processing systems represents a significant challenge that must be addressed to fully realize the sustainability benefits of these materials.

Policy frameworks increasingly recognize the environmental advantages of bio-based materials, with several jurisdictions implementing incentives for their development and adoption. These include carbon credits, extended producer responsibility schemes, and green procurement policies that can accelerate market penetration of bio-based polymer electrolytes while ensuring their environmental performance meets established standards.

Scalability and Industrial Implementation Strategies

The transition from laboratory-scale production to industrial manufacturing of bio-based polymer electrolytes presents significant challenges that require systematic approaches. Current production methods typically involve small-batch synthesis processes that are difficult to scale without compromising the quality and performance characteristics of the final product. To address this, manufacturers must develop continuous flow processes that maintain precise control over reaction conditions while increasing throughput.

Material sourcing represents another critical consideration for industrial implementation. The availability of consistent, high-quality bio-based feedstocks remains variable, with seasonal fluctuations and regional differences affecting supply chains. Strategic partnerships with agricultural producers and biomass processors can help stabilize supply, while investment in preprocessing technologies may improve feedstock uniformity and reduce production variability.

Process optimization for large-scale production necessitates the development of specialized equipment capable of handling the unique rheological properties of bio-based polymers during synthesis and processing. Modifications to existing polymer processing equipment, including extruders and reactors, may be required to accommodate the different thermal and mechanical sensitivities of these materials compared to petroleum-based alternatives.

Quality control systems must evolve to address the inherent variability of bio-based materials. Implementation of real-time monitoring technologies, such as spectroscopic methods and advanced sensors, can enable continuous assessment of critical quality attributes throughout the production process. This approach supports the principles of Quality by Design (QbD) and Process Analytical Technology (PAT) frameworks increasingly adopted by regulatory agencies.

Cost considerations remain paramount for commercial viability. Current production costs for bio-based polymer electrolytes typically exceed those of conventional alternatives by 30-50%. Achieving cost parity requires economies of scale, process intensification, and valorization of by-products. Integrated biorefinery concepts, where multiple value-added products are derived from the same biomass feedstock, offer promising economic models for sustainable production.

Regulatory pathways for bio-based materials in energy storage applications are still evolving. Manufacturers must engage proactively with regulatory bodies to establish appropriate standards and testing protocols. The development of industry consortia focused on standardization can accelerate this process and reduce market entry barriers for innovative products.

Technology transfer from research institutions to industrial partners requires structured approaches that preserve critical know-how while adapting processes for commercial environments. Pilot-scale demonstration facilities serve as crucial intermediaries in this process, allowing for risk reduction and process validation before full-scale implementation.

Material sourcing represents another critical consideration for industrial implementation. The availability of consistent, high-quality bio-based feedstocks remains variable, with seasonal fluctuations and regional differences affecting supply chains. Strategic partnerships with agricultural producers and biomass processors can help stabilize supply, while investment in preprocessing technologies may improve feedstock uniformity and reduce production variability.

Process optimization for large-scale production necessitates the development of specialized equipment capable of handling the unique rheological properties of bio-based polymers during synthesis and processing. Modifications to existing polymer processing equipment, including extruders and reactors, may be required to accommodate the different thermal and mechanical sensitivities of these materials compared to petroleum-based alternatives.

Quality control systems must evolve to address the inherent variability of bio-based materials. Implementation of real-time monitoring technologies, such as spectroscopic methods and advanced sensors, can enable continuous assessment of critical quality attributes throughout the production process. This approach supports the principles of Quality by Design (QbD) and Process Analytical Technology (PAT) frameworks increasingly adopted by regulatory agencies.

Cost considerations remain paramount for commercial viability. Current production costs for bio-based polymer electrolytes typically exceed those of conventional alternatives by 30-50%. Achieving cost parity requires economies of scale, process intensification, and valorization of by-products. Integrated biorefinery concepts, where multiple value-added products are derived from the same biomass feedstock, offer promising economic models for sustainable production.

Regulatory pathways for bio-based materials in energy storage applications are still evolving. Manufacturers must engage proactively with regulatory bodies to establish appropriate standards and testing protocols. The development of industry consortia focused on standardization can accelerate this process and reduce market entry barriers for innovative products.

Technology transfer from research institutions to industrial partners requires structured approaches that preserve critical know-how while adapting processes for commercial environments. Pilot-scale demonstration facilities serve as crucial intermediaries in this process, allowing for risk reduction and process validation before full-scale implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!