Comparison of Biodegradation Rates: Bio-based Polymer vs Polyethylene

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biodegradable Polymers Background and Objectives

The evolution of polymer materials has been a cornerstone of industrial development since the early 20th century, with conventional plastics like polyethylene dominating packaging, construction, and consumer goods sectors. However, the environmental persistence of these petroleum-based polymers has created unprecedented ecological challenges, with an estimated 8 million metric tons of plastic waste entering oceans annually. This growing environmental crisis has catalyzed research into biodegradable alternatives, particularly bio-based polymers derived from renewable resources.

Biodegradable polymers represent a diverse class of materials that can undergo decomposition through natural biological processes, resulting in simpler compounds that reintegrate into natural cycles. The historical trajectory of biodegradable polymer development began in the 1960s with initial research into polyhydroxyalkanoates (PHAs), followed by polylactic acid (PLA) commercialization in the 1990s. Recent decades have witnessed accelerated innovation in this field, driven by increasing environmental regulations and consumer demand for sustainable materials.

The fundamental distinction between bio-based polymers and conventional polyethylene lies in their molecular structure and origin. While polyethylene consists of long hydrocarbon chains resistant to microbial attack, bio-based polymers typically contain hydrolyzable bonds or functional groups that facilitate enzymatic degradation. This structural difference results in dramatically different environmental persistence profiles, with polyethylene potentially remaining intact for centuries while many bio-based alternatives can degrade within months to years under appropriate conditions.

The technical objectives of this research focus on quantitatively comparing biodegradation rates between various bio-based polymers and conventional polyethylene under standardized conditions. Specifically, we aim to evaluate degradation kinetics in marine, soil, and composting environments, identify environmental factors that influence degradation rates, and assess the formation of microplastics during the degradation process. Additionally, we seek to establish correlations between polymer chemical structure and biodegradation behavior to inform future material design.

Current biodegradable polymer technologies include PLA derived from corn starch or sugarcane, PHAs produced through bacterial fermentation, thermoplastic starch (TPS), cellulose-based polymers, and various bio-polyester blends. Each offers distinct advantages in specific applications, though challenges remain in matching the performance characteristics of conventional plastics while maintaining biodegradability. The technological evolution in this field continues to advance toward materials that combine enhanced functionality with accelerated degradation rates.

The global transition toward circular economy principles has positioned biodegradable polymers as a critical technology for sustainable development. Understanding the comparative biodegradation rates between these materials and conventional polyethylene is essential for informing policy decisions, guiding industry innovation, and addressing the growing plastic pollution crisis with evidence-based solutions.

Biodegradable polymers represent a diverse class of materials that can undergo decomposition through natural biological processes, resulting in simpler compounds that reintegrate into natural cycles. The historical trajectory of biodegradable polymer development began in the 1960s with initial research into polyhydroxyalkanoates (PHAs), followed by polylactic acid (PLA) commercialization in the 1990s. Recent decades have witnessed accelerated innovation in this field, driven by increasing environmental regulations and consumer demand for sustainable materials.

The fundamental distinction between bio-based polymers and conventional polyethylene lies in their molecular structure and origin. While polyethylene consists of long hydrocarbon chains resistant to microbial attack, bio-based polymers typically contain hydrolyzable bonds or functional groups that facilitate enzymatic degradation. This structural difference results in dramatically different environmental persistence profiles, with polyethylene potentially remaining intact for centuries while many bio-based alternatives can degrade within months to years under appropriate conditions.

The technical objectives of this research focus on quantitatively comparing biodegradation rates between various bio-based polymers and conventional polyethylene under standardized conditions. Specifically, we aim to evaluate degradation kinetics in marine, soil, and composting environments, identify environmental factors that influence degradation rates, and assess the formation of microplastics during the degradation process. Additionally, we seek to establish correlations between polymer chemical structure and biodegradation behavior to inform future material design.

Current biodegradable polymer technologies include PLA derived from corn starch or sugarcane, PHAs produced through bacterial fermentation, thermoplastic starch (TPS), cellulose-based polymers, and various bio-polyester blends. Each offers distinct advantages in specific applications, though challenges remain in matching the performance characteristics of conventional plastics while maintaining biodegradability. The technological evolution in this field continues to advance toward materials that combine enhanced functionality with accelerated degradation rates.

The global transition toward circular economy principles has positioned biodegradable polymers as a critical technology for sustainable development. Understanding the comparative biodegradation rates between these materials and conventional polyethylene is essential for informing policy decisions, guiding industry innovation, and addressing the growing plastic pollution crisis with evidence-based solutions.

Market Analysis for Sustainable Packaging Solutions

The sustainable packaging market has witnessed significant growth in recent years, driven by increasing environmental awareness and regulatory pressures. Currently valued at approximately $274 billion globally, this market is projected to reach $413 billion by 2027, representing a compound annual growth rate of 8.6%. This growth trajectory is particularly evident in regions with stringent environmental regulations, such as Europe and North America, where consumer demand for eco-friendly packaging solutions continues to rise.

Consumer preferences have shifted dramatically toward sustainable alternatives, with recent surveys indicating that 73% of consumers are willing to pay a premium for products with environmentally friendly packaging. This shift is most pronounced among millennials and Gen Z consumers, who demonstrate stronger environmental consciousness in their purchasing decisions. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, further accelerating market demand.

The biodegradable polymer segment, particularly relevant to the comparison between bio-based polymers and polyethylene, represents one of the fastest-growing sectors within sustainable packaging. This segment is expanding at approximately 9.5% annually, outpacing the broader packaging market. Bio-based polymers derived from renewable resources such as corn starch, sugarcane, and cellulose are gaining significant traction due to their reduced carbon footprint and enhanced biodegradability compared to conventional polyethylene.

Regulatory frameworks worldwide are increasingly favoring biodegradable alternatives. The European Union's Single-Use Plastics Directive, implemented in 2021, has accelerated the transition away from conventional plastics. Similarly, over 127 countries have introduced some form of regulation on plastic bags, creating substantial market opportunities for bio-based alternatives with superior biodegradation rates.

Industry analysis reveals that food and beverage packaging accounts for the largest application segment (42%) for biodegradable polymers, followed by personal care products (18%) and healthcare packaging (15%). This distribution reflects both consumer-facing priorities and technical requirements for different product categories.

Despite positive growth indicators, price sensitivity remains a significant market constraint. Bio-based polymers typically command a 20-30% premium over conventional polyethylene, though this gap has been narrowing as production scales increase. Market research indicates that price parity could be achieved within 5-7 years for certain bio-polymer categories, potentially triggering more widespread adoption across price-sensitive market segments.

The competitive landscape features both established petrochemical companies diversifying into bio-based solutions and specialized startups focused exclusively on innovative biodegradable materials. This dynamic is creating a robust innovation ecosystem that continues to improve the performance characteristics and cost-effectiveness of bio-based alternatives to polyethylene.

Consumer preferences have shifted dramatically toward sustainable alternatives, with recent surveys indicating that 73% of consumers are willing to pay a premium for products with environmentally friendly packaging. This shift is most pronounced among millennials and Gen Z consumers, who demonstrate stronger environmental consciousness in their purchasing decisions. Major retail chains and consumer goods companies have responded by establishing ambitious sustainability targets, further accelerating market demand.

The biodegradable polymer segment, particularly relevant to the comparison between bio-based polymers and polyethylene, represents one of the fastest-growing sectors within sustainable packaging. This segment is expanding at approximately 9.5% annually, outpacing the broader packaging market. Bio-based polymers derived from renewable resources such as corn starch, sugarcane, and cellulose are gaining significant traction due to their reduced carbon footprint and enhanced biodegradability compared to conventional polyethylene.

Regulatory frameworks worldwide are increasingly favoring biodegradable alternatives. The European Union's Single-Use Plastics Directive, implemented in 2021, has accelerated the transition away from conventional plastics. Similarly, over 127 countries have introduced some form of regulation on plastic bags, creating substantial market opportunities for bio-based alternatives with superior biodegradation rates.

Industry analysis reveals that food and beverage packaging accounts for the largest application segment (42%) for biodegradable polymers, followed by personal care products (18%) and healthcare packaging (15%). This distribution reflects both consumer-facing priorities and technical requirements for different product categories.

Despite positive growth indicators, price sensitivity remains a significant market constraint. Bio-based polymers typically command a 20-30% premium over conventional polyethylene, though this gap has been narrowing as production scales increase. Market research indicates that price parity could be achieved within 5-7 years for certain bio-polymer categories, potentially triggering more widespread adoption across price-sensitive market segments.

The competitive landscape features both established petrochemical companies diversifying into bio-based solutions and specialized startups focused exclusively on innovative biodegradable materials. This dynamic is creating a robust innovation ecosystem that continues to improve the performance characteristics and cost-effectiveness of bio-based alternatives to polyethylene.

Current Biodegradation Technologies and Barriers

Current biodegradation technologies for polymers operate through several distinct mechanisms, with microbial degradation being the predominant natural process. Microorganisms such as bacteria and fungi secrete enzymes that break down polymer chains into smaller fragments, eventually converting them to carbon dioxide, water, and biomass. This process is significantly more effective for bio-based polymers compared to conventional polyethylene due to fundamental structural differences.

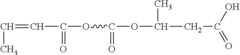

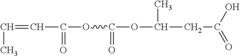

Bio-based polymers typically contain oxygen-rich functional groups (esters, amides) that provide accessible sites for enzymatic attack. In contrast, polyethylene consists of long hydrocarbon chains with strong C-C bonds and lacks these vulnerable points, making it highly resistant to biodegradation. Current technologies have achieved biodegradation rates for some bio-based polymers (such as PLA and PHA) ranging from weeks to months under optimal conditions, while conventional polyethylene may persist for centuries.

Industrial composting represents a controlled biodegradation technology that accelerates the process through optimized temperature (55-60°C), moisture (45-55%), and microbial activity. However, these facilities are not universally available, creating a geographical barrier to effective biodegradation. Additionally, many bio-based polymers require these specific industrial composting conditions and degrade poorly in ambient environments or marine settings.

Enzymatic degradation technologies have shown promise in laboratory settings, with engineered enzymes demonstrating capability to break down even resistant polymers. Recent breakthroughs include the discovery of PETase and MHETase enzymes that can degrade PET plastic. However, scaling these enzymatic approaches to industrial levels remains challenging due to cost constraints and efficiency limitations in real-world conditions.

A significant technological barrier is the trade-off between biodegradability and material performance. Enhancing biodegradation rates often compromises mechanical properties, durability, and processing characteristics. This creates a fundamental challenge for manufacturers seeking to replace conventional polyethylene with bio-based alternatives while maintaining performance standards.

Analytical barriers also exist in standardizing biodegradation measurements. Current testing protocols vary widely, from soil burial tests to respirometric methods measuring CO2 evolution. This inconsistency makes direct comparisons between materials difficult and creates market confusion. Furthermore, many tests are conducted under idealized laboratory conditions that poorly represent real-world disposal environments.

Regulatory frameworks present additional barriers, with inconsistent global standards for biodegradability claims. Some regions require industrial composting certification, while others permit broader environmental claims with minimal verification. This regulatory patchwork complicates technology development and market adoption of truly biodegradable alternatives to polyethylene.

Bio-based polymers typically contain oxygen-rich functional groups (esters, amides) that provide accessible sites for enzymatic attack. In contrast, polyethylene consists of long hydrocarbon chains with strong C-C bonds and lacks these vulnerable points, making it highly resistant to biodegradation. Current technologies have achieved biodegradation rates for some bio-based polymers (such as PLA and PHA) ranging from weeks to months under optimal conditions, while conventional polyethylene may persist for centuries.

Industrial composting represents a controlled biodegradation technology that accelerates the process through optimized temperature (55-60°C), moisture (45-55%), and microbial activity. However, these facilities are not universally available, creating a geographical barrier to effective biodegradation. Additionally, many bio-based polymers require these specific industrial composting conditions and degrade poorly in ambient environments or marine settings.

Enzymatic degradation technologies have shown promise in laboratory settings, with engineered enzymes demonstrating capability to break down even resistant polymers. Recent breakthroughs include the discovery of PETase and MHETase enzymes that can degrade PET plastic. However, scaling these enzymatic approaches to industrial levels remains challenging due to cost constraints and efficiency limitations in real-world conditions.

A significant technological barrier is the trade-off between biodegradability and material performance. Enhancing biodegradation rates often compromises mechanical properties, durability, and processing characteristics. This creates a fundamental challenge for manufacturers seeking to replace conventional polyethylene with bio-based alternatives while maintaining performance standards.

Analytical barriers also exist in standardizing biodegradation measurements. Current testing protocols vary widely, from soil burial tests to respirometric methods measuring CO2 evolution. This inconsistency makes direct comparisons between materials difficult and creates market confusion. Furthermore, many tests are conducted under idealized laboratory conditions that poorly represent real-world disposal environments.

Regulatory frameworks present additional barriers, with inconsistent global standards for biodegradability claims. Some regions require industrial composting certification, while others permit broader environmental claims with minimal verification. This regulatory patchwork complicates technology development and market adoption of truly biodegradable alternatives to polyethylene.

Comparative Biodegradation Methodologies

01 Biodegradation rates of bio-based polymers compared to polyethylene

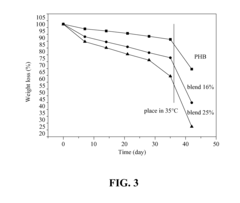

Bio-based polymers generally exhibit higher biodegradation rates compared to conventional polyethylene. These polymers, derived from renewable resources, can degrade under various environmental conditions through microbial action. The biodegradation process typically involves the breakdown of polymer chains into smaller molecules that can be assimilated by microorganisms. Factors affecting biodegradation rates include polymer composition, environmental conditions, and the presence of specific microorganisms.- Biodegradation rates of bio-based polymers compared to polyethylene: Bio-based polymers generally exhibit faster biodegradation rates compared to conventional polyethylene. Studies have shown that while traditional polyethylene may take hundreds of years to degrade, certain bio-based polymers can biodegrade within months to a few years depending on environmental conditions. The biodegradation process involves microorganisms breaking down the polymer chains into simpler compounds, eventually resulting in carbon dioxide, water, and biomass.

- Additives to enhance biodegradation of polyethylene: Various additives can be incorporated into polyethylene to enhance its biodegradation rate. These include pro-oxidants, bio-based fillers, and specific enzymes that can catalyze the breakdown of polymer chains. The additives work by creating vulnerable points in the polymer structure, making it more susceptible to microbial attack and environmental degradation. This approach allows for the production of modified polyethylene with improved end-of-life characteristics while maintaining desired performance properties during use.

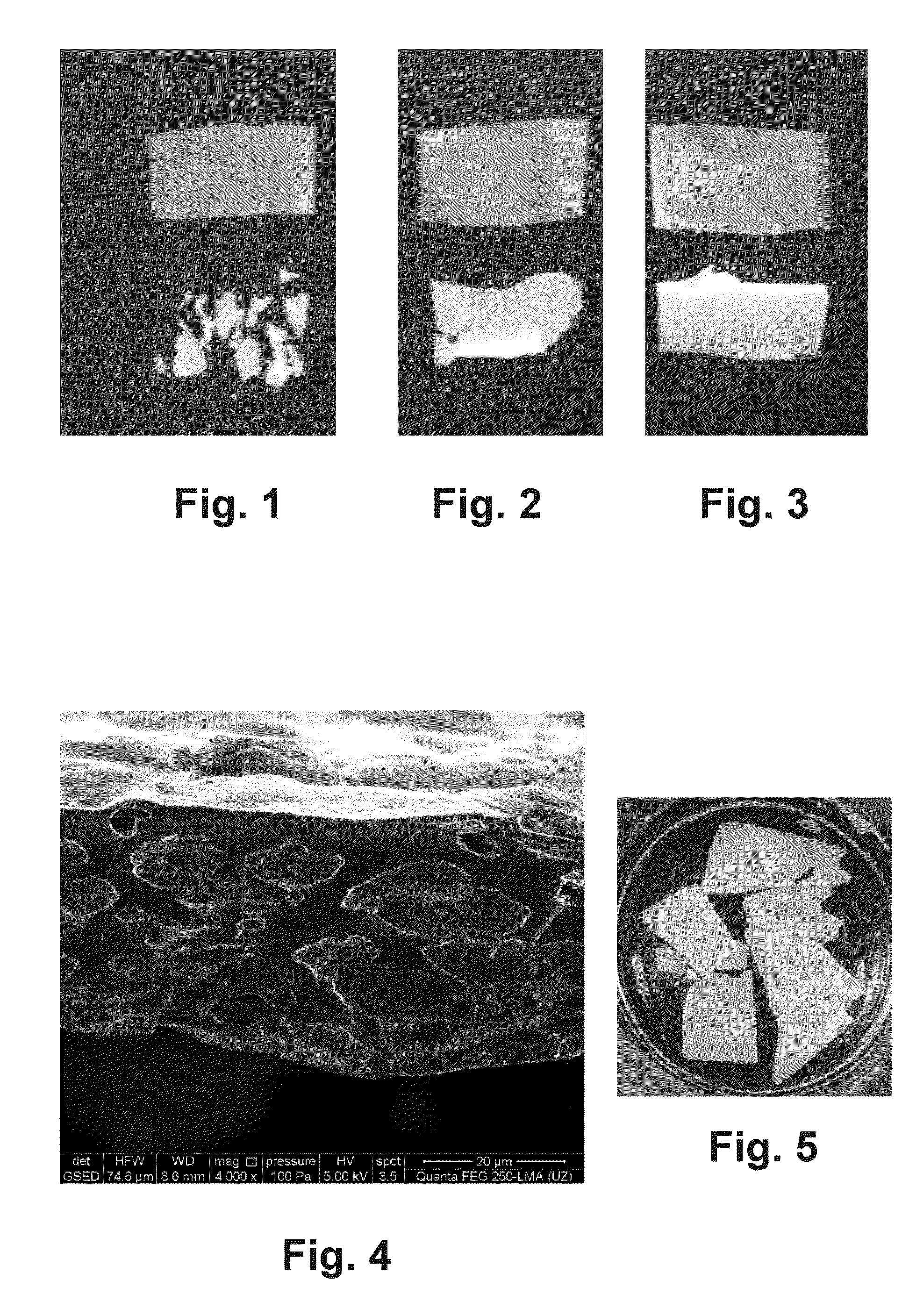

- Blends of bio-based polymers with polyethylene for controlled degradation: Blending bio-based polymers with polyethylene creates materials with tailored biodegradation rates. These blends combine the durability of polyethylene with the biodegradability of bio-based polymers. The ratio of components can be adjusted to achieve specific degradation timeframes suitable for different applications. Additionally, the morphology of the blend, including phase separation and interfacial adhesion, significantly influences the overall biodegradation behavior of the composite material.

- Environmental factors affecting biodegradation rates: The biodegradation rates of both bio-based polymers and polyethylene are significantly influenced by environmental conditions. Factors such as temperature, moisture, pH, oxygen availability, and microbial populations play crucial roles in determining degradation speed. Laboratory testing often shows different results compared to real-world conditions, making standardized testing protocols essential for accurate comparison. Understanding these environmental factors helps in predicting the actual biodegradation behavior of materials in various disposal scenarios.

- Novel bio-based polymers with enhanced biodegradation properties: Recent innovations have led to the development of novel bio-based polymers specifically designed for enhanced biodegradation rates. These advanced materials incorporate optimized molecular structures, controlled crystallinity, and strategic functional groups that facilitate microbial attack. Some of these polymers can achieve complete biodegradation in composting conditions within weeks while maintaining performance properties comparable to conventional polyethylene during their intended use period. These innovations represent significant progress toward sustainable alternatives to traditional petroleum-based plastics.

02 Additives to enhance biodegradation of polyethylene

Various additives can be incorporated into polyethylene to enhance its biodegradation rate. These additives include pro-oxidants, bio-based fillers, and specific enzymes that can catalyze the breakdown of polymer chains. The additives work by creating vulnerable points in the polymer structure, making it more susceptible to microbial attack. By incorporating these additives, conventional polyethylene can achieve improved biodegradation rates while maintaining necessary performance characteristics during its useful life.Expand Specific Solutions03 Blends of bio-based polymers with polyethylene for controlled biodegradation

Blending bio-based polymers with polyethylene creates materials with tailored biodegradation rates. These blends combine the durability of polyethylene with the biodegradability of bio-based polymers. The ratio of components in the blend significantly affects the overall biodegradation rate, with higher bio-based content generally resulting in faster degradation. These blends offer a practical approach to reducing environmental persistence while maintaining necessary material properties for various applications.Expand Specific Solutions04 Environmental factors affecting biodegradation rates

Environmental conditions significantly impact the biodegradation rates of both bio-based polymers and polyethylene. Factors such as temperature, moisture, pH, oxygen availability, and microbial populations play crucial roles in determining degradation rates. Bio-based polymers typically show accelerated degradation in composting conditions with elevated temperatures and humidity, while polyethylene requires more extreme conditions or longer timeframes for significant biodegradation to occur.Expand Specific Solutions05 Novel bio-based polymer formulations with enhanced biodegradation

Recent innovations have led to the development of novel bio-based polymer formulations with significantly enhanced biodegradation rates. These formulations incorporate specific molecular structures, such as ester linkages or other hydrolyzable bonds, that are more susceptible to enzymatic attack. Some formulations also include specialized microorganisms or enzymes that target the polymer structure. These advanced bio-based polymers can achieve complete biodegradation in weeks or months, compared to decades or centuries for conventional polyethylene.Expand Specific Solutions

Leading Companies in Biodegradable Materials

The biodegradable polymer market is currently in a growth phase, with increasing demand driven by environmental concerns and regulatory pressures against conventional plastics. The global bio-based polymer market is projected to reach approximately $25 billion by 2025, growing at a CAGR of 18%. Technologically, biodegradation rates vary significantly between materials, with companies like Novamont, BioLogiQ, and Kingfa leading innovation in fully biodegradable polymers that decompose 10-100 times faster than conventional polyethylene. BASF and PTT Global Chemical are investing heavily in bio-based alternatives, while Solugen and Stora Enso are pioneering novel enzymatic degradation approaches. The competitive landscape features established chemical corporations alongside specialized startups, with technological maturity varying from commercially available products to early-stage research developments.

Bio-Tec Environmental LLC

Technical Solution: Bio-Tec Environmental has developed EcoPure®, an organic additive technology that enhances the biodegradability of conventional polymers including polyethylene. Their proprietary additive creates microenvironments within the polymer matrix that attract microbial activity, leading to accelerated biodegradation compared to untreated polyethylene. Laboratory testing using ASTM D5511 protocols shows that polyethylene treated with EcoPure® can achieve 15-30% biodegradation within 12-18 months in landfill conditions, while untreated polyethylene shows less than 5% degradation over the same period. Bio-Tec's technology focuses on maintaining the performance characteristics of conventional plastics while introducing biodegradable elements that serve as initiators for the breakdown process. Their latest generation additives incorporate organic compounds that serve as nutrients for microorganisms, further accelerating the biodegradation process without compromising the material's functional properties during its intended use period.

Strengths: Can be incorporated into existing polyethylene production with minimal process changes; maintains performance properties of conventional plastics; enables gradual transition to more sustainable materials. Weaknesses: Significantly slower biodegradation rates compared to fully bio-based polymers; environmental benefits limited by the fundamental structure of polyethylene; effectiveness varies widely depending on disposal environment conditions.

Novamont SpA

Technical Solution: Novamont has developed Mater-Bi, a family of biodegradable and compostable bioplastics made from starches, cellulose, vegetable oils, and their combinations. Their proprietary technology creates polymers that can biodegrade in soil, fresh water, and marine environments. Independent studies show Mater-Bi products degrade 40-90% within 180 days in composting conditions, compared to conventional polyethylene which may take hundreds of years to degrade. Novamont's approach involves creating complex biopolyester structures with controlled biodegradation rates through the incorporation of specific functional groups that enhance microbial accessibility. Their latest generation products combine biodegradability with durability during use, addressing a key challenge in bio-based polymer applications.

Strengths: Industry-leading biodegradation rates in multiple environments; versatile application range from packaging to agriculture; products maintain functional properties during intended use period. Weaknesses: Higher production costs compared to conventional polyethylene; some formulations show variable degradation rates depending on environmental conditions; requires specific industrial composting facilities for optimal end-of-life management.

Key Scientific Advances in Polymer Decomposition

Bio-Based and Biodegradable Polymer

PatentActiveUS20140296389A1

Innovation

- A bio-based and biodegradable polymer comprising thermoplastic starch in a co-continuous or continuous phase with a polymer from a stable water or latex dispersion, allowing for increased starch content and improved processing and properties through the use of synthetic or natural latex as a binder and plasticizer.

Biodegradable polymer and method for manufacturing the same

PatentInactiveUS20120232185A1

Innovation

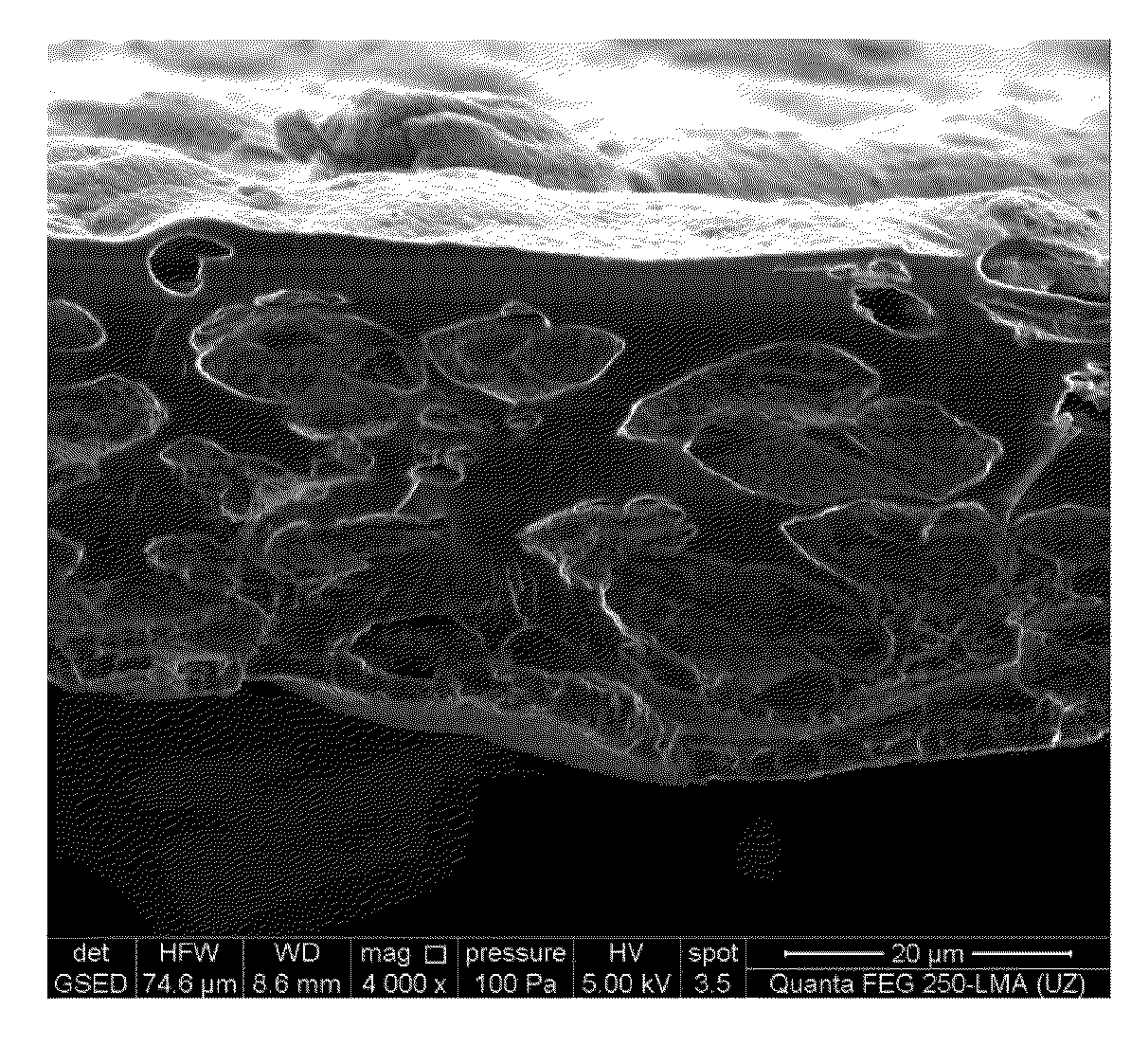

- A biodegradable polymer is created by blending low molecular weight poly-3-hydroxybutyrate (LMWPHB) with high molecular weight polymers, using a method involving mixing with polyethylene glycol, nitrogen atmosphere, heated reaction, and rinsing to produce a degradation-enhancing additive that speeds up bacterial degradation.

Environmental Impact Assessment Framework

The Environmental Impact Assessment Framework for comparing biodegradation rates between bio-based polymers and polyethylene must establish comprehensive methodologies that account for multiple ecological factors. This framework begins with standardized testing protocols that measure decomposition under various environmental conditions, including soil burial tests, composting environments, and marine exposure scenarios.

Key parameters within this framework include time-to-complete degradation, intermediate breakdown products, and the ecological impact of residual materials. For bio-based polymers, assessments typically show 80-95% degradation within 180 days under industrial composting conditions, while conventional polyethylene may persist for centuries with minimal degradation (less than 1% over decades).

The framework incorporates life cycle assessment (LCA) methodologies to evaluate environmental impacts from raw material extraction through disposal. This includes quantification of carbon footprint, water usage, energy consumption, and potential toxicity of degradation byproducts. Bio-based polymers generally demonstrate significantly lower environmental impacts during degradation, with reduced greenhouse gas emissions and absence of microplastic formation.

Standardized testing methods within the framework include ISO 14855 for aerobic biodegradability, ASTM D5338 for controlled composting conditions, and OECD 301 for ready biodegradability in aqueous medium. These protocols ensure consistent measurement approaches across different polymer types and environmental scenarios.

The assessment framework also evaluates ecosystem impacts through ecotoxicological testing of degradation products on soil microbiota, aquatic organisms, and plant systems. This includes monitoring changes in microbial community structures and potential bioaccumulation of persistent compounds.

Regional environmental factors must be incorporated into the framework, as biodegradation rates vary significantly based on temperature, humidity, UV exposure, and microbial activity. The framework therefore includes adjustment factors for different geographical and climatic conditions to provide realistic degradation timelines.

Regulatory compliance metrics form another critical component, measuring alignment with international standards such as EN 13432 (European compostability standard) and ASTM D6400 (American biodegradability standard). These standards establish minimum thresholds for biodegradation rates, disintegration, and ecotoxicity that materials must meet to receive certification.

Key parameters within this framework include time-to-complete degradation, intermediate breakdown products, and the ecological impact of residual materials. For bio-based polymers, assessments typically show 80-95% degradation within 180 days under industrial composting conditions, while conventional polyethylene may persist for centuries with minimal degradation (less than 1% over decades).

The framework incorporates life cycle assessment (LCA) methodologies to evaluate environmental impacts from raw material extraction through disposal. This includes quantification of carbon footprint, water usage, energy consumption, and potential toxicity of degradation byproducts. Bio-based polymers generally demonstrate significantly lower environmental impacts during degradation, with reduced greenhouse gas emissions and absence of microplastic formation.

Standardized testing methods within the framework include ISO 14855 for aerobic biodegradability, ASTM D5338 for controlled composting conditions, and OECD 301 for ready biodegradability in aqueous medium. These protocols ensure consistent measurement approaches across different polymer types and environmental scenarios.

The assessment framework also evaluates ecosystem impacts through ecotoxicological testing of degradation products on soil microbiota, aquatic organisms, and plant systems. This includes monitoring changes in microbial community structures and potential bioaccumulation of persistent compounds.

Regional environmental factors must be incorporated into the framework, as biodegradation rates vary significantly based on temperature, humidity, UV exposure, and microbial activity. The framework therefore includes adjustment factors for different geographical and climatic conditions to provide realistic degradation timelines.

Regulatory compliance metrics form another critical component, measuring alignment with international standards such as EN 13432 (European compostability standard) and ASTM D6400 (American biodegradability standard). These standards establish minimum thresholds for biodegradation rates, disintegration, and ecotoxicity that materials must meet to receive certification.

Standardization and Testing Protocols

The standardization of biodegradation testing protocols is crucial for accurate comparison between bio-based polymers and conventional polyethylene. Currently, several internationally recognized standards govern biodegradation testing, including ASTM D5338, ISO 14855, and EN 13432, which focus on aerobic biodegradation under controlled composting conditions. These standards provide methodological frameworks for measuring CO2 evolution as microorganisms metabolize polymer materials.

For aquatic environments, ASTM D6691 and ISO 14851 offer standardized approaches to measure biodegradation in marine and freshwater conditions respectively. These protocols typically monitor oxygen consumption or carbon dioxide production over specified timeframes, usually ranging from 45 to 180 days depending on the test environment.

A significant challenge in standardization lies in the variability of real-world environmental conditions versus laboratory settings. Temperature, microbial populations, pH levels, and available oxygen significantly impact degradation rates, making direct comparisons between different studies problematic without standardized conditions.

Testing protocols generally involve several key parameters: inoculum preparation (using standardized microbial consortia), sample preparation (controlling surface area and thickness), environmental conditions (temperature, humidity, pH), and measurement techniques (respirometry, mass loss, molecular weight changes, or spectroscopic analysis).

Recent advancements in testing methodologies include accelerated aging techniques that simulate long-term environmental exposure and molecular-level analysis using FTIR and NMR spectroscopy to track chemical changes during degradation. These techniques provide more comprehensive insights into degradation mechanisms beyond simple mass loss measurements.

Certification systems like TÜV Austria's "OK Compost" and the Biodegradable Products Institute's certification program have established standardized criteria for biodegradability claims. These certifications typically require materials to demonstrate 90% biodegradation within 180 days under controlled composting conditions.

Emerging efforts focus on developing standardized protocols for measuring microplastic formation during incomplete biodegradation, addressing concerns about persistent polymer fragments. Additionally, there is growing recognition of the need for standardized tests that better simulate specific end-of-life scenarios such as home composting, soil burial, and various aquatic environments.

Harmonization of testing protocols across different regulatory jurisdictions remains an ongoing challenge, with efforts underway through international standards organizations to develop globally accepted methodologies for biodegradation assessment.

For aquatic environments, ASTM D6691 and ISO 14851 offer standardized approaches to measure biodegradation in marine and freshwater conditions respectively. These protocols typically monitor oxygen consumption or carbon dioxide production over specified timeframes, usually ranging from 45 to 180 days depending on the test environment.

A significant challenge in standardization lies in the variability of real-world environmental conditions versus laboratory settings. Temperature, microbial populations, pH levels, and available oxygen significantly impact degradation rates, making direct comparisons between different studies problematic without standardized conditions.

Testing protocols generally involve several key parameters: inoculum preparation (using standardized microbial consortia), sample preparation (controlling surface area and thickness), environmental conditions (temperature, humidity, pH), and measurement techniques (respirometry, mass loss, molecular weight changes, or spectroscopic analysis).

Recent advancements in testing methodologies include accelerated aging techniques that simulate long-term environmental exposure and molecular-level analysis using FTIR and NMR spectroscopy to track chemical changes during degradation. These techniques provide more comprehensive insights into degradation mechanisms beyond simple mass loss measurements.

Certification systems like TÜV Austria's "OK Compost" and the Biodegradable Products Institute's certification program have established standardized criteria for biodegradability claims. These certifications typically require materials to demonstrate 90% biodegradation within 180 days under controlled composting conditions.

Emerging efforts focus on developing standardized protocols for measuring microplastic formation during incomplete biodegradation, addressing concerns about persistent polymer fragments. Additionally, there is growing recognition of the need for standardized tests that better simulate specific end-of-life scenarios such as home composting, soil burial, and various aquatic environments.

Harmonization of testing protocols across different regulatory jurisdictions remains an ongoing challenge, with efforts underway through international standards organizations to develop globally accepted methodologies for biodegradation assessment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!