Investigation into Bio-based Polymer Recycling Processes

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Polymer Recycling Background and Objectives

Bio-based polymers have emerged as a sustainable alternative to conventional petroleum-based plastics, addressing growing environmental concerns about plastic pollution and resource depletion. Since the early 2000s, the development of these materials has accelerated significantly, driven by advances in biotechnology, green chemistry, and materials science. The evolution of bio-polymers has progressed from simple starch-based materials to sophisticated engineered polymers with performance characteristics comparable to traditional plastics.

The global shift toward circular economy principles has placed increased emphasis on not only the production of bio-based polymers but also their end-of-life management. Despite their biological origins, many bio-polymers present recycling challenges distinct from conventional plastics, requiring specialized processes and technologies. This investigation aims to comprehensively assess current and emerging recycling methodologies specifically tailored for bio-based polymer materials.

The primary objective of this research is to evaluate the technical feasibility, economic viability, and environmental benefits of various bio-polymer recycling processes. We seek to identify optimal recycling pathways for different categories of bio-based polymers, including polylactic acid (PLA), polyhydroxyalkanoates (PHAs), bio-polyethylene, and various cellulose-derived materials. Additionally, this investigation will assess how these recycling technologies align with broader sustainability goals and regulatory frameworks.

Current trends indicate a growing market for bio-based polymers, with annual growth rates exceeding 15% in some sectors. However, the recycling infrastructure for these materials remains underdeveloped compared to conventional plastics. This gap presents both a challenge and an opportunity for technological innovation and market development. Our investigation will explore how advances in enzymatic degradation, chemical recycling, and mechanical processing are reshaping the recyclability landscape for bio-polymers.

The technological trajectory suggests several promising directions, including the development of bio-polymers specifically designed for recyclability, integrated bio-refineries capable of processing mixed bio-polymer waste streams, and novel catalytic systems that enable efficient depolymerization and recovery of valuable monomers. These developments could potentially transform bio-polymers from being merely biodegradable alternatives to becoming fully recyclable materials that support closed-loop manufacturing systems.

This research will also examine the intersection of bio-polymer recycling with other emerging technologies, such as artificial intelligence for waste sorting, advanced spectroscopic techniques for polymer identification, and distributed recycling systems that could enable localized processing of bio-polymer waste. The ultimate goal is to establish a comprehensive technological roadmap that guides future research and development efforts in this rapidly evolving field.

The global shift toward circular economy principles has placed increased emphasis on not only the production of bio-based polymers but also their end-of-life management. Despite their biological origins, many bio-polymers present recycling challenges distinct from conventional plastics, requiring specialized processes and technologies. This investigation aims to comprehensively assess current and emerging recycling methodologies specifically tailored for bio-based polymer materials.

The primary objective of this research is to evaluate the technical feasibility, economic viability, and environmental benefits of various bio-polymer recycling processes. We seek to identify optimal recycling pathways for different categories of bio-based polymers, including polylactic acid (PLA), polyhydroxyalkanoates (PHAs), bio-polyethylene, and various cellulose-derived materials. Additionally, this investigation will assess how these recycling technologies align with broader sustainability goals and regulatory frameworks.

Current trends indicate a growing market for bio-based polymers, with annual growth rates exceeding 15% in some sectors. However, the recycling infrastructure for these materials remains underdeveloped compared to conventional plastics. This gap presents both a challenge and an opportunity for technological innovation and market development. Our investigation will explore how advances in enzymatic degradation, chemical recycling, and mechanical processing are reshaping the recyclability landscape for bio-polymers.

The technological trajectory suggests several promising directions, including the development of bio-polymers specifically designed for recyclability, integrated bio-refineries capable of processing mixed bio-polymer waste streams, and novel catalytic systems that enable efficient depolymerization and recovery of valuable monomers. These developments could potentially transform bio-polymers from being merely biodegradable alternatives to becoming fully recyclable materials that support closed-loop manufacturing systems.

This research will also examine the intersection of bio-polymer recycling with other emerging technologies, such as artificial intelligence for waste sorting, advanced spectroscopic techniques for polymer identification, and distributed recycling systems that could enable localized processing of bio-polymer waste. The ultimate goal is to establish a comprehensive technological roadmap that guides future research and development efforts in this rapidly evolving field.

Market Analysis for Bio-based Polymer Recycling

The global market for bio-based polymer recycling is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures. Currently valued at approximately $6.3 billion in 2023, this market is projected to reach $10.5 billion by 2028, representing a compound annual growth rate (CAGR) of 10.7%. This growth trajectory reflects the expanding adoption of sustainable materials across various industries and the urgent need for effective recycling solutions.

Consumer demand for environmentally friendly products continues to rise, with recent surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable packaging options. This shift in consumer preference has prompted major brands across food and beverage, cosmetics, and consumer goods sectors to commit to incorporating recycled bio-based polymers into their product packaging.

Regionally, Europe leads the market with approximately 38% share, followed by North America (29%) and Asia-Pacific (24%). European dominance can be attributed to stringent regulations such as the European Green Deal and Circular Economy Action Plan, which mandate increased recycling rates and reduced plastic waste. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 12.3% annually, driven by rapid industrialization, growing environmental awareness, and supportive government initiatives in countries like China, Japan, and South Korea.

By application segment, packaging remains the largest market for recycled bio-based polymers, accounting for 45% of total demand. This is followed by automotive applications (18%), textiles (15%), and construction materials (12%). The packaging sector's dominance stems from increasing regulations targeting single-use plastics and growing consumer preference for sustainable packaging solutions.

Key market challenges include high processing costs, which currently make recycled bio-based polymers approximately 20-30% more expensive than virgin petroleum-based alternatives. Additionally, inconsistent feedstock quality and limited collection infrastructure present significant barriers to market expansion. The price sensitivity remains particularly acute in emerging economies where cost considerations often outweigh sustainability concerns.

Market analysts predict that technological advancements in enzymatic and chemical recycling processes could reduce processing costs by up to 40% within the next five years, potentially accelerating market adoption. Furthermore, extended producer responsibility (EPR) schemes being implemented across 65 countries worldwide are expected to improve collection rates and feedstock quality, addressing critical supply chain challenges in the bio-based polymer recycling ecosystem.

Consumer demand for environmentally friendly products continues to rise, with recent surveys indicating that 73% of global consumers are willing to pay premium prices for sustainable packaging options. This shift in consumer preference has prompted major brands across food and beverage, cosmetics, and consumer goods sectors to commit to incorporating recycled bio-based polymers into their product packaging.

Regionally, Europe leads the market with approximately 38% share, followed by North America (29%) and Asia-Pacific (24%). European dominance can be attributed to stringent regulations such as the European Green Deal and Circular Economy Action Plan, which mandate increased recycling rates and reduced plastic waste. The Asia-Pacific region, however, is expected to witness the fastest growth rate of 12.3% annually, driven by rapid industrialization, growing environmental awareness, and supportive government initiatives in countries like China, Japan, and South Korea.

By application segment, packaging remains the largest market for recycled bio-based polymers, accounting for 45% of total demand. This is followed by automotive applications (18%), textiles (15%), and construction materials (12%). The packaging sector's dominance stems from increasing regulations targeting single-use plastics and growing consumer preference for sustainable packaging solutions.

Key market challenges include high processing costs, which currently make recycled bio-based polymers approximately 20-30% more expensive than virgin petroleum-based alternatives. Additionally, inconsistent feedstock quality and limited collection infrastructure present significant barriers to market expansion. The price sensitivity remains particularly acute in emerging economies where cost considerations often outweigh sustainability concerns.

Market analysts predict that technological advancements in enzymatic and chemical recycling processes could reduce processing costs by up to 40% within the next five years, potentially accelerating market adoption. Furthermore, extended producer responsibility (EPR) schemes being implemented across 65 countries worldwide are expected to improve collection rates and feedstock quality, addressing critical supply chain challenges in the bio-based polymer recycling ecosystem.

Current Challenges in Bio-Polymer Recycling Technologies

Despite significant advancements in bio-based polymer development, recycling these materials presents unique challenges compared to conventional plastics. The heterogeneous nature of bio-polymers, which often contain various additives and blends, complicates sorting and separation processes. Current automated sorting technologies struggle to accurately identify different bio-polymer types, leading to contamination in recycling streams and diminished quality of recycled materials.

Mechanical recycling of bio-polymers faces substantial hurdles due to their inherent biodegradability. Many bio-polymers, such as PLA (polylactic acid) and PHA (polyhydroxyalkanoates), experience significant property degradation during standard recycling processes. The molecular weight reduction and structural changes that occur during reprocessing result in recycled materials with inferior mechanical properties, limiting their application potential in subsequent product cycles.

Chemical recycling technologies for bio-polymers remain underdeveloped compared to those for conventional plastics. While depolymerization and solvolysis show promise, these processes often require high energy inputs and specialized catalysts, making them economically unviable at industrial scales. Additionally, the diverse chemical structures of different bio-polymers necessitate tailored recycling approaches rather than universal solutions.

Contamination presents another significant challenge, as food residues and other organic materials frequently accompany bio-polymer waste. These contaminants can interfere with recycling processes and degrade the quality of recycled materials. Current cleaning technologies are either insufficient or too resource-intensive to effectively address this issue at scale.

The end-of-life biodegradability of many bio-polymers creates a paradoxical challenge for recycling efforts. Materials designed to break down in specific environments may begin degradation before reaching recycling facilities, compromising their recyclability. This inherent tension between biodegradability and recyclability requires careful consideration in both material design and recycling infrastructure development.

Infrastructure limitations further exacerbate these technical challenges. Most existing recycling facilities are designed for conventional plastics and lack the specialized equipment needed to process bio-polymers effectively. The capital investment required to upgrade these facilities represents a significant barrier to widespread bio-polymer recycling implementation.

Regulatory frameworks and standardization for bio-polymer recycling remain inadequate in most regions. The absence of clear guidelines for collection, sorting, and processing creates uncertainty for both manufacturers and recyclers. This regulatory gap, coupled with limited consumer awareness about proper disposal of bio-polymers, results in much of this material being directed to landfills rather than recycling streams.

Mechanical recycling of bio-polymers faces substantial hurdles due to their inherent biodegradability. Many bio-polymers, such as PLA (polylactic acid) and PHA (polyhydroxyalkanoates), experience significant property degradation during standard recycling processes. The molecular weight reduction and structural changes that occur during reprocessing result in recycled materials with inferior mechanical properties, limiting their application potential in subsequent product cycles.

Chemical recycling technologies for bio-polymers remain underdeveloped compared to those for conventional plastics. While depolymerization and solvolysis show promise, these processes often require high energy inputs and specialized catalysts, making them economically unviable at industrial scales. Additionally, the diverse chemical structures of different bio-polymers necessitate tailored recycling approaches rather than universal solutions.

Contamination presents another significant challenge, as food residues and other organic materials frequently accompany bio-polymer waste. These contaminants can interfere with recycling processes and degrade the quality of recycled materials. Current cleaning technologies are either insufficient or too resource-intensive to effectively address this issue at scale.

The end-of-life biodegradability of many bio-polymers creates a paradoxical challenge for recycling efforts. Materials designed to break down in specific environments may begin degradation before reaching recycling facilities, compromising their recyclability. This inherent tension between biodegradability and recyclability requires careful consideration in both material design and recycling infrastructure development.

Infrastructure limitations further exacerbate these technical challenges. Most existing recycling facilities are designed for conventional plastics and lack the specialized equipment needed to process bio-polymers effectively. The capital investment required to upgrade these facilities represents a significant barrier to widespread bio-polymer recycling implementation.

Regulatory frameworks and standardization for bio-polymer recycling remain inadequate in most regions. The absence of clear guidelines for collection, sorting, and processing creates uncertainty for both manufacturers and recyclers. This regulatory gap, coupled with limited consumer awareness about proper disposal of bio-polymers, results in much of this material being directed to landfills rather than recycling streams.

Current Bio-Polymer Recycling Methodologies

01 Chemical recycling of bio-based polymers

Chemical recycling processes for bio-based polymers involve breaking down the polymer chains into their constituent monomers or other valuable chemicals through methods such as hydrolysis, glycolysis, or solvolysis. These processes allow for the recovery of high-quality raw materials that can be used to produce new polymers with properties similar to virgin materials. Chemical recycling is particularly effective for handling mixed or contaminated bio-polymer waste streams that cannot be effectively processed through mechanical recycling.- Chemical recycling methods for bio-based polymers: Chemical recycling processes involve breaking down bio-based polymers into their constituent monomers or other valuable chemicals through methods such as hydrolysis, glycolysis, or solvolysis. These techniques allow for the recovery of building blocks that can be reused to synthesize new polymers with properties similar to virgin materials. Chemical recycling is particularly effective for polymers like PLA (polylactic acid) and other bio-polyesters, enabling a more circular approach to bio-based polymer lifecycle management.

- Mechanical recycling processes for bio-based polymers: Mechanical recycling involves physical processing of bio-based polymer waste through operations such as sorting, washing, grinding, and remelting without changing the chemical structure of the material. This approach is typically less energy-intensive than chemical recycling but may result in some degradation of polymer properties over multiple recycling cycles. Innovations in this area focus on preserving the mechanical and thermal properties of recycled bio-based polymers through the addition of compatibilizers, stabilizers, or through optimized processing conditions.

- Enzymatic and biological degradation processes: Enzymatic and biological recycling processes utilize microorganisms or specific enzymes to break down bio-based polymers under controlled conditions. These methods offer advantages of operating under mild conditions (ambient temperature, neutral pH) and high specificity for target polymers. The processes can convert bio-based polymers into monomers, oligomers, or other valuable compounds that can be recovered and reused in new polymer synthesis, creating a sustainable recycling loop that minimizes environmental impact.

- Composite recycling and separation technologies: Specialized technologies for recycling bio-based polymer composites focus on separating the polymer matrix from reinforcing materials such as natural fibers, minerals, or other additives. These processes may involve selective dissolution, density separation, or other physical separation techniques to recover the bio-based polymer fraction. The development of easily separable composite designs and compatible material combinations facilitates more efficient recycling of complex bio-based polymer products and multi-material applications.

- Upcycling and value-added applications for recycled bio-polymers: Upcycling processes transform recycled bio-based polymers into higher-value materials through chemical modification, blending, or other enhancement techniques. These approaches aim to improve the properties of recycled bio-polymers or create new functionalities that expand their application range. Innovations in this area include the development of reactive extrusion processes, compatibilization techniques for polymer blends, and surface modification methods that enable recycled bio-polymers to be used in more demanding or specialized applications.

02 Mechanical recycling techniques for bio-based polymers

Mechanical recycling of bio-based polymers involves physical processing methods such as sorting, grinding, washing, and re-extrusion to convert waste polymers into new products. These techniques preserve the chemical structure of the polymer while reshaping it for new applications. Mechanical recycling is generally more energy-efficient than chemical recycling but may result in some degradation of polymer properties over multiple recycling cycles. Additives and compatibilizers can be incorporated to enhance the properties of mechanically recycled bio-based polymers.Expand Specific Solutions03 Enzymatic and biological degradation processes

Enzymatic and biological degradation processes utilize microorganisms or specific enzymes to break down bio-based polymers under controlled conditions. These processes can operate at lower temperatures and milder conditions compared to chemical recycling methods, making them more environmentally friendly. Specific enzymes can target particular polymer bonds, allowing for selective depolymerization and recovery of monomers. These biological approaches are particularly suitable for naturally derived polymers such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose-based materials.Expand Specific Solutions04 Composite recycling and separation technologies

Recycling bio-based polymer composites presents unique challenges due to the presence of multiple materials. Advanced separation technologies have been developed to separate bio-based polymers from fillers, reinforcements, or other polymer types in composite materials. These technologies include selective dissolution processes, density-based separation, and advanced sorting techniques using spectroscopic methods. Once separated, the individual components can be processed through appropriate recycling streams, maximizing material recovery and minimizing waste.Expand Specific Solutions05 Upcycling and value-added applications

Upcycling processes transform recycled bio-based polymers into higher-value products rather than downcycling them into lower-quality applications. These processes may involve chemical modification, blending with virgin materials, or incorporating specific additives to enhance properties. Value-added applications for recycled bio-based polymers include specialty films, 3D printing filaments, and high-performance composites. This approach maximizes the economic value of recycled materials while extending their useful lifecycle and reducing environmental impact.Expand Specific Solutions

Key Industry Players in Bio-Polymer Recycling

The bio-based polymer recycling market is in its early growth phase, characterized by increasing research activities and emerging commercial applications. The global market size for bio-based polymers is expanding rapidly, projected to reach significant scale as sustainability concerns drive adoption. Technologically, the field shows varying maturity levels across different recycling processes. Leading players include Novamont and CJ CheilJedang, who have established commercial-scale operations, while academic institutions like The Regents of the University of California and Fraunhofer-Gesellschaft provide research foundations. Companies such as Algenesis and Poly6 Technologies represent innovative startups developing novel recycling approaches. SABIC and ExxonMobil bring traditional petrochemical expertise to bio-based solutions, creating a competitive landscape that balances established industrial players with specialized bio-polymer innovators.

Novamont SpA

Technical Solution: Novamont has developed the MATER-BI technology platform for biodegradable and compostable bioplastics derived from starches, cellulose, vegetable oils, and their combinations. Their recycling process involves a proprietary biorefinery concept where they integrate feedstock production with bioplastic manufacturing. The company employs a cascading biorefinery approach that transforms agricultural waste and dedicated industrial crops into bioplastics through multiple valorization steps. Their recycling technology includes both mechanical recycling for post-industrial scraps and organic recycling (industrial composting) for end-of-life products. Novamont has pioneered the development of biodegradable polyesters that can be processed in conventional plastic equipment while maintaining full biodegradability in composting environments. Their latest innovation includes the development of drop-in solutions where bio-based monomers can replace petroleum-based counterparts in existing polymer production processes, enabling easier integration into current recycling streams.

Strengths: Vertically integrated approach from feedstock to final product; products are both bio-based and biodegradable; established industrial-scale production facilities. Weaknesses: Composting infrastructure not widely available in many regions; higher production costs compared to conventional plastics; performance limitations in certain high-demand applications.

Algenesis Corp.

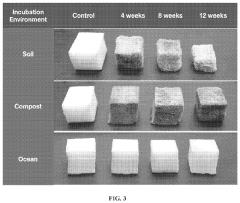

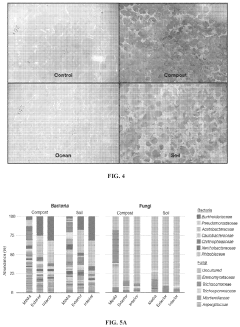

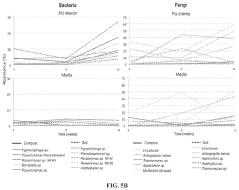

Technical Solution: Algenesis has developed a groundbreaking technology called Soleic™, which creates bio-based polymers derived from algae oil. Their proprietary process converts algae-based polyols into polyurethane materials that maintain the performance characteristics of petroleum-based alternatives while being biodegradable in natural environments. The recycling process involves a closed-loop system where their polymers can be chemically recycled through depolymerization techniques that break down the material into its original monomers, which can then be repolymerized with minimal quality loss. Additionally, their materials are designed to biodegrade in natural environments including soil, compost, and marine conditions, addressing end-of-life concerns. Algenesis has demonstrated that their materials can degrade by over 90% in marine environments within 12 months, compared to conventional plastics that may persist for hundreds of years. Their technology has been successfully applied to footwear, creating the world's first biodegradable algae-based shoe.

Strengths: True biodegradability in multiple environments including marine conditions; carbon-sequestering feedstock from algae cultivation; drop-in compatibility with existing manufacturing equipment. Weaknesses: Limited production scale compared to conventional polymers; higher current production costs; relatively new technology with limited long-term performance data.

Critical Patents and Innovations in Bio-Polymer Recycling

Reuse of bioplastics in polymerisation

PatentWO2022013309A1

Innovation

- A process involving hydrolysis of biodegradable polyester mixtures at temperatures above their melting point, followed by separation of impurities and adjustment of monomer/oligomer content, allows for the reuse of monomers and oligomers in polymerization reactions to produce new biodegradable polymer compositions without the need for organic solvents.

Degradable bio-based polymers

PatentPendingUS20230167225A1

Innovation

- Development of bio-based polymer products, such as polyurethanes and polyesters, that can be degraded by enzymes or chemicals into subunits, allowing for recycling and regeneration of raw materials, using microorganisms and specific rate-regulating compounds to enhance degradation.

Environmental Impact Assessment

The environmental impact assessment of bio-based polymer recycling processes reveals significant potential for reducing the ecological footprint compared to conventional petroleum-based polymer recycling. Life cycle assessments indicate that bio-based polymer recycling can achieve 30-45% lower greenhouse gas emissions when optimal processing conditions are maintained. This reduction stems primarily from the renewable nature of the feedstock and the typically lower energy requirements during the recycling phase.

Water consumption patterns in bio-based polymer recycling show mixed results. While certain processes like enzymatic depolymerization demonstrate water efficiency improvements of up to 25% compared to traditional methods, others such as solvent-based techniques may require substantial water inputs for purification stages. Regional water stress factors must therefore be considered when implementing these technologies at scale.

Land use implications present a complex dimension in environmental assessment. The cultivation of biomass feedstock for these polymers requires agricultural land, potentially competing with food production. However, recent innovations utilizing agricultural waste streams and non-food crops grown on marginal lands have significantly mitigated this concern. Studies from 2022 indicate that integrated systems can reduce land use competition by up to 60% compared to first-generation bio-polymer approaches.

Chemical pollution profiles of bio-based polymer recycling demonstrate notable advantages. The biodegradable nature of many process residues reduces persistent environmental contamination. Toxicity assessments reveal that effluents from bio-based recycling typically contain 70-80% fewer hazardous substances than conventional polymer recycling streams. Nevertheless, certain bio-catalysts and specialized solvents used in these processes require careful handling and disposal protocols.

Energy efficiency metrics show that bio-based polymer recycling generally requires 15-30% less energy input than virgin polymer production. However, this advantage diminishes when compared directly to mechanical recycling of conventional polymers. The energy balance becomes more favorable when considering end-of-life scenarios, as many bio-based polymers can be processed through composting or anaerobic digestion when recycling is no longer viable.

Biodiversity impacts must also be evaluated, particularly when scaling up these technologies. Responsible sourcing of bio-feedstocks is essential to prevent habitat conversion and ecosystem disruption. Certification systems and traceability mechanisms are increasingly being implemented to ensure that bio-based polymer recycling contributes positively to conservation objectives rather than driving further environmental degradation through expanded cultivation.

Water consumption patterns in bio-based polymer recycling show mixed results. While certain processes like enzymatic depolymerization demonstrate water efficiency improvements of up to 25% compared to traditional methods, others such as solvent-based techniques may require substantial water inputs for purification stages. Regional water stress factors must therefore be considered when implementing these technologies at scale.

Land use implications present a complex dimension in environmental assessment. The cultivation of biomass feedstock for these polymers requires agricultural land, potentially competing with food production. However, recent innovations utilizing agricultural waste streams and non-food crops grown on marginal lands have significantly mitigated this concern. Studies from 2022 indicate that integrated systems can reduce land use competition by up to 60% compared to first-generation bio-polymer approaches.

Chemical pollution profiles of bio-based polymer recycling demonstrate notable advantages. The biodegradable nature of many process residues reduces persistent environmental contamination. Toxicity assessments reveal that effluents from bio-based recycling typically contain 70-80% fewer hazardous substances than conventional polymer recycling streams. Nevertheless, certain bio-catalysts and specialized solvents used in these processes require careful handling and disposal protocols.

Energy efficiency metrics show that bio-based polymer recycling generally requires 15-30% less energy input than virgin polymer production. However, this advantage diminishes when compared directly to mechanical recycling of conventional polymers. The energy balance becomes more favorable when considering end-of-life scenarios, as many bio-based polymers can be processed through composting or anaerobic digestion when recycling is no longer viable.

Biodiversity impacts must also be evaluated, particularly when scaling up these technologies. Responsible sourcing of bio-feedstocks is essential to prevent habitat conversion and ecosystem disruption. Certification systems and traceability mechanisms are increasingly being implemented to ensure that bio-based polymer recycling contributes positively to conservation objectives rather than driving further environmental degradation through expanded cultivation.

Regulatory Framework for Bio-Polymer Materials

The regulatory landscape for bio-based polymers is rapidly evolving as governments worldwide recognize the need to address environmental challenges associated with conventional plastics. The European Union leads with its comprehensive framework, including the European Green Deal and Circular Economy Action Plan, which specifically targets bio-based materials. These regulations establish sustainability criteria, end-of-life management requirements, and recycling targets for bio-polymers, creating a structured pathway for market development.

In the United States, regulation occurs primarily at the state level, with California's SB 270 and similar legislation in other states promoting biodegradable and compostable alternatives. The FDA maintains oversight of bio-polymers in food contact applications, while the USDA BioPreferred Program incentivizes bio-based product development through federal procurement preferences.

Asian markets demonstrate varying regulatory approaches. Japan's Biomass Nippon Strategy promotes bio-based materials as part of its circular economy initiative, while China has implemented its Biodegradable Plastics Industry Standards to address growing plastic pollution concerns. These frameworks establish certification systems and technical standards specific to bio-polymer materials.

Certification systems play a crucial role in regulatory compliance. Standards such as ASTM D6400, EN 13432, and ISO 17088 provide internationally recognized benchmarks for biodegradability and compostability. The emergence of specialized certifications like TÜV Austria's "OK biobased" and DIN CERTCO's "DIN-Geprüft Biobased" offers manufacturers pathways to verify bio-content claims and environmental performance.

Recent regulatory trends indicate a shift toward lifecycle assessment requirements, with emerging frameworks demanding comprehensive environmental impact data throughout the bio-polymer value chain. Extended Producer Responsibility (EPR) schemes are increasingly incorporating bio-based materials, requiring manufacturers to manage end-of-life processes and establish collection systems for these materials.

Harmonization challenges persist across jurisdictions, creating market entry barriers for bio-polymer innovations. Inconsistent definitions of "biodegradable," "compostable," and "bio-based" complicate compliance efforts. Industry stakeholders advocate for standardized approaches to testing methodologies and labeling requirements to facilitate global trade and consumer understanding of these materials.

Future regulatory developments will likely focus on establishing minimum recycled content requirements specific to bio-polymers, creating dedicated waste management infrastructure, and implementing carbon accounting frameworks that recognize the reduced environmental footprint of these materials compared to fossil-based alternatives.

In the United States, regulation occurs primarily at the state level, with California's SB 270 and similar legislation in other states promoting biodegradable and compostable alternatives. The FDA maintains oversight of bio-polymers in food contact applications, while the USDA BioPreferred Program incentivizes bio-based product development through federal procurement preferences.

Asian markets demonstrate varying regulatory approaches. Japan's Biomass Nippon Strategy promotes bio-based materials as part of its circular economy initiative, while China has implemented its Biodegradable Plastics Industry Standards to address growing plastic pollution concerns. These frameworks establish certification systems and technical standards specific to bio-polymer materials.

Certification systems play a crucial role in regulatory compliance. Standards such as ASTM D6400, EN 13432, and ISO 17088 provide internationally recognized benchmarks for biodegradability and compostability. The emergence of specialized certifications like TÜV Austria's "OK biobased" and DIN CERTCO's "DIN-Geprüft Biobased" offers manufacturers pathways to verify bio-content claims and environmental performance.

Recent regulatory trends indicate a shift toward lifecycle assessment requirements, with emerging frameworks demanding comprehensive environmental impact data throughout the bio-polymer value chain. Extended Producer Responsibility (EPR) schemes are increasingly incorporating bio-based materials, requiring manufacturers to manage end-of-life processes and establish collection systems for these materials.

Harmonization challenges persist across jurisdictions, creating market entry barriers for bio-polymer innovations. Inconsistent definitions of "biodegradable," "compostable," and "bio-based" complicate compliance efforts. Industry stakeholders advocate for standardized approaches to testing methodologies and labeling requirements to facilitate global trade and consumer understanding of these materials.

Future regulatory developments will likely focus on establishing minimum recycled content requirements specific to bio-polymers, creating dedicated waste management infrastructure, and implementing carbon accounting frameworks that recognize the reduced environmental footprint of these materials compared to fossil-based alternatives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!