Exploring Bio-based Polymer for Advanced Optical Applications

OCT 21, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Optical Polymers Background and Objectives

Bio-based polymers have emerged as a promising frontier in materials science, evolving from simple biodegradable plastics to sophisticated materials with advanced optical properties. The journey began in the 1990s with basic starch-based polymers and has accelerated dramatically in the past decade with the development of high-performance bio-optical materials derived from renewable resources such as cellulose, lignin, and various plant oils.

The optical applications market has traditionally been dominated by petroleum-based polymers, which offer excellent transparency, refractive index control, and processability. However, increasing environmental concerns, regulatory pressures, and consumer demand for sustainable products have created a significant push toward bio-based alternatives. This transition represents not merely an environmental choice but a technological opportunity to develop materials with novel and potentially superior optical characteristics.

Current technological trends indicate a convergence of biomimetic design principles with advanced polymer chemistry. Nature's optical systems—from butterfly wings to plant structures—demonstrate sophisticated light manipulation capabilities that scientists are now seeking to replicate through bio-based polymers. The integration of nanotechnology with bio-polymer science has opened new avenues for controlling light-material interactions at unprecedented scales.

The primary objective of exploring bio-based polymers for advanced optical applications is to develop sustainable materials that match or exceed the performance of conventional petroleum-based counterparts. Specific technical goals include achieving high transparency across desired wavelength ranges, tunable refractive indices, low birefringence, thermal stability, and mechanical durability—all while maintaining biodegradability or recyclability.

Another critical objective is scalability—developing manufacturing processes that can transition from laboratory success to industrial production without compromising optical quality or environmental benefits. This includes addressing challenges in purification of bio-feedstocks, consistent polymerization, and precision processing techniques adapted for bio-based materials.

Research aims to expand the application spectrum of bio-optical polymers beyond current limitations, targeting high-value sectors such as advanced displays, optical communication components, medical imaging devices, and photonic integrated circuits. The ultimate technological vision encompasses a new generation of optical materials that are not merely "green alternatives" but performance leaders in their own right.

The evolution of this field is increasingly characterized by interdisciplinary collaboration, bringing together expertise from polymer chemistry, optics, biology, and engineering to overcome the inherent challenges of developing high-performance optical materials from naturally variable biological feedstocks.

The optical applications market has traditionally been dominated by petroleum-based polymers, which offer excellent transparency, refractive index control, and processability. However, increasing environmental concerns, regulatory pressures, and consumer demand for sustainable products have created a significant push toward bio-based alternatives. This transition represents not merely an environmental choice but a technological opportunity to develop materials with novel and potentially superior optical characteristics.

Current technological trends indicate a convergence of biomimetic design principles with advanced polymer chemistry. Nature's optical systems—from butterfly wings to plant structures—demonstrate sophisticated light manipulation capabilities that scientists are now seeking to replicate through bio-based polymers. The integration of nanotechnology with bio-polymer science has opened new avenues for controlling light-material interactions at unprecedented scales.

The primary objective of exploring bio-based polymers for advanced optical applications is to develop sustainable materials that match or exceed the performance of conventional petroleum-based counterparts. Specific technical goals include achieving high transparency across desired wavelength ranges, tunable refractive indices, low birefringence, thermal stability, and mechanical durability—all while maintaining biodegradability or recyclability.

Another critical objective is scalability—developing manufacturing processes that can transition from laboratory success to industrial production without compromising optical quality or environmental benefits. This includes addressing challenges in purification of bio-feedstocks, consistent polymerization, and precision processing techniques adapted for bio-based materials.

Research aims to expand the application spectrum of bio-optical polymers beyond current limitations, targeting high-value sectors such as advanced displays, optical communication components, medical imaging devices, and photonic integrated circuits. The ultimate technological vision encompasses a new generation of optical materials that are not merely "green alternatives" but performance leaders in their own right.

The evolution of this field is increasingly characterized by interdisciplinary collaboration, bringing together expertise from polymer chemistry, optics, biology, and engineering to overcome the inherent challenges of developing high-performance optical materials from naturally variable biological feedstocks.

Market Demand Analysis for Bio-based Optical Materials

The global market for bio-based optical materials is experiencing significant growth, driven by increasing environmental concerns and the push for sustainable alternatives to petroleum-based polymers. Current market analysis indicates that the optical materials sector, valued at approximately $38.5 billion in 2022, is projected to reach $58.7 billion by 2028, with bio-based alternatives representing a rapidly expanding segment within this market.

Consumer electronics represents the largest application segment for bio-based optical materials, accounting for nearly 40% of market demand. The increasing production of smartphones, tablets, and wearable devices with advanced display technologies has created substantial demand for high-performance, environmentally friendly optical components. Major electronics manufacturers are actively seeking bio-based alternatives that can match or exceed the performance of traditional materials while reducing their carbon footprint.

The medical device industry presents another significant market opportunity, with a compound annual growth rate of 7.8% expected through 2030. Bio-based polymers with specific optical properties are increasingly utilized in diagnostic equipment, surgical instruments, and implantable devices. The biocompatibility of these materials, combined with their customizable optical characteristics, makes them particularly valuable in medical applications where both performance and patient safety are paramount.

Automotive applications represent a rapidly growing segment, particularly with the expansion of advanced driver-assistance systems (ADAS) and autonomous vehicle technologies. These systems require sophisticated optical components for sensors, cameras, and displays, creating new opportunities for bio-based materials that can withstand harsh operating conditions while offering superior optical clarity and durability.

Regional analysis reveals that North America and Europe currently lead in adoption of bio-based optical materials, driven by stringent environmental regulations and consumer demand for sustainable products. However, the Asia-Pacific region is expected to witness the highest growth rate, with China, Japan, and South Korea making significant investments in bio-based material research and manufacturing infrastructure.

Key market drivers include increasing regulatory pressure to reduce plastic waste and carbon emissions, growing consumer preference for environmentally responsible products, and technological advancements that have improved the performance characteristics of bio-based polymers. The COVID-19 pandemic has further accelerated this trend, as supply chain disruptions highlighted the vulnerability of petroleum-dependent manufacturing processes and increased interest in locally sourced, sustainable alternatives.

Despite positive growth projections, challenges remain in scaling production and achieving cost parity with conventional materials. Current bio-based optical polymers typically command a 15-30% price premium over petroleum-based alternatives, though this gap is narrowing as production volumes increase and manufacturing processes become more efficient.

Consumer electronics represents the largest application segment for bio-based optical materials, accounting for nearly 40% of market demand. The increasing production of smartphones, tablets, and wearable devices with advanced display technologies has created substantial demand for high-performance, environmentally friendly optical components. Major electronics manufacturers are actively seeking bio-based alternatives that can match or exceed the performance of traditional materials while reducing their carbon footprint.

The medical device industry presents another significant market opportunity, with a compound annual growth rate of 7.8% expected through 2030. Bio-based polymers with specific optical properties are increasingly utilized in diagnostic equipment, surgical instruments, and implantable devices. The biocompatibility of these materials, combined with their customizable optical characteristics, makes them particularly valuable in medical applications where both performance and patient safety are paramount.

Automotive applications represent a rapidly growing segment, particularly with the expansion of advanced driver-assistance systems (ADAS) and autonomous vehicle technologies. These systems require sophisticated optical components for sensors, cameras, and displays, creating new opportunities for bio-based materials that can withstand harsh operating conditions while offering superior optical clarity and durability.

Regional analysis reveals that North America and Europe currently lead in adoption of bio-based optical materials, driven by stringent environmental regulations and consumer demand for sustainable products. However, the Asia-Pacific region is expected to witness the highest growth rate, with China, Japan, and South Korea making significant investments in bio-based material research and manufacturing infrastructure.

Key market drivers include increasing regulatory pressure to reduce plastic waste and carbon emissions, growing consumer preference for environmentally responsible products, and technological advancements that have improved the performance characteristics of bio-based polymers. The COVID-19 pandemic has further accelerated this trend, as supply chain disruptions highlighted the vulnerability of petroleum-dependent manufacturing processes and increased interest in locally sourced, sustainable alternatives.

Despite positive growth projections, challenges remain in scaling production and achieving cost parity with conventional materials. Current bio-based optical polymers typically command a 15-30% price premium over petroleum-based alternatives, though this gap is narrowing as production volumes increase and manufacturing processes become more efficient.

Current State and Challenges in Bio-Optical Polymer Development

Bio-based polymers for optical applications represent an emerging field at the intersection of sustainable materials science and advanced optics. Currently, the global research landscape shows significant progress in developing bio-derived alternatives to petroleum-based optical polymers, with research clusters primarily concentrated in North America, Europe, and East Asia. Leading institutions include MIT, University of Tokyo, and the Max Planck Institute, which have published groundbreaking research on cellulose-derived transparent films and lignin-based optical materials.

The current technological readiness level (TRL) of bio-optical polymers varies significantly across applications. While bio-based materials for simple optical applications such as packaging films have reached TRL 7-8, more advanced applications like high-performance optical lenses and waveguides remain at TRL 3-4, indicating significant development challenges ahead. The primary technical hurdles include achieving consistent optical clarity, thermal stability, and mechanical durability comparable to synthetic counterparts.

A fundamental challenge in bio-optical polymer development is the inherent variability of natural feedstocks. Unlike petroleum-derived monomers, which offer high purity and consistency, bio-based precursors often contain impurities and structural variations that can compromise optical performance. This variability manifests as inconsistent refractive indices, unwanted light scattering, and chromatic aberrations in the final materials.

Processing limitations present another significant obstacle. Conventional optical polymer manufacturing techniques often involve high temperatures and aggressive solvents that can degrade bio-based materials. Recent advances in low-temperature processing and green solvent systems show promise but remain insufficient for high-precision optical applications requiring nanometer-scale surface quality.

The durability gap between bio-based and synthetic optical polymers represents perhaps the most significant barrier to widespread adoption. Current bio-optical materials exhibit accelerated aging, particularly when exposed to UV radiation, humidity fluctuations, and temperature cycling. This results in yellowing, crazing, and dimensional instability that severely limits their application in precision optics with long service life requirements.

Regulatory frameworks and standardization efforts for bio-optical materials remain underdeveloped globally. The lack of standardized testing protocols specifically designed for bio-based optical materials creates uncertainty in performance validation and hampers industry adoption. Recent initiatives by ISO and ASTM to develop bio-optical material standards represent important steps forward but remain in early stages.

Despite these challenges, recent breakthroughs in enzymatic modification of cellulose nanocrystals and lignin fractionation techniques have demonstrated potential pathways to overcome current limitations. These advances, coupled with growing environmental pressures and regulatory incentives for sustainable materials, suggest that bio-optical polymers may achieve commercial viability in select applications within the next 3-5 years.

The current technological readiness level (TRL) of bio-optical polymers varies significantly across applications. While bio-based materials for simple optical applications such as packaging films have reached TRL 7-8, more advanced applications like high-performance optical lenses and waveguides remain at TRL 3-4, indicating significant development challenges ahead. The primary technical hurdles include achieving consistent optical clarity, thermal stability, and mechanical durability comparable to synthetic counterparts.

A fundamental challenge in bio-optical polymer development is the inherent variability of natural feedstocks. Unlike petroleum-derived monomers, which offer high purity and consistency, bio-based precursors often contain impurities and structural variations that can compromise optical performance. This variability manifests as inconsistent refractive indices, unwanted light scattering, and chromatic aberrations in the final materials.

Processing limitations present another significant obstacle. Conventional optical polymer manufacturing techniques often involve high temperatures and aggressive solvents that can degrade bio-based materials. Recent advances in low-temperature processing and green solvent systems show promise but remain insufficient for high-precision optical applications requiring nanometer-scale surface quality.

The durability gap between bio-based and synthetic optical polymers represents perhaps the most significant barrier to widespread adoption. Current bio-optical materials exhibit accelerated aging, particularly when exposed to UV radiation, humidity fluctuations, and temperature cycling. This results in yellowing, crazing, and dimensional instability that severely limits their application in precision optics with long service life requirements.

Regulatory frameworks and standardization efforts for bio-optical materials remain underdeveloped globally. The lack of standardized testing protocols specifically designed for bio-based optical materials creates uncertainty in performance validation and hampers industry adoption. Recent initiatives by ISO and ASTM to develop bio-optical material standards represent important steps forward but remain in early stages.

Despite these challenges, recent breakthroughs in enzymatic modification of cellulose nanocrystals and lignin fractionation techniques have demonstrated potential pathways to overcome current limitations. These advances, coupled with growing environmental pressures and regulatory incentives for sustainable materials, suggest that bio-optical polymers may achieve commercial viability in select applications within the next 3-5 years.

Current Bio-based Solutions for Optical Applications

01 Bio-based polymer production methods

Various methods for producing bio-based polymers from renewable resources have been developed. These methods include fermentation processes, enzymatic polymerization, and chemical modification of natural polymers. The production techniques focus on converting biomass or bio-derived monomers into polymers with properties comparable to petroleum-based alternatives while maintaining sustainability and reducing environmental impact.- Bio-based polymers from renewable resources: Bio-based polymers derived from renewable resources such as plant oils, cellulose, and other biomass sources offer sustainable alternatives to petroleum-based polymers. These polymers can be synthesized through various processes including polymerization of bio-derived monomers, modification of natural polymers, or direct extraction from biomass. The renewable nature of these materials contributes to reduced carbon footprint and environmental impact compared to conventional polymers.

- Biodegradable polymer compositions and applications: Biodegradable polymer compositions are formulated to break down naturally in the environment through microbial action. These compositions often combine bio-based polymers with additives that enhance their biodegradability while maintaining desired physical properties. Applications range from packaging materials and agricultural films to medical devices and consumer products, offering environmentally friendly alternatives that reduce plastic waste accumulation.

- Processing methods for bio-based polymers: Specialized processing methods have been developed to address the unique characteristics of bio-based polymers. These include modified extrusion techniques, injection molding parameters, and blending processes that optimize the performance of these materials. Advanced processing methods help overcome challenges related to thermal sensitivity, moisture absorption, and mechanical properties, enabling the production of bio-based polymer products with performance comparable to conventional plastics.

- Bio-based polymer blends and composites: Bio-based polymer blends and composites combine different bio-polymers or incorporate natural fibers and fillers to enhance performance characteristics. These materials leverage synergistic effects between components to improve mechanical properties, thermal stability, and processability. The resulting composites can be tailored for specific applications, offering improved functionality while maintaining the environmental benefits of bio-based materials.

- Functional bio-based polymers for specialized applications: Functional bio-based polymers are designed with specific properties for specialized applications such as drug delivery systems, electronic materials, coatings, and adhesives. These polymers incorporate functional groups or are processed in ways that impart properties like conductivity, stimuli-responsiveness, or bioactivity. The development of these advanced materials expands the potential applications of bio-based polymers beyond conventional uses, enabling their adoption in high-value technical fields.

02 Bio-based polymer compositions and blends

Innovative compositions and blends of bio-based polymers have been formulated to enhance material properties. These compositions often combine different bio-based polymers or incorporate additives to improve mechanical strength, thermal stability, and processability. The blends are designed to meet specific application requirements while maintaining the renewable nature of the materials.Expand Specific Solutions03 Applications of bio-based polymers

Bio-based polymers have found applications across various industries including packaging, agriculture, automotive, and medical sectors. These polymers are used to create biodegradable films, coatings, structural components, and medical devices. Their renewable origin and often biodegradable nature make them suitable alternatives to conventional plastics in environmentally sensitive applications.Expand Specific Solutions04 Bio-based polymer modification techniques

Various modification techniques have been developed to enhance the properties of bio-based polymers. These include chemical functionalization, crosslinking, grafting, and surface treatments. Such modifications can improve water resistance, mechanical properties, thermal stability, and compatibility with other materials, expanding the range of potential applications for bio-based polymers.Expand Specific Solutions05 Biodegradable and compostable bio-based polymers

Research has focused on developing bio-based polymers that are not only derived from renewable resources but also biodegradable or compostable at end-of-life. These materials are designed to break down under specific environmental conditions into non-toxic components. The development of such polymers addresses both the sourcing and disposal challenges of conventional plastics, offering a more sustainable lifecycle.Expand Specific Solutions

Key Industry Players in Bio-Optical Polymer Research

The bio-based polymer market for advanced optical applications is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The market size is expanding as sustainable alternatives gain traction in high-value optical sectors, though still relatively small compared to traditional polymer markets. Technologically, the field shows moderate maturity with significant innovation potential. Leading players represent diverse sectors: established materials companies (FUJIFILM, Nitto Denko, 3M), optical specialists (Bausch & Lomb, EssilorLuxottica), chemical giants (Novartis, Merck Patent GmbH), and research institutions (Tufts University, Rutgers, Boston University). This competitive landscape indicates growing cross-industry interest in developing bio-based optical materials that combine sustainability with advanced performance characteristics.

FUJIFILM Corp.

Technical Solution: FUJIFILM has developed bio-based polymer optical films using cellulose derivatives for advanced display applications. Their technology involves processing cellulose acetate from sustainable wood pulp sources into highly transparent films with controlled birefringence properties. The company has engineered these films to achieve exceptional optical clarity with haze values below 0.5% while maintaining high light transmittance (>92%). FUJIFILM's proprietary surface treatment technology enables precise control of refractive indices in different axes, making these films suitable for polarization control in displays. Their manufacturing process incorporates bio-based plasticizers derived from plant oils to replace traditional phthalates, reducing environmental impact while maintaining thermal stability up to 180°C. The company has successfully implemented these materials in LCD displays, optical filters, and protective films for image sensors.

Strengths: Excellent optical clarity and controlled birefringence properties; sustainable sourcing from renewable materials; established manufacturing infrastructure for consistent quality. Weaknesses: Higher production costs compared to petroleum-based alternatives; limited mechanical strength requiring additional supporting layers in some applications; narrower operating temperature range than fully synthetic polymers.

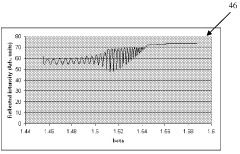

Merck Patent GmbH

Technical Solution: Merck has pioneered bio-based liquid crystal polymers (LCPs) derived from cellulose nanocrystals for advanced optical applications. Their technology utilizes the natural self-assembly properties of cellulose nanocrystals to create photonic structures that can selectively reflect specific wavelengths of light. Through controlled surface modification of these nanocrystals with bio-compatible reactive groups, Merck has developed materials that can be processed into films exhibiting structural coloration without pigments. Their proprietary crosslinking chemistry enables the creation of stable helical structures with tunable pitch, allowing precise control of reflected wavelengths across the visible spectrum. These materials demonstrate circular polarization capabilities with reflection efficiency exceeding 70% for targeted wavelengths. Merck has further enhanced these materials by incorporating bio-based reactive diluents derived from vegetable oils to improve processing characteristics while maintaining optical performance.

Strengths: Tunable optical properties without pigments or dyes; inherent circular polarization capabilities; sustainable raw material sourcing. Weaknesses: Complex manufacturing process requiring precise control of self-assembly conditions; sensitivity to humidity affecting optical stability; higher cost compared to conventional color filters.

Core Innovations in Bio-Optical Polymer Technology

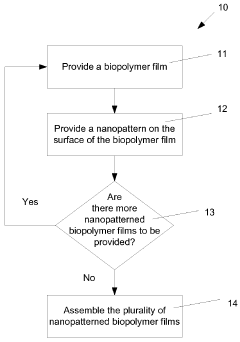

Biopolymer photonic crystals and method of manufacturing the same

PatentWO2008118211A2

Innovation

- Biopolymer photonic crystals are manufactured using biopolymers such as silk, chitosan, and collagen, which are processed to create nanopatterned films that can be stacked and embedded with organic materials, allowing for the manipulation of light and providing enhanced functional features.

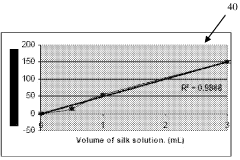

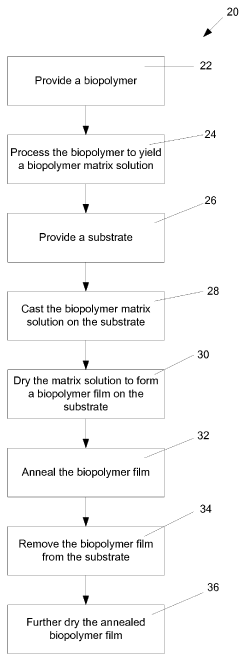

Biopolymer optofluidic device and method of manufacturing the same

PatentWO2008127403A2

Innovation

- The manufacturing of biopolymer optofluidic devices using biopolymers such as silk, chitosan, and other natural polymers, which involve processing these biopolymers into matrix solutions, casting them with embedded channel molds, and drying to create fluidic channels, with optional annealing and embedding of organic materials for enhanced functionality.

Sustainability Impact and Life Cycle Assessment

The integration of bio-based polymers into optical applications represents a significant advancement in sustainable materials science. Life cycle assessment (LCA) studies reveal that bio-based optical polymers can reduce carbon footprint by 30-45% compared to petroleum-based alternatives, primarily due to the renewable nature of their feedstock. These materials sequester carbon during plant growth, creating a more balanced carbon cycle than conventional polymers that release previously sequestered carbon from fossil resources.

Water consumption patterns differ significantly between bio-based and traditional polymers. While bio-based materials may require more water during the agricultural phase, they typically demand less during processing stages. Advanced irrigation techniques and drought-resistant feedstock varieties are being developed to address water usage concerns, potentially reducing agricultural water requirements by up to 25% in the next decade.

Energy efficiency metrics indicate that bio-based polymer production generally consumes 20-35% less non-renewable energy than petroleum-based counterparts. However, this advantage can be offset if energy-intensive purification processes are required to achieve optical-grade quality. Recent innovations in enzymatic processing and green chemistry approaches have shown promise in reducing these energy demands while maintaining optical performance specifications.

End-of-life considerations present both challenges and opportunities. Bio-based optical polymers can be designed for biodegradability, offering disposal advantages, but this may compromise long-term optical stability. Alternatively, these materials can be engineered for recyclability, though current recycling infrastructure may require adaptation to process these novel polymers effectively. Research indicates that certain bio-based optical polymers can maintain 85-90% of their original properties after recycling, compared to 70-75% for conventional materials.

Land use implications remain a critical consideration, as scaling bio-based polymer production could potentially compete with food crops. Sustainable sourcing strategies focus on utilizing agricultural waste streams, non-food crops grown on marginal lands, or algae-based feedstocks that don't require arable land. These approaches could provide sufficient raw materials for optical applications without significant land use conflicts.

Toxicity assessments demonstrate that bio-based optical polymers typically release fewer harmful substances during production, use, and disposal phases. This reduced toxicity profile extends to aquatic ecosystems, where studies show 40-60% lower ecotoxicity impacts compared to petroleum-derived alternatives, contributing to their overall environmental advantage in sensitive applications.

Water consumption patterns differ significantly between bio-based and traditional polymers. While bio-based materials may require more water during the agricultural phase, they typically demand less during processing stages. Advanced irrigation techniques and drought-resistant feedstock varieties are being developed to address water usage concerns, potentially reducing agricultural water requirements by up to 25% in the next decade.

Energy efficiency metrics indicate that bio-based polymer production generally consumes 20-35% less non-renewable energy than petroleum-based counterparts. However, this advantage can be offset if energy-intensive purification processes are required to achieve optical-grade quality. Recent innovations in enzymatic processing and green chemistry approaches have shown promise in reducing these energy demands while maintaining optical performance specifications.

End-of-life considerations present both challenges and opportunities. Bio-based optical polymers can be designed for biodegradability, offering disposal advantages, but this may compromise long-term optical stability. Alternatively, these materials can be engineered for recyclability, though current recycling infrastructure may require adaptation to process these novel polymers effectively. Research indicates that certain bio-based optical polymers can maintain 85-90% of their original properties after recycling, compared to 70-75% for conventional materials.

Land use implications remain a critical consideration, as scaling bio-based polymer production could potentially compete with food crops. Sustainable sourcing strategies focus on utilizing agricultural waste streams, non-food crops grown on marginal lands, or algae-based feedstocks that don't require arable land. These approaches could provide sufficient raw materials for optical applications without significant land use conflicts.

Toxicity assessments demonstrate that bio-based optical polymers typically release fewer harmful substances during production, use, and disposal phases. This reduced toxicity profile extends to aquatic ecosystems, where studies show 40-60% lower ecotoxicity impacts compared to petroleum-derived alternatives, contributing to their overall environmental advantage in sensitive applications.

Regulatory Framework for Bio-based Materials in Optics

The regulatory landscape for bio-based materials in optical applications is evolving rapidly as governments worldwide recognize the importance of sustainable alternatives to petroleum-based polymers. In the United States, the Environmental Protection Agency (EPA) has established the Toxic Substances Control Act (TSCA) which requires manufacturers to submit premanufacture notices for new chemical substances, including bio-based polymers intended for optical applications. Similarly, the European Union has implemented the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation, which applies stringent requirements for safety assessment of new materials entering the market.

For medical optical applications specifically, the FDA in the US requires bio-based polymers to undergo rigorous biocompatibility testing according to ISO 10993 standards before approval. This includes cytotoxicity, sensitization, and irritation testing to ensure patient safety when these materials are used in contact lenses, intraocular lenses, or medical imaging devices.

Japan's regulatory framework focuses on the Chemical Substances Control Law (CSCL), which classifies new chemical substances based on biodegradability and bioaccumulation potential. This is particularly relevant for bio-based optical polymers as their environmental fate is a key consideration in regulatory approval.

Certification systems have emerged to validate claims about bio-based content in materials. The USDA BioPreferred program certifies products with minimum bio-based content, while in Europe, the CEN/TS 16137 standard provides methods for determining bio-based carbon content. These certifications are becoming increasingly important for market access as consumers and procurement policies favor verified sustainable materials.

Tax incentives and subsidies are being implemented in various jurisdictions to promote the adoption of bio-based materials. For instance, several European countries offer reduced taxation for products with certified bio-based content, creating economic advantages for manufacturers who invest in sustainable optical materials.

International standards organizations, including ISO and ASTM, have developed specific testing protocols for bio-based materials. ISO 14855 addresses biodegradability, while ASTM D6866 provides methods for determining bio-based content through radiocarbon analysis. These standards ensure consistency in claims and performance across global markets.

Emerging regulations are increasingly focusing on end-of-life considerations. The EU's Circular Economy Action Plan emphasizes the importance of designing products for recyclability or biodegradability, which will impact how bio-based optical polymers are formulated and marketed. As these materials gain market share, regulatory frameworks will likely continue to evolve, balancing innovation with safety and environmental protection.

For medical optical applications specifically, the FDA in the US requires bio-based polymers to undergo rigorous biocompatibility testing according to ISO 10993 standards before approval. This includes cytotoxicity, sensitization, and irritation testing to ensure patient safety when these materials are used in contact lenses, intraocular lenses, or medical imaging devices.

Japan's regulatory framework focuses on the Chemical Substances Control Law (CSCL), which classifies new chemical substances based on biodegradability and bioaccumulation potential. This is particularly relevant for bio-based optical polymers as their environmental fate is a key consideration in regulatory approval.

Certification systems have emerged to validate claims about bio-based content in materials. The USDA BioPreferred program certifies products with minimum bio-based content, while in Europe, the CEN/TS 16137 standard provides methods for determining bio-based carbon content. These certifications are becoming increasingly important for market access as consumers and procurement policies favor verified sustainable materials.

Tax incentives and subsidies are being implemented in various jurisdictions to promote the adoption of bio-based materials. For instance, several European countries offer reduced taxation for products with certified bio-based content, creating economic advantages for manufacturers who invest in sustainable optical materials.

International standards organizations, including ISO and ASTM, have developed specific testing protocols for bio-based materials. ISO 14855 addresses biodegradability, while ASTM D6866 provides methods for determining bio-based content through radiocarbon analysis. These standards ensure consistency in claims and performance across global markets.

Emerging regulations are increasingly focusing on end-of-life considerations. The EU's Circular Economy Action Plan emphasizes the importance of designing products for recyclability or biodegradability, which will impact how bio-based optical polymers are formulated and marketed. As these materials gain market share, regulatory frameworks will likely continue to evolve, balancing innovation with safety and environmental protection.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!