Exploring Thermoset vs Thermoplastic Bio-based Polymer Applications

OCT 21, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-based Polymer Evolution and Objectives

Bio-based polymers have emerged as a sustainable alternative to conventional petroleum-based plastics, with their development tracing back to the early 20th century. However, significant commercial interest only materialized in the 1990s as environmental concerns and petroleum price volatility intensified. The evolution of these materials has been characterized by three distinct waves: first-generation polymers derived directly from biomass (like cellulose and starch), second-generation polymers synthesized from bio-derived monomers (such as PLA and bio-PET), and third-generation polymers produced through microbial fermentation processes.

The technological trajectory has been shaped by advancements in biotechnology, green chemistry, and materials science. Recent breakthroughs in enzymatic processes and genetic engineering have expanded the range of feedstocks beyond traditional agricultural sources to include agricultural waste, algae, and even CO2 capture technologies, significantly broadening the potential application spectrum of bio-based polymers.

Current market trends indicate a growing divergence in development paths between thermoset and thermoplastic bio-based polymers. Thermoplastics, which can be melted and reformed multiple times, have seen faster commercial adoption due to their compatibility with existing processing infrastructure. Thermosets, which form permanent cross-linked structures upon curing, have found specialized applications where durability and heat resistance are paramount.

The primary objective of this technical research is to comprehensively evaluate the comparative advantages and limitations of thermoset versus thermoplastic bio-based polymers across various industrial applications. This includes assessing their mechanical properties, processing requirements, environmental impact profiles, and economic viability in both current and emerging markets.

Secondary objectives include identifying technological barriers limiting wider adoption of these materials, exploring potential synergistic combinations of thermoset and thermoplastic bio-based systems, and forecasting future innovation trajectories based on patent activity and research funding patterns. The research aims to establish a framework for material selection that balances performance requirements with sustainability metrics.

Long-term goals encompass mapping the potential for these materials to contribute to circular economy principles, evaluating their role in carbon sequestration strategies, and determining how regulatory frameworks might evolve to incentivize their development and adoption. This analysis will provide strategic guidance for R&D investment priorities and potential market positioning opportunities in the rapidly evolving sustainable materials landscape.

The technological trajectory has been shaped by advancements in biotechnology, green chemistry, and materials science. Recent breakthroughs in enzymatic processes and genetic engineering have expanded the range of feedstocks beyond traditional agricultural sources to include agricultural waste, algae, and even CO2 capture technologies, significantly broadening the potential application spectrum of bio-based polymers.

Current market trends indicate a growing divergence in development paths between thermoset and thermoplastic bio-based polymers. Thermoplastics, which can be melted and reformed multiple times, have seen faster commercial adoption due to their compatibility with existing processing infrastructure. Thermosets, which form permanent cross-linked structures upon curing, have found specialized applications where durability and heat resistance are paramount.

The primary objective of this technical research is to comprehensively evaluate the comparative advantages and limitations of thermoset versus thermoplastic bio-based polymers across various industrial applications. This includes assessing their mechanical properties, processing requirements, environmental impact profiles, and economic viability in both current and emerging markets.

Secondary objectives include identifying technological barriers limiting wider adoption of these materials, exploring potential synergistic combinations of thermoset and thermoplastic bio-based systems, and forecasting future innovation trajectories based on patent activity and research funding patterns. The research aims to establish a framework for material selection that balances performance requirements with sustainability metrics.

Long-term goals encompass mapping the potential for these materials to contribute to circular economy principles, evaluating their role in carbon sequestration strategies, and determining how regulatory frameworks might evolve to incentivize their development and adoption. This analysis will provide strategic guidance for R&D investment priorities and potential market positioning opportunities in the rapidly evolving sustainable materials landscape.

Market Demand Analysis for Sustainable Polymers

The global market for sustainable polymers has witnessed significant growth in recent years, driven by increasing environmental awareness and regulatory pressures. The demand for bio-based polymers, both thermoset and thermoplastic, has been expanding at a compound annual growth rate of approximately 15-20% since 2018, outpacing the conventional polymer market which grows at 3-4% annually.

Consumer preferences have shifted dramatically toward sustainable products, with surveys indicating that 73% of global consumers are willing to pay a premium for environmentally friendly packaging and products. This trend is particularly pronounced in developed markets such as Europe and North America, where sustainability has become a key purchasing criterion across multiple industries.

The packaging sector represents the largest application segment for bio-based polymers, accounting for nearly 40% of the total market volume. This is followed by consumer goods (25%), automotive (15%), and construction (10%), with various other applications comprising the remaining 10%. The food and beverage industry has emerged as a particularly strong driver, seeking alternatives to conventional plastics due to increasing consumer and regulatory pressure.

Regulatory frameworks worldwide are increasingly favoring sustainable materials. The European Union's Single-Use Plastics Directive, implemented in 2021, has accelerated the transition toward bio-based alternatives. Similarly, many Asian countries, particularly Japan and South Korea, have established ambitious targets for replacing petroleum-based polymers with sustainable alternatives by 2030.

Price sensitivity remains a significant factor influencing market adoption. Currently, bio-based polymers typically command a 20-30% price premium over their conventional counterparts. However, this gap has been narrowing as production scales increase and manufacturing processes become more efficient. Industry analysts project price parity for certain bio-based polymers by 2027, which would substantially accelerate market penetration.

The distinction between thermoset and thermoplastic bio-based polymers creates different market dynamics. Thermoplastic bio-based polymers currently dominate the market with approximately 70% share due to their recyclability and processing advantages. However, thermoset bio-based polymers are gaining traction in specialized applications requiring superior mechanical properties, heat resistance, and chemical stability.

Regional analysis reveals that Europe leads the sustainable polymer market with approximately 35% of global consumption, followed by North America (30%) and Asia-Pacific (25%). However, the highest growth rates are being observed in emerging economies, particularly in Southeast Asia and Latin America, where increasing industrialization is coinciding with stronger environmental regulations.

Consumer preferences have shifted dramatically toward sustainable products, with surveys indicating that 73% of global consumers are willing to pay a premium for environmentally friendly packaging and products. This trend is particularly pronounced in developed markets such as Europe and North America, where sustainability has become a key purchasing criterion across multiple industries.

The packaging sector represents the largest application segment for bio-based polymers, accounting for nearly 40% of the total market volume. This is followed by consumer goods (25%), automotive (15%), and construction (10%), with various other applications comprising the remaining 10%. The food and beverage industry has emerged as a particularly strong driver, seeking alternatives to conventional plastics due to increasing consumer and regulatory pressure.

Regulatory frameworks worldwide are increasingly favoring sustainable materials. The European Union's Single-Use Plastics Directive, implemented in 2021, has accelerated the transition toward bio-based alternatives. Similarly, many Asian countries, particularly Japan and South Korea, have established ambitious targets for replacing petroleum-based polymers with sustainable alternatives by 2030.

Price sensitivity remains a significant factor influencing market adoption. Currently, bio-based polymers typically command a 20-30% price premium over their conventional counterparts. However, this gap has been narrowing as production scales increase and manufacturing processes become more efficient. Industry analysts project price parity for certain bio-based polymers by 2027, which would substantially accelerate market penetration.

The distinction between thermoset and thermoplastic bio-based polymers creates different market dynamics. Thermoplastic bio-based polymers currently dominate the market with approximately 70% share due to their recyclability and processing advantages. However, thermoset bio-based polymers are gaining traction in specialized applications requiring superior mechanical properties, heat resistance, and chemical stability.

Regional analysis reveals that Europe leads the sustainable polymer market with approximately 35% of global consumption, followed by North America (30%) and Asia-Pacific (25%). However, the highest growth rates are being observed in emerging economies, particularly in Southeast Asia and Latin America, where increasing industrialization is coinciding with stronger environmental regulations.

Thermoset vs Thermoplastic: Technical Challenges

The fundamental distinction between thermoset and thermoplastic bio-based polymers lies in their molecular structure and processing behavior. Thermosets form irreversible cross-linked networks during curing, while thermoplastics maintain linear or branched structures that can be repeatedly melted and reformed. This structural difference creates significant technical challenges that impact their respective applications in sustainable materials development.

Processing challenges for thermoset bio-based polymers include limited recyclability due to their permanent cross-linked structure, which prevents remelting and reforming. The curing process often requires precise temperature control and extended processing times, reducing production efficiency. Additionally, thermoset bio-based formulations frequently exhibit higher viscosity before curing, complicating mold filling and creating potential for void formation in complex geometries.

Thermoplastic bio-based polymers face different technical hurdles. Their lower thermal stability compared to petroleum-based counterparts restricts processing windows and application environments. Many bio-based thermoplastics demonstrate inferior mechanical properties, particularly in strength and impact resistance, limiting their use in demanding applications. Moisture sensitivity remains problematic, as many bio-based thermoplastics absorb atmospheric moisture, leading to dimensional instability and property degradation during processing and use.

Compatibility issues emerge when attempting to blend bio-based components with conventional additives and reinforcements. Both polymer types often require specialized compatibilizers or surface treatments to achieve adequate interfacial adhesion with fillers and fibers. For thermosets, ensuring complete cross-linking with bio-based components presents formulation challenges, while thermoplastics struggle with consistent melt flow characteristics when bio-content increases.

Durability under environmental conditions represents another significant challenge. Bio-based polymers typically exhibit accelerated degradation when exposed to UV radiation, moisture, and microbial activity. Thermosets generally demonstrate better chemical resistance but may experience surface degradation, while thermoplastics often show more pronounced property changes throughout their service life.

Scaling production presents unique obstacles for each type. Thermoset bio-based systems frequently require adaptation of existing manufacturing infrastructure to accommodate different curing profiles and exothermic reactions. Thermoplastic bio-based materials often demand more precise processing control to maintain consistent properties, with narrower processing windows than conventional alternatives. Both types face feedstock variability challenges, as natural raw materials can fluctuate in composition based on growing conditions and harvesting methods.

Cost-performance balance remains perhaps the most significant barrier to widespread adoption. Current bio-based alternatives typically command price premiums of 20-200% over petroleum-based counterparts while often delivering inferior technical performance, creating a challenging value proposition for manufacturers and end-users alike.

Processing challenges for thermoset bio-based polymers include limited recyclability due to their permanent cross-linked structure, which prevents remelting and reforming. The curing process often requires precise temperature control and extended processing times, reducing production efficiency. Additionally, thermoset bio-based formulations frequently exhibit higher viscosity before curing, complicating mold filling and creating potential for void formation in complex geometries.

Thermoplastic bio-based polymers face different technical hurdles. Their lower thermal stability compared to petroleum-based counterparts restricts processing windows and application environments. Many bio-based thermoplastics demonstrate inferior mechanical properties, particularly in strength and impact resistance, limiting their use in demanding applications. Moisture sensitivity remains problematic, as many bio-based thermoplastics absorb atmospheric moisture, leading to dimensional instability and property degradation during processing and use.

Compatibility issues emerge when attempting to blend bio-based components with conventional additives and reinforcements. Both polymer types often require specialized compatibilizers or surface treatments to achieve adequate interfacial adhesion with fillers and fibers. For thermosets, ensuring complete cross-linking with bio-based components presents formulation challenges, while thermoplastics struggle with consistent melt flow characteristics when bio-content increases.

Durability under environmental conditions represents another significant challenge. Bio-based polymers typically exhibit accelerated degradation when exposed to UV radiation, moisture, and microbial activity. Thermosets generally demonstrate better chemical resistance but may experience surface degradation, while thermoplastics often show more pronounced property changes throughout their service life.

Scaling production presents unique obstacles for each type. Thermoset bio-based systems frequently require adaptation of existing manufacturing infrastructure to accommodate different curing profiles and exothermic reactions. Thermoplastic bio-based materials often demand more precise processing control to maintain consistent properties, with narrower processing windows than conventional alternatives. Both types face feedstock variability challenges, as natural raw materials can fluctuate in composition based on growing conditions and harvesting methods.

Cost-performance balance remains perhaps the most significant barrier to widespread adoption. Current bio-based alternatives typically command price premiums of 20-200% over petroleum-based counterparts while often delivering inferior technical performance, creating a challenging value proposition for manufacturers and end-users alike.

Current Thermoset and Thermoplastic Solutions

01 Bio-based thermoplastic polymers from renewable resources

Thermoplastic polymers derived from renewable resources such as plant oils, starches, and cellulose can be processed and reprocessed through heating. These bio-based thermoplastics offer environmental benefits including biodegradability and reduced carbon footprint. They can be modified with additives to enhance properties like flexibility, strength, and thermal stability, making them suitable for various applications including packaging, consumer goods, and automotive components.- Bio-based thermoplastic polymers from renewable resources: Thermoplastic polymers derived from renewable resources such as plant oils, starches, and cellulose can be processed and reused multiple times. These bio-based alternatives to petroleum-based plastics offer similar mechanical properties while providing environmental benefits including biodegradability and reduced carbon footprint. Various processing techniques can be employed to enhance their performance characteristics for applications in packaging, consumer goods, and automotive components.

- Bio-based thermoset polymers and composites: Thermoset polymers derived from bio-based sources such as vegetable oils, lignin, and proteins can be formulated to create durable materials that maintain structural integrity under high temperatures. These polymers undergo irreversible chemical reactions during curing, forming cross-linked networks. Bio-based thermosets are increasingly used in applications requiring high strength, chemical resistance, and thermal stability, including adhesives, coatings, and structural composites.

- Composite materials incorporating bio-based polymers: Bio-based polymers can be combined with natural fibers or other reinforcing materials to create high-performance composite materials. These composites leverage the renewable nature of bio-polymers while enhancing mechanical properties such as strength, stiffness, and impact resistance. Applications include construction materials, automotive components, and consumer products where both sustainability and performance are required.

- Processing technologies for bio-based polymers: Specialized processing technologies have been developed to optimize the production and performance of bio-based polymers. These include modified extrusion techniques, reactive processing, and novel curing methods that address the unique characteristics of bio-based materials. Advanced processing can improve the mechanical properties, thermal stability, and consistency of bio-based polymers, making them more competitive with conventional petroleum-based alternatives.

- Functionalized bio-based polymers with enhanced properties: Chemical modification and functionalization of bio-based polymers can significantly enhance their properties and expand their application range. Techniques such as grafting, cross-linking, and blending with other polymers can improve moisture resistance, thermal stability, mechanical strength, and processability. These modifications enable bio-based polymers to meet specific performance requirements for advanced applications in electronics, medical devices, and specialized industrial uses.

02 Bio-based thermoset polymers and composites

Thermoset polymers derived from bio-based sources like vegetable oils, lignin, and proteins form permanent cross-linked structures when cured. These materials offer excellent mechanical properties, chemical resistance, and thermal stability. Bio-based thermosets are increasingly used in composite materials, where they are combined with natural fibers to create sustainable alternatives to traditional petroleum-based composites for applications in construction, automotive, and aerospace industries.Expand Specific Solutions03 Processing technologies for bio-based polymers

Specialized processing technologies have been developed to address the unique characteristics of bio-based polymers. These include modified extrusion techniques, reactive processing methods, and specialized molding processes that accommodate the different rheological properties and thermal sensitivities of bio-based materials. Advanced processing technologies help overcome challenges related to moisture sensitivity, thermal degradation, and achieving consistent material properties in bio-based polymer manufacturing.Expand Specific Solutions04 Bio-based polymer blends and compatibilization

Blending different bio-based polymers or combining them with conventional polymers can create materials with enhanced properties. Compatibilization techniques are essential to improve the miscibility between different polymer phases, resulting in better mechanical and thermal properties. Various compatibilizers, reactive processing methods, and surface modifications are employed to create high-performance bio-based polymer blends for applications ranging from packaging to durable goods.Expand Specific Solutions05 Applications of bio-based polymers in consumer products

Bio-based polymers are increasingly used in consumer products across various industries. In packaging, these materials offer biodegradable alternatives to conventional plastics. In textiles and personal care products, they provide sustainable options with unique properties. Bio-based polymers are also finding applications in medical devices, sporting goods, and household items, driven by consumer demand for environmentally friendly products and regulatory pressures to reduce plastic waste and carbon emissions.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The bio-based polymer market is experiencing a transition phase, with thermoset and thermoplastic applications showing significant growth potential. Currently in the early commercialization stage, the market is projected to expand substantially as sustainability demands increase. Technologically, thermoplastics have achieved greater maturity, while thermosets are advancing rapidly. Leading academic institutions (MIT, University of Manchester, Jiangnan University) are driving fundamental research, while companies like Kaneka Corp., Covestro, and Eastman Chemical are commercializing applications. Research organizations such as CNRS and NDSU Research Foundation bridge the gap between academic innovation and industrial implementation. The competitive landscape features collaboration between established chemical companies and specialized startups, with increasing focus on biodegradable and renewable polymer solutions.

Kaneka Corp.

Technical Solution: Kaneka has developed PHBH™, a family of polyhydroxyalkanoate (PHA) biopolymers produced through microbial fermentation of plant oils. Their proprietary technology enables precise control of the polymer's side-chain structure, allowing tailored biodegradability profiles for different environments including marine conditions. Kaneka's process utilizes specialized bacteria strains that efficiently convert renewable feedstocks into PHA granules with high purity. For thermoset applications, Kaneka has pioneered bio-based epoxy hardeners derived from cashew nutshell liquid (CNSL), providing improved toughness and flexibility. Their AONILEX™ technology platform extends to thermoplastic applications with controlled biodegradation rates from weeks to years depending on environmental conditions. Kaneka has scaled production to commercial levels (5,000 tons annually) at their facility in Takasago, Japan, demonstrating industrial viability of their microbial fermentation approach.

Strengths: True biodegradability in multiple environments including marine conditions; versatile processing options compatible with existing equipment; high renewable content (>99%). Weaknesses: Higher production costs compared to conventional plastics; limited high-temperature performance; mechanical properties more variable than petroleum-based alternatives.

Covestro Deutschland AG

Technical Solution: Covestro has developed innovative partially bio-based thermoplastic polyurethanes (TPUs) under their DESMOPAN® line, containing up to 60% renewable carbon content derived from corn starch. Their technology focuses on replacing petroleum-based polyether and polyester polyols with bio-based alternatives while maintaining material performance. The company has also pioneered bio-based polycarbonates using plant-derived isosorbide, reducing fossil resource dependency by up to 70%. Covestro's proprietary catalytic process enables efficient conversion of plant oils into polyurethane raw materials, ensuring consistent quality across applications ranging from automotive components to consumer electronics. Their cardyon® technology captures CO2 as a raw material feedstock, further reducing environmental impact while maintaining mechanical properties comparable to conventional polymers.

Strengths: Industry-leading renewable content percentages without compromising mechanical properties; established global manufacturing infrastructure; comprehensive product portfolio spanning both thermoset and thermoplastic applications. Weaknesses: Higher production costs compared to conventional polymers; some bio-based formulations show reduced heat resistance; dependency on agricultural feedstocks subject to price volatility.

Patent Analysis of Bio-based Polymer Technologies

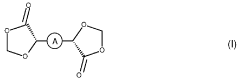

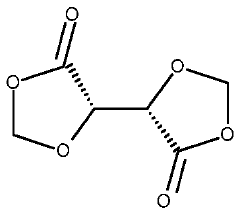

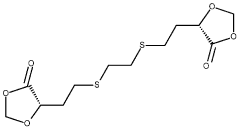

Monomer and polymers

PatentWO2023281004A1

Innovation

- The use of bis(1,3-dioxolan-4-one) (bisDOX) as a cross-linking monomer in ring-opening polymerization to create cross-linked polymers with enhanced mechanical properties, derived from sustainable sources like L-(+)-tartaric acid, which provides superior strength and degradability.

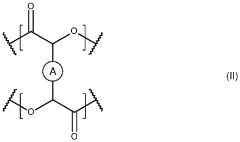

Bio-based thermosets

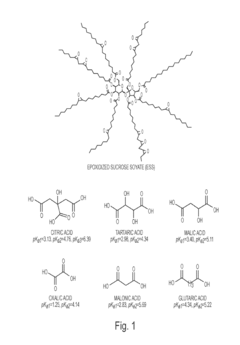

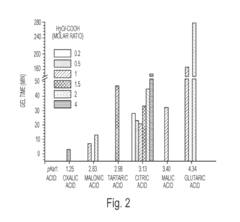

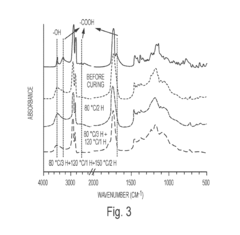

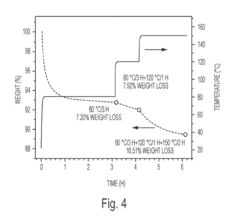

PatentActiveUS20180244834A1

Innovation

- Development of novel bio-based thermosets using highly functional epoxy resins crosslinked with water-soluble multifunctional carboxylic acids, which are curable with water or alcohol, resulting in degradable, VOC-free, and thermally degradable materials suitable for various applications.

Environmental Impact Assessment

The environmental impact assessment of bio-based polymers reveals significant differences between thermoset and thermoplastic varieties throughout their lifecycle. Thermoset bio-based polymers typically demonstrate lower carbon footprints during production compared to their petroleum-based counterparts, with emissions reductions ranging from 30-70% depending on feedstock sources and manufacturing processes. However, their cross-linked structure presents end-of-life challenges, as these materials cannot be conventionally melted and recycled, often necessitating energy-intensive grinding processes or incineration.

Thermoplastic bio-based polymers offer superior environmental credentials regarding circularity, as they can be melted and reformed multiple times. Life cycle assessments indicate that PLA (polylactic acid) and bio-PBS (polybutylene succinate) demonstrate 50-80% lower greenhouse gas emissions compared to conventional plastics when properly recycled. Water usage metrics also favor thermoplastics, with production processes requiring approximately 15-25% less water than comparable thermoset manufacturing.

Land use considerations present complex tradeoffs for both polymer types. First-generation feedstocks (corn, sugarcane) raise concerns about competition with food production, while second-generation feedstocks (agricultural waste, algae) show promise for reducing land use impacts. Thermosets derived from non-food biomass can achieve land use efficiency improvements of approximately 40% compared to first-generation feedstocks.

Biodegradability varies significantly between specific formulations rather than strictly following the thermoset/thermoplastic division. Certain bio-based thermoplastics like PHA (polyhydroxyalkanoates) demonstrate complete biodegradation in marine environments within 3-6 months, while some bio-based thermosets containing natural fibers show enhanced biodegradation compared to conventional thermosets, though still requiring specialized industrial composting facilities.

Energy consumption metrics generally favor thermoplastics, with processing temperatures typically 30-50% lower than those required for thermoset curing. This translates to reduced embodied energy in the final products. However, thermosets often demonstrate superior durability and longer service lives, potentially offsetting initial production impacts through extended product lifecycles.

Chemical emissions and toxicity profiles indicate that both polymer types can reduce harmful substances compared to petroleum-based alternatives. Bio-based thermosets have shown 40-60% reductions in volatile organic compound (VOC) emissions during manufacturing, while thermoplastics generally exhibit lower toxicity concerns during use and disposal phases, particularly important for food packaging and medical applications.

Thermoplastic bio-based polymers offer superior environmental credentials regarding circularity, as they can be melted and reformed multiple times. Life cycle assessments indicate that PLA (polylactic acid) and bio-PBS (polybutylene succinate) demonstrate 50-80% lower greenhouse gas emissions compared to conventional plastics when properly recycled. Water usage metrics also favor thermoplastics, with production processes requiring approximately 15-25% less water than comparable thermoset manufacturing.

Land use considerations present complex tradeoffs for both polymer types. First-generation feedstocks (corn, sugarcane) raise concerns about competition with food production, while second-generation feedstocks (agricultural waste, algae) show promise for reducing land use impacts. Thermosets derived from non-food biomass can achieve land use efficiency improvements of approximately 40% compared to first-generation feedstocks.

Biodegradability varies significantly between specific formulations rather than strictly following the thermoset/thermoplastic division. Certain bio-based thermoplastics like PHA (polyhydroxyalkanoates) demonstrate complete biodegradation in marine environments within 3-6 months, while some bio-based thermosets containing natural fibers show enhanced biodegradation compared to conventional thermosets, though still requiring specialized industrial composting facilities.

Energy consumption metrics generally favor thermoplastics, with processing temperatures typically 30-50% lower than those required for thermoset curing. This translates to reduced embodied energy in the final products. However, thermosets often demonstrate superior durability and longer service lives, potentially offsetting initial production impacts through extended product lifecycles.

Chemical emissions and toxicity profiles indicate that both polymer types can reduce harmful substances compared to petroleum-based alternatives. Bio-based thermosets have shown 40-60% reductions in volatile organic compound (VOC) emissions during manufacturing, while thermoplastics generally exhibit lower toxicity concerns during use and disposal phases, particularly important for food packaging and medical applications.

Manufacturing Scalability Considerations

Manufacturing scalability represents a critical factor in the commercial viability of bio-based polymers, with significant differences between thermoset and thermoplastic production pathways. Thermoplastic bio-based polymers generally demonstrate superior scalability advantages due to their compatibility with existing petroleum-based polymer processing infrastructure. This compatibility allows manufacturers to transition to bio-based alternatives without substantial capital investment in new equipment, representing a significant economic incentive for industrial adoption.

The processing cycle time presents a notable distinction between these polymer categories. Thermoplastics typically feature shorter cycle times as they can be rapidly heated, formed, and cooled without chemical reactions occurring during processing. Conversely, thermoset bio-based polymers require curing time for crosslinking reactions to complete, extending production cycles and potentially limiting throughput in high-volume manufacturing environments.

Equipment requirements also differ substantially between these polymer types. Thermoplastic processing primarily utilizes injection molding, extrusion, and compression molding equipment already widespread in the polymer industry. Thermosets often demand specialized curing ovens, precise temperature control systems, and potentially catalytic activation equipment, increasing both capital expenditure and operational complexity for manufacturers seeking to scale production.

Energy consumption profiles reveal that thermoplastics generally require higher processing temperatures but for shorter durations. Thermosets typically process at lower temperatures but for extended periods, creating different energy utilization patterns that impact both production costs and environmental footprints at scale. This energy consideration becomes increasingly significant as production volumes expand.

Quality control challenges also diverge between these polymer categories. Thermoplastic manufacturing benefits from established in-line quality monitoring techniques, while thermoset production often requires more complex cure monitoring systems to ensure complete crosslinking has occurred. This difference impacts both production reliability and quality assurance costs at industrial scales.

Waste management considerations further differentiate scalability potential. Thermoplastic production generates recyclable process waste that can be reground and reintroduced into the manufacturing stream, enhancing material efficiency. Thermoset production waste, once cured, cannot be reprocessed, creating additional disposal challenges and material inefficiencies that become more pronounced at larger production volumes.

Supply chain resilience must also be evaluated when considering manufacturing scale-up. Thermoplastic bio-based polymers often utilize more established feedstock supply chains with greater geographic distribution, potentially offering more robust supply security for large-scale production compared to some specialized bio-based thermoset precursors.

The processing cycle time presents a notable distinction between these polymer categories. Thermoplastics typically feature shorter cycle times as they can be rapidly heated, formed, and cooled without chemical reactions occurring during processing. Conversely, thermoset bio-based polymers require curing time for crosslinking reactions to complete, extending production cycles and potentially limiting throughput in high-volume manufacturing environments.

Equipment requirements also differ substantially between these polymer types. Thermoplastic processing primarily utilizes injection molding, extrusion, and compression molding equipment already widespread in the polymer industry. Thermosets often demand specialized curing ovens, precise temperature control systems, and potentially catalytic activation equipment, increasing both capital expenditure and operational complexity for manufacturers seeking to scale production.

Energy consumption profiles reveal that thermoplastics generally require higher processing temperatures but for shorter durations. Thermosets typically process at lower temperatures but for extended periods, creating different energy utilization patterns that impact both production costs and environmental footprints at scale. This energy consideration becomes increasingly significant as production volumes expand.

Quality control challenges also diverge between these polymer categories. Thermoplastic manufacturing benefits from established in-line quality monitoring techniques, while thermoset production often requires more complex cure monitoring systems to ensure complete crosslinking has occurred. This difference impacts both production reliability and quality assurance costs at industrial scales.

Waste management considerations further differentiate scalability potential. Thermoplastic production generates recyclable process waste that can be reground and reintroduced into the manufacturing stream, enhancing material efficiency. Thermoset production waste, once cured, cannot be reprocessed, creating additional disposal challenges and material inefficiencies that become more pronounced at larger production volumes.

Supply chain resilience must also be evaluated when considering manufacturing scale-up. Thermoplastic bio-based polymers often utilize more established feedstock supply chains with greater geographic distribution, potentially offering more robust supply security for large-scale production compared to some specialized bio-based thermoset precursors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!