Biomedical Polymers in Portable Diagnostic Devices

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomedical Polymer Evolution and Research Objectives

Biomedical polymers have undergone significant evolution since their initial applications in healthcare during the mid-20th century. The trajectory began with simple applications such as sutures and wound dressings, progressing to more sophisticated implementations in drug delivery systems and tissue engineering. The last decade has witnessed an accelerated development in polymer science specifically tailored for diagnostic applications, driven by advances in material science, nanotechnology, and molecular biology.

The integration of biomedical polymers into portable diagnostic devices represents a convergence of multiple technological domains. These materials offer unique advantages including biocompatibility, flexibility, cost-effectiveness, and adaptability to various manufacturing processes such as 3D printing and microfluidic fabrication. The evolution has been particularly notable in the development of stimuli-responsive polymers that can react to specific biological markers, enabling real-time diagnostics without complex laboratory infrastructure.

Recent technological milestones include the development of conductive polymers capable of direct signal transduction, biodegradable polymers that eliminate disposal concerns, and polymer-based microfluidic platforms that facilitate complex sample processing in miniaturized formats. The COVID-19 pandemic further accelerated innovation in this field, highlighting the critical need for rapid, accessible diagnostic technologies deployable in resource-limited settings.

The primary research objectives in this domain focus on enhancing the sensitivity, specificity, and stability of polymer-based diagnostic platforms. Researchers aim to develop polymers with improved molecular recognition capabilities, reduced non-specific binding, and enhanced signal amplification properties. Another critical objective involves creating polymer systems that maintain functionality across varying environmental conditions, addressing challenges related to temperature fluctuations, humidity, and shelf-life limitations.

Additionally, research efforts are directed toward developing sustainable manufacturing processes for these materials, reducing production costs while maintaining performance standards. The integration of artificial intelligence and machine learning algorithms with polymer-based sensors represents another frontier, potentially enabling more sophisticated data analysis and interpretation directly within portable devices.

The ultimate goal of current research trajectories is to democratize advanced diagnostic capabilities through polymer-based portable devices that combine high analytical performance with user-friendly interfaces, minimal power requirements, and connectivity features for telemedicine applications. This vision aligns with global health initiatives seeking to address healthcare disparities through accessible point-of-care technologies.

The integration of biomedical polymers into portable diagnostic devices represents a convergence of multiple technological domains. These materials offer unique advantages including biocompatibility, flexibility, cost-effectiveness, and adaptability to various manufacturing processes such as 3D printing and microfluidic fabrication. The evolution has been particularly notable in the development of stimuli-responsive polymers that can react to specific biological markers, enabling real-time diagnostics without complex laboratory infrastructure.

Recent technological milestones include the development of conductive polymers capable of direct signal transduction, biodegradable polymers that eliminate disposal concerns, and polymer-based microfluidic platforms that facilitate complex sample processing in miniaturized formats. The COVID-19 pandemic further accelerated innovation in this field, highlighting the critical need for rapid, accessible diagnostic technologies deployable in resource-limited settings.

The primary research objectives in this domain focus on enhancing the sensitivity, specificity, and stability of polymer-based diagnostic platforms. Researchers aim to develop polymers with improved molecular recognition capabilities, reduced non-specific binding, and enhanced signal amplification properties. Another critical objective involves creating polymer systems that maintain functionality across varying environmental conditions, addressing challenges related to temperature fluctuations, humidity, and shelf-life limitations.

Additionally, research efforts are directed toward developing sustainable manufacturing processes for these materials, reducing production costs while maintaining performance standards. The integration of artificial intelligence and machine learning algorithms with polymer-based sensors represents another frontier, potentially enabling more sophisticated data analysis and interpretation directly within portable devices.

The ultimate goal of current research trajectories is to democratize advanced diagnostic capabilities through polymer-based portable devices that combine high analytical performance with user-friendly interfaces, minimal power requirements, and connectivity features for telemedicine applications. This vision aligns with global health initiatives seeking to address healthcare disparities through accessible point-of-care technologies.

Market Analysis for Polymer-Based Diagnostic Devices

The global market for polymer-based diagnostic devices is experiencing robust growth, driven by increasing demand for point-of-care testing and personalized medicine. Current market valuation stands at approximately 12 billion USD with a compound annual growth rate of 8.3% projected through 2028. This growth trajectory is supported by rising healthcare expenditures worldwide and the expanding geriatric population requiring frequent diagnostic monitoring.

North America currently dominates the market share at 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth due to improving healthcare infrastructure, increasing disposable income, and greater awareness about preventive healthcare in countries like China and India.

Consumer demand patterns indicate a strong preference for portable, user-friendly diagnostic devices that provide rapid results with minimal sample volumes. The COVID-19 pandemic has significantly accelerated this trend, creating unprecedented demand for at-home testing solutions that utilize polymer-based technologies. Market research indicates that 67% of healthcare providers now recommend portable diagnostic devices for chronic disease management.

Key market segments include glucose monitoring devices (largest segment at 32% market share), infectious disease testing kits, cardiovascular diagnostic devices, and cancer biomarker detection systems. Polymer-based microfluidic chips represent the fastest-growing sub-segment with 14.2% annual growth, driven by their versatility and cost-effectiveness in various diagnostic applications.

Pricing trends show a gradual decrease in manufacturing costs as production scales up and polymer technologies mature. This cost reduction is enabling broader market penetration, particularly in emerging economies where price sensitivity is high. The average selling price of polymer-based diagnostic platforms has decreased by 18% over the past five years.

Reimbursement policies and regulatory frameworks significantly influence market dynamics. Countries with favorable reimbursement structures for preventive diagnostics show 2.3 times higher adoption rates compared to those without such policies. The FDA's recent initiatives to streamline approval processes for innovative diagnostic technologies have reduced time-to-market by approximately 30% for polymer-based devices.

Consumer behavior analysis reveals that ease of use, accuracy, and connectivity features are the primary purchasing factors for end-users. Devices offering smartphone integration and cloud-based data management are experiencing 22% higher market uptake compared to traditional standalone devices.

North America currently dominates the market share at 38%, followed by Europe at 29% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to witness the fastest growth due to improving healthcare infrastructure, increasing disposable income, and greater awareness about preventive healthcare in countries like China and India.

Consumer demand patterns indicate a strong preference for portable, user-friendly diagnostic devices that provide rapid results with minimal sample volumes. The COVID-19 pandemic has significantly accelerated this trend, creating unprecedented demand for at-home testing solutions that utilize polymer-based technologies. Market research indicates that 67% of healthcare providers now recommend portable diagnostic devices for chronic disease management.

Key market segments include glucose monitoring devices (largest segment at 32% market share), infectious disease testing kits, cardiovascular diagnostic devices, and cancer biomarker detection systems. Polymer-based microfluidic chips represent the fastest-growing sub-segment with 14.2% annual growth, driven by their versatility and cost-effectiveness in various diagnostic applications.

Pricing trends show a gradual decrease in manufacturing costs as production scales up and polymer technologies mature. This cost reduction is enabling broader market penetration, particularly in emerging economies where price sensitivity is high. The average selling price of polymer-based diagnostic platforms has decreased by 18% over the past five years.

Reimbursement policies and regulatory frameworks significantly influence market dynamics. Countries with favorable reimbursement structures for preventive diagnostics show 2.3 times higher adoption rates compared to those without such policies. The FDA's recent initiatives to streamline approval processes for innovative diagnostic technologies have reduced time-to-market by approximately 30% for polymer-based devices.

Consumer behavior analysis reveals that ease of use, accuracy, and connectivity features are the primary purchasing factors for end-users. Devices offering smartphone integration and cloud-based data management are experiencing 22% higher market uptake compared to traditional standalone devices.

Current Challenges in Biomedical Polymer Technology

Despite significant advancements in biomedical polymer technology for portable diagnostic devices, several critical challenges continue to impede progress in this rapidly evolving field. Material biocompatibility remains a primary concern, as polymers must maintain functionality while avoiding adverse biological reactions when in contact with bodily fluids or tissues. Current polymers often trigger inflammatory responses or protein adsorption that can compromise diagnostic accuracy and device performance over time.

Stability under various environmental conditions presents another substantial hurdle. Portable diagnostic devices are frequently exposed to fluctuating temperatures, humidity levels, and mechanical stresses during transport and operation. Many existing polymers exhibit degradation, dimensional changes, or altered mechanical properties under these conditions, affecting the reliability and shelf life of diagnostic products.

Manufacturing scalability poses significant technical difficulties, particularly for complex polymer formulations with specialized functionalities. The transition from laboratory-scale production to commercial manufacturing often results in inconsistent material properties, compromising quality control and increasing production costs. Additionally, batch-to-batch variations can affect diagnostic accuracy and reliability.

Surface modification and functionalization techniques for polymers remain challenging to standardize and control. The precise attachment of biorecognition elements (antibodies, enzymes, aptamers) to polymer surfaces is critical for diagnostic sensitivity and specificity. Current methods often suffer from non-specific binding, orientation issues, and gradual loss of biomolecule activity, limiting device performance and shelf life.

Regulatory compliance presents a complex landscape for biomedical polymers. Meeting stringent requirements for biocompatibility, leachables, extractables, and long-term stability requires extensive testing and documentation. Many promising polymer technologies face significant delays in market entry due to these regulatory hurdles, particularly for novel materials without established safety profiles.

Integration challenges exist between polymers and other device components, including electronics, microfluidics, and detection systems. Interface compatibility issues often lead to delamination, leakage, or signal interference. The development of polymer systems that maintain stable interfaces with multiple materials while preserving their functional properties remains technically demanding.

Sustainability concerns are increasingly prominent, with growing pressure to develop biodegradable or recyclable polymers for diagnostic applications. However, balancing environmental considerations with performance requirements presents significant technical challenges, as more sustainable alternatives often exhibit inferior mechanical properties, chemical resistance, or shelf stability compared to conventional polymers.

Stability under various environmental conditions presents another substantial hurdle. Portable diagnostic devices are frequently exposed to fluctuating temperatures, humidity levels, and mechanical stresses during transport and operation. Many existing polymers exhibit degradation, dimensional changes, or altered mechanical properties under these conditions, affecting the reliability and shelf life of diagnostic products.

Manufacturing scalability poses significant technical difficulties, particularly for complex polymer formulations with specialized functionalities. The transition from laboratory-scale production to commercial manufacturing often results in inconsistent material properties, compromising quality control and increasing production costs. Additionally, batch-to-batch variations can affect diagnostic accuracy and reliability.

Surface modification and functionalization techniques for polymers remain challenging to standardize and control. The precise attachment of biorecognition elements (antibodies, enzymes, aptamers) to polymer surfaces is critical for diagnostic sensitivity and specificity. Current methods often suffer from non-specific binding, orientation issues, and gradual loss of biomolecule activity, limiting device performance and shelf life.

Regulatory compliance presents a complex landscape for biomedical polymers. Meeting stringent requirements for biocompatibility, leachables, extractables, and long-term stability requires extensive testing and documentation. Many promising polymer technologies face significant delays in market entry due to these regulatory hurdles, particularly for novel materials without established safety profiles.

Integration challenges exist between polymers and other device components, including electronics, microfluidics, and detection systems. Interface compatibility issues often lead to delamination, leakage, or signal interference. The development of polymer systems that maintain stable interfaces with multiple materials while preserving their functional properties remains technically demanding.

Sustainability concerns are increasingly prominent, with growing pressure to develop biodegradable or recyclable polymers for diagnostic applications. However, balancing environmental considerations with performance requirements presents significant technical challenges, as more sustainable alternatives often exhibit inferior mechanical properties, chemical resistance, or shelf stability compared to conventional polymers.

Current Polymer Solutions for Portable Diagnostics

01 Biodegradable polymers for medical applications

Biodegradable polymers are extensively used in biomedical applications due to their ability to break down in the body over time. These polymers can be formulated into various structures such as scaffolds, films, and microspheres for tissue engineering, drug delivery systems, and implantable medical devices. The degradation rate can be controlled by modifying the polymer composition, allowing for customized release profiles of therapeutic agents or gradual transfer of mechanical load to healing tissues.- Biodegradable polymers for medical applications: Biodegradable polymers are extensively used in medical applications due to their ability to break down safely in the body over time. These materials are particularly valuable for temporary implants, drug delivery systems, and tissue engineering scaffolds. Common biodegradable polymers include polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers, which offer controlled degradation rates and biocompatibility. These materials eliminate the need for surgical removal of temporary implants and can be designed with specific mechanical properties and degradation profiles to suit various medical applications.

- Smart polymers for biosensing and drug delivery: Smart polymers respond to environmental stimuli such as temperature, pH, or specific biomolecules, making them valuable for biosensing and controlled drug delivery applications. These materials can undergo reversible physical or chemical changes when exposed to specific triggers, allowing for precise control over drug release or providing detectable signals for diagnostic purposes. Applications include glucose-responsive insulin delivery systems, temperature-sensitive drug carriers that release their payload at specific body sites, and polymer-based biosensors that can detect disease markers with high sensitivity and specificity.

- Polymer-based biomedical implants and devices: Polymeric materials are increasingly used to create biomedical implants and devices due to their versatility, processability, and tunable properties. These include cardiovascular implants, orthopedic devices, neural interfaces, and artificial organs. Advanced manufacturing techniques like 3D printing allow for patient-specific designs. Polymers can be engineered to have specific mechanical properties, surface characteristics, and bioactivity to optimize their performance in different physiological environments and minimize adverse reactions such as inflammation or foreign body responses.

- Conductive polymers for bioelectronics: Conductive polymers combine electrical conductivity with the flexibility and biocompatibility of polymeric materials, making them ideal for bioelectronic applications. These materials bridge the gap between electronic devices and biological systems, enabling applications such as neural interfaces, biosensors, and stimuli-responsive drug delivery systems. Their soft mechanical properties better match biological tissues compared to traditional metal electrodes, reducing inflammatory responses. Additionally, these polymers can be functionalized with bioactive molecules to enhance their integration with living tissues and improve their long-term performance in vivo.

- Polymer surface modifications for biocompatibility: Surface modification of polymers is crucial for improving their biocompatibility and functionality in medical applications. Techniques include plasma treatment, chemical grafting, and coating with bioactive molecules to control protein adsorption, cell adhesion, and tissue integration. These modifications can prevent adverse reactions like blood clotting on cardiovascular implants or bacterial colonization on catheters. By engineering the interface between synthetic materials and biological environments, researchers can enhance the performance and longevity of biomedical devices while minimizing complications and improving patient outcomes.

02 Biocompatible polymers for implantable devices

Biocompatible polymers are designed to interact with biological systems without causing adverse effects. These materials are crucial for developing implantable medical devices such as sensors, prosthetics, and drug delivery systems. Key considerations include surface properties, mechanical strength, and long-term stability in the physiological environment. Advanced biocompatible polymers incorporate features like anti-fouling surfaces, controlled drug elution capabilities, and tissue integration properties to enhance device performance and patient outcomes.Expand Specific Solutions03 Smart polymers with stimuli-responsive properties

Smart polymers exhibit changes in their properties in response to environmental stimuli such as temperature, pH, light, or electrical signals. In biomedical applications, these materials enable the development of intelligent drug delivery systems, biosensors, and tissue engineering scaffolds. For example, temperature-responsive polymers can facilitate controlled drug release at specific body sites, while pH-sensitive polymers can target drug delivery to specific organs or cellular compartments based on their local pH environment.Expand Specific Solutions04 Polymer-based drug delivery systems

Polymeric materials are widely used in drug delivery systems to improve therapeutic efficacy and reduce side effects. These systems can be designed as nanoparticles, hydrogels, micelles, or implantable devices that provide controlled release of pharmaceutical agents. The polymer composition and structure can be tailored to achieve specific release kinetics, targeting capabilities, and biodegradation profiles. Advanced polymer-based delivery systems incorporate features like triggered release mechanisms and targeting moieties to enhance therapeutic outcomes.Expand Specific Solutions05 Conductive polymers for bioelectronic applications

Conductive polymers combine electrical conductivity with the versatility and biocompatibility of polymeric materials, making them valuable for bioelectronic applications. These materials are used in neural interfaces, biosensors, and tissue engineering constructs that require electrical stimulation or sensing capabilities. The unique properties of conductive polymers allow for the development of flexible, soft electronic devices that can better interface with biological tissues compared to traditional rigid electronic materials.Expand Specific Solutions

Leading Companies in Biomedical Polymer Industry

The biomedical polymers market for portable diagnostic devices is in a growth phase, with increasing demand driven by the shift toward point-of-care testing and personalized medicine. The global market is projected to reach significant scale as healthcare systems prioritize rapid, accessible diagnostics. Technologically, the field shows varying maturity levels across applications, with companies demonstrating different specialization areas. Medtronic and Boston Scientific lead with established polymer-based diagnostic platforms, while Abbott Cardiovascular Systems focuses on integrating polymers into cardiovascular monitoring devices. Academic institutions like Rutgers and Arizona State University contribute fundamental research, while specialized firms like Biotectix and T2 Biosystems develop novel conductive polymers and diagnostic applications, creating a competitive landscape balanced between established medical device manufacturers and innovative startups.

Koninklijke Philips NV

Technical Solution: Philips has developed an integrated approach to biomedical polymers for portable diagnostics through their Minicare platform. Their technology utilizes specialized conducting polymers combined with proprietary surface chemistry to create highly sensitive electrochemical sensors. The company has pioneered the use of molecularly imprinted polymers (MIPs) that function as synthetic antibodies with enhanced stability compared to biological recognition elements. Philips' portable diagnostic devices incorporate microfluidic cartridges made from engineered polymers with precise channel geometries that enable controlled sample flow and mixing. Their Magnotech technology combines magnetic nanoparticles with polymer-based capture surfaces to achieve rapid separation and concentration of target analytes from complex biological samples. Philips has also developed specialized polymer formulations that maintain reagent stability in dried form, allowing their portable diagnostic devices to be stored at ambient temperatures for extended periods without performance degradation.

Strengths: Highly integrated systems combining sample preparation, analysis and detection; excellent manufacturing scalability; robust performance in field conditions; long shelf life without refrigeration. Weaknesses: Higher initial device cost compared to simpler diagnostic platforms; proprietary cartridge design limits third-party development; more complex user interface requiring some training.

Surmodics, Inc.

Technical Solution: Surmodics has pioneered advanced surface modification technologies using proprietary biomedical polymers for diagnostic applications. Their PhotoLink® technology creates covalently bound polymer coatings on various substrate materials, enabling precise control of surface properties critical for diagnostic device performance. The company has developed specialized hydrophilic and hydrophobic polymer formulations that can be patterned at microscale resolution to create defined reaction zones in microfluidic diagnostic devices. Surmodics' polymer coatings incorporate functional groups that can immobilize capture antibodies, enzymes, or nucleic acids while maintaining their biological activity and orientation. Their technology addresses key challenges in portable diagnostics including non-specific binding, protein denaturation, and signal interference. The company has also developed biodegradable polymer matrices that can incorporate reagents in dry form, enabling ambient storage of diagnostic tests without refrigeration—a critical feature for portable devices used in resource-limited settings.

Strengths: Exceptional surface modification capabilities that enhance biomolecule immobilization and orientation; reduced non-specific binding leading to improved test sensitivity; extended shelf life without refrigeration; compatibility with multiple substrate materials. Weaknesses: Higher manufacturing complexity compared to unmodified surfaces; requires specialized equipment for polymer application; potential for batch-to-batch variability in coating performance.

Key Patents in Biomedical Polymer Applications

Biomedical devices

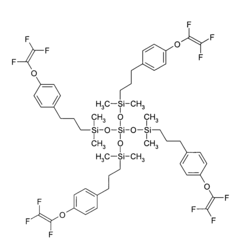

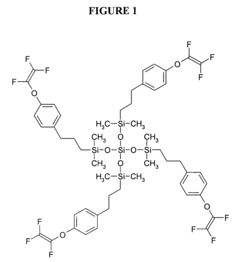

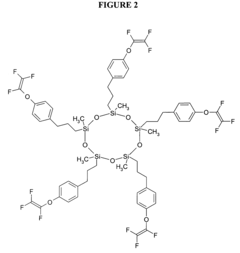

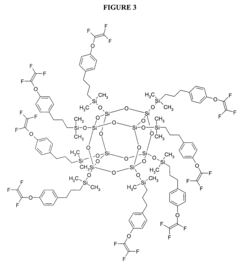

PatentInactiveUS7534836B2

Innovation

- The development of biomedical devices formed from polymerization products of monomeric mixtures containing trifluorovinyl groups, specifically perfluorocyclobutane polymers, which enhance oxygen permeability and wettability through free radical or thermal polymerization, resulting in materials suitable for contact lenses with improved physical and chemical properties.

Biocompatible polymers for medical devices

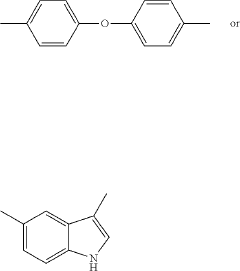

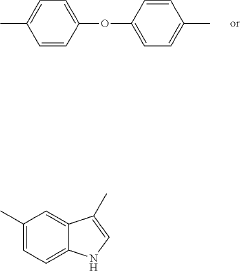

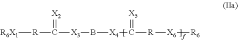

PatentActiveUS20190185624A1

Innovation

- Development of new classes of monomeric compounds that can be polymerized to form novel biodegradable and bioresorbable polymers and co-polymers, incorporating aromatic repeating units analogous to tyrosine, thyronine, tryptophan, and other naturally occurring compounds, which can be adapted for radio-opacity and used in medical devices and therapeutic formulations.

Biocompatibility and Safety Considerations

Biocompatibility represents a critical consideration in the development of biomedical polymers for portable diagnostic devices. These materials must interact with biological systems without causing adverse reactions, particularly when in direct contact with bodily fluids or tissues. The ISO 10993 standards provide comprehensive guidelines for evaluating biocompatibility, including cytotoxicity, sensitization, irritation, and systemic toxicity assessments. Manufacturers must rigorously test polymeric materials to ensure they do not release harmful leachables or extractables when exposed to biological environments.

Safety considerations extend beyond biocompatibility to include chemical stability during storage and use. Polymers employed in diagnostic devices must maintain their structural integrity and functional properties throughout the product lifecycle, even under varying environmental conditions. This stability ensures consistent diagnostic results and prevents the formation of potentially harmful degradation products. Additionally, sterilization compatibility represents another crucial safety aspect, as polymers must withstand common sterilization methods such as ethylene oxide treatment, gamma irradiation, or autoclave procedures without compromising their performance or releasing toxic byproducts.

Regulatory frameworks governing biomedical polymers have become increasingly stringent, with agencies like the FDA and EMA requiring extensive documentation of safety profiles. The regulatory landscape emphasizes risk assessment methodologies that evaluate both short-term and long-term safety implications. Manufacturers must demonstrate that their polymeric materials pose minimal risk to patients and healthcare workers throughout the intended use period of the diagnostic device.

Recent advances in polymer science have focused on developing inherently biocompatible materials that incorporate anti-fouling properties to prevent protein adsorption and bacterial adhesion. These innovations help minimize interference with diagnostic assays while reducing infection risks. Surface modification techniques, including plasma treatment and chemical grafting, have emerged as effective approaches to enhance biocompatibility without altering the bulk properties of the polymer.

Environmental and disposal considerations have gained prominence in safety assessments of biomedical polymers. The potential environmental impact of polymer waste from single-use diagnostic devices has prompted research into biodegradable alternatives that maintain the necessary performance characteristics. This ecological dimension of safety extends the evaluation criteria beyond immediate patient safety to encompass broader public health considerations related to waste management and environmental contamination.

Safety considerations extend beyond biocompatibility to include chemical stability during storage and use. Polymers employed in diagnostic devices must maintain their structural integrity and functional properties throughout the product lifecycle, even under varying environmental conditions. This stability ensures consistent diagnostic results and prevents the formation of potentially harmful degradation products. Additionally, sterilization compatibility represents another crucial safety aspect, as polymers must withstand common sterilization methods such as ethylene oxide treatment, gamma irradiation, or autoclave procedures without compromising their performance or releasing toxic byproducts.

Regulatory frameworks governing biomedical polymers have become increasingly stringent, with agencies like the FDA and EMA requiring extensive documentation of safety profiles. The regulatory landscape emphasizes risk assessment methodologies that evaluate both short-term and long-term safety implications. Manufacturers must demonstrate that their polymeric materials pose minimal risk to patients and healthcare workers throughout the intended use period of the diagnostic device.

Recent advances in polymer science have focused on developing inherently biocompatible materials that incorporate anti-fouling properties to prevent protein adsorption and bacterial adhesion. These innovations help minimize interference with diagnostic assays while reducing infection risks. Surface modification techniques, including plasma treatment and chemical grafting, have emerged as effective approaches to enhance biocompatibility without altering the bulk properties of the polymer.

Environmental and disposal considerations have gained prominence in safety assessments of biomedical polymers. The potential environmental impact of polymer waste from single-use diagnostic devices has prompted research into biodegradable alternatives that maintain the necessary performance characteristics. This ecological dimension of safety extends the evaluation criteria beyond immediate patient safety to encompass broader public health considerations related to waste management and environmental contamination.

Sustainability of Biomedical Polymer Materials

The sustainability of biomedical polymer materials in portable diagnostic devices represents a critical consideration as healthcare technology advances toward more accessible point-of-care solutions. Current biomedical polymers predominantly rely on petroleum-based resources, raising significant environmental concerns regarding their production, usage, and disposal. The carbon footprint associated with conventional polymer manufacturing processes contributes substantially to greenhouse gas emissions, while the non-biodegradable nature of many synthetic polymers leads to persistent environmental contamination.

In response to these challenges, the industry has begun shifting toward bio-based polymers derived from renewable resources such as corn starch, cellulose, and algae. These materials offer comparable mechanical and chemical properties while significantly reducing environmental impact. For instance, polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) demonstrate promising biodegradability profiles while maintaining the structural integrity necessary for diagnostic applications.

Life cycle assessment (LCA) studies indicate that transitioning to sustainable biomedical polymers can reduce environmental impact by 30-60% compared to traditional petroleum-based alternatives. However, challenges remain in scaling production processes to achieve cost parity with conventional materials, particularly for specialized applications requiring precise material specifications.

Regulatory frameworks worldwide are increasingly emphasizing environmental considerations in medical device approval processes. The European Union's Medical Device Regulation now includes provisions for evaluating environmental impact, while the FDA has initiated programs to encourage sustainable material selection in medical device development. These regulatory shifts are accelerating industry adoption of eco-friendly polymer alternatives.

Circular economy principles are being integrated into portable diagnostic device design through strategies such as material recovery systems, modular components for easier recycling, and biodegradable disposable elements. Companies like Roche and Abbott have implemented take-back programs for their diagnostic devices, while startups are developing fully compostable test strips and cartridges using algae-derived polymers.

The economic viability of sustainable biomedical polymers continues to improve as production scales increase and manufacturing processes become more efficient. Market analysis suggests that the price premium for sustainable alternatives has decreased from approximately 300% to 30-50% over the past decade, with projections indicating potential cost parity within 5-7 years for certain applications.

Future research directions focus on developing hybrid materials that combine the performance advantages of synthetic polymers with the sustainability benefits of bio-based alternatives. Advanced manufacturing techniques such as 3D printing with sustainable biomedical polymers are enabling more resource-efficient production of customized diagnostic components, further enhancing the sustainability profile of next-generation portable diagnostic devices.

In response to these challenges, the industry has begun shifting toward bio-based polymers derived from renewable resources such as corn starch, cellulose, and algae. These materials offer comparable mechanical and chemical properties while significantly reducing environmental impact. For instance, polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) demonstrate promising biodegradability profiles while maintaining the structural integrity necessary for diagnostic applications.

Life cycle assessment (LCA) studies indicate that transitioning to sustainable biomedical polymers can reduce environmental impact by 30-60% compared to traditional petroleum-based alternatives. However, challenges remain in scaling production processes to achieve cost parity with conventional materials, particularly for specialized applications requiring precise material specifications.

Regulatory frameworks worldwide are increasingly emphasizing environmental considerations in medical device approval processes. The European Union's Medical Device Regulation now includes provisions for evaluating environmental impact, while the FDA has initiated programs to encourage sustainable material selection in medical device development. These regulatory shifts are accelerating industry adoption of eco-friendly polymer alternatives.

Circular economy principles are being integrated into portable diagnostic device design through strategies such as material recovery systems, modular components for easier recycling, and biodegradable disposable elements. Companies like Roche and Abbott have implemented take-back programs for their diagnostic devices, while startups are developing fully compostable test strips and cartridges using algae-derived polymers.

The economic viability of sustainable biomedical polymers continues to improve as production scales increase and manufacturing processes become more efficient. Market analysis suggests that the price premium for sustainable alternatives has decreased from approximately 300% to 30-50% over the past decade, with projections indicating potential cost parity within 5-7 years for certain applications.

Future research directions focus on developing hybrid materials that combine the performance advantages of synthetic polymers with the sustainability benefits of bio-based alternatives. Advanced manufacturing techniques such as 3D printing with sustainable biomedical polymers are enabling more resource-efficient production of customized diagnostic components, further enhancing the sustainability profile of next-generation portable diagnostic devices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!