How Biomedical Polymers Can Reduce Medical Waste

OCT 24, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biomedical Polymers Evolution and Waste Reduction Goals

Biomedical polymers have evolved significantly over the past several decades, transforming from simple structural materials to sophisticated functional components in medical devices and applications. The journey began in the 1960s with the introduction of basic synthetic polymers like polyethylene and polyvinyl chloride in medical applications. These early materials offered limited functionality but established the foundation for future innovations in the field.

By the 1980s, biodegradable polymers such as polylactic acid (PLA) and polyglycolic acid (PGA) emerged, marking a pivotal shift toward materials designed to break down naturally in the body. This development represented the first significant step toward reducing medical waste through material science, as these polymers eliminated the need for secondary surgical procedures to remove temporary implants.

The 1990s and early 2000s witnessed the rise of smart polymers with stimuli-responsive properties, capable of changing their characteristics in response to environmental factors like temperature, pH, or electrical stimulation. These advanced materials enabled more precise drug delivery systems and tissue engineering scaffolds, further enhancing medical outcomes while potentially reducing resource consumption.

Current technological trends are focused on developing fully biobased polymers derived from renewable resources rather than petroleum-based feedstocks. This shift aligns with broader sustainability goals and addresses the growing concern about the environmental impact of medical waste. Concurrently, research into polymers with enhanced biodegradability under specific conditions is accelerating, aiming to create materials that perform reliably during use but decompose rapidly after disposal.

The primary goal in this field is to develop biomedical polymers that maintain or improve therapeutic efficacy while significantly reducing environmental impact throughout their lifecycle. This includes creating materials that require less energy to produce, generate fewer toxic byproducts during manufacturing, function effectively during their intended use period, and decompose safely after disposal.

Another critical objective is designing polymers that enable the transition from single-use to multiple-use medical devices without compromising patient safety. This involves developing materials with enhanced durability, improved sterilization resistance, and maintained biocompatibility over multiple use cycles.

The ultimate technical target remains the creation of "zero-waste" biomedical polymers—materials that either completely biodegrade into non-toxic components or can be efficiently recycled into new medical products. This ambitious goal requires interdisciplinary collaboration between polymer scientists, medical professionals, environmental engineers, and regulatory experts to ensure that new materials meet both clinical requirements and environmental standards.

By the 1980s, biodegradable polymers such as polylactic acid (PLA) and polyglycolic acid (PGA) emerged, marking a pivotal shift toward materials designed to break down naturally in the body. This development represented the first significant step toward reducing medical waste through material science, as these polymers eliminated the need for secondary surgical procedures to remove temporary implants.

The 1990s and early 2000s witnessed the rise of smart polymers with stimuli-responsive properties, capable of changing their characteristics in response to environmental factors like temperature, pH, or electrical stimulation. These advanced materials enabled more precise drug delivery systems and tissue engineering scaffolds, further enhancing medical outcomes while potentially reducing resource consumption.

Current technological trends are focused on developing fully biobased polymers derived from renewable resources rather than petroleum-based feedstocks. This shift aligns with broader sustainability goals and addresses the growing concern about the environmental impact of medical waste. Concurrently, research into polymers with enhanced biodegradability under specific conditions is accelerating, aiming to create materials that perform reliably during use but decompose rapidly after disposal.

The primary goal in this field is to develop biomedical polymers that maintain or improve therapeutic efficacy while significantly reducing environmental impact throughout their lifecycle. This includes creating materials that require less energy to produce, generate fewer toxic byproducts during manufacturing, function effectively during their intended use period, and decompose safely after disposal.

Another critical objective is designing polymers that enable the transition from single-use to multiple-use medical devices without compromising patient safety. This involves developing materials with enhanced durability, improved sterilization resistance, and maintained biocompatibility over multiple use cycles.

The ultimate technical target remains the creation of "zero-waste" biomedical polymers—materials that either completely biodegrade into non-toxic components or can be efficiently recycled into new medical products. This ambitious goal requires interdisciplinary collaboration between polymer scientists, medical professionals, environmental engineers, and regulatory experts to ensure that new materials meet both clinical requirements and environmental standards.

Market Demand for Sustainable Medical Materials

The healthcare industry is witnessing a significant shift towards sustainable practices, driven by increasing environmental concerns and regulatory pressures. The global medical waste management market was valued at $7.8 billion in 2022 and is projected to reach $12.3 billion by 2030, with a compound annual growth rate of 5.8%. This substantial growth underscores the urgent need for sustainable medical materials, particularly biomedical polymers that can reduce medical waste.

Healthcare facilities generate enormous amounts of plastic waste, with hospitals in the United States alone producing approximately 14,000 tons of waste daily. Single-use medical devices, packaging materials, and disposable supplies constitute a significant portion of this waste. The COVID-19 pandemic has further exacerbated this issue, with the increased use of personal protective equipment (PPE) contributing to medical waste volumes.

Market research indicates that 78% of healthcare professionals express concern about the environmental impact of medical waste, and 65% of hospitals are actively seeking sustainable alternatives to traditional medical materials. This growing awareness has created a robust demand for biodegradable and compostable biomedical polymers that maintain the necessary performance characteristics while reducing environmental footprint.

Regulatory developments are also driving market demand. The European Union's Single-Use Plastics Directive and similar regulations worldwide are imposing stricter requirements on plastic waste management. Healthcare institutions face increasing pressure to comply with these regulations, creating a market pull for sustainable alternatives that can help meet compliance requirements while maintaining quality care.

Patient preferences are evolving as well, with 72% of patients expressing preference for healthcare providers that demonstrate environmental responsibility. This consumer sentiment is influencing purchasing decisions at institutional levels, creating additional market incentives for sustainable medical materials.

The economic benefits of sustainable medical materials are becoming increasingly apparent. Hospitals implementing waste reduction programs through sustainable materials have reported cost savings of 15-30% in waste management expenses. These financial incentives, coupled with corporate social responsibility goals, are driving healthcare systems to invest in sustainable alternatives.

Regional market analysis reveals that North America and Europe currently lead in the adoption of sustainable medical materials, but the Asia-Pacific region is expected to show the highest growth rate in the coming years due to rapid healthcare infrastructure development and increasing environmental regulations. Emerging economies present significant growth opportunities as they build new healthcare facilities with sustainability considerations integrated from the outset.

Healthcare facilities generate enormous amounts of plastic waste, with hospitals in the United States alone producing approximately 14,000 tons of waste daily. Single-use medical devices, packaging materials, and disposable supplies constitute a significant portion of this waste. The COVID-19 pandemic has further exacerbated this issue, with the increased use of personal protective equipment (PPE) contributing to medical waste volumes.

Market research indicates that 78% of healthcare professionals express concern about the environmental impact of medical waste, and 65% of hospitals are actively seeking sustainable alternatives to traditional medical materials. This growing awareness has created a robust demand for biodegradable and compostable biomedical polymers that maintain the necessary performance characteristics while reducing environmental footprint.

Regulatory developments are also driving market demand. The European Union's Single-Use Plastics Directive and similar regulations worldwide are imposing stricter requirements on plastic waste management. Healthcare institutions face increasing pressure to comply with these regulations, creating a market pull for sustainable alternatives that can help meet compliance requirements while maintaining quality care.

Patient preferences are evolving as well, with 72% of patients expressing preference for healthcare providers that demonstrate environmental responsibility. This consumer sentiment is influencing purchasing decisions at institutional levels, creating additional market incentives for sustainable medical materials.

The economic benefits of sustainable medical materials are becoming increasingly apparent. Hospitals implementing waste reduction programs through sustainable materials have reported cost savings of 15-30% in waste management expenses. These financial incentives, coupled with corporate social responsibility goals, are driving healthcare systems to invest in sustainable alternatives.

Regional market analysis reveals that North America and Europe currently lead in the adoption of sustainable medical materials, but the Asia-Pacific region is expected to show the highest growth rate in the coming years due to rapid healthcare infrastructure development and increasing environmental regulations. Emerging economies present significant growth opportunities as they build new healthcare facilities with sustainability considerations integrated from the outset.

Current State and Challenges in Biodegradable Medical Polymers

The global biomedical polymer market has witnessed significant growth in recent years, reaching approximately $14.5 billion in 2022 and projected to exceed $25 billion by 2030. However, the environmental impact of these materials presents a substantial challenge, with medical waste contributing to approximately 5% of global waste production. Currently, most medical polymers are petroleum-based and non-biodegradable, leading to accumulation in landfills and oceans, with degradation times ranging from decades to centuries.

Biodegradable medical polymers represent a promising solution, with materials like polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers (PLGA) leading the field. These materials have demonstrated successful applications in sutures, drug delivery systems, and tissue engineering scaffolds. However, their widespread adoption faces significant technical challenges, including inconsistent degradation rates, mechanical property limitations, and higher production costs compared to conventional polymers.

The regulatory landscape presents additional hurdles, with stringent approval processes from bodies like the FDA and EMA requiring extensive testing for both biocompatibility and environmental impact. This dual requirement often creates conflicting design parameters, as materials must maintain stability during use while degrading safely after disposal.

Manufacturing scalability remains problematic, with current production methods for biodegradable polymers being energy-intensive and costly. The average production cost for biodegradable medical polymers exceeds that of conventional alternatives by 30-200%, depending on the specific material and application. This cost differential significantly impedes market penetration, particularly in cost-sensitive healthcare systems.

Performance consistency across different physiological environments represents another major challenge. Biodegradable polymers can exhibit variable degradation rates depending on pH, temperature, and mechanical stress, making predictable performance difficult to achieve in diverse medical applications. This variability creates concerns regarding product reliability and safety in critical medical applications.

Research efforts are increasingly focused on developing composite and hybrid materials that combine synthetic biodegradable polymers with natural polymers like chitosan, alginate, and cellulose derivatives. These approaches aim to enhance both performance characteristics and degradation profiles. Additionally, emerging technologies in polymer chemistry, such as click chemistry and controlled polymerization techniques, are enabling more precise control over material properties.

Geographically, North America and Europe lead in biodegradable medical polymer research and development, with approximately 65% of patents originating from these regions. However, Asia-Pacific countries, particularly China, Japan, and South Korea, are rapidly increasing their research output and manufacturing capabilities, suggesting a shifting landscape in technological leadership.

Biodegradable medical polymers represent a promising solution, with materials like polylactic acid (PLA), polyglycolic acid (PGA), and their copolymers (PLGA) leading the field. These materials have demonstrated successful applications in sutures, drug delivery systems, and tissue engineering scaffolds. However, their widespread adoption faces significant technical challenges, including inconsistent degradation rates, mechanical property limitations, and higher production costs compared to conventional polymers.

The regulatory landscape presents additional hurdles, with stringent approval processes from bodies like the FDA and EMA requiring extensive testing for both biocompatibility and environmental impact. This dual requirement often creates conflicting design parameters, as materials must maintain stability during use while degrading safely after disposal.

Manufacturing scalability remains problematic, with current production methods for biodegradable polymers being energy-intensive and costly. The average production cost for biodegradable medical polymers exceeds that of conventional alternatives by 30-200%, depending on the specific material and application. This cost differential significantly impedes market penetration, particularly in cost-sensitive healthcare systems.

Performance consistency across different physiological environments represents another major challenge. Biodegradable polymers can exhibit variable degradation rates depending on pH, temperature, and mechanical stress, making predictable performance difficult to achieve in diverse medical applications. This variability creates concerns regarding product reliability and safety in critical medical applications.

Research efforts are increasingly focused on developing composite and hybrid materials that combine synthetic biodegradable polymers with natural polymers like chitosan, alginate, and cellulose derivatives. These approaches aim to enhance both performance characteristics and degradation profiles. Additionally, emerging technologies in polymer chemistry, such as click chemistry and controlled polymerization techniques, are enabling more precise control over material properties.

Geographically, North America and Europe lead in biodegradable medical polymer research and development, with approximately 65% of patents originating from these regions. However, Asia-Pacific countries, particularly China, Japan, and South Korea, are rapidly increasing their research output and manufacturing capabilities, suggesting a shifting landscape in technological leadership.

Existing Biomedical Polymer Waste Reduction Solutions

01 Biodegradable polymers for medical waste management

Biodegradable polymers are being utilized in medical waste management to reduce environmental impact. These polymers can break down naturally after disposal, minimizing the long-term effects of medical waste. The incorporation of specific enzymes or microorganisms can accelerate the degradation process of these polymers, making them particularly suitable for single-use medical items that constitute a significant portion of medical waste.- Biodegradable polymers for medical waste management: Biodegradable polymers are being utilized in medical waste management to reduce environmental impact. These polymers naturally decompose over time, minimizing the long-term effects of medical waste disposal. Various biodegradable materials such as polylactic acid (PLA), polyhydroxyalkanoates (PHA), and starch-based polymers are incorporated into medical products designed for single-use applications, helping to address the growing concern of medical waste accumulation.

- Antimicrobial biomedical polymers for waste reduction: Antimicrobial biomedical polymers are being developed to extend the usable life of medical devices and reduce waste generation. These polymers contain antimicrobial agents that prevent bacterial colonization and biofilm formation, allowing for longer use periods and fewer replacements. The incorporation of silver nanoparticles, quaternary ammonium compounds, and other antimicrobial substances into polymer matrices creates materials that maintain sterility while reducing the frequency of disposal, thereby decreasing medical waste volume.

- Polymer-based medical waste treatment systems: Innovative polymer-based systems are being developed for the treatment and processing of medical waste. These systems utilize specialized polymers to encapsulate, neutralize, or safely break down hazardous medical waste components. Some approaches involve polymer gels that solidify liquid biohazardous waste, while others use polymer membranes for filtration and separation of dangerous substances. These technologies provide safer alternatives to traditional medical waste disposal methods such as incineration or landfilling.

- Smart polymers for medical waste tracking and management: Smart polymer technologies are being implemented for improved tracking and management of medical waste. These advanced materials incorporate sensors, RFID technology, or color-changing indicators that respond to environmental conditions or contamination levels. The integration of smart polymers in medical waste containers and packaging allows for real-time monitoring of waste status, helping healthcare facilities ensure proper segregation, handling, and disposal of different types of medical waste while optimizing collection schedules and reducing environmental risks.

- Recyclable and reprocessable biomedical polymers: Development of recyclable and reprocessable biomedical polymers aims to create a circular economy for medical products. These specialized polymers can be collected after use, sterilized, and reprocessed into new medical devices or other products. Thermoplastic polymers that maintain their mechanical properties after multiple processing cycles are particularly valuable in this context. Some innovations focus on designing medical products with easily separable components to facilitate recycling of the polymer portions while safely disposing of contaminated parts.

02 Antimicrobial biomedical polymers for waste reduction

Antimicrobial biomedical polymers are designed to inhibit microbial growth, extending the usable life of medical devices and reducing the frequency of disposal. These polymers incorporate agents such as silver nanoparticles or quaternary ammonium compounds that provide sustained antimicrobial activity. By preventing contamination and infection, these materials help decrease the volume of medical waste generated while improving patient safety.Expand Specific Solutions03 Smart polymers for medical waste tracking and disposal

Smart polymers with embedded sensors or RFID technology are being developed for tracking medical waste from generation to disposal. These advanced materials can change properties in response to environmental stimuli, aiding in waste segregation and treatment. The technology enables healthcare facilities to monitor waste management processes, ensure regulatory compliance, and optimize disposal methods for different types of biomedical waste.Expand Specific Solutions04 Recyclable biomedical polymers for sustainable healthcare

Recyclable biomedical polymers are being engineered to maintain their structural integrity and sterility during use while allowing for efficient recycling after disposal. These materials can be processed to remove contaminants and reformed into new medical products, creating a circular economy within healthcare settings. The development focuses on polymers that can withstand sterilization processes multiple times without significant degradation of their mechanical or functional properties.Expand Specific Solutions05 Polymer-based medical waste treatment systems

Innovative polymer-based systems are being developed for on-site treatment of medical waste. These systems utilize specialized polymers that can encapsulate hazardous components or facilitate the breakdown of biological materials through controlled chemical reactions. Some approaches incorporate hydrogels or polymer matrices that can absorb and neutralize harmful substances in medical waste, reducing the need for expensive off-site processing and minimizing transportation-related environmental impacts.Expand Specific Solutions

Key Industry Players in Sustainable Medical Polymers

The biomedical polymers market for medical waste reduction is in a growth phase, with increasing adoption driven by sustainability concerns in healthcare. The market is expanding rapidly, estimated to reach several billion dollars by 2025, as hospitals seek to reduce their environmental footprint. Technologically, the field shows varying maturity levels across applications. Industry leaders like Medtronic and Johnson & Johnson (through Ethicon) have established advanced polymer technologies for biodegradable medical devices, while companies such as DSM IP Assets and Surmodics are pioneering innovative surface modification technologies. Academic institutions including University of Southampton and Johns Hopkins University are contributing breakthrough research in novel biodegradable polymers. Regional players like Allgens Medical Technology and Nippon Shokubai are developing specialized applications, indicating the global nature of this emerging field.

DSM IP Assets BV

Technical Solution: DSM has developed a portfolio of bio-based and biodegradable polymers specifically designed for medical applications. Their technology focuses on polyhydroxyalkanoates (PHAs) derived from renewable resources that can fully biodegrade in controlled environments. These polymers are engineered to maintain necessary mechanical properties and biocompatibility while in use, but decompose into non-toxic components after disposal. DSM's approach includes specialized polymer blends that combine biodegradable components with performance-enhancing additives to meet stringent medical requirements. Their materials are designed for single-use medical devices, packaging, and drug delivery systems, reducing the environmental footprint compared to traditional petroleum-based plastics. The company has also developed proprietary processing technologies that allow these materials to be manufactured using conventional equipment, facilitating industry adoption without significant capital investment.

Strengths: Fully biodegradable materials that leave no harmful residues; maintains required mechanical and barrier properties during use; compatible with existing manufacturing processes. Weaknesses: Higher production costs compared to conventional plastics; degradation rates can be difficult to precisely control in varied disposal environments; may require specialized waste handling infrastructure for optimal decomposition.

Medtronic, Inc.

Technical Solution: Medtronic has pioneered a comprehensive approach to reducing medical waste through their "Sustainable Polymer Initiative." Their technology centers on developing medical-grade biopolymers derived from renewable resources that maintain the rigorous performance standards required for medical devices. The company has created proprietary blends of polylactic acid (PLA) and polyhydroxyalkanoates (PHA) that are engineered specifically for different medical applications, from packaging to device components. Their innovation includes specialized manufacturing processes that reduce material waste during production by up to 30% compared to traditional methods. Medtronic has also developed smart packaging solutions using these biopolymers that require 40% less material while maintaining sterility and protection. Additionally, their polymer technology incorporates end-of-life considerations, with materials designed to be compatible with existing hospital waste management systems, including options for composting or recycling depending on the specific application and local infrastructure.

Strengths: Comprehensive approach addressing the entire lifecycle of medical products; materials maintain high performance standards required for medical applications; compatible with existing hospital waste management systems. Weaknesses: Higher initial costs compared to traditional materials; requires changes to established manufacturing processes; performance in long-term implantable applications still limited compared to conventional polymers.

Core Innovations in Biodegradable Polymer Technologies

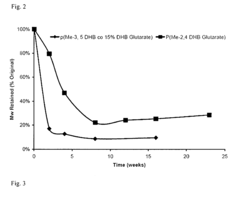

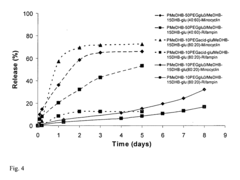

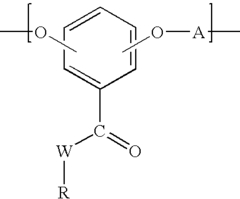

Dihydroxybenzoate Polymers and Uses Thereof

PatentActiveUS20100129417A1

Innovation

- Development of biocompatible, biodegradable, and resorbable polymers derived from dihydroxybenzoic acid (DHB) and resorcinol derivatives, which can be used in various medical applications, including drug delivery systems and medical devices, with customizable degradation times and drug release profiles.

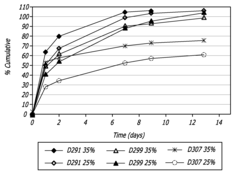

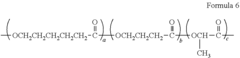

Degradable polymers incorporating gamma-butyrolactone

PatentActiveUS7897168B2

Innovation

- Biodegradable polymers with polyester, polycarbonate, and polyether backbones formed from γ-butyrolactone and additional hydrophilic or hydrophobic monomers, such as polyethylene glycol, trimethylene carbonate, and lactide, which allow for controlled in situ drug release and are tailored for specific drug and device applications.

Environmental Impact Assessment of Medical Polymer Alternatives

The environmental impact of medical waste has become a critical concern in healthcare systems worldwide, with an estimated 16 billion injections administered annually and significant quantities of plastic-based medical products discarded after single use. Traditional medical polymers, primarily petroleum-based plastics such as polyvinyl chloride (PVC), polyethylene (PE), and polypropylene (PP), contribute substantially to healthcare's environmental footprint through resource depletion, greenhouse gas emissions, and waste accumulation.

When assessing alternative biomedical polymers, life cycle analysis (LCA) reveals promising environmental advantages. Biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) demonstrate 50-70% lower carbon footprints compared to conventional plastics. These materials decompose under controlled conditions within 3-6 months, whereas traditional medical plastics may persist for centuries. Additionally, bio-based polymers derived from renewable resources reduce dependency on fossil fuels, with studies indicating a potential 30-45% reduction in non-renewable energy consumption across their lifecycle.

Water pollution metrics show particular promise for alternative polymers. Conventional medical plastics contribute to microplastic pollution, with an estimated 8-12 million tons entering aquatic ecosystems annually. Biodegradable alternatives significantly reduce this impact, though complete assessment requires consideration of degradation byproducts and their ecological effects in various environmental conditions.

Land use impacts present a more complex picture. While bio-based polymers reduce landfill burden, their production requires agricultural resources. Recent innovations in utilizing agricultural waste streams and non-food biomass for polymer production have improved this aspect, potentially creating circular economy opportunities that transform waste into valuable medical materials.

Toxicity comparisons between conventional and alternative medical polymers reveal additional environmental benefits. Many traditional medical plastics contain plasticizers like phthalates and heavy metal stabilizers that can leach into the environment. Alternative polymers typically eliminate these concerning additives, reducing ecotoxicological risks and potential endocrine disruption effects in wildlife and ecosystems.

Energy efficiency metrics across manufacturing processes show that while some bio-based polymers currently require more energy-intensive processing, technological advancements are rapidly closing this gap. Innovations in low-temperature processing and catalysis have reduced energy requirements for PLA and PHA production by approximately 25% in the past decade, with further improvements anticipated as these technologies mature and scale.

When assessing alternative biomedical polymers, life cycle analysis (LCA) reveals promising environmental advantages. Biodegradable polymers like polylactic acid (PLA) and polyhydroxyalkanoates (PHAs) demonstrate 50-70% lower carbon footprints compared to conventional plastics. These materials decompose under controlled conditions within 3-6 months, whereas traditional medical plastics may persist for centuries. Additionally, bio-based polymers derived from renewable resources reduce dependency on fossil fuels, with studies indicating a potential 30-45% reduction in non-renewable energy consumption across their lifecycle.

Water pollution metrics show particular promise for alternative polymers. Conventional medical plastics contribute to microplastic pollution, with an estimated 8-12 million tons entering aquatic ecosystems annually. Biodegradable alternatives significantly reduce this impact, though complete assessment requires consideration of degradation byproducts and their ecological effects in various environmental conditions.

Land use impacts present a more complex picture. While bio-based polymers reduce landfill burden, their production requires agricultural resources. Recent innovations in utilizing agricultural waste streams and non-food biomass for polymer production have improved this aspect, potentially creating circular economy opportunities that transform waste into valuable medical materials.

Toxicity comparisons between conventional and alternative medical polymers reveal additional environmental benefits. Many traditional medical plastics contain plasticizers like phthalates and heavy metal stabilizers that can leach into the environment. Alternative polymers typically eliminate these concerning additives, reducing ecotoxicological risks and potential endocrine disruption effects in wildlife and ecosystems.

Energy efficiency metrics across manufacturing processes show that while some bio-based polymers currently require more energy-intensive processing, technological advancements are rapidly closing this gap. Innovations in low-temperature processing and catalysis have reduced energy requirements for PLA and PHA production by approximately 25% in the past decade, with further improvements anticipated as these technologies mature and scale.

Regulatory Framework for Sustainable Medical Materials

The regulatory landscape governing biomedical polymers and sustainable medical materials is complex and evolving rapidly in response to growing environmental concerns. At the international level, organizations such as the World Health Organization (WHO) and the International Organization for Standardization (ISO) have established guidelines that influence the development and disposal of medical materials. ISO 14001 for environmental management systems and ISO 13485 for medical device quality management provide foundational frameworks that manufacturers must consider when developing sustainable biomedical polymers.

In the United States, the Food and Drug Administration (FDA) has begun incorporating sustainability considerations into its approval processes for medical devices and materials. The FDA's recent guidance documents encourage manufacturers to consider the entire lifecycle of medical products, including end-of-life management. Similarly, the European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) include provisions related to environmental impact assessment and waste reduction.

The EU has taken additional steps through its Circular Economy Action Plan, which specifically addresses medical waste reduction. This includes requirements for extended producer responsibility (EPR) schemes that hold manufacturers accountable for the environmental impact of their products throughout their lifecycle. These regulations incentivize the development of biodegradable or recyclable biomedical polymers that can reduce medical waste.

Emerging economies are also developing regulatory frameworks for sustainable medical materials. China's recent Five-Year Plan includes specific targets for reducing medical waste and promoting green healthcare technologies. India has implemented the Biomedical Waste Management Rules, which establish protocols for the segregation, treatment, and disposal of medical waste, creating market opportunities for sustainable polymer solutions.

Certification systems and eco-labels specific to healthcare products are gaining prominence. Programs such as Cradle to Cradle Certified™ and the Healthcare Plastics Recycling Council (HPRC) guidelines provide standards that manufacturers can follow to demonstrate their commitment to sustainability. These certifications are increasingly becoming market differentiators as healthcare facilities prioritize environmentally responsible purchasing decisions.

Regulatory compliance challenges include the need to balance safety and efficacy with environmental considerations. Biomedical polymers must still meet stringent requirements for biocompatibility, sterility, and performance while also addressing end-of-life environmental impacts. This regulatory tension creates innovation opportunities for materials scientists and medical device manufacturers to develop novel solutions that satisfy both sets of requirements.

In the United States, the Food and Drug Administration (FDA) has begun incorporating sustainability considerations into its approval processes for medical devices and materials. The FDA's recent guidance documents encourage manufacturers to consider the entire lifecycle of medical products, including end-of-life management. Similarly, the European Union's Medical Device Regulation (MDR) and In Vitro Diagnostic Regulation (IVDR) include provisions related to environmental impact assessment and waste reduction.

The EU has taken additional steps through its Circular Economy Action Plan, which specifically addresses medical waste reduction. This includes requirements for extended producer responsibility (EPR) schemes that hold manufacturers accountable for the environmental impact of their products throughout their lifecycle. These regulations incentivize the development of biodegradable or recyclable biomedical polymers that can reduce medical waste.

Emerging economies are also developing regulatory frameworks for sustainable medical materials. China's recent Five-Year Plan includes specific targets for reducing medical waste and promoting green healthcare technologies. India has implemented the Biomedical Waste Management Rules, which establish protocols for the segregation, treatment, and disposal of medical waste, creating market opportunities for sustainable polymer solutions.

Certification systems and eco-labels specific to healthcare products are gaining prominence. Programs such as Cradle to Cradle Certified™ and the Healthcare Plastics Recycling Council (HPRC) guidelines provide standards that manufacturers can follow to demonstrate their commitment to sustainability. These certifications are increasingly becoming market differentiators as healthcare facilities prioritize environmentally responsible purchasing decisions.

Regulatory compliance challenges include the need to balance safety and efficacy with environmental considerations. Biomedical polymers must still meet stringent requirements for biocompatibility, sterility, and performance while also addressing end-of-life environmental impacts. This regulatory tension creates innovation opportunities for materials scientists and medical device manufacturers to develop novel solutions that satisfy both sets of requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!