Blade Battery's Position in the Evolving Automotive Supply Chain

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution

The blade battery represents a significant evolution in lithium-ion battery technology, particularly for electric vehicles. Developed by BYD, this innovative design addresses key challenges in the automotive industry, including safety, energy density, and cost-effectiveness.

The evolution of the blade battery began with BYD's recognition of the limitations in traditional lithium-ion battery pack designs. Conventional battery packs often utilize cylindrical or prismatic cells, which require complex structural support and cooling systems. This complexity not only increases production costs but also reduces the overall energy density of the battery pack.

BYD's approach with the blade battery was to fundamentally rethink the cell and pack design. The blade battery utilizes long, thin cells that can be arranged in a parallel configuration, similar to a pack of blades. This design allows for more efficient space utilization within the battery pack, resulting in higher energy density and improved thermal management.

A key milestone in the blade battery's evolution was the development of a new cathode material. BYD opted for lithium iron phosphate (LFP) chemistry, known for its stability and safety characteristics. The company further enhanced the LFP technology to improve its energy density, addressing one of the primary drawbacks of LFP batteries compared to other lithium-ion chemistries.

The blade battery's unique cell structure also contributes to its safety profile. The long, thin cells are less prone to internal short circuits and thermal runaway, reducing the risk of battery fires – a critical concern in the automotive industry. BYD demonstrated this improved safety through various extreme tests, including nail penetration tests, which the blade battery passed without ignition or explosion.

Another significant aspect of the blade battery's evolution is its integration into BYD's vertical manufacturing strategy. By controlling the entire production process from raw materials to finished vehicles, BYD has been able to optimize the blade battery's design for mass production and cost-effectiveness. This vertical integration has positioned BYD as a formidable player in the global electric vehicle market.

The blade battery's evolution continues as BYD explores ways to further improve its performance and reduce costs. Recent developments include efforts to increase the energy density of LFP cells and enhance the battery management systems for more efficient operation. These ongoing improvements are crucial for maintaining the blade battery's competitive edge in the rapidly evolving automotive supply chain.

The evolution of the blade battery began with BYD's recognition of the limitations in traditional lithium-ion battery pack designs. Conventional battery packs often utilize cylindrical or prismatic cells, which require complex structural support and cooling systems. This complexity not only increases production costs but also reduces the overall energy density of the battery pack.

BYD's approach with the blade battery was to fundamentally rethink the cell and pack design. The blade battery utilizes long, thin cells that can be arranged in a parallel configuration, similar to a pack of blades. This design allows for more efficient space utilization within the battery pack, resulting in higher energy density and improved thermal management.

A key milestone in the blade battery's evolution was the development of a new cathode material. BYD opted for lithium iron phosphate (LFP) chemistry, known for its stability and safety characteristics. The company further enhanced the LFP technology to improve its energy density, addressing one of the primary drawbacks of LFP batteries compared to other lithium-ion chemistries.

The blade battery's unique cell structure also contributes to its safety profile. The long, thin cells are less prone to internal short circuits and thermal runaway, reducing the risk of battery fires – a critical concern in the automotive industry. BYD demonstrated this improved safety through various extreme tests, including nail penetration tests, which the blade battery passed without ignition or explosion.

Another significant aspect of the blade battery's evolution is its integration into BYD's vertical manufacturing strategy. By controlling the entire production process from raw materials to finished vehicles, BYD has been able to optimize the blade battery's design for mass production and cost-effectiveness. This vertical integration has positioned BYD as a formidable player in the global electric vehicle market.

The blade battery's evolution continues as BYD explores ways to further improve its performance and reduce costs. Recent developments include efforts to increase the energy density of LFP cells and enhance the battery management systems for more efficient operation. These ongoing improvements are crucial for maintaining the blade battery's competitive edge in the rapidly evolving automotive supply chain.

EV Market Demand Analysis

The global electric vehicle (EV) market has been experiencing unprecedented growth, driven by increasing environmental awareness, government incentives, and technological advancements. This surge in demand has significant implications for the automotive supply chain, particularly for battery manufacturers like BYD with their Blade Battery technology.

Market research indicates that the global EV sales are projected to reach 10.5 million units in 2022, representing a 61% increase from the previous year. This rapid growth is expected to continue, with forecasts suggesting that EVs could account for over 30% of new vehicle sales by 2030 in major markets such as China, Europe, and the United States.

The demand for EVs is not uniform across all segments. While passenger vehicles currently dominate the market, there is growing interest in electrifying commercial vehicles, including buses and trucks. This diversification of demand presents both opportunities and challenges for battery suppliers like BYD.

Consumer preferences are shifting towards EVs with longer ranges and faster charging capabilities. The Blade Battery's high energy density and improved safety features position it well to meet these evolving consumer demands. Additionally, the increasing focus on sustainability in the automotive industry aligns with the Blade Battery's more efficient use of materials and improved recyclability.

Government policies and regulations play a crucial role in shaping EV market demand. Many countries have implemented stringent emissions standards and offer financial incentives for EV purchases, driving adoption rates. For instance, the European Union's target to reduce CO2 emissions from new cars by 37.5% by 2030 is accelerating the transition to electric mobility in the region.

The COVID-19 pandemic initially disrupted the automotive supply chain, but the EV sector has shown remarkable resilience. In fact, while overall car sales declined in 2020, EV sales continued to grow, highlighting the strong underlying demand for electric vehicles.

Price parity between EVs and internal combustion engine vehicles is a key factor influencing market demand. As battery technology improves and production scales up, the total cost of ownership for EVs is becoming increasingly competitive. The Blade Battery's potential for cost reduction through its innovative design and manufacturing process could further accelerate this trend.

In conclusion, the EV market demand analysis reveals a robust and rapidly growing sector with significant potential for battery manufacturers. The Blade Battery's position in this evolving landscape will depend on its ability to meet the increasing demand for high-performance, safe, and cost-effective energy storage solutions in the automotive industry.

Market research indicates that the global EV sales are projected to reach 10.5 million units in 2022, representing a 61% increase from the previous year. This rapid growth is expected to continue, with forecasts suggesting that EVs could account for over 30% of new vehicle sales by 2030 in major markets such as China, Europe, and the United States.

The demand for EVs is not uniform across all segments. While passenger vehicles currently dominate the market, there is growing interest in electrifying commercial vehicles, including buses and trucks. This diversification of demand presents both opportunities and challenges for battery suppliers like BYD.

Consumer preferences are shifting towards EVs with longer ranges and faster charging capabilities. The Blade Battery's high energy density and improved safety features position it well to meet these evolving consumer demands. Additionally, the increasing focus on sustainability in the automotive industry aligns with the Blade Battery's more efficient use of materials and improved recyclability.

Government policies and regulations play a crucial role in shaping EV market demand. Many countries have implemented stringent emissions standards and offer financial incentives for EV purchases, driving adoption rates. For instance, the European Union's target to reduce CO2 emissions from new cars by 37.5% by 2030 is accelerating the transition to electric mobility in the region.

The COVID-19 pandemic initially disrupted the automotive supply chain, but the EV sector has shown remarkable resilience. In fact, while overall car sales declined in 2020, EV sales continued to grow, highlighting the strong underlying demand for electric vehicles.

Price parity between EVs and internal combustion engine vehicles is a key factor influencing market demand. As battery technology improves and production scales up, the total cost of ownership for EVs is becoming increasingly competitive. The Blade Battery's potential for cost reduction through its innovative design and manufacturing process could further accelerate this trend.

In conclusion, the EV market demand analysis reveals a robust and rapidly growing sector with significant potential for battery manufacturers. The Blade Battery's position in this evolving landscape will depend on its ability to meet the increasing demand for high-performance, safe, and cost-effective energy storage solutions in the automotive industry.

Technical Challenges

The development of Blade Battery technology presents several significant technical challenges within the evolving automotive supply chain. One of the primary hurdles is achieving the optimal balance between energy density and safety. While Blade Batteries offer improved safety features compared to traditional lithium-ion batteries, there is ongoing pressure to increase energy density to extend electric vehicle range without compromising safety standards.

Manufacturing scalability poses another substantial challenge. The unique design of Blade Batteries requires specialized production processes and equipment, which can be costly to implement at scale. Ensuring consistent quality across high-volume production runs while maintaining cost-effectiveness is a complex task that requires significant investment and expertise.

Thermal management remains a critical issue for Blade Batteries. Although they have demonstrated improved heat dissipation properties, managing temperature fluctuations during rapid charging and discharging cycles, especially in extreme weather conditions, continues to be a technical hurdle. Developing advanced cooling systems that are both efficient and lightweight is crucial for optimizing battery performance and longevity.

Integration of Blade Batteries into existing vehicle architectures presents its own set of challenges. The long, thin form factor of these batteries may require redesigns of vehicle platforms to fully capitalize on their space-saving potential. This necessitates close collaboration between battery manufacturers and automakers to ensure seamless integration and optimal performance.

The supply chain for raw materials, particularly those used in cathode production, is another area of concern. Securing a stable and sustainable supply of key materials such as lithium, nickel, and cobalt is essential for large-scale production of Blade Batteries. Developing alternative cathode chemistries that reduce reliance on scarce or environmentally problematic materials is an ongoing challenge.

Recycling and end-of-life management for Blade Batteries also present technical difficulties. The unique structure of these batteries may require the development of new recycling processes to efficiently recover valuable materials. Establishing a robust recycling infrastructure that can handle the anticipated volume of spent batteries is crucial for the long-term sustainability of this technology.

Lastly, the rapid pace of innovation in battery technology creates a moving target for Blade Battery development. Staying ahead of emerging technologies and continuously improving performance metrics such as charging speed, cycle life, and cost per kilowatt-hour is essential for maintaining competitiveness in the evolving automotive market.

Manufacturing scalability poses another substantial challenge. The unique design of Blade Batteries requires specialized production processes and equipment, which can be costly to implement at scale. Ensuring consistent quality across high-volume production runs while maintaining cost-effectiveness is a complex task that requires significant investment and expertise.

Thermal management remains a critical issue for Blade Batteries. Although they have demonstrated improved heat dissipation properties, managing temperature fluctuations during rapid charging and discharging cycles, especially in extreme weather conditions, continues to be a technical hurdle. Developing advanced cooling systems that are both efficient and lightweight is crucial for optimizing battery performance and longevity.

Integration of Blade Batteries into existing vehicle architectures presents its own set of challenges. The long, thin form factor of these batteries may require redesigns of vehicle platforms to fully capitalize on their space-saving potential. This necessitates close collaboration between battery manufacturers and automakers to ensure seamless integration and optimal performance.

The supply chain for raw materials, particularly those used in cathode production, is another area of concern. Securing a stable and sustainable supply of key materials such as lithium, nickel, and cobalt is essential for large-scale production of Blade Batteries. Developing alternative cathode chemistries that reduce reliance on scarce or environmentally problematic materials is an ongoing challenge.

Recycling and end-of-life management for Blade Batteries also present technical difficulties. The unique structure of these batteries may require the development of new recycling processes to efficiently recover valuable materials. Establishing a robust recycling infrastructure that can handle the anticipated volume of spent batteries is crucial for the long-term sustainability of this technology.

Lastly, the rapid pace of innovation in battery technology creates a moving target for Blade Battery development. Staying ahead of emerging technologies and continuously improving performance metrics such as charging speed, cycle life, and cost per kilowatt-hour is essential for maintaining competitiveness in the evolving automotive market.

Current Blade Solutions

01 Blade battery structure and design

Blade batteries are designed with a unique flat and long structure, allowing for more efficient space utilization in electric vehicles. This design improves energy density and overall battery performance while enhancing safety features.- Blade battery structure and design: Blade batteries feature a unique structural design that optimizes space utilization and enhances energy density. The thin, elongated shape allows for efficient packaging in electric vehicles, improving overall battery performance and range. This design also contributes to improved thermal management and safety features.

- Safety mechanisms in blade batteries: Blade batteries incorporate advanced safety mechanisms to prevent thermal runaway and enhance overall battery safety. These may include improved insulation materials, innovative cell design, and integrated monitoring systems that detect and mitigate potential safety risks during operation and charging.

- Manufacturing processes for blade batteries: Specialized manufacturing techniques are employed in the production of blade batteries to ensure consistency, quality, and cost-effectiveness. These processes may involve automated assembly lines, precision cutting and stacking of electrode materials, and advanced quality control measures to maintain high standards in battery production.

- Integration of blade batteries in electric vehicles: Blade batteries are designed for seamless integration into electric vehicle platforms. Their compact form factor allows for flexible placement within the vehicle chassis, potentially improving weight distribution and vehicle dynamics. Specialized mounting systems and cooling solutions are developed to optimize the performance and longevity of blade batteries in automotive applications.

- Battery management systems for blade batteries: Advanced battery management systems are crucial for optimizing the performance and lifespan of blade batteries. These systems monitor cell voltages, temperatures, and other parameters to ensure efficient operation, balanced charging, and protection against overcharging or deep discharging. They may also incorporate predictive algorithms for battery health monitoring and maintenance scheduling.

02 Thermal management systems for blade batteries

Advanced thermal management systems are integrated into blade batteries to regulate temperature and prevent overheating. These systems may include cooling channels, heat dissipation materials, and intelligent temperature control mechanisms to ensure optimal performance and safety.Expand Specific Solutions03 Manufacturing processes for blade batteries

Innovative manufacturing techniques are employed in the production of blade batteries, including advanced electrode coating methods, precision assembly processes, and quality control measures. These processes aim to enhance battery consistency, reliability, and production efficiency.Expand Specific Solutions04 Battery management systems for blade batteries

Sophisticated battery management systems are developed specifically for blade batteries to monitor and control various parameters such as voltage, current, and state of charge. These systems optimize battery performance, extend lifespan, and ensure safe operation in electric vehicles.Expand Specific Solutions05 Integration of blade batteries in electric vehicles

Blade batteries are designed for seamless integration into electric vehicle platforms. This includes optimized packaging solutions, structural reinforcements, and electrical connections to maximize energy storage capacity while maintaining vehicle safety and performance.Expand Specific Solutions

Key Industry Players

The Blade Battery technology is emerging as a significant player in the evolving automotive supply chain, particularly in the electric vehicle (EV) sector. The market is in a growth phase, with increasing demand for safer and more efficient battery solutions. Major companies like BYD, CATL, and Svolt are at the forefront of this technology, investing heavily in research and development. The market size is expanding rapidly, driven by the global shift towards electrification in the automotive industry. While the technology is still maturing, it shows promise in addressing key challenges such as safety and energy density. Companies like Hyundai and Toyota are also exploring partnerships to integrate this technology into their EV lineups, indicating growing industry acceptance and potential for widespread adoption.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL, as a leading battery manufacturer, has developed its own Cell-to-Pack (CTP) technology to compete with BYD's Blade Battery. Their third-generation CTP technology, known as Qilin, achieves a volume utilization efficiency of 72% and an energy density of up to 255 Wh/kg for ternary battery systems[4]. CATL has also introduced sodium-ion batteries as a potential alternative to lithium-ion batteries, offering advantages in low-temperature performance and fast-charging capabilities[5]. The company's strong R&D focus and partnerships with major automakers position it as a key player in shaping the future of EV batteries.

Strengths: Diverse battery technology portfolio, strong industry partnerships, and high production capacity. Weaknesses: Intense competition in the market, potential supply chain vulnerabilities due to raw material dependencies.

BYD Co., Ltd.

Technical Solution: BYD's Blade Battery represents a significant advancement in lithium iron phosphate (LFP) battery technology. This innovative design utilizes long cells that span the battery pack, improving space utilization and energy density. The Blade Battery offers enhanced safety, with a nail penetration test showing no smoke or fire[1]. BYD has integrated this technology into their vehicle lineup, including the popular Han EV, which can achieve a range of up to 605 km (NEDC) with a 76.9 kWh pack[2]. The company has also expanded its supply chain influence by providing Blade Batteries to other automakers, such as Tesla for their Model Y production in Germany[3].

Strengths: Superior safety performance, high energy density, and cost-effectiveness. Weaknesses: Limited track record compared to traditional battery designs, potential challenges in scaling production to meet growing demand.

Core Blade Innovations

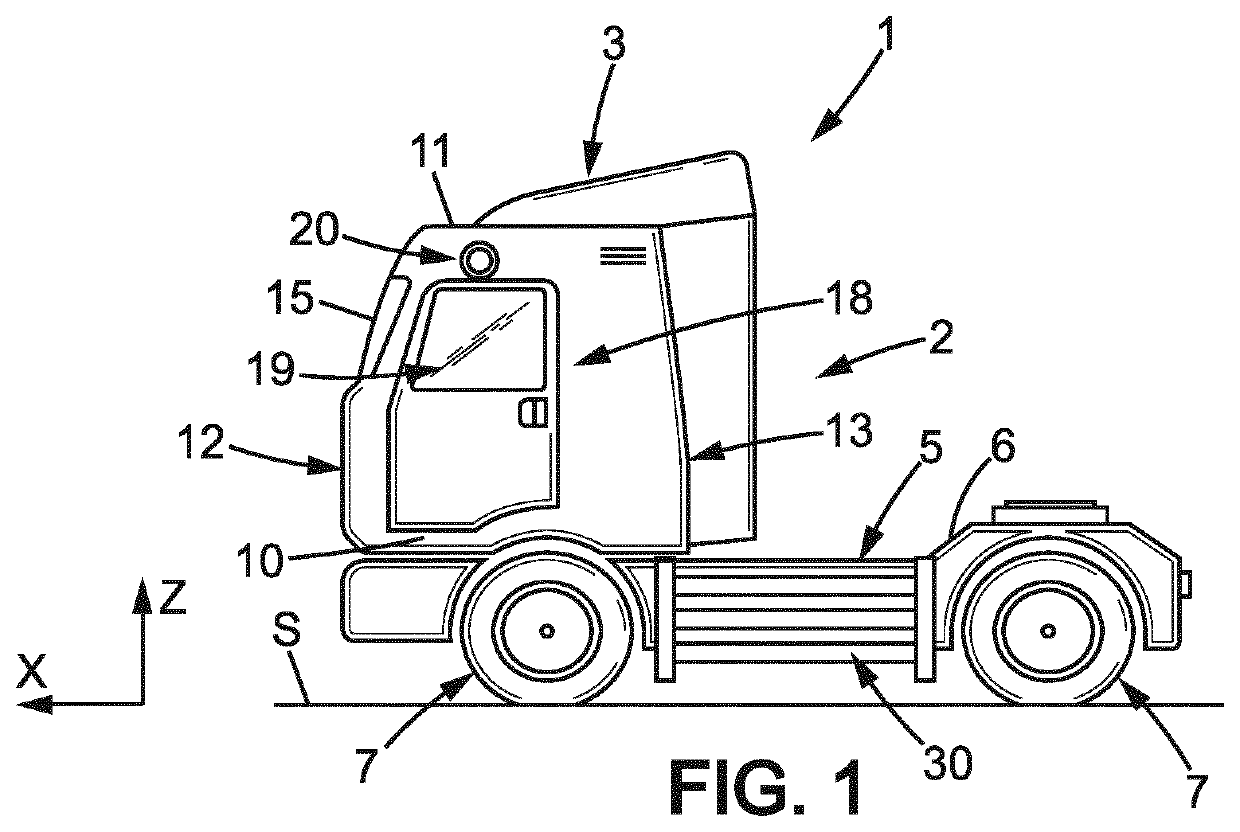

Electrically driven vehicle

PatentActiveIN2113DELNP2015A

Innovation

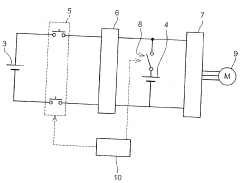

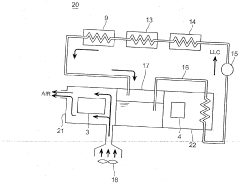

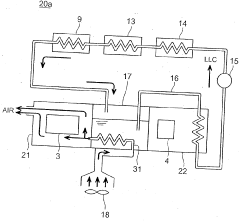

- The vehicle employs a liquid-cooled cooler for the high-output battery and an air-cooled temperature adjuster for the high-capacity battery, utilizing a circulation channel and reserve tank to efficiently manage heat exchange and temperature adjustment, with the air-cooled system activating when the liquid cooling medium exceeds a threshold temperature or during low-frequency usage.

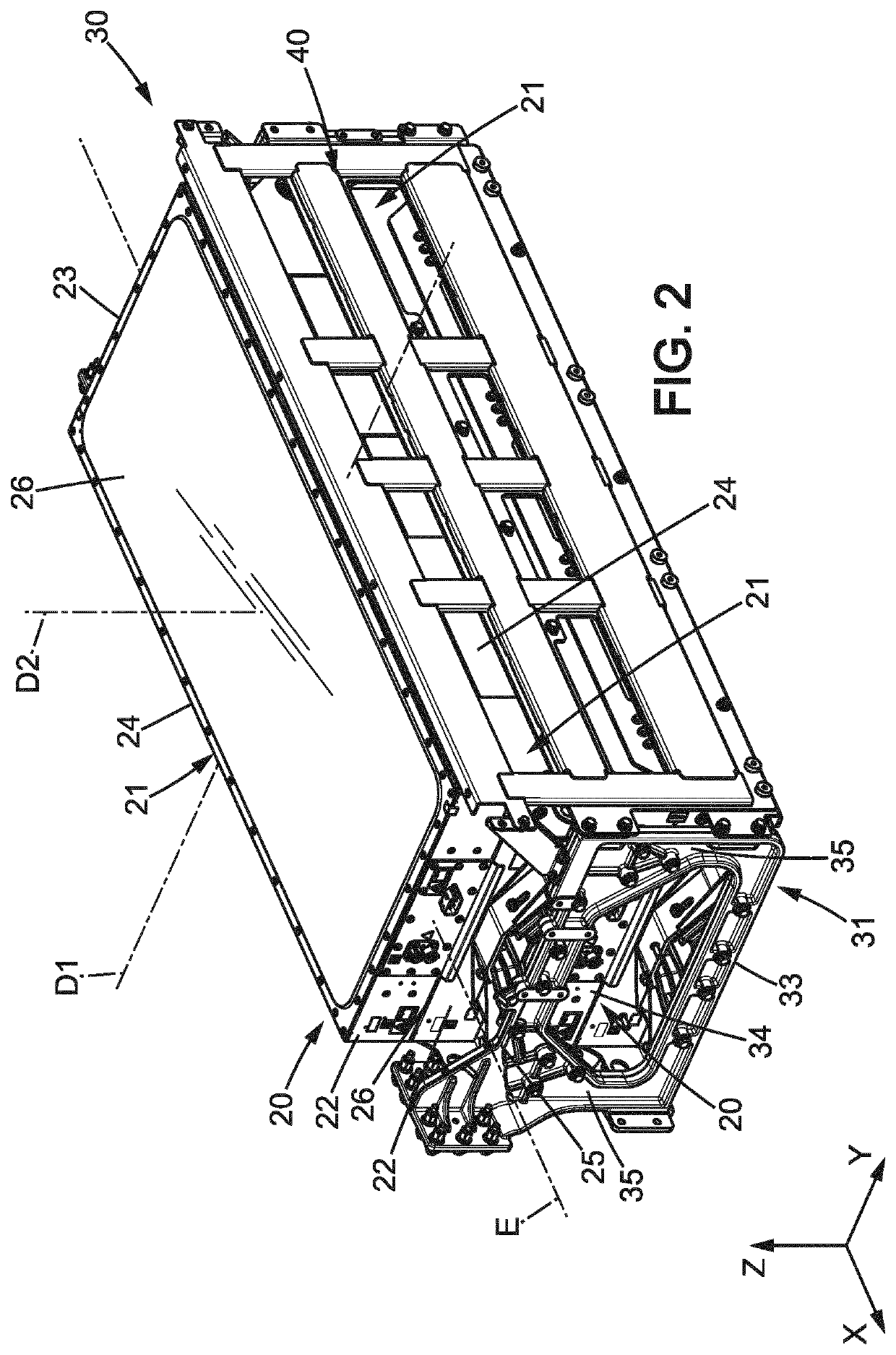

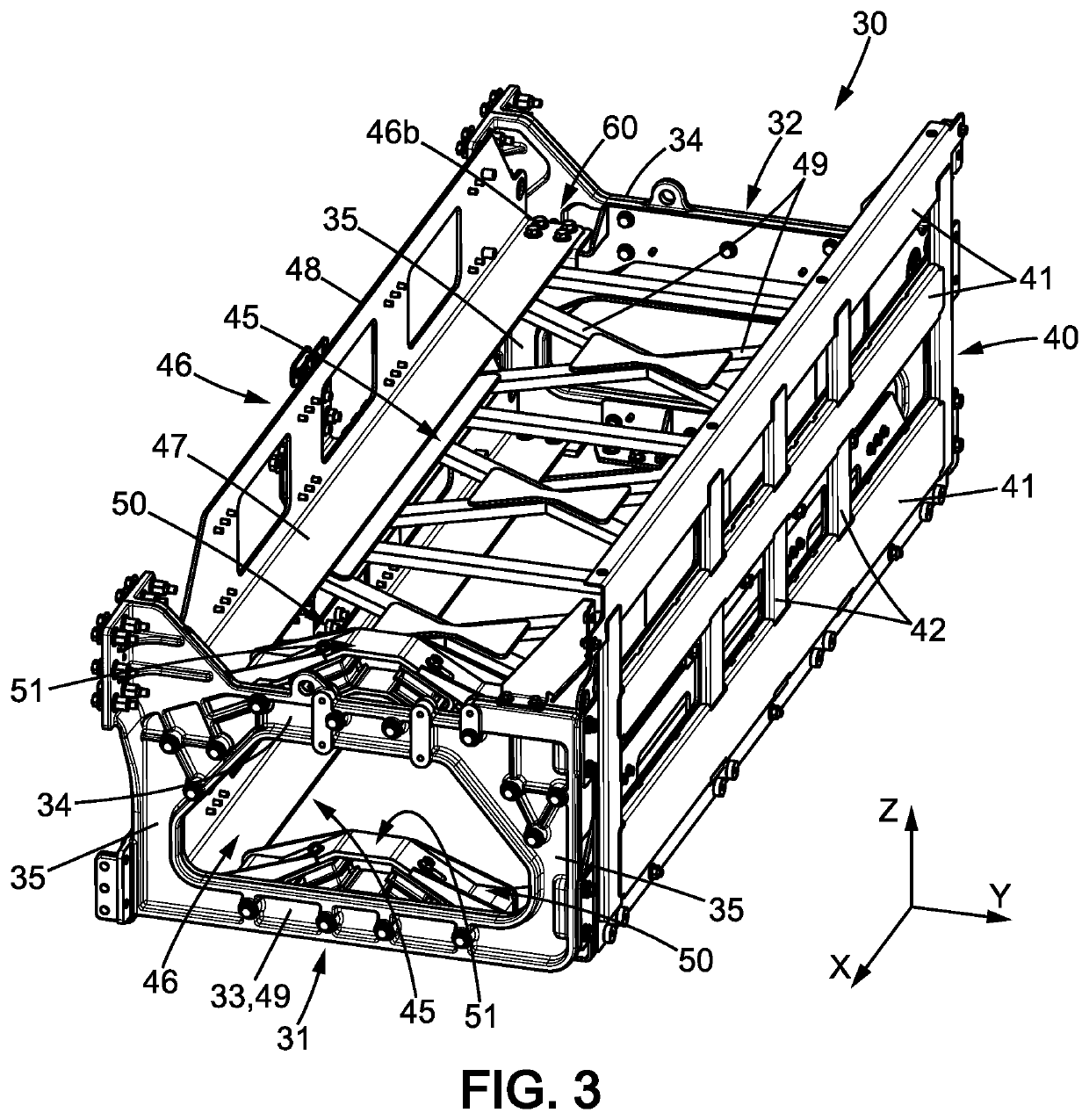

Electrically powered commercial vehicle having a battery structure

PatentActiveUS20220097537A1

Innovation

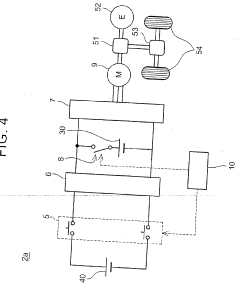

- A battery structure with resiliently deformable arrangements and fixation points that decouple the battery from the chassis, providing a three-point mounting system to absorb torsion and enhance crash protection, including a damping device for vertical vibrations and side crash protection members.

Supply Chain Integration

The integration of Blade Battery technology into the automotive supply chain represents a significant shift in the industry's approach to power management and vehicle electrification. As automakers increasingly transition towards electric vehicles (EVs), the demand for high-performance, safe, and cost-effective battery solutions has intensified. The Blade Battery, developed by BYD, has emerged as a promising contender in this evolving landscape, offering advantages in energy density, safety, and production efficiency.

The integration of Blade Batteries into the automotive supply chain involves a complex network of suppliers, manufacturers, and distributors. This process requires careful coordination and collaboration among various stakeholders to ensure seamless production and delivery. One key aspect of this integration is the establishment of strategic partnerships between battery manufacturers and automakers. These partnerships often involve long-term supply agreements, joint research and development initiatives, and shared investments in production facilities.

The supply chain for Blade Batteries also necessitates the development of specialized manufacturing processes and equipment. This includes the creation of dedicated production lines capable of handling the unique form factor and assembly requirements of Blade Batteries. As a result, suppliers and manufacturers must invest in new technologies and adapt their existing infrastructure to accommodate these innovative battery designs.

Furthermore, the integration of Blade Batteries into the automotive supply chain has implications for raw material sourcing and logistics. The specific composition of Blade Batteries may require adjustments to existing supply networks for critical materials such as lithium, cobalt, and nickel. This could lead to the emergence of new suppliers or the restructuring of existing relationships within the supply chain.

Quality control and safety measures play a crucial role in the integration of Blade Batteries into the automotive supply chain. Rigorous testing and certification processes must be implemented at various stages of production and distribution to ensure the reliability and safety of these advanced battery systems. This may involve the development of new industry standards and regulatory frameworks specific to Blade Battery technology.

The integration of Blade Batteries also impacts downstream elements of the automotive supply chain, including dealerships and service centers. These entities must adapt to the unique maintenance and repair requirements of vehicles equipped with Blade Batteries, necessitating additional training and specialized equipment. This shift in aftermarket services further underscores the far-reaching effects of Blade Battery integration on the entire automotive ecosystem.

The integration of Blade Batteries into the automotive supply chain involves a complex network of suppliers, manufacturers, and distributors. This process requires careful coordination and collaboration among various stakeholders to ensure seamless production and delivery. One key aspect of this integration is the establishment of strategic partnerships between battery manufacturers and automakers. These partnerships often involve long-term supply agreements, joint research and development initiatives, and shared investments in production facilities.

The supply chain for Blade Batteries also necessitates the development of specialized manufacturing processes and equipment. This includes the creation of dedicated production lines capable of handling the unique form factor and assembly requirements of Blade Batteries. As a result, suppliers and manufacturers must invest in new technologies and adapt their existing infrastructure to accommodate these innovative battery designs.

Furthermore, the integration of Blade Batteries into the automotive supply chain has implications for raw material sourcing and logistics. The specific composition of Blade Batteries may require adjustments to existing supply networks for critical materials such as lithium, cobalt, and nickel. This could lead to the emergence of new suppliers or the restructuring of existing relationships within the supply chain.

Quality control and safety measures play a crucial role in the integration of Blade Batteries into the automotive supply chain. Rigorous testing and certification processes must be implemented at various stages of production and distribution to ensure the reliability and safety of these advanced battery systems. This may involve the development of new industry standards and regulatory frameworks specific to Blade Battery technology.

The integration of Blade Batteries also impacts downstream elements of the automotive supply chain, including dealerships and service centers. These entities must adapt to the unique maintenance and repair requirements of vehicles equipped with Blade Batteries, necessitating additional training and specialized equipment. This shift in aftermarket services further underscores the far-reaching effects of Blade Battery integration on the entire automotive ecosystem.

Sustainability Impact

The sustainability impact of Blade Batteries in the evolving automotive supply chain is significant and multifaceted. These innovative batteries, developed by BYD, offer several environmental advantages over traditional lithium-ion batteries. Firstly, Blade Batteries have a higher energy density, which allows for increased range in electric vehicles (EVs) without increasing battery size or weight. This efficiency improvement reduces the overall material requirements for EV production, contributing to resource conservation.

Moreover, Blade Batteries demonstrate enhanced safety features, particularly in terms of thermal runaway resistance. This increased safety not only protects consumers but also reduces the likelihood of battery-related accidents and subsequent environmental contamination. The improved stability of Blade Batteries also extends their lifespan, potentially reducing the frequency of battery replacements and associated waste generation.

From a manufacturing perspective, Blade Batteries utilize a more streamlined production process, which can lead to reduced energy consumption and emissions during manufacturing. The simplified design also facilitates easier recycling at the end of the battery's life cycle, aligning with circular economy principles and reducing the environmental impact of battery disposal.

In the context of the automotive supply chain, the adoption of Blade Batteries can drive sustainability improvements across multiple tiers. Suppliers may need to adapt their processes and materials to meet the specific requirements of Blade Battery production, potentially leading to more sustainable practices throughout the supply network. This ripple effect could encourage innovation in related components and systems, further enhancing the overall sustainability of EV production.

The integration of Blade Batteries into the automotive supply chain also has implications for raw material sourcing. Their design potentially reduces the reliance on certain critical materials, which could alleviate pressure on environmentally sensitive mining operations. This shift may contribute to more responsible resource extraction practices and reduce the carbon footprint associated with battery material procurement.

As Blade Batteries gain traction in the market, their impact on sustainability extends beyond production and use phases. The automotive industry may see a transformation in maintenance and service networks, with specialized facilities emerging to handle the unique characteristics of these batteries. This evolution could lead to more efficient and environmentally conscious aftermarket services, reducing waste and extending the operational life of EVs.

Moreover, Blade Batteries demonstrate enhanced safety features, particularly in terms of thermal runaway resistance. This increased safety not only protects consumers but also reduces the likelihood of battery-related accidents and subsequent environmental contamination. The improved stability of Blade Batteries also extends their lifespan, potentially reducing the frequency of battery replacements and associated waste generation.

From a manufacturing perspective, Blade Batteries utilize a more streamlined production process, which can lead to reduced energy consumption and emissions during manufacturing. The simplified design also facilitates easier recycling at the end of the battery's life cycle, aligning with circular economy principles and reducing the environmental impact of battery disposal.

In the context of the automotive supply chain, the adoption of Blade Batteries can drive sustainability improvements across multiple tiers. Suppliers may need to adapt their processes and materials to meet the specific requirements of Blade Battery production, potentially leading to more sustainable practices throughout the supply network. This ripple effect could encourage innovation in related components and systems, further enhancing the overall sustainability of EV production.

The integration of Blade Batteries into the automotive supply chain also has implications for raw material sourcing. Their design potentially reduces the reliance on certain critical materials, which could alleviate pressure on environmentally sensitive mining operations. This shift may contribute to more responsible resource extraction practices and reduce the carbon footprint associated with battery material procurement.

As Blade Batteries gain traction in the market, their impact on sustainability extends beyond production and use phases. The automotive industry may see a transformation in maintenance and service networks, with specialized facilities emerging to handle the unique characteristics of these batteries. This evolution could lead to more efficient and environmentally conscious aftermarket services, reducing waste and extending the operational life of EVs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!