Blade Battery's Role in Enhancing Autonomous Vehicle Safety

AUG 7, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution

The evolution of Blade Battery technology represents a significant advancement in the field of electric vehicle (EV) power systems, with profound implications for autonomous vehicle safety. Initially developed by BYD, a leading Chinese automotive manufacturer, the Blade Battery emerged as a response to the growing demand for safer, more efficient, and longer-lasting energy storage solutions in the EV industry.

The Blade Battery's journey began with the recognition of the limitations and safety concerns associated with traditional lithium-ion batteries. Conventional battery designs often faced issues such as thermal runaway, which could lead to fires or explosions under certain conditions. This was particularly problematic for autonomous vehicles, where system reliability and safety are paramount.

BYD's innovative approach involved redesigning the battery cell structure to create a long, thin form factor resembling a blade. This unique configuration allowed for more efficient space utilization within the battery pack, resulting in higher energy density and improved thermal management. The Blade Battery's design also incorporated advanced materials and manufacturing techniques to enhance its structural integrity and resistance to physical damage.

As the technology progressed, subsequent iterations of the Blade Battery focused on improving its performance characteristics. Engineers worked on optimizing the battery chemistry to increase energy density while maintaining the high safety standards that had become the hallmark of the Blade Battery. This led to the development of batteries with longer range capabilities, faster charging times, and improved cycle life.

The evolution of the Blade Battery also saw advancements in its integration with vehicle management systems. This was particularly crucial for autonomous vehicles, where the battery needed to communicate seamlessly with the vehicle's AI and sensor systems. Improved battery management systems were developed to provide real-time data on battery health, state of charge, and potential issues, enhancing the overall safety and reliability of autonomous operations.

Furthermore, the Blade Battery's evolution included refinements in its manufacturing process. BYD and other adopters of the technology invested in automated production lines and quality control measures to ensure consistency and reliability in battery production. This was essential for scaling up production to meet the growing demand for electric and autonomous vehicles.

As the technology matured, it began to attract attention from other automotive manufacturers and technology companies involved in autonomous vehicle development. The Blade Battery's reputation for safety and performance made it an attractive option for integration into various autonomous vehicle platforms, leading to collaborations and partnerships across the industry.

The Blade Battery's journey began with the recognition of the limitations and safety concerns associated with traditional lithium-ion batteries. Conventional battery designs often faced issues such as thermal runaway, which could lead to fires or explosions under certain conditions. This was particularly problematic for autonomous vehicles, where system reliability and safety are paramount.

BYD's innovative approach involved redesigning the battery cell structure to create a long, thin form factor resembling a blade. This unique configuration allowed for more efficient space utilization within the battery pack, resulting in higher energy density and improved thermal management. The Blade Battery's design also incorporated advanced materials and manufacturing techniques to enhance its structural integrity and resistance to physical damage.

As the technology progressed, subsequent iterations of the Blade Battery focused on improving its performance characteristics. Engineers worked on optimizing the battery chemistry to increase energy density while maintaining the high safety standards that had become the hallmark of the Blade Battery. This led to the development of batteries with longer range capabilities, faster charging times, and improved cycle life.

The evolution of the Blade Battery also saw advancements in its integration with vehicle management systems. This was particularly crucial for autonomous vehicles, where the battery needed to communicate seamlessly with the vehicle's AI and sensor systems. Improved battery management systems were developed to provide real-time data on battery health, state of charge, and potential issues, enhancing the overall safety and reliability of autonomous operations.

Furthermore, the Blade Battery's evolution included refinements in its manufacturing process. BYD and other adopters of the technology invested in automated production lines and quality control measures to ensure consistency and reliability in battery production. This was essential for scaling up production to meet the growing demand for electric and autonomous vehicles.

As the technology matured, it began to attract attention from other automotive manufacturers and technology companies involved in autonomous vehicle development. The Blade Battery's reputation for safety and performance made it an attractive option for integration into various autonomous vehicle platforms, leading to collaborations and partnerships across the industry.

AV Safety Market Demand

The market demand for autonomous vehicle (AV) safety solutions has been growing exponentially as the automotive industry rapidly advances towards higher levels of automation. This surge in demand is driven by several factors, including increasing consumer awareness of safety concerns, stringent regulatory requirements, and the automotive industry's commitment to developing safer transportation systems.

Consumer safety concerns have become a primary driver of market demand for AV safety solutions. As autonomous vehicles transition from concept to reality, potential users are expressing heightened interest in the safety features and capabilities of these vehicles. This has led to a growing demand for advanced safety technologies, including robust battery systems that can withstand various scenarios and maintain vehicle integrity during accidents or emergencies.

Regulatory bodies worldwide are implementing stricter safety standards for autonomous vehicles, further fueling the demand for advanced safety solutions. These regulations often require manufacturers to demonstrate the reliability and safety of their AV systems, including critical components like batteries. This regulatory pressure has created a significant market opportunity for innovative safety technologies, such as blade batteries, which offer enhanced safety features and performance characteristics.

The automotive industry's commitment to developing safer transportation systems has also contributed to the increasing demand for AV safety solutions. Major automakers and technology companies are investing heavily in research and development to create safer autonomous vehicles, recognizing that safety is a key factor in consumer adoption and market success. This industry-wide focus on safety has led to a growing market for advanced battery technologies that can improve overall vehicle safety.

The potential market size for AV safety solutions, including advanced battery systems, is substantial. As autonomous vehicle technology continues to mature and gain wider acceptance, the demand for safety-enhancing components is expected to grow significantly. This presents a considerable opportunity for manufacturers of blade batteries and other safety-focused technologies to capture a share of this expanding market.

Furthermore, the integration of blade batteries in autonomous vehicles addresses specific safety concerns related to battery performance and stability. The unique design and composition of blade batteries offer improved thermal management and reduced risk of thermal runaway, making them particularly attractive for use in AVs where safety is paramount. This alignment between the safety features of blade batteries and the specific needs of the AV market is driving increased demand and market potential.

In conclusion, the market demand for AV safety solutions, particularly those involving advanced battery technologies like blade batteries, is robust and growing. This demand is driven by a combination of consumer expectations, regulatory requirements, and industry commitment to safety, creating a significant market opportunity for innovative safety technologies in the autonomous vehicle sector.

Consumer safety concerns have become a primary driver of market demand for AV safety solutions. As autonomous vehicles transition from concept to reality, potential users are expressing heightened interest in the safety features and capabilities of these vehicles. This has led to a growing demand for advanced safety technologies, including robust battery systems that can withstand various scenarios and maintain vehicle integrity during accidents or emergencies.

Regulatory bodies worldwide are implementing stricter safety standards for autonomous vehicles, further fueling the demand for advanced safety solutions. These regulations often require manufacturers to demonstrate the reliability and safety of their AV systems, including critical components like batteries. This regulatory pressure has created a significant market opportunity for innovative safety technologies, such as blade batteries, which offer enhanced safety features and performance characteristics.

The automotive industry's commitment to developing safer transportation systems has also contributed to the increasing demand for AV safety solutions. Major automakers and technology companies are investing heavily in research and development to create safer autonomous vehicles, recognizing that safety is a key factor in consumer adoption and market success. This industry-wide focus on safety has led to a growing market for advanced battery technologies that can improve overall vehicle safety.

The potential market size for AV safety solutions, including advanced battery systems, is substantial. As autonomous vehicle technology continues to mature and gain wider acceptance, the demand for safety-enhancing components is expected to grow significantly. This presents a considerable opportunity for manufacturers of blade batteries and other safety-focused technologies to capture a share of this expanding market.

Furthermore, the integration of blade batteries in autonomous vehicles addresses specific safety concerns related to battery performance and stability. The unique design and composition of blade batteries offer improved thermal management and reduced risk of thermal runaway, making them particularly attractive for use in AVs where safety is paramount. This alignment between the safety features of blade batteries and the specific needs of the AV market is driving increased demand and market potential.

In conclusion, the market demand for AV safety solutions, particularly those involving advanced battery technologies like blade batteries, is robust and growing. This demand is driven by a combination of consumer expectations, regulatory requirements, and industry commitment to safety, creating a significant market opportunity for innovative safety technologies in the autonomous vehicle sector.

Blade Battery Challenges

Despite the promising potential of blade batteries in enhancing autonomous vehicle safety, several significant challenges need to be addressed. One of the primary concerns is the thermal management of these batteries. While blade batteries offer improved heat dissipation compared to traditional lithium-ion batteries, the high-power demands of autonomous vehicles can still lead to thermal runaway risks. Engineers must develop more advanced cooling systems to maintain optimal operating temperatures under various driving conditions and climates.

Another challenge lies in the integration of blade batteries with autonomous driving systems. The unique form factor of blade batteries requires redesigning vehicle architectures to accommodate their shape while ensuring optimal weight distribution and crash safety. This integration process is complex and requires extensive testing to validate the structural integrity and performance of the entire system.

The manufacturing scalability of blade batteries also presents a hurdle. As demand for autonomous vehicles grows, producers must develop efficient, high-volume production methods for blade batteries without compromising quality or safety standards. This includes sourcing raw materials, streamlining assembly processes, and implementing rigorous quality control measures.

Longevity and degradation are additional concerns. While blade batteries show promise in terms of cycle life, the constant high-power demands of autonomous vehicles may accelerate battery degradation. Researchers need to conduct long-term studies to understand how these batteries perform over extended periods in real-world autonomous driving scenarios.

Safety testing and certification pose another challenge. Regulatory bodies must develop new standards and testing protocols specifically for blade batteries in autonomous vehicles. This process involves extensive crash testing, environmental exposure trials, and electromagnetic compatibility assessments to ensure these batteries meet or exceed current safety standards.

Lastly, the cost of blade batteries remains a significant barrier to widespread adoption in autonomous vehicles. Although prices are expected to decrease with increased production, the initial investment in research, development, and manufacturing infrastructure is substantial. Manufacturers must find ways to reduce costs without compromising on performance or safety to make autonomous vehicles equipped with blade batteries economically viable for mass-market adoption.

Another challenge lies in the integration of blade batteries with autonomous driving systems. The unique form factor of blade batteries requires redesigning vehicle architectures to accommodate their shape while ensuring optimal weight distribution and crash safety. This integration process is complex and requires extensive testing to validate the structural integrity and performance of the entire system.

The manufacturing scalability of blade batteries also presents a hurdle. As demand for autonomous vehicles grows, producers must develop efficient, high-volume production methods for blade batteries without compromising quality or safety standards. This includes sourcing raw materials, streamlining assembly processes, and implementing rigorous quality control measures.

Longevity and degradation are additional concerns. While blade batteries show promise in terms of cycle life, the constant high-power demands of autonomous vehicles may accelerate battery degradation. Researchers need to conduct long-term studies to understand how these batteries perform over extended periods in real-world autonomous driving scenarios.

Safety testing and certification pose another challenge. Regulatory bodies must develop new standards and testing protocols specifically for blade batteries in autonomous vehicles. This process involves extensive crash testing, environmental exposure trials, and electromagnetic compatibility assessments to ensure these batteries meet or exceed current safety standards.

Lastly, the cost of blade batteries remains a significant barrier to widespread adoption in autonomous vehicles. Although prices are expected to decrease with increased production, the initial investment in research, development, and manufacturing infrastructure is substantial. Manufacturers must find ways to reduce costs without compromising on performance or safety to make autonomous vehicles equipped with blade batteries economically viable for mass-market adoption.

Current Blade Solutions

01 Battery cell structure and design

Blade batteries employ a unique structural design to enhance safety. This includes optimized cell arrangement, improved heat dissipation mechanisms, and reinforced casing materials. The design aims to prevent thermal runaway and minimize the risk of fire or explosion, even under extreme conditions.- Battery cell structure and design: Blade batteries employ a unique structural design to enhance safety. This includes optimized cell arrangement, improved heat dissipation mechanisms, and reinforced casing materials. The design aims to prevent thermal runaway and minimize the risk of fire or explosion in case of physical damage or overheating.

- Safety monitoring and control systems: Advanced monitoring and control systems are integrated into blade batteries to ensure safe operation. These systems include temperature sensors, voltage monitors, and intelligent management algorithms that can detect abnormalities and trigger protective measures such as power cut-off or cooling activation to prevent safety incidents.

- Thermal management solutions: Effective thermal management is crucial for blade battery safety. This involves innovative cooling systems, heat-resistant materials, and thermal insulation techniques. These solutions help maintain optimal operating temperatures, prevent overheating, and reduce the risk of thermal runaway in high-stress conditions.

- Manufacturing processes and quality control: Specialized manufacturing processes and stringent quality control measures are implemented to enhance blade battery safety. This includes precision assembly techniques, advanced testing procedures, and rigorous inspection protocols to identify and eliminate potential defects or weaknesses that could compromise battery safety.

- Safety certification and testing standards: Blade batteries undergo comprehensive safety certification and testing to meet or exceed industry standards. This involves subjecting the batteries to extreme conditions, impact tests, and simulated abuse scenarios to verify their safety performance and ensure compliance with regulatory requirements.

02 Safety monitoring and control systems

Advanced monitoring and control systems are integrated into blade batteries to ensure safe operation. These systems continuously monitor temperature, voltage, and current, and can quickly detect and respond to abnormal conditions. They may include features like automatic shut-off mechanisms and intelligent battery management systems.Expand Specific Solutions03 Thermal management techniques

Effective thermal management is crucial for blade battery safety. This involves innovative cooling systems, heat-resistant materials, and thermal insulation techniques. These measures help maintain optimal operating temperatures and prevent overheating, which is a common cause of battery failures.Expand Specific Solutions04 Manufacturing processes and quality control

Specialized manufacturing processes and stringent quality control measures are employed to enhance the safety of blade batteries. This includes precision assembly techniques, advanced testing procedures, and the use of high-quality materials. These processes aim to minimize defects and ensure consistent performance and safety across all produced batteries.Expand Specific Solutions05 Safety standards and certification

Blade batteries are subject to rigorous safety standards and certification processes. This involves comprehensive testing under various conditions, including extreme temperatures, physical stress, and electrical abuse. Compliance with international safety standards and obtaining relevant certifications are crucial steps in ensuring the overall safety of blade batteries for commercial use.Expand Specific Solutions

Key EV Battery Players

The Blade Battery's role in enhancing autonomous vehicle safety is evolving within a competitive landscape characterized by rapid technological advancements and growing market demand. The industry is in a transitional phase, with major players like Contemporary Amperex Technology Co., Ltd., Svolt Energy Technology Co., Ltd., and LG Energy Solution Ltd. driving innovation. The market size for autonomous vehicle safety technologies is expanding, fueled by increasing adoption of electric and self-driving vehicles. While the technology is progressing, it's not yet fully mature, with companies like Robert Bosch GmbH, Zhejiang Geely Holding Group Co., Ltd., and Toyota Motor Corp. investing heavily in research and development to improve safety features and battery performance for autonomous vehicles.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's Blade Battery technology represents a significant advancement in enhancing autonomous vehicle safety. The Blade Battery utilizes LFP (Lithium Iron Phosphate) chemistry, which offers superior thermal stability compared to traditional lithium-ion batteries[1]. This innovative design allows for better heat dissipation and reduces the risk of thermal runaway, a critical safety concern in electric vehicles. The battery cells are arranged in a blade-like structure, increasing energy density while maintaining a compact form factor[2]. This design enables more efficient space utilization in autonomous vehicles, potentially allowing for larger battery packs and extended driving ranges. CATL has also implemented advanced battery management systems (BMS) that continuously monitor cell performance, temperature, and charge levels, further enhancing safety and longevity[3]. The Blade Battery has demonstrated exceptional performance in nail penetration tests, showing no smoke or fire even when punctured, which is crucial for autonomous vehicle safety in collision scenarios[4].

Strengths: Superior thermal stability, high energy density, improved safety in collision scenarios, and efficient space utilization. Weaknesses: Potentially higher production costs due to the novel design and the need for specialized manufacturing processes.

Robert Bosch GmbH

Technical Solution: Bosch's approach to enhancing autonomous vehicle safety through battery technology focuses on integrating advanced battery management systems (BMS) with their comprehensive autonomous driving platform. Their BMS utilizes AI-driven predictive analytics to optimize battery performance and longevity while ensuring safety[1]. Bosch has developed high-precision sensors that monitor battery temperature, charge state, and overall health in real-time, allowing for immediate response to potential issues[2]. Their system also incorporates advanced cooling technologies to maintain optimal battery temperature, crucial for both performance and safety in autonomous vehicles. Bosch's battery technology is designed to work seamlessly with their autonomous driving sensors and software, creating a holistic safety ecosystem[3]. They have also invested in solid-state battery research, aiming to develop batteries with higher energy density and improved safety characteristics for future autonomous vehicles[4].

Strengths: Comprehensive integration with autonomous driving systems, advanced predictive analytics, and focus on holistic vehicle safety. Weaknesses: Dependency on partnerships for battery cell production and potential challenges in scaling up new battery technologies.

Blade Battery Innovations

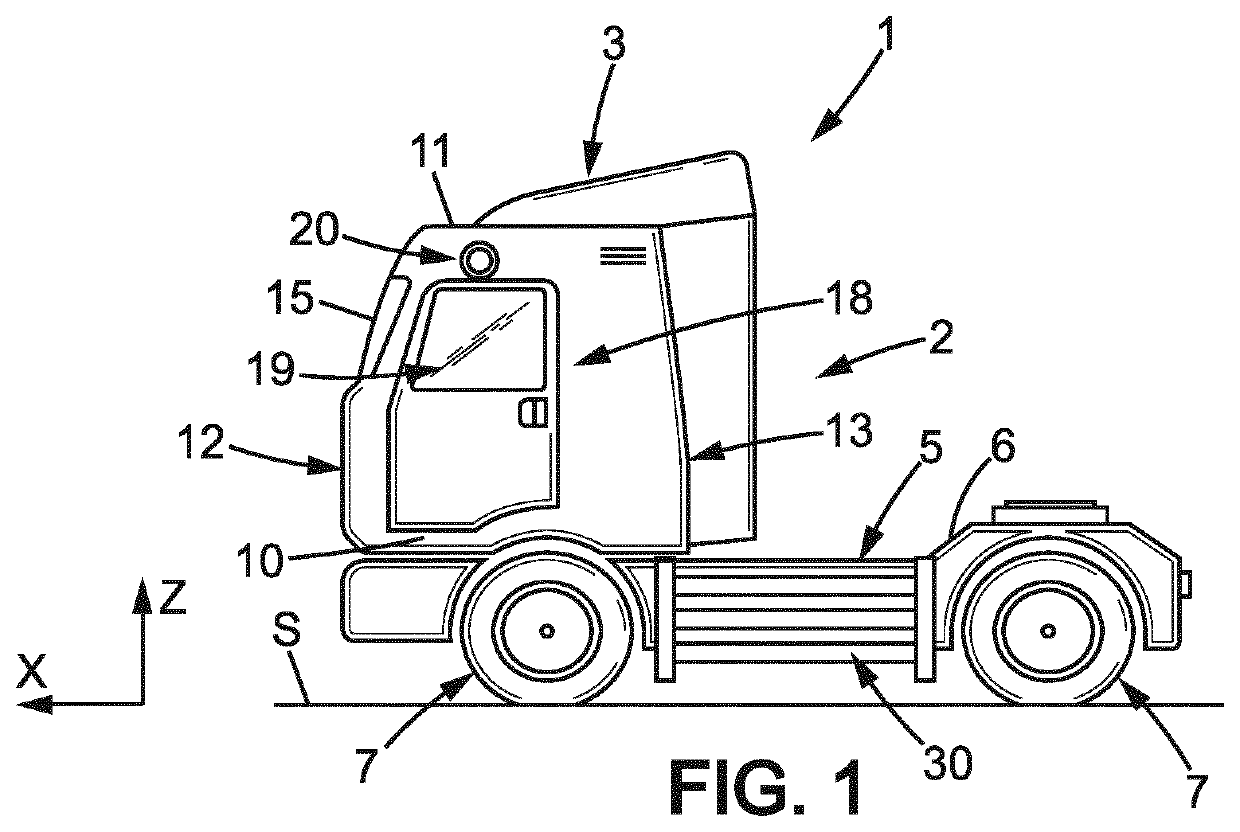

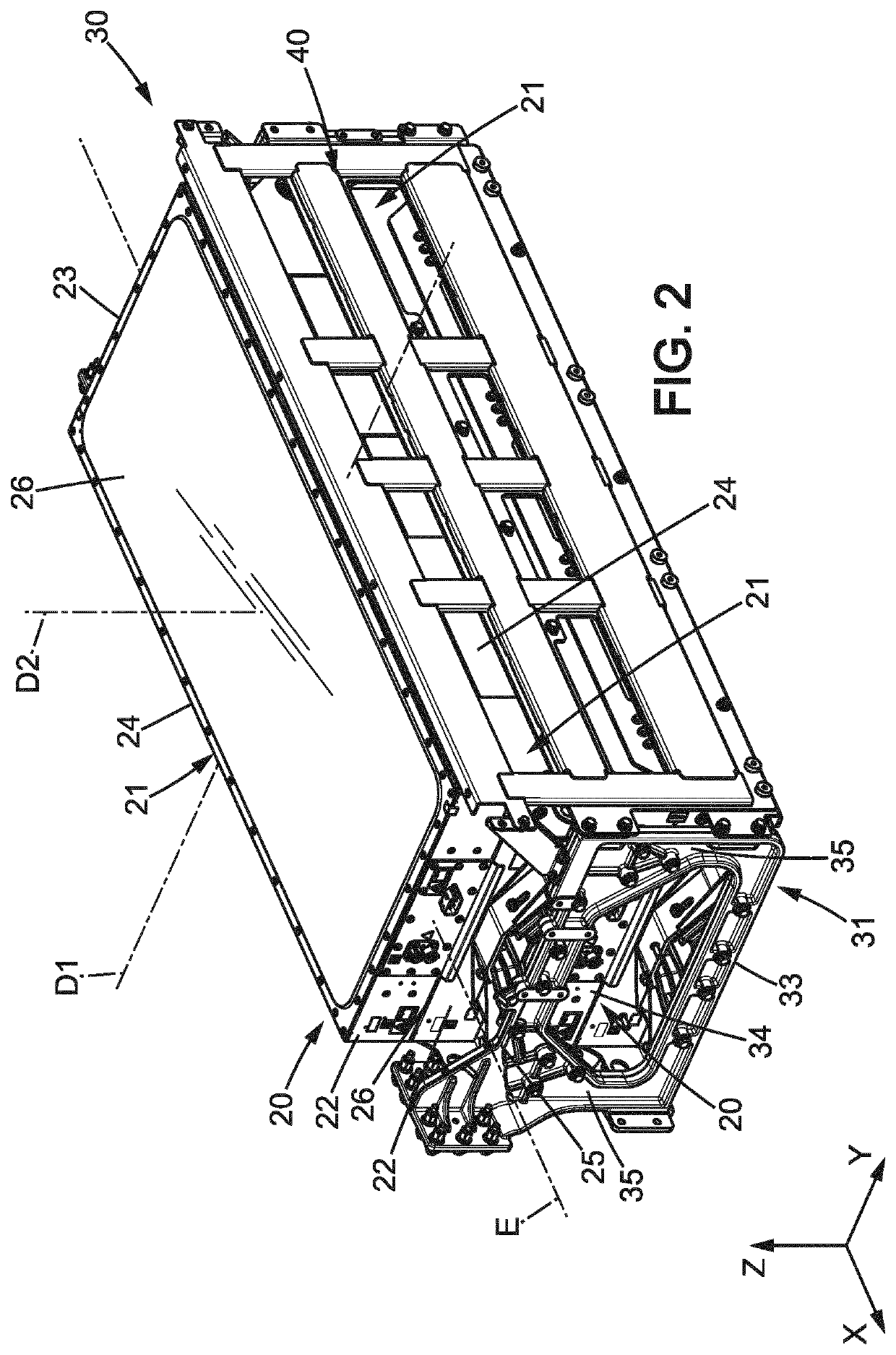

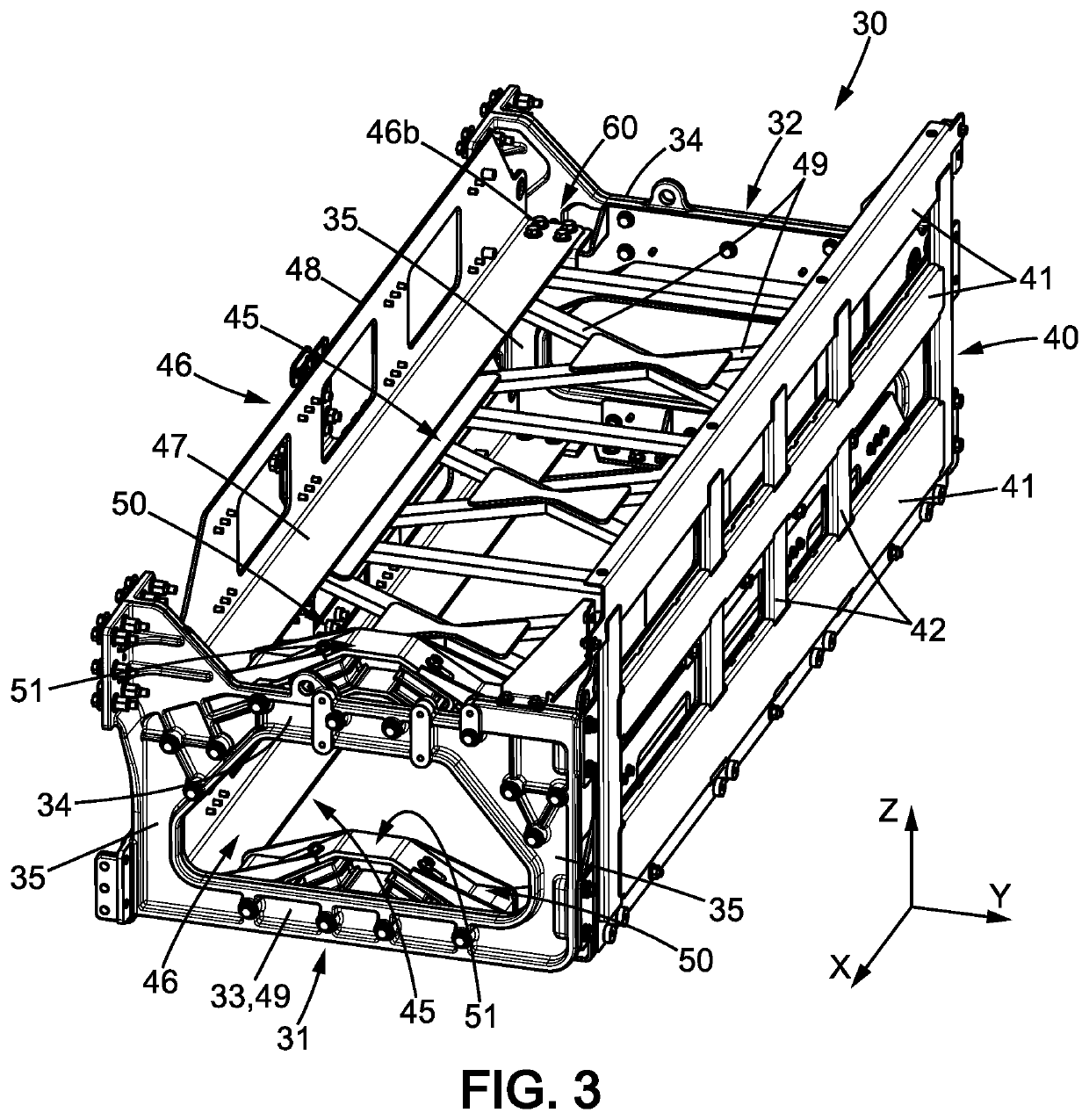

Electrically powered commercial vehicle having a battery structure

PatentActiveUS20220097537A1

Innovation

- A battery structure with resiliently deformable arrangements and fixation points that decouple the battery from the chassis, providing a three-point mounting system to absorb torsion and enhance crash protection, including a damping device for vertical vibrations and side crash protection members.

Regulatory Framework

The regulatory framework surrounding Blade Battery technology in autonomous vehicles is a critical aspect of its implementation and widespread adoption. As autonomous vehicles become more prevalent, governments and regulatory bodies are developing comprehensive guidelines to ensure the safety and reliability of these advanced transportation systems. The integration of Blade Battery technology into autonomous vehicles necessitates a thorough examination of existing regulations and the potential need for new standards.

Current regulations for autonomous vehicles primarily focus on operational safety, data privacy, and liability issues. However, the unique characteristics of Blade Battery technology, such as its enhanced safety features and improved energy density, require specific consideration within the regulatory landscape. Regulatory bodies are working to establish standards for battery performance, safety testing protocols, and integration requirements for autonomous vehicle systems.

One key area of regulatory focus is the development of safety standards for Blade Battery technology in autonomous vehicles. These standards aim to address potential risks associated with battery thermal runaway, electrical safety, and crash protection. Regulatory agencies are collaborating with industry experts to define comprehensive testing procedures that evaluate the battery's performance under various operating conditions and potential accident scenarios.

Additionally, regulations are being developed to ensure the proper integration of Blade Battery technology with autonomous vehicle systems. This includes guidelines for battery management systems, power distribution, and thermal management. The regulatory framework also addresses the need for standardized communication protocols between the battery system and the vehicle's autonomous driving components to ensure seamless operation and optimal safety performance.

Environmental considerations are another crucial aspect of the regulatory framework. As Blade Battery technology offers improved energy efficiency and reduced environmental impact, regulators are developing guidelines to promote the adoption of this technology in autonomous vehicles. This includes incentives for manufacturers to incorporate Blade Batteries into their designs and standards for end-of-life battery recycling and disposal.

The regulatory landscape also encompasses cybersecurity requirements for autonomous vehicles equipped with Blade Battery technology. As these vehicles rely heavily on interconnected systems, regulations are being established to protect against potential cyber threats that could compromise battery performance or vehicle safety. This includes guidelines for secure data transmission, remote monitoring, and over-the-air updates for battery management systems.

As the technology continues to evolve, regulatory bodies are adopting a flexible approach to accommodate future advancements in Blade Battery technology and autonomous vehicle systems. This includes provisions for regular review and updates to existing regulations, as well as mechanisms for fast-tracking the approval of innovative safety features and performance enhancements.

Current regulations for autonomous vehicles primarily focus on operational safety, data privacy, and liability issues. However, the unique characteristics of Blade Battery technology, such as its enhanced safety features and improved energy density, require specific consideration within the regulatory landscape. Regulatory bodies are working to establish standards for battery performance, safety testing protocols, and integration requirements for autonomous vehicle systems.

One key area of regulatory focus is the development of safety standards for Blade Battery technology in autonomous vehicles. These standards aim to address potential risks associated with battery thermal runaway, electrical safety, and crash protection. Regulatory agencies are collaborating with industry experts to define comprehensive testing procedures that evaluate the battery's performance under various operating conditions and potential accident scenarios.

Additionally, regulations are being developed to ensure the proper integration of Blade Battery technology with autonomous vehicle systems. This includes guidelines for battery management systems, power distribution, and thermal management. The regulatory framework also addresses the need for standardized communication protocols between the battery system and the vehicle's autonomous driving components to ensure seamless operation and optimal safety performance.

Environmental considerations are another crucial aspect of the regulatory framework. As Blade Battery technology offers improved energy efficiency and reduced environmental impact, regulators are developing guidelines to promote the adoption of this technology in autonomous vehicles. This includes incentives for manufacturers to incorporate Blade Batteries into their designs and standards for end-of-life battery recycling and disposal.

The regulatory landscape also encompasses cybersecurity requirements for autonomous vehicles equipped with Blade Battery technology. As these vehicles rely heavily on interconnected systems, regulations are being established to protect against potential cyber threats that could compromise battery performance or vehicle safety. This includes guidelines for secure data transmission, remote monitoring, and over-the-air updates for battery management systems.

As the technology continues to evolve, regulatory bodies are adopting a flexible approach to accommodate future advancements in Blade Battery technology and autonomous vehicle systems. This includes provisions for regular review and updates to existing regulations, as well as mechanisms for fast-tracking the approval of innovative safety features and performance enhancements.

Environmental Impact

The environmental impact of Blade Batteries in autonomous vehicles is a crucial aspect to consider as the automotive industry shifts towards more sustainable and safer transportation solutions. Blade Batteries, developed by BYD, offer significant advantages in terms of environmental sustainability compared to traditional lithium-ion batteries used in electric vehicles.

One of the primary environmental benefits of Blade Batteries is their improved energy density and longer lifespan. This results in fewer battery replacements over the vehicle's lifetime, reducing the overall environmental footprint associated with battery production and disposal. The extended lifespan of Blade Batteries also contributes to a more efficient use of resources, as fewer raw materials are required for battery manufacturing in the long term.

The manufacturing process of Blade Batteries is designed to be more environmentally friendly than that of conventional lithium-ion batteries. BYD has implemented advanced production techniques that minimize waste and energy consumption during the manufacturing phase. This approach not only reduces the carbon footprint of battery production but also helps conserve valuable resources.

In terms of safety, Blade Batteries exhibit superior thermal stability and resistance to combustion, which significantly reduces the risk of fires or explosions in autonomous vehicles. This enhanced safety feature indirectly contributes to environmental protection by minimizing the potential for hazardous incidents that could lead to environmental contamination or resource-intensive emergency responses.

The use of Blade Batteries in autonomous vehicles also supports the broader goal of reducing greenhouse gas emissions in the transportation sector. As these batteries enable longer driving ranges and faster charging times, they make electric autonomous vehicles more practical and appealing to consumers, potentially accelerating the transition away from fossil fuel-powered vehicles.

Furthermore, the compact design of Blade Batteries allows for more efficient use of space within autonomous vehicles. This optimization can lead to lighter vehicle weights, which in turn improves overall energy efficiency and reduces the environmental impact of vehicle operation.

At the end of their lifecycle, Blade Batteries present opportunities for more effective recycling and material recovery compared to traditional lithium-ion batteries. The simplified structure and composition of Blade Batteries facilitate easier disassembly and separation of components, potentially increasing the recycling rate and reducing the environmental burden associated with battery disposal.

One of the primary environmental benefits of Blade Batteries is their improved energy density and longer lifespan. This results in fewer battery replacements over the vehicle's lifetime, reducing the overall environmental footprint associated with battery production and disposal. The extended lifespan of Blade Batteries also contributes to a more efficient use of resources, as fewer raw materials are required for battery manufacturing in the long term.

The manufacturing process of Blade Batteries is designed to be more environmentally friendly than that of conventional lithium-ion batteries. BYD has implemented advanced production techniques that minimize waste and energy consumption during the manufacturing phase. This approach not only reduces the carbon footprint of battery production but also helps conserve valuable resources.

In terms of safety, Blade Batteries exhibit superior thermal stability and resistance to combustion, which significantly reduces the risk of fires or explosions in autonomous vehicles. This enhanced safety feature indirectly contributes to environmental protection by minimizing the potential for hazardous incidents that could lead to environmental contamination or resource-intensive emergency responses.

The use of Blade Batteries in autonomous vehicles also supports the broader goal of reducing greenhouse gas emissions in the transportation sector. As these batteries enable longer driving ranges and faster charging times, they make electric autonomous vehicles more practical and appealing to consumers, potentially accelerating the transition away from fossil fuel-powered vehicles.

Furthermore, the compact design of Blade Batteries allows for more efficient use of space within autonomous vehicles. This optimization can lead to lighter vehicle weights, which in turn improves overall energy efficiency and reduces the environmental impact of vehicle operation.

At the end of their lifecycle, Blade Batteries present opportunities for more effective recycling and material recovery compared to traditional lithium-ion batteries. The simplified structure and composition of Blade Batteries facilitate easier disassembly and separation of components, potentially increasing the recycling rate and reducing the environmental burden associated with battery disposal.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!