Blade Battery's Role in Facilitating Global Electric Mobility

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Blade Battery Evolution

The evolution of the Blade Battery represents a significant milestone in the advancement of electric vehicle (EV) technology, particularly in addressing key challenges related to safety, energy density, and cost-effectiveness. Developed by BYD, a leading Chinese automotive manufacturer, the Blade Battery was first introduced in 2020 as a revolutionary lithium iron phosphate (LFP) battery design.

The Blade Battery's journey began with the recognition of the limitations in traditional battery pack designs. Conventional EV batteries often faced issues such as thermal runaway, limited energy density, and complex manufacturing processes. BYD's engineers set out to create a solution that would overcome these obstacles while maintaining high performance standards.

The innovative design of the Blade Battery features long, thin cells arranged in a parallel configuration, resembling blades in appearance. This unique structure allows for more efficient space utilization within the battery pack, resulting in a higher energy density compared to traditional LFP batteries. The design also facilitates better heat dissipation, significantly reducing the risk of thermal runaway and enhancing overall safety.

As the Blade Battery evolved, it underwent rigorous testing and refinement. BYD conducted extensive safety tests, including the notorious nail penetration test, which demonstrated the battery's exceptional resistance to combustion and explosion. This breakthrough in safety features has set a new standard for the EV industry, addressing one of the primary concerns among potential electric vehicle adopters.

The manufacturing process for the Blade Battery has also seen continuous improvement. BYD has invested in advanced production facilities and techniques to streamline the manufacturing of these batteries, leading to increased production efficiency and reduced costs. This has played a crucial role in making EVs more affordable and accessible to a broader market.

Over time, the Blade Battery has expanded its application beyond BYD's own vehicle lineup. The company has begun supplying this technology to other automakers, contributing to the wider adoption of safer and more efficient EV batteries across the industry. This expansion has further accelerated the evolution of the Blade Battery, as it adapts to meet the diverse requirements of different vehicle models and manufacturers.

Recent developments in the Blade Battery technology have focused on enhancing its performance characteristics. Researchers have been working on improving the battery's charging speed, cycle life, and overall longevity. These advancements aim to address some of the remaining challenges in EV adoption, such as range anxiety and long-term reliability.

The evolution of the Blade Battery continues to play a pivotal role in facilitating global electric mobility. Its ongoing development and refinement are contributing to the creation of EVs that are safer, more efficient, and increasingly cost-competitive with traditional internal combustion engine vehicles. As the technology matures, it is expected to further accelerate the transition towards sustainable transportation on a global scale.

The Blade Battery's journey began with the recognition of the limitations in traditional battery pack designs. Conventional EV batteries often faced issues such as thermal runaway, limited energy density, and complex manufacturing processes. BYD's engineers set out to create a solution that would overcome these obstacles while maintaining high performance standards.

The innovative design of the Blade Battery features long, thin cells arranged in a parallel configuration, resembling blades in appearance. This unique structure allows for more efficient space utilization within the battery pack, resulting in a higher energy density compared to traditional LFP batteries. The design also facilitates better heat dissipation, significantly reducing the risk of thermal runaway and enhancing overall safety.

As the Blade Battery evolved, it underwent rigorous testing and refinement. BYD conducted extensive safety tests, including the notorious nail penetration test, which demonstrated the battery's exceptional resistance to combustion and explosion. This breakthrough in safety features has set a new standard for the EV industry, addressing one of the primary concerns among potential electric vehicle adopters.

The manufacturing process for the Blade Battery has also seen continuous improvement. BYD has invested in advanced production facilities and techniques to streamline the manufacturing of these batteries, leading to increased production efficiency and reduced costs. This has played a crucial role in making EVs more affordable and accessible to a broader market.

Over time, the Blade Battery has expanded its application beyond BYD's own vehicle lineup. The company has begun supplying this technology to other automakers, contributing to the wider adoption of safer and more efficient EV batteries across the industry. This expansion has further accelerated the evolution of the Blade Battery, as it adapts to meet the diverse requirements of different vehicle models and manufacturers.

Recent developments in the Blade Battery technology have focused on enhancing its performance characteristics. Researchers have been working on improving the battery's charging speed, cycle life, and overall longevity. These advancements aim to address some of the remaining challenges in EV adoption, such as range anxiety and long-term reliability.

The evolution of the Blade Battery continues to play a pivotal role in facilitating global electric mobility. Its ongoing development and refinement are contributing to the creation of EVs that are safer, more efficient, and increasingly cost-competitive with traditional internal combustion engine vehicles. As the technology matures, it is expected to further accelerate the transition towards sustainable transportation on a global scale.

EV Market Demand Analysis

The global electric vehicle (EV) market has experienced unprecedented growth in recent years, driven by increasing environmental awareness, government incentives, and technological advancements. This surge in demand for EVs has created a significant market opportunity for innovative battery technologies, such as the Blade Battery.

Consumer preferences are shifting towards electric mobility, with a growing emphasis on longer driving ranges, faster charging times, and enhanced safety features. The Blade Battery, with its unique design and improved energy density, addresses these key consumer demands. Its ability to provide extended range without compromising safety aligns well with market expectations, potentially accelerating EV adoption rates.

Market analysis indicates that the global EV sales are projected to continue their upward trajectory. Major automotive markets, including China, Europe, and North America, are witnessing robust growth in EV sales, supported by favorable government policies and expanding charging infrastructure. This trend is expected to persist, creating a substantial demand for advanced battery technologies like the Blade Battery.

The commercial vehicle sector, including buses and trucks, is also showing increased interest in electrification. The Blade Battery's high energy density and improved safety features make it an attractive option for this segment, which requires long-range capabilities and reliable performance under heavy-duty conditions.

Emerging markets in Asia, South America, and Africa are beginning to embrace electric mobility, presenting new growth opportunities. As these markets develop, there will be a rising demand for cost-effective and efficient battery solutions, a niche where the Blade Battery could potentially excel.

The shift towards electric mobility is not limited to personal transportation. The rise of electric micro-mobility solutions, such as e-bikes and e-scooters, is creating additional demand for compact, lightweight, and safe battery technologies. The Blade Battery's design principles could be adapted to serve this growing market segment effectively.

Consumer concerns about battery safety and longevity continue to influence purchasing decisions. The Blade Battery's enhanced safety features and potential for improved cycle life address these concerns directly, potentially boosting consumer confidence and accelerating EV adoption rates across various market segments.

As the EV market matures, there is an increasing focus on sustainability and environmental impact throughout the battery lifecycle. The Blade Battery's potential for improved resource utilization and recyclability aligns with this market trend, potentially offering a competitive advantage in environmentally conscious markets.

Consumer preferences are shifting towards electric mobility, with a growing emphasis on longer driving ranges, faster charging times, and enhanced safety features. The Blade Battery, with its unique design and improved energy density, addresses these key consumer demands. Its ability to provide extended range without compromising safety aligns well with market expectations, potentially accelerating EV adoption rates.

Market analysis indicates that the global EV sales are projected to continue their upward trajectory. Major automotive markets, including China, Europe, and North America, are witnessing robust growth in EV sales, supported by favorable government policies and expanding charging infrastructure. This trend is expected to persist, creating a substantial demand for advanced battery technologies like the Blade Battery.

The commercial vehicle sector, including buses and trucks, is also showing increased interest in electrification. The Blade Battery's high energy density and improved safety features make it an attractive option for this segment, which requires long-range capabilities and reliable performance under heavy-duty conditions.

Emerging markets in Asia, South America, and Africa are beginning to embrace electric mobility, presenting new growth opportunities. As these markets develop, there will be a rising demand for cost-effective and efficient battery solutions, a niche where the Blade Battery could potentially excel.

The shift towards electric mobility is not limited to personal transportation. The rise of electric micro-mobility solutions, such as e-bikes and e-scooters, is creating additional demand for compact, lightweight, and safe battery technologies. The Blade Battery's design principles could be adapted to serve this growing market segment effectively.

Consumer concerns about battery safety and longevity continue to influence purchasing decisions. The Blade Battery's enhanced safety features and potential for improved cycle life address these concerns directly, potentially boosting consumer confidence and accelerating EV adoption rates across various market segments.

As the EV market matures, there is an increasing focus on sustainability and environmental impact throughout the battery lifecycle. The Blade Battery's potential for improved resource utilization and recyclability aligns with this market trend, potentially offering a competitive advantage in environmentally conscious markets.

Blade Battery Tech Status

Blade batteries have emerged as a significant technological advancement in the electric vehicle (EV) industry, offering a promising solution to address key challenges in battery performance and safety. Developed by BYD, a leading Chinese automaker and battery manufacturer, blade batteries represent a novel approach to lithium-iron-phosphate (LFP) battery design and construction.

The current technological status of blade batteries is characterized by several key features that set them apart from traditional lithium-ion batteries. Firstly, their unique structural design allows for more efficient space utilization within the battery pack. By arranging long, thin cells in a blade-like configuration, these batteries can achieve higher energy density and improved thermal management compared to conventional battery designs.

One of the most notable aspects of blade batteries is their enhanced safety profile. The LFP chemistry used in these batteries is inherently more stable than other lithium-ion chemistries, reducing the risk of thermal runaway and fire. Additionally, the blade-like structure of the cells contributes to better heat dissipation, further improving safety and longevity.

In terms of performance, blade batteries have demonstrated impressive capabilities. They offer fast charging rates, with some models capable of reaching 80% charge in less than 30 minutes. This rapid charging ability is crucial for addressing range anxiety and improving the practicality of EVs for long-distance travel.

The energy density of blade batteries, while not as high as some high-nickel NMC (Nickel Manganese Cobalt) batteries, is competitive within the LFP category. This balance of energy density, safety, and cost-effectiveness makes blade batteries particularly attractive for mass-market EVs, where affordability and reliability are key considerations.

Durability is another area where blade batteries excel. They have shown remarkable cycle life, with some estimates suggesting they can maintain over 90% of their original capacity after 3,000 charge cycles. This longevity translates to reduced battery degradation over time, potentially extending the usable life of EVs and improving their long-term value proposition.

From a manufacturing perspective, blade batteries benefit from a relatively simple and cost-effective production process. The use of LFP chemistry eliminates the need for costly and ethically problematic cobalt, while the streamlined cell design facilitates more efficient assembly of battery packs.

However, challenges remain in the widespread adoption of blade battery technology. The primary limitation is the lower energy density compared to high-nickel NMC batteries, which can impact vehicle range. Additionally, while the technology has shown promise, it is still relatively new, and long-term performance data in real-world conditions across various climates and usage patterns is still being gathered.

The current technological status of blade batteries is characterized by several key features that set them apart from traditional lithium-ion batteries. Firstly, their unique structural design allows for more efficient space utilization within the battery pack. By arranging long, thin cells in a blade-like configuration, these batteries can achieve higher energy density and improved thermal management compared to conventional battery designs.

One of the most notable aspects of blade batteries is their enhanced safety profile. The LFP chemistry used in these batteries is inherently more stable than other lithium-ion chemistries, reducing the risk of thermal runaway and fire. Additionally, the blade-like structure of the cells contributes to better heat dissipation, further improving safety and longevity.

In terms of performance, blade batteries have demonstrated impressive capabilities. They offer fast charging rates, with some models capable of reaching 80% charge in less than 30 minutes. This rapid charging ability is crucial for addressing range anxiety and improving the practicality of EVs for long-distance travel.

The energy density of blade batteries, while not as high as some high-nickel NMC (Nickel Manganese Cobalt) batteries, is competitive within the LFP category. This balance of energy density, safety, and cost-effectiveness makes blade batteries particularly attractive for mass-market EVs, where affordability and reliability are key considerations.

Durability is another area where blade batteries excel. They have shown remarkable cycle life, with some estimates suggesting they can maintain over 90% of their original capacity after 3,000 charge cycles. This longevity translates to reduced battery degradation over time, potentially extending the usable life of EVs and improving their long-term value proposition.

From a manufacturing perspective, blade batteries benefit from a relatively simple and cost-effective production process. The use of LFP chemistry eliminates the need for costly and ethically problematic cobalt, while the streamlined cell design facilitates more efficient assembly of battery packs.

However, challenges remain in the widespread adoption of blade battery technology. The primary limitation is the lower energy density compared to high-nickel NMC batteries, which can impact vehicle range. Additionally, while the technology has shown promise, it is still relatively new, and long-term performance data in real-world conditions across various climates and usage patterns is still being gathered.

Blade Battery Solutions

01 Battery structure and design

Blade batteries feature a unique structural design that optimizes space utilization and improves energy density. The design typically involves thin, elongated cells arranged in a parallel configuration, resembling blades. This structure allows for more efficient packaging within electric vehicles, potentially increasing range and performance.- Blade battery structure and design: Blade batteries feature a unique structural design that optimizes space utilization and energy density. The thin, elongated shape allows for efficient packaging in electric vehicles, improving overall battery performance and range. This design also enhances heat dissipation and structural integrity, contributing to improved safety and longevity of the battery pack.

- Safety features of blade batteries: Blade batteries incorporate advanced safety features to prevent thermal runaway and enhance overall battery safety. These may include improved thermal management systems, robust cell separators, and specialized electrolyte formulations. The design also allows for better pressure distribution and structural reinforcement, reducing the risk of punctures or deformation during impact events.

- Manufacturing processes for blade batteries: The production of blade batteries involves specialized manufacturing techniques to achieve the desired thin profile and high energy density. This may include advanced electrode coating methods, precision assembly processes, and innovative cell stacking techniques. The manufacturing process also focuses on quality control measures to ensure consistency and reliability in battery performance.

- Integration of blade batteries in electric vehicles: Blade batteries are designed for seamless integration into electric vehicle platforms. Their slim profile allows for flexible placement within the vehicle chassis, potentially improving weight distribution and vehicle dynamics. The integration process may involve specialized mounting systems, cooling arrangements, and electrical connections to optimize performance and safety in automotive applications.

- Battery management systems for blade batteries: Advanced battery management systems are crucial for optimizing the performance and longevity of blade batteries. These systems monitor and control various parameters such as cell voltage, temperature, and state of charge. They may also incorporate predictive algorithms for battery health monitoring and adaptive charging strategies to maximize efficiency and lifespan of the blade battery pack.

02 Safety features and thermal management

Blade batteries incorporate advanced safety features and thermal management systems. These may include improved heat dissipation mechanisms, fire-resistant materials, and enhanced structural integrity to prevent thermal runaway and improve overall battery safety in electric vehicles.Expand Specific Solutions03 Manufacturing and assembly processes

The production of blade batteries involves specialized manufacturing and assembly techniques. This includes methods for precise cell alignment, innovative bonding processes, and automated assembly systems to ensure consistent quality and performance of the battery packs.Expand Specific Solutions04 Battery management and control systems

Blade batteries utilize sophisticated management and control systems to optimize performance, longevity, and safety. These systems may include advanced monitoring of individual cells, intelligent charge/discharge control, and predictive maintenance algorithms.Expand Specific Solutions05 Integration with electric vehicle systems

The integration of blade batteries into electric vehicle systems requires specific design considerations. This includes optimizing the battery pack's placement within the vehicle chassis, developing efficient cooling systems, and ensuring compatibility with the vehicle's power management and drivetrain systems.Expand Specific Solutions

Key EV Battery Players

The Blade Battery technology in facilitating global electric mobility is at a critical juncture, with the market rapidly expanding and technology maturing. The industry is transitioning from early adoption to mainstream acceptance, driven by increasing demand for electric vehicles and energy storage solutions. Major players like Contemporary Amperex Technology Co., Ltd. (CATL), LG Energy Solution, and Hefei Guoxuan High-Tech Power Energy Co., Ltd. are leading innovation in this space. The market size is projected to grow significantly, with automotive giants such as Renault, Toyota, and Subaru incorporating advanced battery technologies into their electric vehicle lineups. As the technology evolves, we're seeing a shift towards higher energy density, faster charging capabilities, and improved safety features, positioning Blade Battery as a key enabler in the global transition to electric mobility.

Contemporary Amperex Technology Co., Ltd.

Technical Solution: CATL's Blade Battery technology represents a significant advancement in electric vehicle (EV) battery design. The Blade Battery utilizes LFP (lithium iron phosphate) chemistry in a novel cell-to-pack design, eliminating the need for modules. This approach increases energy density by 50% compared to conventional LFP batteries[1]. The cells are arranged in a blade-like format, allowing for more efficient space utilization within the battery pack. CATL claims the Blade Battery can achieve an energy density of up to 160Wh/kg at the pack level[2]. The design also incorporates advanced thermal management systems, enabling faster charging capabilities of up to 80% in 15 minutes[3]. Additionally, the Blade Battery has demonstrated exceptional safety performance, passing nail penetration tests without catching fire or exploding[4].

Strengths: High energy density, improved safety, fast charging capability, and cost-effectiveness due to LFP chemistry. Weaknesses: Lower energy density compared to NMC batteries, potentially limiting long-range EV applications.

Toyota Motor Corp.

Technical Solution: Toyota has been developing solid-state battery technology as a key component of its electric mobility strategy. Their solid-state batteries use a solid electrolyte instead of liquid, potentially offering higher energy density, faster charging times, and improved safety. Toyota claims their solid-state batteries can achieve an energy density of over 400 Wh/L[10], significantly higher than current lithium-ion technologies. The company has also reported that these batteries can charge to 80% capacity in just 10 minutes[11]. Toyota's approach includes the use of sulfide-based solid electrolytes and has demonstrated the ability to operate at room temperature, a crucial factor for practical application. They have also developed new manufacturing processes to address the challenges of mass-producing solid-state batteries[12].

Strengths: Potential for high energy density, fast charging, and improved safety. Pioneer in solid-state battery research for automotive applications. Weaknesses: Technology still in development phase, challenges in scaling up production, potentially high initial costs.

Blade Battery Innovations

Electrically powered commercial vehicle having a battery structure

PatentActiveUS11993157B2

Innovation

- A battery structure with resiliently deformable arrangements and fixation points that decouple the battery from the chassis, providing a three-point mounting system to absorb torsion and enhance crash protection, including a damping device for vertical vibrations and side crash protection members.

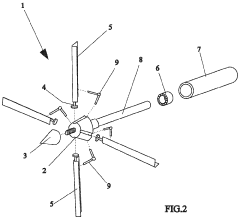

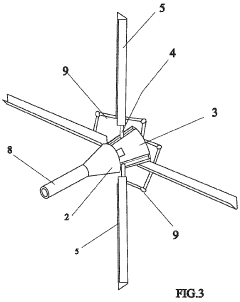

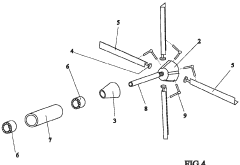

Rotor provided with self-adjustable blades for converting kinetic energy into rotary movement

PatentWO2023230681A1

Innovation

- A rotor equipped with self-adjustable blades that convert kinetic energy from fluid displacement into rotary motion by mechanically adjusting blade inclination to maintain a safe RPM range, leveraging drag forces to optimize energy capture and generation.

Global EV Policy Landscape

The global electric vehicle (EV) policy landscape plays a crucial role in shaping the adoption and development of electric mobility worldwide. Governments across the globe are implementing various policies and incentives to accelerate the transition to electric vehicles, recognizing their potential to reduce greenhouse gas emissions and improve air quality.

In many countries, financial incentives form the cornerstone of EV promotion policies. These include purchase subsidies, tax credits, and rebates for consumers who choose to buy electric vehicles. For instance, Norway has become a leader in EV adoption by offering substantial tax exemptions and benefits for EV owners, resulting in electric cars accounting for over 50% of new vehicle sales in recent years.

Regulatory measures also play a significant role in driving EV adoption. Several nations have announced plans to phase out internal combustion engine vehicles in the coming decades. The United Kingdom, for example, has set a target to ban the sale of new petrol and diesel cars by 2030, while California in the United States aims to achieve 100% zero-emission vehicle sales by 2035.

Infrastructure development is another key focus of global EV policies. Governments are investing in the expansion of charging networks to address range anxiety concerns and facilitate long-distance travel for EV owners. China, the world's largest EV market, has been aggressively building charging stations nationwide, with plans to have 20 million charging points by 2025.

Many countries are also implementing stricter emissions standards and fuel economy regulations, indirectly promoting the shift towards electric vehicles. The European Union's CO2 emissions standards for new cars and vans are among the most stringent globally, pushing automakers to increase their EV offerings to comply with these regulations.

Research and development support is another critical aspect of EV policies. Governments are allocating funds to promote innovation in battery technology, charging infrastructure, and EV manufacturing. This support aims to reduce costs, improve performance, and enhance the overall competitiveness of electric vehicles in the global market.

In the context of Blade Battery technology, the global EV policy landscape presents both opportunities and challenges. As governments worldwide continue to push for electrification, innovative battery technologies like the Blade Battery can play a crucial role in addressing key concerns such as range, safety, and cost-effectiveness. The supportive policy environment creates a favorable market for advanced battery solutions, potentially accelerating the adoption of technologies that can overcome current limitations in electric mobility.

In many countries, financial incentives form the cornerstone of EV promotion policies. These include purchase subsidies, tax credits, and rebates for consumers who choose to buy electric vehicles. For instance, Norway has become a leader in EV adoption by offering substantial tax exemptions and benefits for EV owners, resulting in electric cars accounting for over 50% of new vehicle sales in recent years.

Regulatory measures also play a significant role in driving EV adoption. Several nations have announced plans to phase out internal combustion engine vehicles in the coming decades. The United Kingdom, for example, has set a target to ban the sale of new petrol and diesel cars by 2030, while California in the United States aims to achieve 100% zero-emission vehicle sales by 2035.

Infrastructure development is another key focus of global EV policies. Governments are investing in the expansion of charging networks to address range anxiety concerns and facilitate long-distance travel for EV owners. China, the world's largest EV market, has been aggressively building charging stations nationwide, with plans to have 20 million charging points by 2025.

Many countries are also implementing stricter emissions standards and fuel economy regulations, indirectly promoting the shift towards electric vehicles. The European Union's CO2 emissions standards for new cars and vans are among the most stringent globally, pushing automakers to increase their EV offerings to comply with these regulations.

Research and development support is another critical aspect of EV policies. Governments are allocating funds to promote innovation in battery technology, charging infrastructure, and EV manufacturing. This support aims to reduce costs, improve performance, and enhance the overall competitiveness of electric vehicles in the global market.

In the context of Blade Battery technology, the global EV policy landscape presents both opportunities and challenges. As governments worldwide continue to push for electrification, innovative battery technologies like the Blade Battery can play a crucial role in addressing key concerns such as range, safety, and cost-effectiveness. The supportive policy environment creates a favorable market for advanced battery solutions, potentially accelerating the adoption of technologies that can overcome current limitations in electric mobility.

Sustainability Impact

The adoption of Blade Battery technology in electric vehicles (EVs) has significant implications for sustainability in the global automotive industry. This innovative battery design offers several environmental benefits that contribute to the overall reduction of carbon emissions and resource consumption.

Firstly, the Blade Battery's improved energy density and longer lifespan directly impact the sustainability of EVs. With higher energy storage capacity, these batteries enable longer driving ranges, reducing the frequency of charging cycles and potentially extending the overall life of the vehicle. This longevity translates to fewer battery replacements over time, minimizing the environmental impact associated with battery production and disposal.

The Blade Battery's enhanced safety features also play a crucial role in sustainability. Its resistance to thermal runaway and improved stability reduce the risk of battery-related fires or explosions. This increased safety not only protects users but also minimizes the potential environmental hazards associated with battery accidents, such as toxic chemical releases or fire-related pollution.

Furthermore, the Blade Battery's design allows for more efficient use of raw materials. The cell-to-pack (CTP) technology employed in Blade Batteries reduces the number of components needed, streamlining the manufacturing process and potentially decreasing the overall environmental footprint of battery production. This efficiency in material use contributes to the conservation of valuable resources and reduces waste generation.

The Blade Battery's potential to accelerate the adoption of EVs globally also has far-reaching sustainability implications. As more consumers switch to electric vehicles powered by advanced battery technologies like the Blade Battery, there is a corresponding reduction in fossil fuel consumption and greenhouse gas emissions from the transportation sector. This shift aligns with global efforts to combat climate change and improve air quality in urban areas.

Additionally, the Blade Battery's compatibility with fast-charging technologies supports the development of more sustainable charging infrastructure. Faster charging times can lead to more efficient use of charging stations, potentially reducing the need for extensive charging infrastructure and its associated environmental impact.

In conclusion, the Blade Battery's role in facilitating global electric mobility extends beyond mere technological advancement. Its contributions to sustainability through improved energy efficiency, enhanced safety, resource conservation, and support for widespread EV adoption position it as a key player in the transition towards a more sustainable transportation ecosystem.

Firstly, the Blade Battery's improved energy density and longer lifespan directly impact the sustainability of EVs. With higher energy storage capacity, these batteries enable longer driving ranges, reducing the frequency of charging cycles and potentially extending the overall life of the vehicle. This longevity translates to fewer battery replacements over time, minimizing the environmental impact associated with battery production and disposal.

The Blade Battery's enhanced safety features also play a crucial role in sustainability. Its resistance to thermal runaway and improved stability reduce the risk of battery-related fires or explosions. This increased safety not only protects users but also minimizes the potential environmental hazards associated with battery accidents, such as toxic chemical releases or fire-related pollution.

Furthermore, the Blade Battery's design allows for more efficient use of raw materials. The cell-to-pack (CTP) technology employed in Blade Batteries reduces the number of components needed, streamlining the manufacturing process and potentially decreasing the overall environmental footprint of battery production. This efficiency in material use contributes to the conservation of valuable resources and reduces waste generation.

The Blade Battery's potential to accelerate the adoption of EVs globally also has far-reaching sustainability implications. As more consumers switch to electric vehicles powered by advanced battery technologies like the Blade Battery, there is a corresponding reduction in fossil fuel consumption and greenhouse gas emissions from the transportation sector. This shift aligns with global efforts to combat climate change and improve air quality in urban areas.

Additionally, the Blade Battery's compatibility with fast-charging technologies supports the development of more sustainable charging infrastructure. Faster charging times can lead to more efficient use of charging stations, potentially reducing the need for extensive charging infrastructure and its associated environmental impact.

In conclusion, the Blade Battery's role in facilitating global electric mobility extends beyond mere technological advancement. Its contributions to sustainability through improved energy efficiency, enhanced safety, resource conservation, and support for widespread EV adoption position it as a key player in the transition towards a more sustainable transportation ecosystem.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!