Carbon Tetrachloride in Modern Research Labs: Techniques and Challenges

JUL 2, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

CCl4 Research Evolution

Carbon tetrachloride (CCl4) has undergone a significant evolution in its role within research laboratories over the past century. Initially discovered in the 1840s, CCl4 quickly gained prominence as a versatile solvent and reagent in organic chemistry due to its unique properties. Its non-flammability and excellent solvating capabilities made it a staple in many laboratory procedures.

In the early 20th century, CCl4 found widespread use in various industrial and commercial applications, including fire extinguishers, dry cleaning, and refrigerants. This period marked the peak of its utilization, with researchers extensively exploring its chemical properties and potential applications. However, the 1970s brought a turning point in CCl4 research as its harmful effects on human health and the environment became increasingly apparent.

The discovery of CCl4's ozone-depleting properties led to a significant shift in research focus. Scientists began investigating alternatives and developing new techniques to minimize its use. This era saw a surge in studies on CCl4's atmospheric chemistry, its impact on stratospheric ozone, and its role in global warming. Concurrently, toxicological research intensified, revealing the compound's hepatotoxic and carcinogenic properties.

The late 20th century witnessed a dramatic decline in CCl4 usage following international regulations like the Montreal Protocol. Research efforts pivoted towards developing safer substitutes and remediation technologies for CCl4-contaminated sites. Analytical chemists worked on improving detection methods for trace amounts of CCl4 in environmental samples, leading to advancements in chromatography and spectroscopy techniques.

In modern research labs, CCl4 has transitioned from a common reagent to a carefully controlled substance. Current research focuses on understanding its long-term environmental impacts, developing more efficient degradation methods, and exploring its potential in specialized applications where substitutes are not yet available. Nanotechnology and green chemistry approaches are being investigated to mitigate CCl4's harmful effects and find novel uses in controlled settings.

The evolution of CCl4 research reflects broader trends in environmental awareness and safety standards in scientific practice. It serves as a case study in how scientific understanding can drive policy changes and reshape research priorities. Today, while its use is heavily restricted, CCl4 continues to be a subject of study, particularly in atmospheric sciences and environmental remediation, highlighting the ongoing challenges in managing legacy chemicals in research and industry.

In the early 20th century, CCl4 found widespread use in various industrial and commercial applications, including fire extinguishers, dry cleaning, and refrigerants. This period marked the peak of its utilization, with researchers extensively exploring its chemical properties and potential applications. However, the 1970s brought a turning point in CCl4 research as its harmful effects on human health and the environment became increasingly apparent.

The discovery of CCl4's ozone-depleting properties led to a significant shift in research focus. Scientists began investigating alternatives and developing new techniques to minimize its use. This era saw a surge in studies on CCl4's atmospheric chemistry, its impact on stratospheric ozone, and its role in global warming. Concurrently, toxicological research intensified, revealing the compound's hepatotoxic and carcinogenic properties.

The late 20th century witnessed a dramatic decline in CCl4 usage following international regulations like the Montreal Protocol. Research efforts pivoted towards developing safer substitutes and remediation technologies for CCl4-contaminated sites. Analytical chemists worked on improving detection methods for trace amounts of CCl4 in environmental samples, leading to advancements in chromatography and spectroscopy techniques.

In modern research labs, CCl4 has transitioned from a common reagent to a carefully controlled substance. Current research focuses on understanding its long-term environmental impacts, developing more efficient degradation methods, and exploring its potential in specialized applications where substitutes are not yet available. Nanotechnology and green chemistry approaches are being investigated to mitigate CCl4's harmful effects and find novel uses in controlled settings.

The evolution of CCl4 research reflects broader trends in environmental awareness and safety standards in scientific practice. It serves as a case study in how scientific understanding can drive policy changes and reshape research priorities. Today, while its use is heavily restricted, CCl4 continues to be a subject of study, particularly in atmospheric sciences and environmental remediation, highlighting the ongoing challenges in managing legacy chemicals in research and industry.

Market Demand Analysis

Carbon tetrachloride (CCl4) continues to play a significant role in modern research laboratories, despite its well-known environmental and health concerns. The market demand for this compound is driven by its unique properties and applications in various scientific fields. In the chemical industry, CCl4 remains a valuable solvent and reagent, particularly in organic synthesis and as a cleaning agent for specialized laboratory equipment.

The pharmaceutical sector represents a substantial portion of the market demand for carbon tetrachloride. Its use in drug discovery and development processes, especially in the synthesis of complex organic molecules, maintains a steady demand. Additionally, CCl4 finds applications in analytical chemistry, where it serves as a reference standard in spectroscopic techniques and as a solvent in various analytical procedures.

Environmental research laboratories constitute another significant market segment. Ironically, while CCl4 is known for its ozone-depleting properties, it is used in atmospheric studies to track pollution and understand climate change mechanisms. This dual nature of being both a subject of study and a tool for research creates a unique demand dynamic in the environmental science sector.

In materials science and engineering, carbon tetrachloride is utilized in the development and testing of new materials, particularly in studying corrosion resistance and material degradation. The semiconductor industry also contributes to the market demand, using CCl4 in the production of silicon wafers and in cleaning processes for electronic components.

However, the market demand for carbon tetrachloride is heavily influenced by regulatory constraints. Many countries have implemented strict regulations on its production, use, and disposal due to its environmental impact. This has led to a gradual decline in overall demand, particularly in consumer and industrial applications outside of research settings.

The research community is actively seeking alternatives to CCl4, driven by both regulatory pressure and environmental concerns. This trend is reshaping the market, with increasing demand for safer substitutes that can replicate the useful properties of carbon tetrachloride without its negative impacts. As a result, the market is experiencing a shift towards more sustainable practices, with a focus on developing green chemistry alternatives.

Despite these challenges, the specialized nature of carbon tetrachloride's applications in research ensures a persistent, albeit limited, demand. The compound's unique properties make it difficult to replace entirely in certain scientific procedures, maintaining its relevance in specialized research environments. This creates a niche market where high-purity, research-grade CCl4 commands premium prices, offsetting the overall decline in volume demand.

The pharmaceutical sector represents a substantial portion of the market demand for carbon tetrachloride. Its use in drug discovery and development processes, especially in the synthesis of complex organic molecules, maintains a steady demand. Additionally, CCl4 finds applications in analytical chemistry, where it serves as a reference standard in spectroscopic techniques and as a solvent in various analytical procedures.

Environmental research laboratories constitute another significant market segment. Ironically, while CCl4 is known for its ozone-depleting properties, it is used in atmospheric studies to track pollution and understand climate change mechanisms. This dual nature of being both a subject of study and a tool for research creates a unique demand dynamic in the environmental science sector.

In materials science and engineering, carbon tetrachloride is utilized in the development and testing of new materials, particularly in studying corrosion resistance and material degradation. The semiconductor industry also contributes to the market demand, using CCl4 in the production of silicon wafers and in cleaning processes for electronic components.

However, the market demand for carbon tetrachloride is heavily influenced by regulatory constraints. Many countries have implemented strict regulations on its production, use, and disposal due to its environmental impact. This has led to a gradual decline in overall demand, particularly in consumer and industrial applications outside of research settings.

The research community is actively seeking alternatives to CCl4, driven by both regulatory pressure and environmental concerns. This trend is reshaping the market, with increasing demand for safer substitutes that can replicate the useful properties of carbon tetrachloride without its negative impacts. As a result, the market is experiencing a shift towards more sustainable practices, with a focus on developing green chemistry alternatives.

Despite these challenges, the specialized nature of carbon tetrachloride's applications in research ensures a persistent, albeit limited, demand. The compound's unique properties make it difficult to replace entirely in certain scientific procedures, maintaining its relevance in specialized research environments. This creates a niche market where high-purity, research-grade CCl4 commands premium prices, offsetting the overall decline in volume demand.

Current Challenges

Despite the historical significance of carbon tetrachloride in various scientific applications, its use in modern research laboratories faces numerous challenges. The primary concern is the compound's toxicity and environmental impact, which have led to strict regulations and limitations on its use. Researchers must navigate complex safety protocols and obtain special permits to work with carbon tetrachloride, often resulting in increased costs and administrative burdens.

The handling and storage of carbon tetrachloride pose significant safety risks. Its volatile nature and potential for harmful vapor inhalation require specialized ventilation systems and personal protective equipment. This necessitates substantial investments in infrastructure and safety measures, which can be prohibitive for smaller research facilities or educational institutions.

Another challenge lies in finding suitable alternatives for experiments traditionally conducted with carbon tetrachloride. While efforts have been made to develop safer substitutes, many of these alternatives do not perfectly replicate the unique properties of carbon tetrachloride, potentially affecting experimental outcomes or requiring modifications to established protocols.

The disposal of carbon tetrachloride and contaminated materials presents additional difficulties. Strict environmental regulations mandate specific disposal procedures, often involving specialized waste management services. This not only increases operational costs but also requires meticulous record-keeping and compliance monitoring.

Researchers face the challenge of balancing the scientific benefits of using carbon tetrachloride against its known risks. In some cases, the compound's unique properties make it irreplaceable for certain analytical techniques or chemical syntheses. This creates a dilemma where scientific progress must be weighed against safety and environmental concerns.

The global effort to phase out ozone-depleting substances has further complicated the use of carbon tetrachloride in research. As production and importation become more restricted, laboratories may face supply chain issues and increased costs for procuring the compound. This scarcity can impact long-term research projects and potentially hinder scientific advancements in fields that rely on carbon tetrachloride.

Lastly, there is an ongoing challenge in educating and training new generations of researchers on the proper handling and alternatives to carbon tetrachloride. As its use becomes less common, there is a risk of losing institutional knowledge and expertise in safely working with this compound, potentially leading to increased accidents or misuse in the future.

The handling and storage of carbon tetrachloride pose significant safety risks. Its volatile nature and potential for harmful vapor inhalation require specialized ventilation systems and personal protective equipment. This necessitates substantial investments in infrastructure and safety measures, which can be prohibitive for smaller research facilities or educational institutions.

Another challenge lies in finding suitable alternatives for experiments traditionally conducted with carbon tetrachloride. While efforts have been made to develop safer substitutes, many of these alternatives do not perfectly replicate the unique properties of carbon tetrachloride, potentially affecting experimental outcomes or requiring modifications to established protocols.

The disposal of carbon tetrachloride and contaminated materials presents additional difficulties. Strict environmental regulations mandate specific disposal procedures, often involving specialized waste management services. This not only increases operational costs but also requires meticulous record-keeping and compliance monitoring.

Researchers face the challenge of balancing the scientific benefits of using carbon tetrachloride against its known risks. In some cases, the compound's unique properties make it irreplaceable for certain analytical techniques or chemical syntheses. This creates a dilemma where scientific progress must be weighed against safety and environmental concerns.

The global effort to phase out ozone-depleting substances has further complicated the use of carbon tetrachloride in research. As production and importation become more restricted, laboratories may face supply chain issues and increased costs for procuring the compound. This scarcity can impact long-term research projects and potentially hinder scientific advancements in fields that rely on carbon tetrachloride.

Lastly, there is an ongoing challenge in educating and training new generations of researchers on the proper handling and alternatives to carbon tetrachloride. As its use becomes less common, there is a risk of losing institutional knowledge and expertise in safely working with this compound, potentially leading to increased accidents or misuse in the future.

Modern CCl4 Techniques

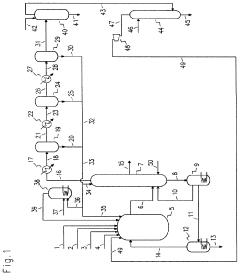

01 Production and purification of carbon tetrachloride

Various methods for producing and purifying carbon tetrachloride are described. These include chemical synthesis processes, distillation techniques, and purification methods to obtain high-quality carbon tetrachloride for industrial and laboratory use.- Production and purification of carbon tetrachloride: Various methods for producing and purifying carbon tetrachloride are described. These include chemical synthesis processes, distillation techniques, and purification methods to obtain high-quality carbon tetrachloride for industrial and laboratory use.

- Applications of carbon tetrachloride in chemical processes: Carbon tetrachloride is utilized in various chemical processes, including as a solvent, reagent, or intermediate in the production of other chemicals. Its unique properties make it valuable in specific industrial applications and chemical reactions.

- Environmental and safety considerations: Due to its environmental impact and health hazards, there are concerns and regulations regarding the use and handling of carbon tetrachloride. Alternative substances and methods are being developed to replace its use in various applications, focusing on safer and more environmentally friendly options.

- Detection and analysis methods for carbon tetrachloride: Various analytical techniques and methods have been developed for detecting and quantifying carbon tetrachloride in different matrices. These include spectroscopic methods, chromatography, and specialized sensors for environmental monitoring and quality control purposes.

- Historical uses and developments: Carbon tetrachloride has a long history of industrial and commercial use. Early patents describe its applications in fire extinguishers, cleaning agents, and as a refrigerant. Over time, its use has evolved due to increased understanding of its properties and environmental impact.

02 Applications of carbon tetrachloride in chemical processes

Carbon tetrachloride is utilized in various chemical processes, including as a solvent, reagent, or intermediate in the production of other chemicals. Its applications span across different industries, such as pharmaceuticals, agrochemicals, and materials science.Expand Specific Solutions03 Environmental and safety considerations

Due to its environmental impact and health hazards, research focuses on developing alternatives to carbon tetrachloride and methods for its safe handling, storage, and disposal. This includes techniques for detecting and monitoring carbon tetrachloride in various environments.Expand Specific Solutions04 Carbon tetrachloride in analytical chemistry

Carbon tetrachloride plays a role in analytical chemistry, particularly in spectroscopic and chromatographic techniques. It is used as a solvent or reference material in various analytical methods for identifying and quantifying chemical compounds.Expand Specific Solutions05 Historical uses and patents related to carbon tetrachloride

Early patents and historical documents describe various applications of carbon tetrachloride, including its use as a fire extinguishing agent, cleaning solvent, and in the production of refrigerants. These historical uses provide context for the compound's significance in industrial development.Expand Specific Solutions

Key Industry Players

The carbon tetrachloride research landscape is characterized by a mature market with established players and evolving regulatory challenges. Major companies like DuPont de Nemours, Evonik Operations, and Dow Global Technologies dominate the field, leveraging their extensive experience in chemical manufacturing. The market size remains stable, primarily driven by industrial applications and research needs. However, environmental concerns and stricter regulations have led to a shift towards developing safer alternatives. Universities such as Xuzhou University of Technology and Central South University contribute to advancing techniques and addressing challenges in modern research labs. The industry is in a transitional phase, balancing traditional uses with the need for more sustainable practices, fostering innovation in handling and application methodologies.

DuPont de Nemours, Inc.

Technical Solution: DuPont has developed advanced handling and containment techniques for carbon tetrachloride in research labs. Their approach includes the use of specialized fume hoods with enhanced ventilation systems and activated carbon filters to minimize exposure risks[1]. They have also implemented a closed-loop recycling system for carbon tetrachloride, reducing waste and environmental impact. DuPont's research focuses on finding safer alternatives to carbon tetrachloride while maintaining its effectiveness in various applications, such as polymer synthesis and analytical chemistry[2].

Strengths: Extensive experience in chemical handling, strong focus on safety and environmental responsibility. Weaknesses: Potential regulatory challenges due to the hazardous nature of carbon tetrachloride.

Dow Global Technologies LLC

Technical Solution: Dow has developed a novel approach to carbon tetrachloride usage in research labs, focusing on microreactor technology. This method allows for precise control of reaction conditions and minimizes the amount of carbon tetrachloride needed[3]. They have also implemented advanced real-time monitoring systems to detect any leaks or emissions, ensuring worker safety and environmental protection. Dow's research includes exploring supercritical carbon dioxide as a potential replacement for carbon tetrachloride in certain applications, reducing the overall reliance on this hazardous substance[4].

Strengths: Innovative microreactor technology, strong commitment to finding safer alternatives. Weaknesses: Potential high costs associated with implementing new technologies and processes.

Innovative CCl4 Studies

High selectivity catalyst for the conversion of carbon tetrachloride to chloroform

PatentInactiveEP1753532A1

Innovation

- A bimetallic catalyst composition of platinum and iridium supported on alumina, with optional promotion by metals like tin, rhenium, or bismuth, is used, where the platinum and iridium are distributed within a specific depth range from the catalyst surface, and the catalyst is pretreated with a chloride source to enhance selectivity and stability.

Chlorinolysis process for producing carbon tetrachloride

PatentActiveUS20210130266A1

Innovation

- A process involving a chlorination zone with chlorine, a C1 chlorinated compound, and a carbon/second chlorine source to produce a reaction mixture that favors the formation of carbon tetrachloride over perchloroethylene, using waste products as the carbon/second chlorine source to enhance efficiency and reduce impurity formation.

Safety Regulations

Safety regulations surrounding the use of carbon tetrachloride in modern research laboratories have become increasingly stringent due to the compound's known toxicity and environmental hazards. Regulatory bodies such as the Occupational Safety and Health Administration (OSHA) and the Environmental Protection Agency (EPA) have established strict guidelines for its handling, storage, and disposal.

In the United States, the permissible exposure limit (PEL) for carbon tetrachloride has been set at 10 ppm as an 8-hour time-weighted average. This low threshold necessitates the implementation of robust engineering controls, including the use of fume hoods and local exhaust ventilation systems, to minimize worker exposure. Personal protective equipment (PPE) requirements typically include chemical-resistant gloves, safety goggles, and appropriate respiratory protection when working with this substance.

Storage regulations mandate that carbon tetrachloride be kept in tightly sealed containers in well-ventilated areas, away from sources of heat or ignition. Laboratories must maintain detailed inventories and implement strict access controls to prevent unauthorized use or accidental release. Many institutions have opted to phase out carbon tetrachloride entirely, replacing it with less hazardous alternatives whenever possible.

Disposal of carbon tetrachloride and its waste products is subject to rigorous protocols. It is classified as a hazardous waste under the Resource Conservation and Recovery Act (RCRA) and must be handled accordingly. Proper disposal typically involves specialized waste management services and may require incineration or other approved treatment methods to ensure environmental safety.

Training and documentation requirements for personnel working with carbon tetrachloride have also been enhanced. Laboratories must provide comprehensive hazard communication training, including the proper use of safety data sheets (SDS) and emergency response procedures. Regular safety audits and inspections are mandated to ensure ongoing compliance with these regulations.

International regulations, such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program, have further restricted the use of carbon tetrachloride. These global initiatives have led to increased harmonization of safety standards across borders, impacting research collaborations and the transfer of materials between laboratories worldwide.

As awareness of the long-term health and environmental impacts of carbon tetrachloride continues to grow, regulatory bodies are likely to further tighten restrictions on its use in research settings. This evolving regulatory landscape presents ongoing challenges for laboratories that still rely on carbon tetrachloride for specific applications, necessitating continuous adaptation of safety protocols and exploration of alternative methodologies.

In the United States, the permissible exposure limit (PEL) for carbon tetrachloride has been set at 10 ppm as an 8-hour time-weighted average. This low threshold necessitates the implementation of robust engineering controls, including the use of fume hoods and local exhaust ventilation systems, to minimize worker exposure. Personal protective equipment (PPE) requirements typically include chemical-resistant gloves, safety goggles, and appropriate respiratory protection when working with this substance.

Storage regulations mandate that carbon tetrachloride be kept in tightly sealed containers in well-ventilated areas, away from sources of heat or ignition. Laboratories must maintain detailed inventories and implement strict access controls to prevent unauthorized use or accidental release. Many institutions have opted to phase out carbon tetrachloride entirely, replacing it with less hazardous alternatives whenever possible.

Disposal of carbon tetrachloride and its waste products is subject to rigorous protocols. It is classified as a hazardous waste under the Resource Conservation and Recovery Act (RCRA) and must be handled accordingly. Proper disposal typically involves specialized waste management services and may require incineration or other approved treatment methods to ensure environmental safety.

Training and documentation requirements for personnel working with carbon tetrachloride have also been enhanced. Laboratories must provide comprehensive hazard communication training, including the proper use of safety data sheets (SDS) and emergency response procedures. Regular safety audits and inspections are mandated to ensure ongoing compliance with these regulations.

International regulations, such as the European Union's REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) program, have further restricted the use of carbon tetrachloride. These global initiatives have led to increased harmonization of safety standards across borders, impacting research collaborations and the transfer of materials between laboratories worldwide.

As awareness of the long-term health and environmental impacts of carbon tetrachloride continues to grow, regulatory bodies are likely to further tighten restrictions on its use in research settings. This evolving regulatory landscape presents ongoing challenges for laboratories that still rely on carbon tetrachloride for specific applications, necessitating continuous adaptation of safety protocols and exploration of alternative methodologies.

Environmental Impact

Carbon tetrachloride (CCl4) usage in modern research laboratories poses significant environmental concerns due to its potent ozone-depleting properties and contribution to global warming. As a chlorinated compound, CCl4 has been identified as a major contributor to stratospheric ozone depletion, with an ozone depletion potential (ODP) of 0.72 relative to CFC-11. This high ODP value underscores the severe impact even small releases can have on the Earth's protective ozone layer.

The global warming potential (GWP) of carbon tetrachloride is also substantial, estimated at 1,730 times that of carbon dioxide over a 100-year time horizon. This means that CCl4 emissions have a disproportionately large impact on climate change compared to many other greenhouse gases. The long atmospheric lifetime of CCl4, approximately 26 years, further exacerbates its environmental persistence and cumulative effects.

In aquatic environments, CCl4 can be particularly harmful. It is highly toxic to various aquatic organisms, including fish, crustaceans, and algae. The compound's ability to bioaccumulate in aquatic food chains poses risks to higher trophic levels and potentially to human health through consumption of contaminated seafood. Groundwater contamination is another significant concern, as CCl4 can leach into soil and water systems, persisting for extended periods due to its resistance to biodegradation.

Soil contamination by carbon tetrachloride can lead to long-term ecological damage. The compound's high mobility in soil increases the risk of widespread contamination, affecting soil microorganisms, plant growth, and potentially entering the food chain through agricultural products. Remediation of CCl4-contaminated sites is often challenging and costly, requiring specialized techniques such as soil vapor extraction or in-situ chemical oxidation.

The production and use of carbon tetrachloride also contribute to air pollution. Volatile organic compound (VOC) emissions from CCl4 can participate in photochemical reactions, leading to the formation of ground-level ozone and smog. These secondary pollutants have adverse effects on human health, vegetation, and overall air quality in affected areas.

Given these environmental impacts, strict regulations have been implemented globally to phase out the production and use of carbon tetrachloride. The Montreal Protocol and subsequent amendments have been instrumental in reducing CCl4 emissions. However, the continued use of CCl4 in research laboratories, albeit in smaller quantities, necessitates rigorous containment, handling, and disposal protocols to minimize environmental release and associated ecological risks.

The global warming potential (GWP) of carbon tetrachloride is also substantial, estimated at 1,730 times that of carbon dioxide over a 100-year time horizon. This means that CCl4 emissions have a disproportionately large impact on climate change compared to many other greenhouse gases. The long atmospheric lifetime of CCl4, approximately 26 years, further exacerbates its environmental persistence and cumulative effects.

In aquatic environments, CCl4 can be particularly harmful. It is highly toxic to various aquatic organisms, including fish, crustaceans, and algae. The compound's ability to bioaccumulate in aquatic food chains poses risks to higher trophic levels and potentially to human health through consumption of contaminated seafood. Groundwater contamination is another significant concern, as CCl4 can leach into soil and water systems, persisting for extended periods due to its resistance to biodegradation.

Soil contamination by carbon tetrachloride can lead to long-term ecological damage. The compound's high mobility in soil increases the risk of widespread contamination, affecting soil microorganisms, plant growth, and potentially entering the food chain through agricultural products. Remediation of CCl4-contaminated sites is often challenging and costly, requiring specialized techniques such as soil vapor extraction or in-situ chemical oxidation.

The production and use of carbon tetrachloride also contribute to air pollution. Volatile organic compound (VOC) emissions from CCl4 can participate in photochemical reactions, leading to the formation of ground-level ozone and smog. These secondary pollutants have adverse effects on human health, vegetation, and overall air quality in affected areas.

Given these environmental impacts, strict regulations have been implemented globally to phase out the production and use of carbon tetrachloride. The Montreal Protocol and subsequent amendments have been instrumental in reducing CCl4 emissions. However, the continued use of CCl4 in research laboratories, albeit in smaller quantities, necessitates rigorous containment, handling, and disposal protocols to minimize environmental release and associated ecological risks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!