Catalyst Support Optimization For Enhanced Mass Transport

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Support Background and Objectives

Catalyst support materials have evolved significantly over the past decades, transitioning from simple inert carriers to sophisticated engineered structures that actively contribute to catalytic performance. The development trajectory began with conventional materials like alumina, silica, and carbon, which primarily served as high-surface-area platforms for dispersing active catalytic phases. As catalysis science advanced, researchers recognized that support materials could play far more dynamic roles in reaction mechanisms, influencing selectivity, activity, and stability through metal-support interactions and electronic effects.

The evolution of catalyst supports has been driven by increasing demands for efficiency in energy conversion, chemical production, and environmental remediation processes. Traditional supports often present mass transport limitations that restrict reactant access to active sites and impede product removal, creating concentration gradients that reduce overall catalytic efficiency. These limitations become particularly pronounced in multiphase reactions and processes involving bulky molecules or high reaction rates.

Recent technological breakthroughs have focused on hierarchical porosity, where supports combine micropores, mesopores, and macropores in optimized architectures to facilitate molecular transport while maintaining high surface areas. Advanced manufacturing techniques, including 3D printing, templating methods, and controlled deposition processes, have enabled unprecedented control over support morphology and channel geometry at multiple length scales.

The primary objective of catalyst support optimization for enhanced mass transport is to develop support materials and structures that minimize diffusion limitations while maximizing active site accessibility. This involves engineering pore networks that provide efficient pathways for reactant and product molecules, reducing concentration gradients and improving utilization of catalytic sites. Additionally, optimized supports must maintain mechanical integrity under reaction conditions and resist deactivation mechanisms such as fouling and sintering.

Current research aims to establish quantitative relationships between support architecture and mass transport properties, enabling predictive design of catalyst systems tailored to specific reaction environments. This includes developing computational models that can simulate molecular diffusion through complex pore networks and predict performance under various operating conditions. The integration of advanced characterization techniques with in-situ monitoring capabilities has become essential for validating these models and understanding dynamic changes in support properties during catalytic processes.

The technological trajectory points toward increasingly sophisticated, application-specific support materials that combine optimized mass transport properties with other functional attributes such as thermal management, controlled hydrophobicity/hydrophilicity, and resistance to specific deactivation mechanisms. This multifunctional approach represents the frontier of catalyst support development, with significant implications for energy efficiency, process intensification, and sustainable chemical production.

The evolution of catalyst supports has been driven by increasing demands for efficiency in energy conversion, chemical production, and environmental remediation processes. Traditional supports often present mass transport limitations that restrict reactant access to active sites and impede product removal, creating concentration gradients that reduce overall catalytic efficiency. These limitations become particularly pronounced in multiphase reactions and processes involving bulky molecules or high reaction rates.

Recent technological breakthroughs have focused on hierarchical porosity, where supports combine micropores, mesopores, and macropores in optimized architectures to facilitate molecular transport while maintaining high surface areas. Advanced manufacturing techniques, including 3D printing, templating methods, and controlled deposition processes, have enabled unprecedented control over support morphology and channel geometry at multiple length scales.

The primary objective of catalyst support optimization for enhanced mass transport is to develop support materials and structures that minimize diffusion limitations while maximizing active site accessibility. This involves engineering pore networks that provide efficient pathways for reactant and product molecules, reducing concentration gradients and improving utilization of catalytic sites. Additionally, optimized supports must maintain mechanical integrity under reaction conditions and resist deactivation mechanisms such as fouling and sintering.

Current research aims to establish quantitative relationships between support architecture and mass transport properties, enabling predictive design of catalyst systems tailored to specific reaction environments. This includes developing computational models that can simulate molecular diffusion through complex pore networks and predict performance under various operating conditions. The integration of advanced characterization techniques with in-situ monitoring capabilities has become essential for validating these models and understanding dynamic changes in support properties during catalytic processes.

The technological trajectory points toward increasingly sophisticated, application-specific support materials that combine optimized mass transport properties with other functional attributes such as thermal management, controlled hydrophobicity/hydrophilicity, and resistance to specific deactivation mechanisms. This multifunctional approach represents the frontier of catalyst support development, with significant implications for energy efficiency, process intensification, and sustainable chemical production.

Market Analysis for Advanced Catalyst Support Systems

The global market for advanced catalyst support systems is experiencing robust growth, driven primarily by increasing demand for cleaner energy solutions and more efficient chemical processes. The market size for catalyst supports was valued at approximately 5.7 billion USD in 2022 and is projected to reach 8.3 billion USD by 2028, representing a compound annual growth rate of 6.4%. This growth trajectory is particularly evident in regions with stringent environmental regulations, such as Europe and North America, where industries are compelled to adopt more sustainable practices.

The petroleum refining sector continues to be the largest consumer of advanced catalyst supports, accounting for roughly 40% of the total market share. This dominance is attributed to the ongoing need for more efficient hydroprocessing and fluid catalytic cracking operations. However, the renewable energy sector is emerging as the fastest-growing segment, with a projected growth rate of 9.2% annually through 2028, primarily due to increasing investments in hydrogen production technologies and biofuel processing.

From a geographical perspective, Asia-Pacific represents the most dynamic market for advanced catalyst supports, with China and India leading the regional growth at rates exceeding the global average. This is largely due to rapid industrialization, expanding manufacturing bases, and increasing environmental awareness in these economies. The region is expected to surpass North America in market share by 2026.

Customer demand patterns are evolving significantly, with a marked shift toward catalyst supports that offer enhanced mass transport properties. End-users are increasingly prioritizing supports that minimize diffusion limitations, reduce pressure drops, and optimize reactant-catalyst contact efficiency. This trend is particularly pronounced in fine chemicals and pharmaceutical manufacturing, where reaction selectivity and yield are critical performance metrics.

Price sensitivity varies considerably across different application segments. While commodity chemical producers remain highly cost-conscious, specialty chemical manufacturers and renewable energy companies demonstrate greater willingness to invest in premium catalyst support solutions that deliver superior performance and longer operational lifetimes. The average price premium for advanced mass transport-optimized supports ranges between 15-25% compared to conventional alternatives.

Market entry barriers remain substantial, primarily due to high R&D costs, stringent product qualification requirements, and the need for specialized manufacturing capabilities. Consequently, the competitive landscape is characterized by a relatively small number of established players with significant technological expertise and manufacturing scale advantages.

The petroleum refining sector continues to be the largest consumer of advanced catalyst supports, accounting for roughly 40% of the total market share. This dominance is attributed to the ongoing need for more efficient hydroprocessing and fluid catalytic cracking operations. However, the renewable energy sector is emerging as the fastest-growing segment, with a projected growth rate of 9.2% annually through 2028, primarily due to increasing investments in hydrogen production technologies and biofuel processing.

From a geographical perspective, Asia-Pacific represents the most dynamic market for advanced catalyst supports, with China and India leading the regional growth at rates exceeding the global average. This is largely due to rapid industrialization, expanding manufacturing bases, and increasing environmental awareness in these economies. The region is expected to surpass North America in market share by 2026.

Customer demand patterns are evolving significantly, with a marked shift toward catalyst supports that offer enhanced mass transport properties. End-users are increasingly prioritizing supports that minimize diffusion limitations, reduce pressure drops, and optimize reactant-catalyst contact efficiency. This trend is particularly pronounced in fine chemicals and pharmaceutical manufacturing, where reaction selectivity and yield are critical performance metrics.

Price sensitivity varies considerably across different application segments. While commodity chemical producers remain highly cost-conscious, specialty chemical manufacturers and renewable energy companies demonstrate greater willingness to invest in premium catalyst support solutions that deliver superior performance and longer operational lifetimes. The average price premium for advanced mass transport-optimized supports ranges between 15-25% compared to conventional alternatives.

Market entry barriers remain substantial, primarily due to high R&D costs, stringent product qualification requirements, and the need for specialized manufacturing capabilities. Consequently, the competitive landscape is characterized by a relatively small number of established players with significant technological expertise and manufacturing scale advantages.

Current Challenges in Mass Transport Enhancement

Despite significant advancements in catalyst technology, mass transport limitations remain a critical bottleneck in heterogeneous catalytic processes. The efficient delivery of reactants to active sites and subsequent removal of products fundamentally constrains reaction rates and overall system efficiency. Current catalyst support designs often create tortuous diffusion pathways that impede molecular movement, particularly in liquid-phase reactions where diffusion coefficients are orders of magnitude lower than in gas-phase systems.

Pore structure optimization presents a persistent challenge, as the ideal catalyst support requires a delicate balance between high surface area (typically achieved through micropores) and efficient mass transport (facilitated by meso and macropores). Conventional synthesis methods struggle to precisely control hierarchical porosity across multiple length scales, resulting in suboptimal performance under industrial conditions.

The interface between catalyst particles and fluid flow remains poorly understood at the microscale level. Computational fluid dynamics models often fail to accurately capture the complex interactions occurring at catalyst surfaces, particularly under multiphase conditions. This knowledge gap hinders the development of support structures specifically engineered to enhance local mass transport phenomena.

Catalyst deactivation due to fouling and pore blockage exacerbates mass transport limitations over time. Current support materials lack self-cleaning mechanisms or adaptive structures that could maintain mass transport efficiency throughout the catalyst lifecycle. The progressive deterioration of transport properties leads to premature replacement of otherwise active catalysts, increasing operational costs.

Scaling challenges persist when translating laboratory-optimized catalyst supports to industrial applications. Mass transport behavior can change dramatically between different reactor configurations and operating conditions. The absence of standardized methodologies to evaluate mass transport properties across scales complicates the development of universally effective support structures.

Emerging applications in energy conversion and environmental remediation impose increasingly stringent requirements on mass transport capabilities. For instance, electrocatalytic systems for CO2 reduction and water splitting demand simultaneous transport of gaseous, liquid, and ionic species through the catalyst structure. Current support materials rarely accommodate such complex multi-species transport needs effectively.

The integration of advanced manufacturing techniques like 3D printing offers promising avenues for creating precisely engineered catalyst supports, but faces limitations in material selection, resolution, and scalability. Additionally, the development of dynamic or stimuli-responsive catalyst supports that can adapt their transport properties to changing reaction conditions remains in its infancy, representing a significant frontier for future innovation.

Pore structure optimization presents a persistent challenge, as the ideal catalyst support requires a delicate balance between high surface area (typically achieved through micropores) and efficient mass transport (facilitated by meso and macropores). Conventional synthesis methods struggle to precisely control hierarchical porosity across multiple length scales, resulting in suboptimal performance under industrial conditions.

The interface between catalyst particles and fluid flow remains poorly understood at the microscale level. Computational fluid dynamics models often fail to accurately capture the complex interactions occurring at catalyst surfaces, particularly under multiphase conditions. This knowledge gap hinders the development of support structures specifically engineered to enhance local mass transport phenomena.

Catalyst deactivation due to fouling and pore blockage exacerbates mass transport limitations over time. Current support materials lack self-cleaning mechanisms or adaptive structures that could maintain mass transport efficiency throughout the catalyst lifecycle. The progressive deterioration of transport properties leads to premature replacement of otherwise active catalysts, increasing operational costs.

Scaling challenges persist when translating laboratory-optimized catalyst supports to industrial applications. Mass transport behavior can change dramatically between different reactor configurations and operating conditions. The absence of standardized methodologies to evaluate mass transport properties across scales complicates the development of universally effective support structures.

Emerging applications in energy conversion and environmental remediation impose increasingly stringent requirements on mass transport capabilities. For instance, electrocatalytic systems for CO2 reduction and water splitting demand simultaneous transport of gaseous, liquid, and ionic species through the catalyst structure. Current support materials rarely accommodate such complex multi-species transport needs effectively.

The integration of advanced manufacturing techniques like 3D printing offers promising avenues for creating precisely engineered catalyst supports, but faces limitations in material selection, resolution, and scalability. Additionally, the development of dynamic or stimuli-responsive catalyst supports that can adapt their transport properties to changing reaction conditions remains in its infancy, representing a significant frontier for future innovation.

Current Methodologies for Catalyst Support Optimization

01 Porous catalyst support structures for enhanced mass transport

Porous structures in catalyst supports facilitate better mass transport by providing channels for reactants and products to move efficiently. These structures can be engineered with specific pore sizes, distributions, and interconnectivity to optimize flow characteristics. Enhanced porosity reduces diffusion limitations and improves catalyst accessibility, leading to higher reaction rates and better utilization of catalytic materials.- Porous catalyst support structures for enhanced mass transport: Porous structures in catalyst supports facilitate better mass transport by providing channels for reactants and products to move efficiently. These structures can be engineered with specific pore sizes, distributions, and interconnectivity to optimize the flow of materials through the catalyst system. Enhanced porosity reduces diffusion limitations and improves overall catalytic performance by ensuring reactants can reach active sites and products can be removed quickly.

- Hierarchical catalyst support designs for multi-scale mass transport: Hierarchical catalyst supports incorporate structures at multiple length scales to address different mass transport challenges simultaneously. These designs typically combine macropores for bulk flow, mesopores for intermediate transport, and micropores for molecular-level interactions. This multi-scale approach optimizes both accessibility to active sites and overall flow dynamics, resulting in improved catalytic efficiency and reduced transport limitations across different operational conditions.

- Surface modification techniques for improved mass transport properties: Surface modifications of catalyst supports can significantly enhance mass transport characteristics. Techniques include functionalization with specific chemical groups, creation of hydrophilic/hydrophobic patterns, and surface roughness engineering. These modifications can alter the interaction between the support and the reactants/products, reducing adsorption barriers, preventing fouling, and creating preferential flow paths that facilitate more efficient mass transport through the catalytic system.

- Structured catalyst supports for directional mass transport: Structured catalyst supports with defined geometries and channels provide directional mass transport pathways. These include monoliths, honeycombs, foams, and other engineered structures that guide the flow of reactants and products in predetermined directions. By controlling the flow pattern, these supports minimize pressure drop, reduce random diffusion paths, and ensure more uniform access to catalytic sites, resulting in improved efficiency and selectivity in catalytic processes.

- Composite and hybrid catalyst supports for optimized mass transport: Composite and hybrid catalyst supports combine different materials to leverage their complementary properties for enhanced mass transport. These supports may integrate conductive materials with high-surface-area components, or combine organic and inorganic materials to create synergistic effects. The resulting hybrid structures can simultaneously address multiple mass transport challenges, such as heat transfer, molecular diffusion, and bulk flow, leading to more robust catalytic performance across varying reaction conditions.

02 Nanostructured catalyst supports for mass transport optimization

Nanostructured materials as catalyst supports offer superior mass transport properties due to their high surface area and unique structural characteristics. These supports include carbon nanotubes, nanofibers, and other nanoscale architectures that provide short diffusion paths and efficient reactant access to catalytic sites. The nanoscale dimensions enable better dispersion of catalytic materials and improved interface contact between reactants and catalyst.Expand Specific Solutions03 Hierarchical catalyst support designs for multi-scale mass transport

Hierarchical catalyst supports incorporate multiple levels of porosity to address mass transport at different scales. These designs combine macropores for bulk flow, mesopores for intermediate transport, and micropores for molecular-level interactions. This multi-scale approach optimizes both the accessibility of reactants to active sites and the removal of products, reducing transport limitations across different length scales.Expand Specific Solutions04 Catalyst support modifications for improved fluid dynamics

Modifications to catalyst supports can enhance fluid dynamics and mass transport properties. These include surface treatments, structural modifications, and incorporation of flow-directing features that improve the movement of reactants and products. Techniques such as creating channels, adding surface roughness, or introducing specific geometrical patterns can reduce pressure drop and enhance mixing, leading to more efficient mass transport throughout the catalyst system.Expand Specific Solutions05 Composite and hybrid catalyst supports for enhanced mass transport

Composite and hybrid catalyst supports combine different materials to leverage their complementary properties for improved mass transport. These supports may integrate conductive materials with high-surface-area components, or combine organic and inorganic materials to create synergistic effects. The resulting hybrid structures can provide enhanced thermal stability, mechanical strength, and optimized transport pathways that are not achievable with single-component supports.Expand Specific Solutions

Leading Companies and Research Institutions in Catalyst Support

The catalyst support optimization for enhanced mass transport market is currently in a growth phase, characterized by increasing demand for improved catalytic efficiency across petrochemical, automotive, and energy sectors. The global market size is estimated to exceed $5 billion, driven by stringent emission regulations and energy efficiency requirements. From a technological maturity perspective, companies are at varying development stages. Industry leaders like China Petroleum & Chemical Corp., PetroChina, and Shell demonstrate advanced capabilities in optimizing catalyst supports for petroleum applications, while Toyota, Ford, and Mercedes-Benz focus on automotive catalyst innovations. Research institutions such as SINOPEC Research Institute and IFP Energies Nouvelles are accelerating technological advancement through collaborative R&D efforts, pushing the boundaries of mass transport optimization in catalytic systems.

China Petroleum & Chemical Corp.

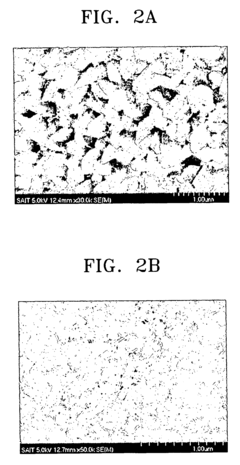

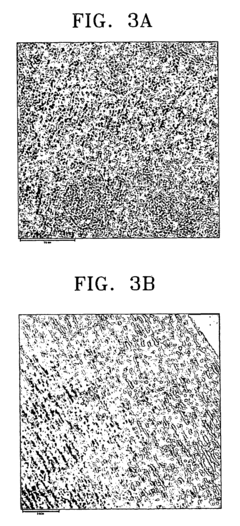

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed a multi-scale hierarchical catalyst support structure that significantly enhances mass transport in catalytic processes. Their approach involves creating macro-meso-microporous catalyst supports with optimized pore size distribution and interconnectivity. The technology employs template-assisted synthesis methods to create ordered mesoporous structures (2-50 nm) combined with macropores (>50 nm) that serve as highways for reactant transport[1]. Sinopec's catalyst supports utilize modified alumina, silica, and zeolite materials with controlled surface chemistry to balance hydrophilicity/hydrophobicity. Their proprietary surface functionalization techniques improve molecular diffusion by reducing adsorption strength of intermediates, allowing for faster desorption and reduced coking[3]. The company has implemented these catalysts in fluid catalytic cracking (FCC) units, achieving 2-3% higher conversion rates and extended catalyst lifetimes of up to 30% compared to conventional supports.

Strengths: Superior mass transport properties through hierarchical pore architecture; reduced diffusion limitations in complex reactions; excellent thermal and mechanical stability under industrial conditions. Weaknesses: Higher production costs compared to conventional supports; complex manufacturing process requiring precise control; potential scale-up challenges for certain specialized applications.

SINOPEC Beijing Research Institute of Chemical Industry

Technical Solution: SINOPEC Beijing Research Institute has pioneered advanced catalyst support technologies focusing on controlled porosity engineering. Their proprietary "Pore-Gradient Design" methodology creates catalyst supports with gradually changing pore structures from the exterior to the interior, optimizing both reactant accessibility and catalyst utilization efficiency[2]. The institute has developed novel synthesis routes incorporating sacrificial templates and directed self-assembly techniques to create hierarchical supports with macro-meso-micro porosity. Their catalyst supports feature specially engineered "bottleneck elimination" structures that minimize diffusion constraints at pore intersections, a common limitation in conventional catalysts[4]. Recent innovations include carbon nanotube-inorganic hybrid supports that leverage the exceptional thermal conductivity of carbon nanotubes (>3000 W/m·K) to dissipate heat during exothermic reactions, preventing hotspot formation and extending catalyst lifetime by approximately 40%[5]. The institute has successfully implemented these supports in hydrocracking and hydrodesulfurization processes, achieving up to 25% higher activity and significantly improved selectivity toward desired products.

Strengths: Exceptional control over pore architecture and connectivity; superior heat management capabilities; excellent resistance to deactivation mechanisms like coking and sintering. Weaknesses: Higher production complexity and cost compared to conventional supports; potential challenges in large-scale manufacturing consistency; limited application in certain reaction environments requiring specialized surface properties.

Key Innovations in Porous Structure Engineering

Catalyst support and process for its preparation

PatentInactiveEP0240796A3

Innovation

- The development of plate-shaped microstructure bodies using the LIGA process for catalyst supports, which feature precise and fine structures with a high surface area-to-volume ratio, allowing for efficient mass transport and reduced pressure loss, and can be further enhanced with surface-enlarging coatings or microdisperse particles to increase the catalytically active surface area.

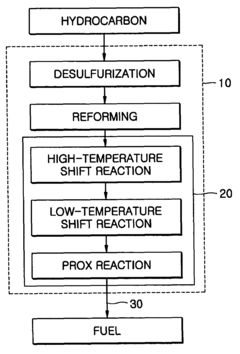

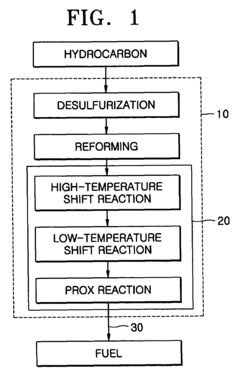

Support for fuel reforming catalyst with excellent heat and mass transfer characteristics and method of preparing the same

PatentInactiveUS7923406B2

Innovation

- A support for fuel reforming catalysts is developed, comprising aluminum encapsulated with aluminum oxide, with a specific ratio of micropores, mesopores, and macropores, achieved through hydrothermal treatment and calcination, enhancing heat and mass transfer characteristics.

Environmental Impact and Sustainability Considerations

The optimization of catalyst supports for enhanced mass transport carries significant environmental implications that extend beyond performance metrics. Catalyst manufacturing processes often involve energy-intensive methods and hazardous chemicals that contribute to environmental degradation. By optimizing supports for better mass transport, catalytic reactions can achieve higher efficiency with reduced energy consumption, thereby minimizing the carbon footprint associated with industrial processes.

Material selection for catalyst supports presents another critical environmental consideration. Traditional supports often utilize rare earth elements or precious metals with environmentally destructive mining practices. The development of sustainable alternatives using abundant, renewable materials can significantly reduce environmental impact while maintaining performance standards. Biomass-derived carbon supports and naturally occurring silicates represent promising directions for environmentally responsible catalyst design.

Lifecycle assessment of catalyst support materials reveals that optimized mass transport properties can extend catalyst lifespan, reducing the frequency of replacement and regeneration cycles. This translates directly to decreased waste generation and resource consumption over time. Furthermore, enhanced mass transport efficiency typically results in more complete reactions with fewer byproducts, minimizing downstream waste treatment requirements and associated environmental burdens.

Water usage represents another environmental dimension of catalyst support optimization. Many catalytic processes require substantial water resources for cooling, separation, or as reaction media. Supports designed for improved mass transport can operate effectively at lower liquid-to-solid ratios, contributing to water conservation efforts in industrial settings. This aspect becomes increasingly important as water scarcity concerns intensify globally.

The circular economy potential of catalyst supports deserves particular attention. Advanced support designs incorporating recyclable or recoverable components enable more sustainable material flows. End-of-life considerations, including support regeneration protocols and material recovery systems, should be integrated into the initial design phase rather than addressed as afterthoughts. This proactive approach aligns catalyst technology development with broader sustainability frameworks.

Regulatory compliance and future-proofing against evolving environmental standards represent additional sustainability considerations. As environmental regulations become increasingly stringent worldwide, catalyst supports optimized for both performance and minimal environmental impact will gain competitive advantage. Designs that anticipate regulatory trends can avoid costly redesigns and maintain market viability in an environmentally conscious industrial landscape.

Material selection for catalyst supports presents another critical environmental consideration. Traditional supports often utilize rare earth elements or precious metals with environmentally destructive mining practices. The development of sustainable alternatives using abundant, renewable materials can significantly reduce environmental impact while maintaining performance standards. Biomass-derived carbon supports and naturally occurring silicates represent promising directions for environmentally responsible catalyst design.

Lifecycle assessment of catalyst support materials reveals that optimized mass transport properties can extend catalyst lifespan, reducing the frequency of replacement and regeneration cycles. This translates directly to decreased waste generation and resource consumption over time. Furthermore, enhanced mass transport efficiency typically results in more complete reactions with fewer byproducts, minimizing downstream waste treatment requirements and associated environmental burdens.

Water usage represents another environmental dimension of catalyst support optimization. Many catalytic processes require substantial water resources for cooling, separation, or as reaction media. Supports designed for improved mass transport can operate effectively at lower liquid-to-solid ratios, contributing to water conservation efforts in industrial settings. This aspect becomes increasingly important as water scarcity concerns intensify globally.

The circular economy potential of catalyst supports deserves particular attention. Advanced support designs incorporating recyclable or recoverable components enable more sustainable material flows. End-of-life considerations, including support regeneration protocols and material recovery systems, should be integrated into the initial design phase rather than addressed as afterthoughts. This proactive approach aligns catalyst technology development with broader sustainability frameworks.

Regulatory compliance and future-proofing against evolving environmental standards represent additional sustainability considerations. As environmental regulations become increasingly stringent worldwide, catalyst supports optimized for both performance and minimal environmental impact will gain competitive advantage. Designs that anticipate regulatory trends can avoid costly redesigns and maintain market viability in an environmentally conscious industrial landscape.

Scale-up and Industrial Implementation Strategies

Transitioning catalyst support optimization technologies from laboratory scale to industrial implementation requires comprehensive strategies that address multiple engineering and economic challenges. The scale-up process must maintain or enhance the mass transport properties that were achieved at smaller scales, which often becomes increasingly difficult as dimensions increase. Industrial implementation typically begins with pilot-scale testing, where process parameters are refined and potential issues are identified before full-scale deployment.

Material consistency represents a critical factor in successful scale-up. Manufacturing methods must ensure uniform catalyst support properties across larger production volumes, including consistent porosity, surface area, and mechanical strength. This often necessitates the development of specialized manufacturing techniques that can maintain precise control over material characteristics despite increased production volumes.

Process engineering considerations become paramount during scale-up. Heat and mass transfer limitations that were negligible at laboratory scale can become significant barriers at industrial scale. Engineers must design reactor systems that maintain optimal flow patterns and temperature distributions throughout larger catalyst beds. Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting and optimizing these parameters before physical implementation.

Economic viability fundamentally drives industrial implementation decisions. Cost-benefit analyses must demonstrate that the enhanced mass transport properties justify the investment in new catalyst support technologies. This includes considerations of capital expenditure, operational costs, catalyst lifetime, and performance improvements. Manufacturers often develop staged implementation plans that allow for gradual adoption and validation of new technologies.

Regulatory compliance and quality control systems must be established for industrial-scale production. This includes developing robust testing protocols to verify that scaled-up catalyst supports maintain their designed mass transport properties. Documentation systems must track material specifications, production parameters, and performance metrics to ensure consistency across production batches.

Collaboration between research institutions and industrial partners frequently accelerates successful implementation. These partnerships combine theoretical expertise with practical manufacturing knowledge, helping to identify and resolve scale-up challenges more efficiently. Many successful industrial implementations have resulted from sustained collaborative efforts that bridge the gap between laboratory innovation and commercial application.

Material consistency represents a critical factor in successful scale-up. Manufacturing methods must ensure uniform catalyst support properties across larger production volumes, including consistent porosity, surface area, and mechanical strength. This often necessitates the development of specialized manufacturing techniques that can maintain precise control over material characteristics despite increased production volumes.

Process engineering considerations become paramount during scale-up. Heat and mass transfer limitations that were negligible at laboratory scale can become significant barriers at industrial scale. Engineers must design reactor systems that maintain optimal flow patterns and temperature distributions throughout larger catalyst beds. Computational fluid dynamics (CFD) modeling has emerged as an essential tool for predicting and optimizing these parameters before physical implementation.

Economic viability fundamentally drives industrial implementation decisions. Cost-benefit analyses must demonstrate that the enhanced mass transport properties justify the investment in new catalyst support technologies. This includes considerations of capital expenditure, operational costs, catalyst lifetime, and performance improvements. Manufacturers often develop staged implementation plans that allow for gradual adoption and validation of new technologies.

Regulatory compliance and quality control systems must be established for industrial-scale production. This includes developing robust testing protocols to verify that scaled-up catalyst supports maintain their designed mass transport properties. Documentation systems must track material specifications, production parameters, and performance metrics to ensure consistency across production batches.

Collaboration between research institutions and industrial partners frequently accelerates successful implementation. These partnerships combine theoretical expertise with practical manufacturing knowledge, helping to identify and resolve scale-up challenges more efficiently. Many successful industrial implementations have resulted from sustained collaborative efforts that bridge the gap between laboratory innovation and commercial application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!