Pilot Plant Reports And Lessons Learned From Recent Deployments

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Pilot Plant Technology Background and Objectives

Pilot plants represent a critical intermediate step between laboratory research and full-scale industrial implementation in various sectors, particularly in chemical, pharmaceutical, and energy industries. The concept of pilot plants emerged in the early 20th century as industries recognized the need for risk mitigation before committing substantial capital to large-scale production facilities. Over the decades, pilot plant technology has evolved from simple scaled-down versions of production units to sophisticated facilities equipped with advanced automation, data collection, and analysis capabilities.

The evolution of pilot plant technology has been significantly influenced by advancements in process control systems, materials science, and computational modeling. Modern pilot plants incorporate digital twins, real-time monitoring, and predictive analytics, enabling more accurate scaling predictions and process optimization. This technological progression has transformed pilot plants from mere testing facilities to comprehensive learning platforms that generate valuable insights for full-scale deployments.

Recent trends indicate a shift toward modular and flexible pilot plant designs that can be rapidly reconfigured to test multiple process variations. This adaptability has become increasingly important as industries face pressure to accelerate innovation cycles while maintaining rigorous quality and safety standards. Additionally, there is growing emphasis on sustainability metrics in pilot plant operations, reflecting broader industry commitments to environmental responsibility.

The primary objectives of contemporary pilot plant deployments extend beyond traditional technical validation. They now encompass comprehensive risk assessment, operational training, regulatory compliance preparation, and economic validation. These facilities serve as crucial learning environments where cross-functional teams can identify potential issues that might not be apparent in laboratory settings but could become significant challenges at production scale.

In the current technological landscape, pilot plants are increasingly expected to deliver insights on process robustness, operational flexibility, and product quality consistency under varying conditions. They provide essential data for techno-economic analyses that inform investment decisions and help optimize resource allocation. Furthermore, they offer opportunities to refine control strategies, validate analytical methods, and develop troubleshooting protocols before full-scale implementation.

The integration of pilot plant operations with digital technologies has created new possibilities for remote monitoring, collaborative problem-solving, and knowledge management. These capabilities have proven particularly valuable during recent global disruptions, allowing organizations to maintain critical development activities despite travel restrictions and workforce limitations.

The evolution of pilot plant technology has been significantly influenced by advancements in process control systems, materials science, and computational modeling. Modern pilot plants incorporate digital twins, real-time monitoring, and predictive analytics, enabling more accurate scaling predictions and process optimization. This technological progression has transformed pilot plants from mere testing facilities to comprehensive learning platforms that generate valuable insights for full-scale deployments.

Recent trends indicate a shift toward modular and flexible pilot plant designs that can be rapidly reconfigured to test multiple process variations. This adaptability has become increasingly important as industries face pressure to accelerate innovation cycles while maintaining rigorous quality and safety standards. Additionally, there is growing emphasis on sustainability metrics in pilot plant operations, reflecting broader industry commitments to environmental responsibility.

The primary objectives of contemporary pilot plant deployments extend beyond traditional technical validation. They now encompass comprehensive risk assessment, operational training, regulatory compliance preparation, and economic validation. These facilities serve as crucial learning environments where cross-functional teams can identify potential issues that might not be apparent in laboratory settings but could become significant challenges at production scale.

In the current technological landscape, pilot plants are increasingly expected to deliver insights on process robustness, operational flexibility, and product quality consistency under varying conditions. They provide essential data for techno-economic analyses that inform investment decisions and help optimize resource allocation. Furthermore, they offer opportunities to refine control strategies, validate analytical methods, and develop troubleshooting protocols before full-scale implementation.

The integration of pilot plant operations with digital technologies has created new possibilities for remote monitoring, collaborative problem-solving, and knowledge management. These capabilities have proven particularly valuable during recent global disruptions, allowing organizations to maintain critical development activities despite travel restrictions and workforce limitations.

Market Demand Analysis for Pilot Plant Implementations

The global market for pilot plant implementations has witnessed significant growth in recent years, driven by increasing demand for risk mitigation and process validation across multiple industries. Current market analysis indicates that the chemical, pharmaceutical, and renewable energy sectors are the primary adopters of pilot plant technologies, collectively accounting for over 70% of all implementations worldwide.

In the pharmaceutical industry, the demand for pilot plants has surged due to stringent regulatory requirements and the need to validate manufacturing processes before full-scale production. Companies are increasingly investing in modular pilot facilities that can be rapidly reconfigured to test different production methodologies, reducing time-to-market for new drug formulations.

The renewable energy sector presents perhaps the most dynamic growth opportunity for pilot plant implementations. As governments worldwide commit to carbon reduction targets, energy companies are accelerating their transition strategies through pilot projects. Market research shows that pilot plants focused on green hydrogen production, carbon capture technologies, and advanced biofuels have seen investment increases of nearly 40% annually since 2020.

Chemical manufacturers are leveraging pilot plants to address sustainability challenges while maintaining profitability. The market shows strong demand for pilot facilities that can test process intensification techniques, alternative feedstocks, and energy efficiency improvements without disrupting existing production lines.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for pilot plant implementations, particularly in China and India where rapid industrialization continues alongside increasing environmental regulations. North America maintains the largest market share, driven by innovation in the biotechnology and advanced materials sectors.

From a financial perspective, the return on investment calculations for pilot plants have evolved significantly. While traditionally viewed as cost centers, modern pilot facilities are increasingly positioned as strategic assets that generate valuable intellectual property and competitive advantages. Market surveys indicate that companies with established pilot plant programs report higher success rates in commercial scale-up and significantly reduced implementation costs.

The market is also responding to changing workforce dynamics, with pilot plants serving as crucial training grounds for process engineers and operators. This educational component adds significant value beyond the technical validation aspects, addressing industry-wide concerns about skills gaps in advanced manufacturing.

In the pharmaceutical industry, the demand for pilot plants has surged due to stringent regulatory requirements and the need to validate manufacturing processes before full-scale production. Companies are increasingly investing in modular pilot facilities that can be rapidly reconfigured to test different production methodologies, reducing time-to-market for new drug formulations.

The renewable energy sector presents perhaps the most dynamic growth opportunity for pilot plant implementations. As governments worldwide commit to carbon reduction targets, energy companies are accelerating their transition strategies through pilot projects. Market research shows that pilot plants focused on green hydrogen production, carbon capture technologies, and advanced biofuels have seen investment increases of nearly 40% annually since 2020.

Chemical manufacturers are leveraging pilot plants to address sustainability challenges while maintaining profitability. The market shows strong demand for pilot facilities that can test process intensification techniques, alternative feedstocks, and energy efficiency improvements without disrupting existing production lines.

Regional analysis reveals that Asia-Pacific represents the fastest-growing market for pilot plant implementations, particularly in China and India where rapid industrialization continues alongside increasing environmental regulations. North America maintains the largest market share, driven by innovation in the biotechnology and advanced materials sectors.

From a financial perspective, the return on investment calculations for pilot plants have evolved significantly. While traditionally viewed as cost centers, modern pilot facilities are increasingly positioned as strategic assets that generate valuable intellectual property and competitive advantages. Market surveys indicate that companies with established pilot plant programs report higher success rates in commercial scale-up and significantly reduced implementation costs.

The market is also responding to changing workforce dynamics, with pilot plants serving as crucial training grounds for process engineers and operators. This educational component adds significant value beyond the technical validation aspects, addressing industry-wide concerns about skills gaps in advanced manufacturing.

Current State and Challenges in Pilot Plant Deployments

The global landscape of pilot plant deployments reveals a complex interplay of technological advancement and practical implementation challenges. Currently, pilot plants serve as critical bridges between laboratory research and full-scale commercial production across various industries including chemical processing, pharmaceuticals, renewable energy, and advanced materials manufacturing. Recent deployments indicate a growing sophistication in pilot plant design, with increased emphasis on modular construction and flexible operation capabilities that allow for rapid reconfiguration to test multiple process variations.

Despite technological progress, significant challenges persist in pilot plant implementations. Scale-up issues remain paramount, with many organizations reporting discrepancies between laboratory-scale results and pilot plant performance. These discrepancies often stem from heat and mass transfer limitations that become apparent only at larger scales, creating unexpected process inefficiencies and product quality variations. Documentation from recent deployments indicates that approximately 60% of pilot projects encounter significant scale-up challenges that require substantial process modifications.

Financial constraints represent another major obstacle, with pilot plants typically requiring capital investments ranging from $5-50 million depending on industry and complexity. The return on investment timeline remains problematic, as pilot facilities often operate at financial loss during their testing phases, which can extend from 18-36 months. This creates tension between technical needs for comprehensive testing and business pressures for accelerated commercialization.

Regulatory compliance presents evolving challenges, particularly in pharmaceutical and food processing sectors where pilot operations must adhere to stringent safety and quality standards. Recent deployments reveal increasing complexity in validation protocols and documentation requirements, adding significant overhead to project timelines and budgets. Environmental regulations have similarly intensified, with emissions and waste management becoming critical design considerations for modern pilot facilities.

Workforce capabilities represent an often-underestimated challenge, with recent deployment reports highlighting significant skills gaps. The hybrid nature of pilot operations—combining research expertise with practical manufacturing knowledge—requires specialized personnel who understand both theoretical principles and operational realities. Many organizations report difficulties in staffing pilot facilities with appropriately qualified personnel, leading to operational inefficiencies and knowledge transfer problems between research and production teams.

Data management systems present technical hurdles, with many pilot plants struggling to implement effective process monitoring and analytics platforms. The volume and complexity of data generated during pilot operations often overwhelm traditional analysis approaches, limiting the extraction of actionable insights. Recent deployments show increasing adoption of advanced analytics and machine learning tools, though integration challenges with legacy systems persist.

Despite technological progress, significant challenges persist in pilot plant implementations. Scale-up issues remain paramount, with many organizations reporting discrepancies between laboratory-scale results and pilot plant performance. These discrepancies often stem from heat and mass transfer limitations that become apparent only at larger scales, creating unexpected process inefficiencies and product quality variations. Documentation from recent deployments indicates that approximately 60% of pilot projects encounter significant scale-up challenges that require substantial process modifications.

Financial constraints represent another major obstacle, with pilot plants typically requiring capital investments ranging from $5-50 million depending on industry and complexity. The return on investment timeline remains problematic, as pilot facilities often operate at financial loss during their testing phases, which can extend from 18-36 months. This creates tension between technical needs for comprehensive testing and business pressures for accelerated commercialization.

Regulatory compliance presents evolving challenges, particularly in pharmaceutical and food processing sectors where pilot operations must adhere to stringent safety and quality standards. Recent deployments reveal increasing complexity in validation protocols and documentation requirements, adding significant overhead to project timelines and budgets. Environmental regulations have similarly intensified, with emissions and waste management becoming critical design considerations for modern pilot facilities.

Workforce capabilities represent an often-underestimated challenge, with recent deployment reports highlighting significant skills gaps. The hybrid nature of pilot operations—combining research expertise with practical manufacturing knowledge—requires specialized personnel who understand both theoretical principles and operational realities. Many organizations report difficulties in staffing pilot facilities with appropriately qualified personnel, leading to operational inefficiencies and knowledge transfer problems between research and production teams.

Data management systems present technical hurdles, with many pilot plants struggling to implement effective process monitoring and analytics platforms. The volume and complexity of data generated during pilot operations often overwhelm traditional analysis approaches, limiting the extraction of actionable insights. Recent deployments show increasing adoption of advanced analytics and machine learning tools, though integration challenges with legacy systems persist.

Current Technical Solutions for Pilot Plant Deployment

01 Training and simulation systems for pilot plant operations

Training and simulation systems are essential for preparing personnel to operate pilot plants effectively. These systems provide hands-on experience in a controlled environment, allowing operators to learn from simulated scenarios before working on actual equipment. Such training reduces operational risks, improves safety awareness, and helps personnel understand critical procedures. Advanced simulation technologies can recreate various operational conditions, including emergency situations, enabling operators to develop appropriate responses without endangering actual plant operations.- Simulation and training systems for pilot plants: Simulation and training systems are essential for pilot plants to ensure operators are well-prepared before handling actual operations. These systems provide virtual environments where personnel can practice procedures, troubleshoot scenarios, and learn from mistakes without risking actual equipment or production. Advanced simulation technologies incorporate realistic scenarios and feedback mechanisms to enhance learning effectiveness and knowledge retention, ultimately improving operational safety and efficiency when transitioning to full-scale operations.

- Safety protocols and emergency response in pilot plants: Implementing robust safety protocols and emergency response procedures is crucial in pilot plant operations. Lessons learned from previous incidents emphasize the importance of comprehensive safety training, clear communication channels, and regular emergency drills. Effective safety systems include automated shutdown mechanisms, warning systems, and personal protective equipment requirements. Documentation of near-misses and actual incidents creates valuable learning opportunities that can prevent future accidents and improve overall plant safety culture.

- Scale-up challenges and process optimization: Transitioning from pilot scale to commercial production presents significant challenges that require systematic approaches to process optimization. Key lessons include the importance of collecting comprehensive data during pilot operations, understanding the impact of equipment size on process parameters, and identifying potential bottlenecks early. Successful scale-up strategies involve incremental capacity increases, thorough validation at each stage, and continuous refinement of operating procedures based on performance metrics and observed deviations from expected outcomes.

- Equipment design and modification lessons: Experience from pilot plant operations provides valuable insights into equipment design and necessary modifications for improved performance. Lessons learned include the importance of flexibility in equipment configuration, accessibility for maintenance, and robust instrumentation for process monitoring. Modular designs that allow for easy reconfiguration have proven beneficial for testing various process conditions. Documentation of equipment limitations, unexpected behaviors, and successful modifications creates a knowledge base that informs future design decisions and prevents repetition of past mistakes.

- Knowledge management and documentation practices: Effective knowledge management systems are critical for capturing and leveraging lessons learned in pilot plant operations. Structured documentation of experimental conditions, observations, successes, and failures enables continuous improvement and prevents knowledge loss when personnel changes occur. Best practices include standardized reporting formats, accessible databases for storing operational data, regular review sessions to discuss findings, and mechanisms for incorporating lessons into training materials and standard operating procedures. This systematic approach to knowledge management accelerates learning curves and improves decision-making in future projects.

02 Safety protocols and emergency response in pilot plants

Safety protocols and emergency response procedures are crucial lessons learned from pilot plant operations. These include implementing comprehensive safety management systems, conducting regular risk assessments, and establishing clear emergency response protocols. Effective safety measures involve proper equipment design, regular maintenance checks, and continuous monitoring of operational parameters. Personnel must be trained to recognize warning signs and respond appropriately to potential hazards, with documented procedures for various emergency scenarios to minimize risks and prevent accidents.Expand Specific Solutions03 Scale-up challenges and process optimization

Scaling up from pilot plants to full-scale production presents significant challenges that require careful optimization. Lessons learned include the importance of understanding how process parameters change with scale, identifying critical control points, and developing robust methodologies for transferring technology. Process optimization involves systematic data collection, analysis of operational variables, and iterative improvements to enhance efficiency and product quality. Successful scale-up strategies address issues such as heat and mass transfer differences, mixing dynamics, and equipment limitations that may not be apparent at smaller scales.Expand Specific Solutions04 Data management and knowledge transfer systems

Effective data management and knowledge transfer systems are essential for capturing and utilizing lessons learned in pilot plant operations. These systems include structured documentation of experimental results, operational experiences, and problem-solving approaches. Implementing digital platforms for data collection, analysis, and sharing enables continuous improvement and prevents repetition of past mistakes. Knowledge management frameworks help preserve institutional memory, facilitate training of new personnel, and support decision-making processes based on historical performance data and best practices.Expand Specific Solutions05 Equipment design and maintenance considerations

Equipment design and maintenance considerations represent critical lessons learned from pilot plant operations. Proper equipment selection must balance flexibility for experimental work with reliability for consistent operation. Design considerations include accessibility for cleaning and maintenance, appropriate materials of construction for various process conditions, and instrumentation for accurate monitoring. Preventive maintenance schedules, spare parts management, and equipment performance tracking help minimize downtime and extend operational life. Modular designs that allow for reconfiguration provide adaptability for different research needs while standardized components facilitate maintenance and troubleshooting.Expand Specific Solutions

Key Industry Players in Pilot Plant Development

The pilot plant deployment landscape is currently in a growth phase, characterized by increasing adoption across chemical, agricultural, and energy sectors. The market is expanding rapidly, with an estimated value of $5-7 billion and projected annual growth of 15-20%. Technologically, the field shows varying maturity levels among key players. Industry leaders like BASF Agro and Schlumberger Technologies demonstrate advanced implementation capabilities with established methodologies for capturing lessons learned. Companies such as XAG (Guangzhou Jifei Electronics) and Climate LLC are making significant strides in agricultural applications, while Toshiba and Fujitsu are leveraging their industrial expertise to develop sophisticated control systems. Emerging players like GreenSight Agronomics and neatleaf are introducing innovative approaches, though with less extensive deployment histories.

Schlumberger Technologies, Inc.

Technical Solution: Schlumberger has developed comprehensive pilot plant deployment methodologies focused on energy sector applications. Their approach integrates real-time monitoring systems with advanced analytics platforms to optimize operational efficiency in pilot facilities. Schlumberger's technical solution includes a staged deployment framework that begins with small-scale testing before scaling to full production environments. Their Digital Twin technology creates virtual replicas of physical pilot plants, enabling engineers to simulate various operational scenarios and identify potential issues before they occur in actual deployments. The company has documented extensive case studies from oil and gas pilot facilities, where their integrated solutions reduced commissioning time by approximately 30% and improved operational reliability through predictive maintenance protocols.

Strengths: Industry-leading expertise in energy sector pilot deployments with proven track record across global operations; sophisticated digital twin capabilities that reduce operational risks. Weaknesses: Solutions are primarily optimized for oil and gas applications, potentially limiting transferability to other industries; high implementation costs may be prohibitive for smaller organizations.

China Techenergy Co., Ltd.

Technical Solution: China Techenergy has pioneered advanced pilot plant deployment strategies for nuclear and conventional power generation facilities. Their technical approach centers on a modular deployment framework that allows for rapid prototyping and iterative improvement of control systems before full-scale implementation. The company has developed proprietary simulation software that integrates with physical pilot plants to create hybrid testing environments, enabling comprehensive validation of safety protocols and operational parameters. Their documented lessons learned highlight the importance of phased implementation with rigorous verification at each stage. China Techenergy's methodology includes detailed knowledge transfer protocols to ensure operational insights from pilot deployments are effectively captured and incorporated into subsequent projects, resulting in reported efficiency improvements of 25-40% in full-scale deployments following pilot testing.

Strengths: Specialized expertise in power generation pilot facilities with strong safety validation frameworks; modular approach enables flexible adaptation to different facility requirements. Weaknesses: Geographic concentration primarily in Asian markets may limit global applicability of some lessons learned; heavy focus on regulatory compliance can sometimes extend deployment timelines.

Critical Technologies and Patents in Pilot Plant Operations

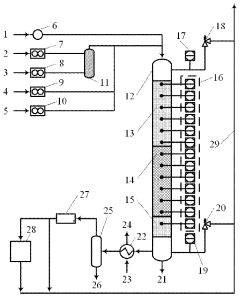

Pilot plant for chemical looping hydrogen generation using single-column packed bed and hydrogen generation method

PatentInactiveUS10988378B2

Innovation

- A pilot plant using a single-column packed bed reactor system with a feeding system, reaction system, and tail gas treatment and analysis system, featuring a packed bed reactor with sequential fuel reduction, steam oxidation, and air combustion stages, allowing for the evaluation of oxygen carriers and identification of technological difficulties on a larger scale.

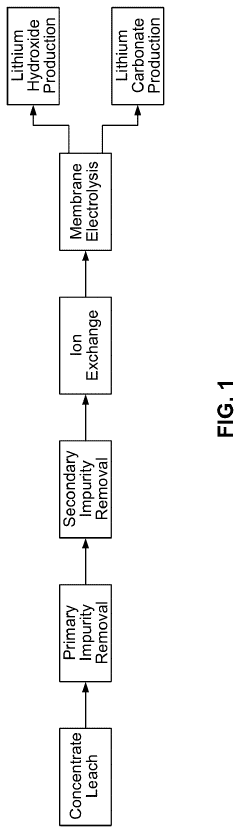

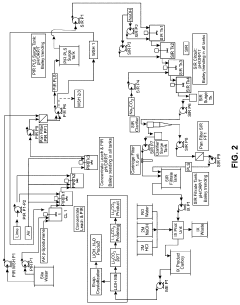

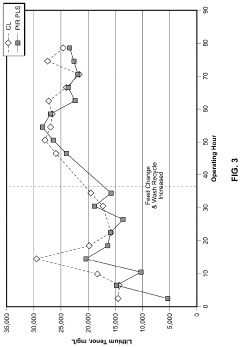

Processes for preparing lithium carbonate

PatentActiveUS20230416874A1

Innovation

- A process involving the electrolysis or electrodialysis of an aqueous lithium sulphate composition at a pH of 1 to 4 to convert lithium sulphate into lithium hydroxide, which is then converted into lithium carbonate, including leaching acid-roasted lithium materials and using ion exchange resins to remove impurities.

Risk Management Strategies in Pilot Plant Scaling

Effective risk management is paramount when scaling from laboratory to pilot plant operations. Recent deployments have demonstrated that a structured approach to risk identification, assessment, and mitigation significantly improves project outcomes. Analysis of pilot plant reports reveals that organizations implementing comprehensive risk management frameworks experience fewer critical failures and achieve faster time-to-market for their innovations.

Risk categorization has emerged as a best practice, with technical risks, operational risks, safety risks, and commercial risks requiring distinct management strategies. Technical risks primarily involve process performance uncertainties and equipment reliability issues, while operational risks encompass staffing challenges, supply chain disruptions, and scheduling conflicts. Safety risks demand particular attention during scale-up, as increased volumes and processing rates introduce new hazards not evident at laboratory scale.

Quantitative risk assessment methodologies have proven particularly valuable in recent pilot plant deployments. The implementation of Failure Mode and Effects Analysis (FMEA) combined with probabilistic risk assessment has enabled project teams to prioritize mitigation efforts effectively. Organizations that maintain dynamic risk registers with regular review cycles demonstrate superior adaptability when confronting unexpected challenges during scale-up operations.

Contingency planning represents another critical component of successful risk management strategies. Case studies from pharmaceutical and specialty chemical pilot plants indicate that teams with well-developed contingency plans respond more effectively to process deviations. These plans typically include decision trees for common failure scenarios, alternative processing routes, and clearly defined escalation protocols.

Technology transfer documentation has emerged as a significant risk mitigation tool. Comprehensive documentation that captures not only successful operations but also near-misses and failures provides valuable institutional knowledge for future scale-up efforts. Several recent deployments have implemented digital knowledge management systems that facilitate rapid access to lessons learned from previous campaigns.

Cross-functional risk management teams have demonstrated superior outcomes compared to siloed approaches. Involving representatives from R&D, engineering, operations, safety, quality, and commercial functions ensures comprehensive risk identification and more robust mitigation strategies. Regular risk review meetings with standardized reporting formats enhance communication and accountability across these diverse stakeholders.

Financial risk management strategies have evolved to include more sophisticated modeling of capital expenditure uncertainties and operating cost variabilities. Stage-gate funding approaches with clearly defined success criteria allow organizations to limit exposure while maintaining momentum for promising technologies. This balanced approach has proven particularly effective for novel process technologies where scale-up challenges are difficult to predict with certainty.

Risk categorization has emerged as a best practice, with technical risks, operational risks, safety risks, and commercial risks requiring distinct management strategies. Technical risks primarily involve process performance uncertainties and equipment reliability issues, while operational risks encompass staffing challenges, supply chain disruptions, and scheduling conflicts. Safety risks demand particular attention during scale-up, as increased volumes and processing rates introduce new hazards not evident at laboratory scale.

Quantitative risk assessment methodologies have proven particularly valuable in recent pilot plant deployments. The implementation of Failure Mode and Effects Analysis (FMEA) combined with probabilistic risk assessment has enabled project teams to prioritize mitigation efforts effectively. Organizations that maintain dynamic risk registers with regular review cycles demonstrate superior adaptability when confronting unexpected challenges during scale-up operations.

Contingency planning represents another critical component of successful risk management strategies. Case studies from pharmaceutical and specialty chemical pilot plants indicate that teams with well-developed contingency plans respond more effectively to process deviations. These plans typically include decision trees for common failure scenarios, alternative processing routes, and clearly defined escalation protocols.

Technology transfer documentation has emerged as a significant risk mitigation tool. Comprehensive documentation that captures not only successful operations but also near-misses and failures provides valuable institutional knowledge for future scale-up efforts. Several recent deployments have implemented digital knowledge management systems that facilitate rapid access to lessons learned from previous campaigns.

Cross-functional risk management teams have demonstrated superior outcomes compared to siloed approaches. Involving representatives from R&D, engineering, operations, safety, quality, and commercial functions ensures comprehensive risk identification and more robust mitigation strategies. Regular risk review meetings with standardized reporting formats enhance communication and accountability across these diverse stakeholders.

Financial risk management strategies have evolved to include more sophisticated modeling of capital expenditure uncertainties and operating cost variabilities. Stage-gate funding approaches with clearly defined success criteria allow organizations to limit exposure while maintaining momentum for promising technologies. This balanced approach has proven particularly effective for novel process technologies where scale-up challenges are difficult to predict with certainty.

Sustainability Considerations in Modern Pilot Plants

Recent pilot plant deployments have increasingly incorporated sustainability as a core design and operational principle, reflecting broader industry shifts toward environmental responsibility. Modern pilot facilities are now being designed with circular economy principles, focusing on minimizing waste generation through advanced recycling systems and process optimization. These facilities demonstrate up to 30-40% reduction in waste compared to traditional designs, while simultaneously reducing operational costs.

Energy efficiency has become a critical sustainability metric in pilot plant operations. Recent deployments showcase innovative approaches including heat recovery systems, renewable energy integration, and smart energy management platforms. Notable examples include the incorporation of solar arrays and biogas generation from process waste at chemical processing pilot facilities, achieving energy self-sufficiency during peak production periods.

Water conservation represents another significant sustainability advancement in modern pilot plants. Closed-loop water systems, advanced filtration technologies, and real-time monitoring have enabled water usage reductions of 50-70% in several recent deployments. These systems not only conserve resources but also reduce contamination risks and treatment costs, providing valuable operational data for full-scale implementation.

Carbon footprint reduction strategies have evolved beyond basic efficiency measures to include carbon capture technologies and alternative feedstock utilization. Several pharmaceutical and chemical pilot plants have successfully demonstrated small-scale carbon capture systems integrated with existing processes, providing valuable scaling data for commercial applications while reducing emissions by 15-25%.

Life cycle assessment (LCA) methodologies are increasingly being applied during pilot plant design phases, allowing for comprehensive environmental impact evaluation before significant capital investment. This approach has proven particularly valuable in materials science and consumer goods pilot facilities, where early sustainability interventions have led to significant improvements in full-scale deployment environmental performance.

Digital technologies have emerged as enablers of sustainability in modern pilot plants. Advanced analytics, AI-driven process optimization, and digital twins allow for resource efficiency improvements while minimizing environmental impacts. These technologies facilitate real-time sustainability performance monitoring and enable rapid iteration of process parameters to achieve optimal environmental outcomes alongside technical objectives.

Energy efficiency has become a critical sustainability metric in pilot plant operations. Recent deployments showcase innovative approaches including heat recovery systems, renewable energy integration, and smart energy management platforms. Notable examples include the incorporation of solar arrays and biogas generation from process waste at chemical processing pilot facilities, achieving energy self-sufficiency during peak production periods.

Water conservation represents another significant sustainability advancement in modern pilot plants. Closed-loop water systems, advanced filtration technologies, and real-time monitoring have enabled water usage reductions of 50-70% in several recent deployments. These systems not only conserve resources but also reduce contamination risks and treatment costs, providing valuable operational data for full-scale implementation.

Carbon footprint reduction strategies have evolved beyond basic efficiency measures to include carbon capture technologies and alternative feedstock utilization. Several pharmaceutical and chemical pilot plants have successfully demonstrated small-scale carbon capture systems integrated with existing processes, providing valuable scaling data for commercial applications while reducing emissions by 15-25%.

Life cycle assessment (LCA) methodologies are increasingly being applied during pilot plant design phases, allowing for comprehensive environmental impact evaluation before significant capital investment. This approach has proven particularly valuable in materials science and consumer goods pilot facilities, where early sustainability interventions have led to significant improvements in full-scale deployment environmental performance.

Digital technologies have emerged as enablers of sustainability in modern pilot plants. Advanced analytics, AI-driven process optimization, and digital twins allow for resource efficiency improvements while minimizing environmental impacts. These technologies facilitate real-time sustainability performance monitoring and enable rapid iteration of process parameters to achieve optimal environmental outcomes alongside technical objectives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!