Electrode Fouling Mechanisms In Real Feedstocks And Cleaning Protocols

AUG 28, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrode Fouling Background and Research Objectives

Electrode fouling represents a significant challenge in electrochemical processes across various industries, from biosensors and environmental monitoring to energy conversion and storage systems. This phenomenon, characterized by the accumulation of unwanted materials on electrode surfaces, has been observed since the early applications of electrochemistry in the 19th century. However, it has gained particular attention in recent decades as electrochemical technologies have become increasingly vital in sustainable energy solutions and analytical applications.

The evolution of electrode fouling research has progressed from simple empirical observations to sophisticated mechanistic studies. Initially, fouling was primarily addressed through trial-and-error approaches, with limited understanding of the underlying mechanisms. The 1970s and 1980s saw the emergence of more systematic investigations, particularly in industrial electrochemistry where fouling significantly impacted process efficiency and electrode lifespan.

Recent technological advancements in surface characterization techniques, including atomic force microscopy, scanning electron microscopy, and spectroscopic methods, have enabled more detailed examination of fouling processes at the molecular level. This has led to improved understanding of the complex interactions between electrodes and real-world feedstocks, which often contain multiple components that can contribute to fouling through various mechanisms.

The primary objective of this research is to elucidate the fundamental mechanisms of electrode fouling when operating in real feedstock environments, which present significantly greater complexity than laboratory-prepared solutions. Understanding these mechanisms is crucial for developing effective mitigation strategies and cleaning protocols that can be implemented in practical applications.

Specifically, this investigation aims to identify the key chemical and physical processes that lead to fouling in different types of feedstocks, including biomass-derived liquids, industrial wastewaters, and complex organic mixtures. By correlating fouling patterns with feedstock composition and operating conditions, we seek to establish predictive models that can anticipate fouling behavior in diverse electrochemical systems.

Additionally, this research endeavors to develop and validate efficient cleaning protocols tailored to specific fouling mechanisms. The goal is to establish standardized procedures that can be readily implemented in industrial settings to restore electrode performance with minimal downtime and resource consumption. This includes exploring both in-situ cleaning methods that can be applied during operation and ex-situ techniques for more thorough regeneration of severely fouled electrodes.

The technological trajectory suggests that addressing electrode fouling will become increasingly important as electrochemical processes expand into new applications and more challenging feedstock environments. This research aims to provide the fundamental knowledge and practical solutions necessary to overcome this critical limitation in electrochemical technology deployment.

The evolution of electrode fouling research has progressed from simple empirical observations to sophisticated mechanistic studies. Initially, fouling was primarily addressed through trial-and-error approaches, with limited understanding of the underlying mechanisms. The 1970s and 1980s saw the emergence of more systematic investigations, particularly in industrial electrochemistry where fouling significantly impacted process efficiency and electrode lifespan.

Recent technological advancements in surface characterization techniques, including atomic force microscopy, scanning electron microscopy, and spectroscopic methods, have enabled more detailed examination of fouling processes at the molecular level. This has led to improved understanding of the complex interactions between electrodes and real-world feedstocks, which often contain multiple components that can contribute to fouling through various mechanisms.

The primary objective of this research is to elucidate the fundamental mechanisms of electrode fouling when operating in real feedstock environments, which present significantly greater complexity than laboratory-prepared solutions. Understanding these mechanisms is crucial for developing effective mitigation strategies and cleaning protocols that can be implemented in practical applications.

Specifically, this investigation aims to identify the key chemical and physical processes that lead to fouling in different types of feedstocks, including biomass-derived liquids, industrial wastewaters, and complex organic mixtures. By correlating fouling patterns with feedstock composition and operating conditions, we seek to establish predictive models that can anticipate fouling behavior in diverse electrochemical systems.

Additionally, this research endeavors to develop and validate efficient cleaning protocols tailored to specific fouling mechanisms. The goal is to establish standardized procedures that can be readily implemented in industrial settings to restore electrode performance with minimal downtime and resource consumption. This includes exploring both in-situ cleaning methods that can be applied during operation and ex-situ techniques for more thorough regeneration of severely fouled electrodes.

The technological trajectory suggests that addressing electrode fouling will become increasingly important as electrochemical processes expand into new applications and more challenging feedstock environments. This research aims to provide the fundamental knowledge and practical solutions necessary to overcome this critical limitation in electrochemical technology deployment.

Market Analysis for Anti-fouling Electrode Technologies

The anti-fouling electrode technology market is experiencing significant growth driven by increasing applications in electrochemical processes across multiple industries. Current market valuation stands at approximately 3.2 billion USD with a compound annual growth rate projected at 7.8% through 2028, according to recent industry analyses. This growth trajectory is primarily fueled by expanding applications in water treatment, biosensing, energy storage, and industrial electrochemistry sectors.

Water treatment represents the largest market segment, where electrochemical processes are increasingly adopted for contaminant removal and disinfection. The biosensing sector follows closely, with medical diagnostics and environmental monitoring applications driving demand for fouling-resistant electrodes that maintain sensitivity and accuracy over extended operational periods.

Market segmentation by technology type reveals three dominant categories: surface modification technologies (42% market share), advanced material solutions (35%), and integrated cleaning systems (23%). Surface modification technologies, including hydrophobic coatings and antimicrobial surfaces, currently lead the market due to their cost-effectiveness and relatively straightforward implementation.

Geographically, North America holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 9.3% annually, driven by rapid industrialization in China and India, coupled with increasing environmental regulations mandating cleaner industrial processes.

Customer demand patterns indicate a clear shift toward solutions offering longer electrode lifespan and reduced maintenance requirements. End-users increasingly prioritize total cost of ownership over initial acquisition costs, creating market opportunities for premium solutions that demonstrate superior long-term performance and reliability.

Key market drivers include stringent environmental regulations, growing industrial automation, increasing adoption of electrochemical sensors in healthcare, and rising demand for energy-efficient water treatment technologies. The push toward sustainable manufacturing processes has particularly accelerated demand for electrodes that maintain efficiency while minimizing chemical cleaning requirements.

Market challenges primarily revolve around high initial implementation costs, technical complexity of advanced anti-fouling solutions, and the need for customization across different applications. Additionally, the fragmented nature of end-user industries creates barriers to standardization, requiring specialized solutions for specific operational environments.

Emerging market opportunities include the development of self-cleaning electrode systems, bio-inspired anti-fouling surfaces, and smart monitoring solutions that predict and prevent fouling events before they impact performance. The integration of anti-fouling technologies with IoT and predictive maintenance systems represents a particularly promising growth segment with potential to command premium pricing.

Water treatment represents the largest market segment, where electrochemical processes are increasingly adopted for contaminant removal and disinfection. The biosensing sector follows closely, with medical diagnostics and environmental monitoring applications driving demand for fouling-resistant electrodes that maintain sensitivity and accuracy over extended operational periods.

Market segmentation by technology type reveals three dominant categories: surface modification technologies (42% market share), advanced material solutions (35%), and integrated cleaning systems (23%). Surface modification technologies, including hydrophobic coatings and antimicrobial surfaces, currently lead the market due to their cost-effectiveness and relatively straightforward implementation.

Geographically, North America holds the largest market share at 38%, followed by Europe (29%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 9.3% annually, driven by rapid industrialization in China and India, coupled with increasing environmental regulations mandating cleaner industrial processes.

Customer demand patterns indicate a clear shift toward solutions offering longer electrode lifespan and reduced maintenance requirements. End-users increasingly prioritize total cost of ownership over initial acquisition costs, creating market opportunities for premium solutions that demonstrate superior long-term performance and reliability.

Key market drivers include stringent environmental regulations, growing industrial automation, increasing adoption of electrochemical sensors in healthcare, and rising demand for energy-efficient water treatment technologies. The push toward sustainable manufacturing processes has particularly accelerated demand for electrodes that maintain efficiency while minimizing chemical cleaning requirements.

Market challenges primarily revolve around high initial implementation costs, technical complexity of advanced anti-fouling solutions, and the need for customization across different applications. Additionally, the fragmented nature of end-user industries creates barriers to standardization, requiring specialized solutions for specific operational environments.

Emerging market opportunities include the development of self-cleaning electrode systems, bio-inspired anti-fouling surfaces, and smart monitoring solutions that predict and prevent fouling events before they impact performance. The integration of anti-fouling technologies with IoT and predictive maintenance systems represents a particularly promising growth segment with potential to command premium pricing.

Current Challenges in Real Feedstock Environments

Real feedstock environments present significant challenges for electrochemical processes due to their complex and variable compositions. Unlike controlled laboratory conditions with pure substrates, real feedstocks contain numerous impurities and contaminants that directly impact electrode performance and longevity. These feedstocks, whether derived from biomass, industrial waste streams, or natural resources, introduce particulate matter, organic compounds, and inorganic species that interact with electrode surfaces in detrimental ways.

The primary challenge observed in industrial applications is accelerated electrode fouling, which manifests as performance degradation over significantly shorter timeframes than predicted by laboratory studies. This fouling occurs through multiple mechanisms, including surface adsorption of organic molecules, precipitation of insoluble compounds, and formation of polymeric films that block active sites. The heterogeneous nature of real feedstocks makes predicting these interactions exceptionally difficult.

Biomass-derived feedstocks present particularly complex challenges due to their high content of proteins, carbohydrates, and lignin derivatives. These compounds can undergo electrochemical polymerization at electrode surfaces, forming insulating layers that rapidly diminish catalytic activity. Additionally, the presence of sulfur compounds, even in trace amounts, can lead to irreversible poisoning of precious metal catalysts commonly used in advanced electrochemical systems.

Mineral content in real feedstocks introduces another dimension of complexity. Calcium, magnesium, and other multivalent ions can precipitate as hydroxides or carbonates under the alkaline conditions often generated at cathode surfaces. These precipitates form scale-like deposits that not only block active sites but can also alter the electrode's microstructure over time, leading to mechanical degradation.

Temperature fluctuations and pH variations inherent in industrial processes further exacerbate fouling mechanisms. These parameters can dramatically alter solubility equilibria, accelerating precipitation reactions or enabling new fouling pathways not observed under controlled conditions. The synergistic effects between different contaminants often produce fouling behaviors that cannot be predicted from studying individual components in isolation.

Current cleaning protocols show limited efficacy in real feedstock environments. Chemical cleaning agents that perform well in laboratory settings often fail to fully restore electrode performance in industrial applications. This gap highlights the need for more robust cleaning strategies specifically designed for complex media. Furthermore, the frequency of required cleaning interventions significantly impacts process economics, creating a critical barrier to commercial implementation of many promising electrochemical technologies.

The development of in-situ monitoring techniques remains inadequate for real-time detection of fouling onset in complex media. This limitation prevents the implementation of preventative maintenance strategies that could potentially extend electrode lifetimes and maintain performance metrics within acceptable parameters.

The primary challenge observed in industrial applications is accelerated electrode fouling, which manifests as performance degradation over significantly shorter timeframes than predicted by laboratory studies. This fouling occurs through multiple mechanisms, including surface adsorption of organic molecules, precipitation of insoluble compounds, and formation of polymeric films that block active sites. The heterogeneous nature of real feedstocks makes predicting these interactions exceptionally difficult.

Biomass-derived feedstocks present particularly complex challenges due to their high content of proteins, carbohydrates, and lignin derivatives. These compounds can undergo electrochemical polymerization at electrode surfaces, forming insulating layers that rapidly diminish catalytic activity. Additionally, the presence of sulfur compounds, even in trace amounts, can lead to irreversible poisoning of precious metal catalysts commonly used in advanced electrochemical systems.

Mineral content in real feedstocks introduces another dimension of complexity. Calcium, magnesium, and other multivalent ions can precipitate as hydroxides or carbonates under the alkaline conditions often generated at cathode surfaces. These precipitates form scale-like deposits that not only block active sites but can also alter the electrode's microstructure over time, leading to mechanical degradation.

Temperature fluctuations and pH variations inherent in industrial processes further exacerbate fouling mechanisms. These parameters can dramatically alter solubility equilibria, accelerating precipitation reactions or enabling new fouling pathways not observed under controlled conditions. The synergistic effects between different contaminants often produce fouling behaviors that cannot be predicted from studying individual components in isolation.

Current cleaning protocols show limited efficacy in real feedstock environments. Chemical cleaning agents that perform well in laboratory settings often fail to fully restore electrode performance in industrial applications. This gap highlights the need for more robust cleaning strategies specifically designed for complex media. Furthermore, the frequency of required cleaning interventions significantly impacts process economics, creating a critical barrier to commercial implementation of many promising electrochemical technologies.

The development of in-situ monitoring techniques remains inadequate for real-time detection of fouling onset in complex media. This limitation prevents the implementation of preventative maintenance strategies that could potentially extend electrode lifetimes and maintain performance metrics within acceptable parameters.

Existing Cleaning Protocols and Maintenance Strategies

01 Electrochemical fouling mechanisms in industrial electrodes

Electrodes in industrial applications often experience fouling due to electrochemical reactions that lead to deposit formation on electrode surfaces. These deposits can include mineral scale, organic compounds, and reaction byproducts that adhere to the electrode surface during operation. The accumulation of these materials reduces electrode efficiency, increases electrical resistance, and can lead to system failure if not properly managed. Understanding these electrochemical mechanisms is crucial for developing effective anti-fouling strategies.- Chemical fouling mechanisms in electrodes: Chemical fouling of electrodes occurs when substances in the environment react with the electrode material, forming deposits or films that impair functionality. This can involve oxidation, corrosion, or chemical reactions with contaminants. These reactions can create insulating layers that reduce conductivity and sensitivity. Chemical fouling is particularly problematic in harsh environments with reactive chemicals or in applications where electrodes are exposed to diverse substances.

- Physical deposition and particulate fouling: Physical fouling occurs when particles, debris, or other materials physically accumulate on electrode surfaces. This can include dust, sediment, or other particulate matter that adheres to the electrode. The buildup creates a barrier that interferes with electrical conductivity and signal transmission. Physical fouling is common in industrial applications, environmental monitoring, and systems where electrodes are exposed to particulate-laden environments.

- Biological fouling of electrode surfaces: Biological fouling involves the accumulation of microorganisms, biofilms, or organic materials on electrode surfaces. Bacteria, algae, and other microorganisms can colonize electrodes, forming biofilms that impede electrical performance. This type of fouling is particularly problematic in aquatic environments, medical devices, and sensors used in biological applications. The biological material creates barriers to electron transfer and can produce metabolic byproducts that further damage electrode surfaces.

- Thermal and operational stress-induced fouling: Fouling can result from thermal and operational stresses that cause physical changes to electrode materials. High temperatures, electrical discharges, or operational cycling can lead to material degradation, cracking, or structural changes that promote fouling. This mechanism often involves the transformation of electrode materials or the creation of conditions that accelerate other fouling processes. The thermal stress can also cause precipitation of dissolved solids onto electrode surfaces during heating and cooling cycles.

- Anti-fouling technologies and prevention methods: Various technologies and methods have been developed to prevent or mitigate electrode fouling. These include specialized coatings that resist adhesion of fouling agents, self-cleaning mechanisms that periodically remove deposits, and design modifications that minimize areas prone to fouling. Some approaches involve regular maintenance protocols, chemical treatments, or the application of electrical pulses to disrupt fouling processes. Advanced materials with inherent anti-fouling properties are also being developed to extend electrode life and maintain performance in challenging environments.

02 Mechanical and physical fouling processes

Mechanical fouling of electrodes occurs when particulate matter, debris, or other physical contaminants accumulate on electrode surfaces. This type of fouling is often caused by suspended solids in the electrolyte, wear particles from system components, or external contaminants. Physical fouling can block active electrode sites, create uneven current distribution, and lead to localized heating. The physical properties of the electrode surface, such as roughness and porosity, significantly influence the rate and extent of mechanical fouling.Expand Specific Solutions03 Biological fouling of electrode systems

Biological fouling involves the colonization of electrode surfaces by microorganisms that form biofilms. These biofilms can develop in various electrode applications, particularly in aqueous environments. The microorganisms secrete extracellular polymeric substances that enhance adhesion and protect the colony. Biological fouling not only creates a physical barrier on the electrode surface but can also influence electrochemical reactions through microbial metabolic activities. This type of fouling is particularly challenging as biofilms can be highly resistant to conventional cleaning methods.Expand Specific Solutions04 Thermal effects on electrode fouling

Temperature variations significantly impact electrode fouling mechanisms. High temperatures can accelerate chemical reactions that lead to deposit formation, while thermal cycling can cause expansion and contraction that affects the adhesion of fouling materials. In some cases, thermal gradients across electrode surfaces create zones with different fouling characteristics. Heat-induced crystallization of dissolved solids is a common fouling mechanism in many electrode systems, particularly in applications involving mineral-rich electrolytes or cooling systems.Expand Specific Solutions05 Anti-fouling technologies and prevention methods

Various technologies have been developed to prevent or mitigate electrode fouling. These include surface modifications to create fouling-resistant electrode materials, periodic polarity reversal to dislodge accumulated deposits, ultrasonic cleaning systems, and chemical treatments that inhibit fouling mechanisms. Advanced monitoring systems can detect early signs of fouling, allowing for timely intervention. Proper electrode design that considers fluid dynamics can also minimize dead zones where fouling typically initiates. Implementing appropriate maintenance protocols is essential for extending electrode lifespan and maintaining optimal performance.Expand Specific Solutions

Leading Companies and Research Institutions in Electrode Technology

Electrode fouling in real feedstocks represents a critical challenge in the evolving biofuel and petrochemical processing industry. The market is currently in a growth phase, with an estimated global value exceeding $5 billion and projected annual growth of 8-10%. Major oil companies including ExxonMobil, Shell, Chevron, and BP are leading research efforts alongside specialized technology firms like Lam Research and NAURA Microelectronics. The competitive landscape shows varying levels of technological maturity, with established players focusing on proprietary cleaning protocols while academic institutions like National University of Singapore and Zhejiang University contribute fundamental research. The industry is witnessing increased collaboration between petroleum giants and equipment manufacturers to develop more resilient electrode technologies and automated cleaning systems that can withstand complex real-world feedstock conditions.

Neste Oyj

Technical Solution: Neste has pioneered the REFEED electrode protection system specifically designed for renewable diesel and sustainable aviation fuel production processes. Their technology addresses the unique fouling challenges posed by diverse bio-based feedstocks, including vegetable oils, waste fats, and residual biomass. Neste's approach combines real-time electrochemical impedance spectroscopy with advanced data analytics to characterize fouling mechanisms at the molecular level. Their system employs proprietary electrode materials with specialized coatings that resist protein and lipid adsorption—common fouling agents in bio-feedstocks. Neste's cleaning protocols utilize a combination of enzymatic treatments, targeted solvent flushing, and pulsed electrochemical techniques that remove deposits without compromising electrode performance. The company has also developed feedstock pre-treatment processes that remove potential fouling precursors before they contact electrode surfaces, significantly extending operational cycles between maintenance interventions.

Strengths: Specialized expertise in renewable feedstock processing; integration with existing biorefinery systems; minimal environmental impact of cleaning protocols. Weaknesses: Less applicable to traditional petroleum processes; requires specialized consumables for cleaning procedures; higher implementation costs for smaller facilities.

ExxonMobil Technology & Engineering Co.

Technical Solution: ExxonMobil has developed a multi-faceted approach to electrode fouling management called EFMS (Electrode Fouling Mitigation System). This technology addresses fouling in both petroleum and renewable feedstock processing. Their system characterizes fouling mechanisms at the molecular level, identifying specific compounds that cause electrode degradation in different feedstock types. ExxonMobil's approach includes proprietary electrode coating technologies that minimize adsorption of fouling agents while maintaining electrochemical performance. Their cleaning protocols utilize a sequential application of chemical, thermal, and electrochemical methods optimized through machine learning algorithms that analyze historical fouling patterns. The company has also developed specialized in-line filtration systems that remove potential fouling precursors before they reach electrode surfaces, significantly extending operational periods between maintenance cycles.

Strengths: Comprehensive understanding of molecular fouling mechanisms; integration with existing refinery infrastructure; proven effectiveness across diverse feedstock types. Weaknesses: System complexity requires specialized maintenance; initial implementation costs are substantial; some cleaning protocols require temporary process shutdown.

Critical Patents and Literature on Fouling Mechanisms

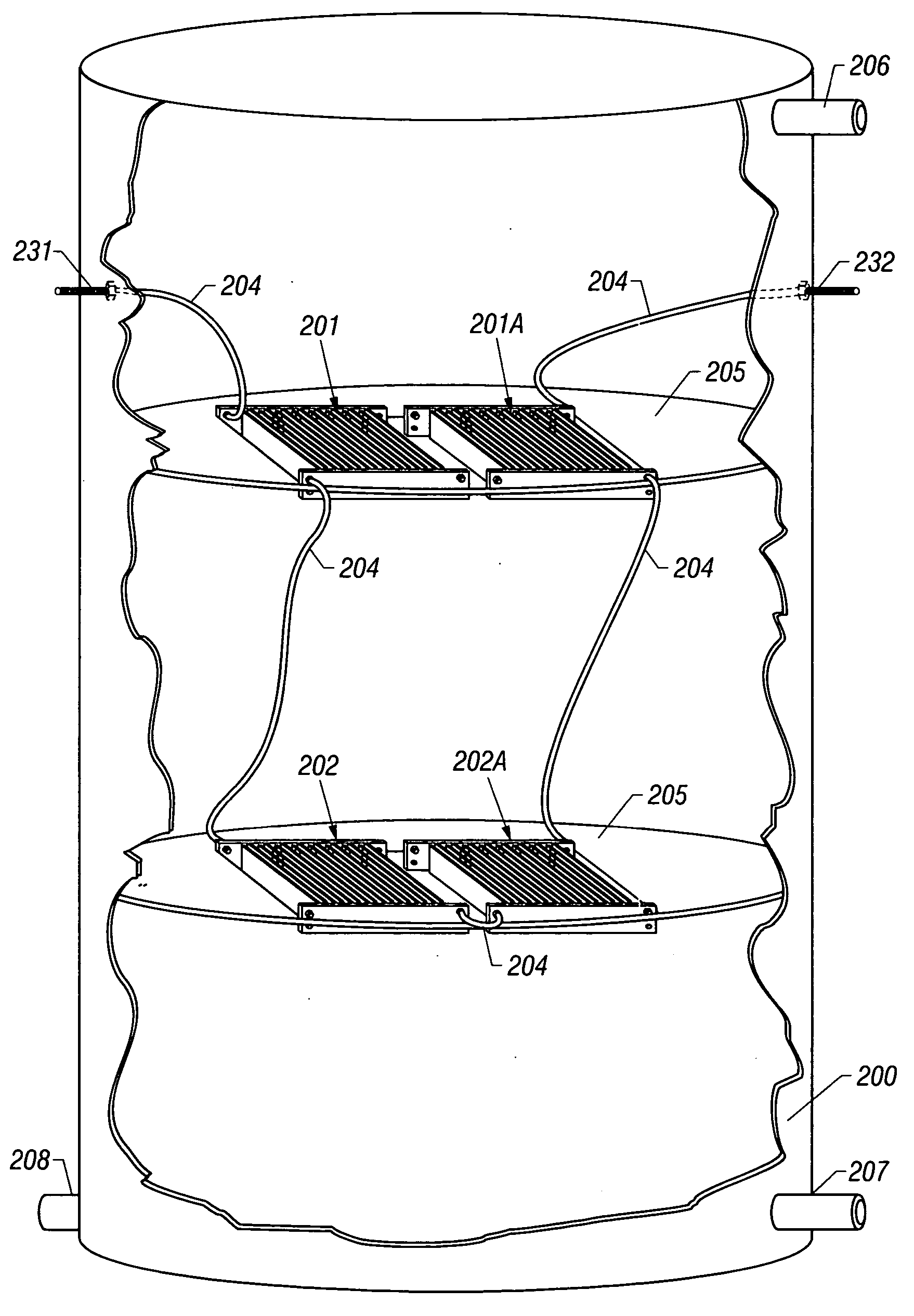

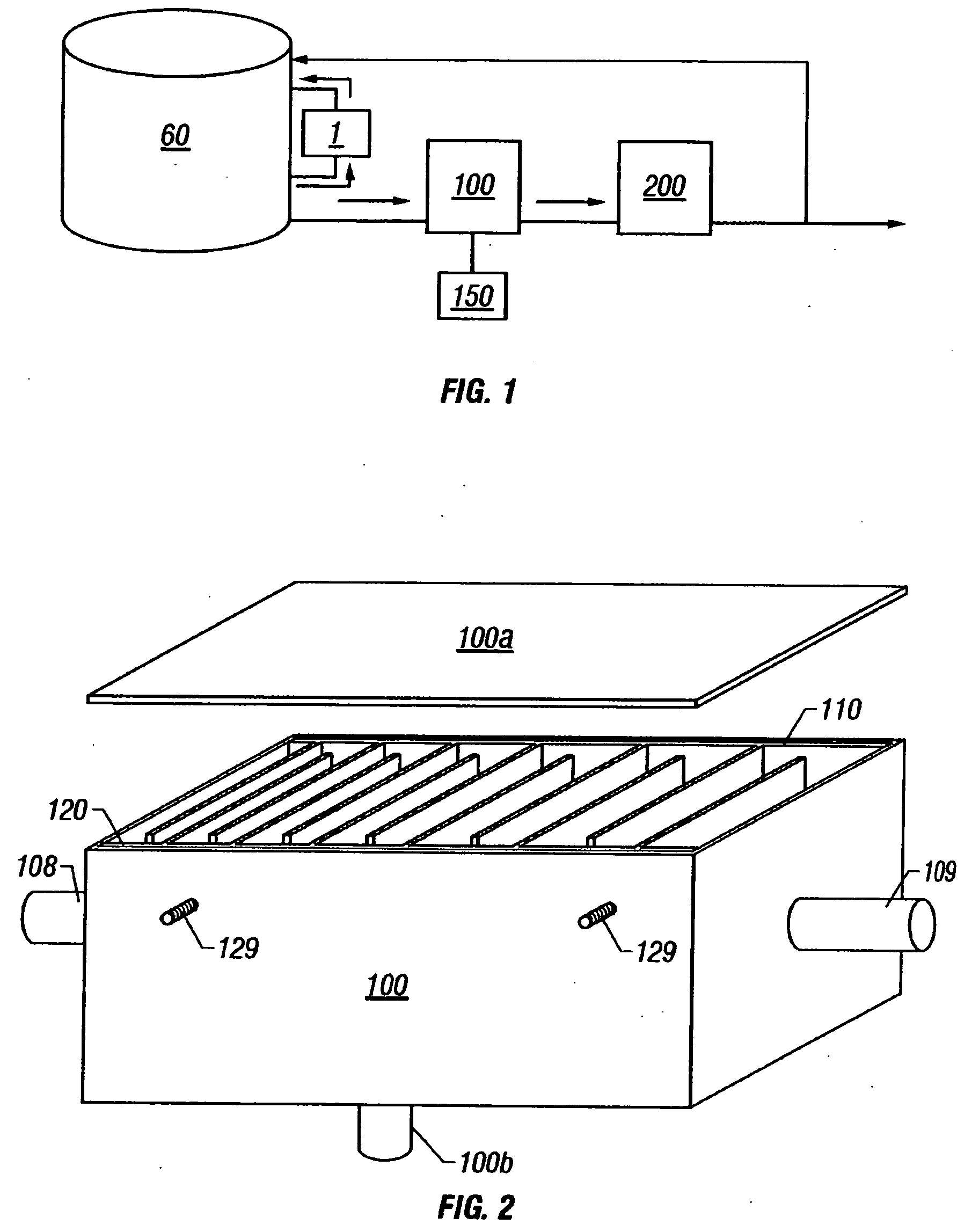

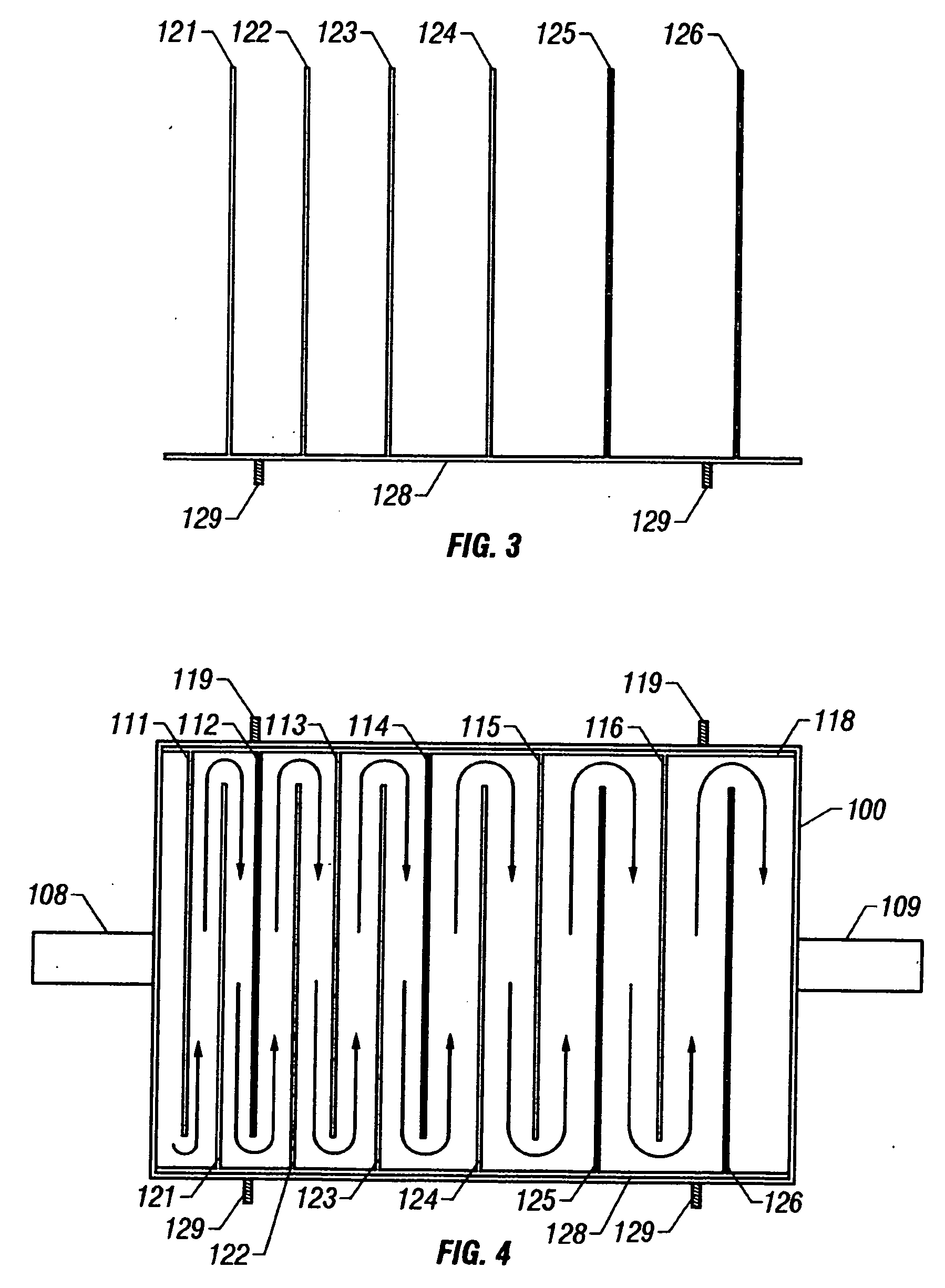

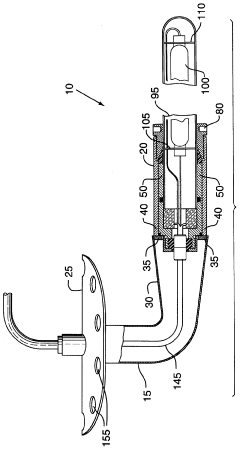

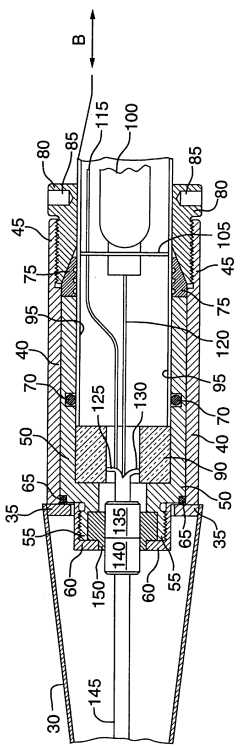

Method and apparatus for removing contaminants from conduits and fluid columns

PatentInactiveUS20060175200A1

Innovation

- A method and apparatus using a magnetic field generator to suspend contaminants and a reactor with variably spaced electrodes of dissimilar metals, driven by a single power supply, which applies electrical energy to induce flocculation and separation of contaminants, enhancing treatment efficiency and reducing energy consumption.

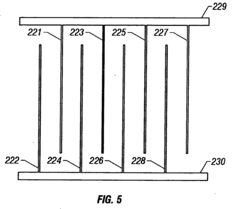

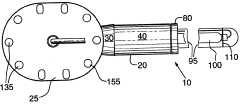

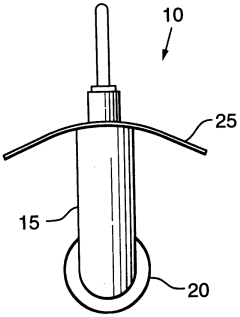

Method of cleaning fouling materials from a radiation module

PatentInactiveCA2160730C

Innovation

- A self-cleaning radiation module with vibration generation means, such as a piezo-electric ceramic transducer, is integrated into the system to inhibit fouling materials from adhering to the radiation module by subjecting it to mechanical vibration during fluid treatment, preventing fouling and allowing continuous operation.

Material Science Advancements for Fouling-resistant Electrodes

Recent advancements in materials science have opened promising avenues for developing fouling-resistant electrodes, addressing one of the most persistent challenges in electrochemical systems operating with real feedstocks. Traditional electrode materials such as carbon, platinum, and various metal oxides often suffer from rapid performance degradation due to fouling mechanisms, necessitating frequent cleaning or replacement.

Emerging nanomaterials represent a significant breakthrough in this domain. Carbon nanotubes (CNTs) and graphene-based electrodes demonstrate remarkable fouling resistance due to their unique surface properties and electronic structures. These materials exhibit reduced adsorption of organic contaminants while maintaining excellent conductivity and electrochemical activity. Particularly, nitrogen-doped carbon nanomaterials have shown enhanced resistance to protein and biomolecule fouling in biofuel applications.

Self-cleaning surfaces inspired by natural phenomena represent another innovative approach. Superhydrophobic coatings modeled after lotus leaves create surfaces where contaminants have minimal contact area, facilitating their removal during operation. Conversely, superhydrophilic surfaces can form protective water layers that prevent direct contact between foulants and electrode surfaces. These biomimetic approaches have demonstrated promising results in extending electrode operational lifetimes.

Composite materials combining conventional electrode substrates with fouling-resistant coatings offer practical solutions for immediate implementation. Polymer-modified electrodes incorporating perfluorinated compounds or zwitterionic polymers create surfaces that resist protein adsorption and biofilm formation. These modifications maintain electrical conductivity while significantly reducing fouling rates in complex media.

Metal-organic frameworks (MOFs) represent an emerging class of materials with tunable properties ideal for electrode applications. Their highly ordered porous structures can be designed to selectively interact with target molecules while repelling potential foulants. MOF-modified electrodes have demonstrated exceptional stability in organic-rich feedstocks where conventional electrodes rapidly degrade.

Stimuli-responsive materials that can dynamically alter their surface properties in response to external triggers (pH, temperature, electric potential) offer revolutionary possibilities for self-maintaining electrodes. These "smart" materials can transition between fouling-resistant and fouling-release states, effectively shedding accumulated contaminants during operation cycles without external intervention.

The integration of these advanced materials with conventional electrode fabrication techniques remains challenging but represents a critical path toward commercial implementation. Scalable manufacturing processes for these novel materials will be essential for their widespread adoption in industrial electrochemical applications dealing with complex real-world feedstocks.

Emerging nanomaterials represent a significant breakthrough in this domain. Carbon nanotubes (CNTs) and graphene-based electrodes demonstrate remarkable fouling resistance due to their unique surface properties and electronic structures. These materials exhibit reduced adsorption of organic contaminants while maintaining excellent conductivity and electrochemical activity. Particularly, nitrogen-doped carbon nanomaterials have shown enhanced resistance to protein and biomolecule fouling in biofuel applications.

Self-cleaning surfaces inspired by natural phenomena represent another innovative approach. Superhydrophobic coatings modeled after lotus leaves create surfaces where contaminants have minimal contact area, facilitating their removal during operation. Conversely, superhydrophilic surfaces can form protective water layers that prevent direct contact between foulants and electrode surfaces. These biomimetic approaches have demonstrated promising results in extending electrode operational lifetimes.

Composite materials combining conventional electrode substrates with fouling-resistant coatings offer practical solutions for immediate implementation. Polymer-modified electrodes incorporating perfluorinated compounds or zwitterionic polymers create surfaces that resist protein adsorption and biofilm formation. These modifications maintain electrical conductivity while significantly reducing fouling rates in complex media.

Metal-organic frameworks (MOFs) represent an emerging class of materials with tunable properties ideal for electrode applications. Their highly ordered porous structures can be designed to selectively interact with target molecules while repelling potential foulants. MOF-modified electrodes have demonstrated exceptional stability in organic-rich feedstocks where conventional electrodes rapidly degrade.

Stimuli-responsive materials that can dynamically alter their surface properties in response to external triggers (pH, temperature, electric potential) offer revolutionary possibilities for self-maintaining electrodes. These "smart" materials can transition between fouling-resistant and fouling-release states, effectively shedding accumulated contaminants during operation cycles without external intervention.

The integration of these advanced materials with conventional electrode fabrication techniques remains challenging but represents a critical path toward commercial implementation. Scalable manufacturing processes for these novel materials will be essential for their widespread adoption in industrial electrochemical applications dealing with complex real-world feedstocks.

Environmental Impact of Electrode Cleaning Chemicals

The environmental impact of electrode cleaning chemicals represents a significant concern in electrochemical processes dealing with real feedstocks. Traditional cleaning protocols often employ harsh chemicals including strong acids (sulfuric, hydrochloric, nitric), organic solvents (acetone, methanol), and oxidizing agents (hydrogen peroxide, potassium permanganate), which pose substantial environmental risks when improperly managed.

These cleaning agents can contribute to water pollution when discharged into aquatic ecosystems without adequate treatment. Acidic cleaning solutions alter pH levels in receiving water bodies, potentially disrupting aquatic life and ecosystem balance. Heavy metals mobilized during cleaning processes may bioaccumulate in aquatic organisms, leading to toxicity throughout the food chain.

Volatile organic compounds (VOCs) released from organic solvents during electrode cleaning contribute to air pollution and photochemical smog formation. Many cleaning chemicals also have high global warming potential or ozone depletion capabilities, exacerbating climate change concerns when released into the atmosphere.

The manufacturing of these cleaning chemicals itself carries a substantial carbon footprint, with energy-intensive production processes and transportation requirements. Additionally, the disposal of spent cleaning solutions generates hazardous waste streams requiring specialized treatment facilities, further increasing the environmental burden.

Regulatory frameworks worldwide are increasingly imposing stricter controls on chemical usage and discharge limits. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions mandate comprehensive environmental impact assessments and waste management protocols for industrial chemical usage.

Industry response has focused on developing greener alternatives, including biodegradable surfactants, enzyme-based cleaners, and ultrasonic cleaning methods that reduce chemical dependence. Electrochemical regeneration techniques that restore electrode performance without chemical intervention show particular promise for minimizing environmental impact.

Closed-loop systems that capture, treat, and reuse cleaning chemicals represent another advancement in reducing environmental footprint. These systems minimize discharge volumes while recovering valuable components from spent solutions. Implementation of such systems has demonstrated reduction in fresh chemical consumption by up to 80% in some industrial applications.

Cost-benefit analyses indicate that while environmentally friendly cleaning protocols may require higher initial investment, they often yield long-term economic benefits through reduced waste management costs, regulatory compliance, and improved corporate sustainability profiles.

These cleaning agents can contribute to water pollution when discharged into aquatic ecosystems without adequate treatment. Acidic cleaning solutions alter pH levels in receiving water bodies, potentially disrupting aquatic life and ecosystem balance. Heavy metals mobilized during cleaning processes may bioaccumulate in aquatic organisms, leading to toxicity throughout the food chain.

Volatile organic compounds (VOCs) released from organic solvents during electrode cleaning contribute to air pollution and photochemical smog formation. Many cleaning chemicals also have high global warming potential or ozone depletion capabilities, exacerbating climate change concerns when released into the atmosphere.

The manufacturing of these cleaning chemicals itself carries a substantial carbon footprint, with energy-intensive production processes and transportation requirements. Additionally, the disposal of spent cleaning solutions generates hazardous waste streams requiring specialized treatment facilities, further increasing the environmental burden.

Regulatory frameworks worldwide are increasingly imposing stricter controls on chemical usage and discharge limits. The European Union's REACH regulations, the United States EPA guidelines, and similar frameworks in Asia-Pacific regions mandate comprehensive environmental impact assessments and waste management protocols for industrial chemical usage.

Industry response has focused on developing greener alternatives, including biodegradable surfactants, enzyme-based cleaners, and ultrasonic cleaning methods that reduce chemical dependence. Electrochemical regeneration techniques that restore electrode performance without chemical intervention show particular promise for minimizing environmental impact.

Closed-loop systems that capture, treat, and reuse cleaning chemicals represent another advancement in reducing environmental footprint. These systems minimize discharge volumes while recovering valuable components from spent solutions. Implementation of such systems has demonstrated reduction in fresh chemical consumption by up to 80% in some industrial applications.

Cost-benefit analyses indicate that while environmentally friendly cleaning protocols may require higher initial investment, they often yield long-term economic benefits through reduced waste management costs, regulatory compliance, and improved corporate sustainability profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!