Electrochemical Reactor Heat Management For Industrial Throughput

AUG 29, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Reactor Thermal Evolution and Objectives

Electrochemical reactors have undergone significant thermal evolution since their inception in the early 20th century. Initially, these systems operated at ambient temperatures with minimal consideration for heat management. The 1950s marked a turning point when researchers recognized that temperature control directly impacts reaction kinetics, selectivity, and overall efficiency. This realization led to the development of rudimentary cooling systems, primarily using water jackets and simple heat exchangers.

By the 1970s and 1980s, as industrial applications expanded, more sophisticated thermal management approaches emerged. The introduction of computer-controlled temperature regulation systems allowed for precise thermal profiles across reactor components. This period also witnessed the first comprehensive studies correlating heat distribution patterns with electrochemical performance metrics.

The 1990s through early 2000s saw integration of advanced materials with superior thermal conductivity properties, enabling more efficient heat transfer within reactor systems. Computational fluid dynamics (CFD) modeling became instrumental in predicting thermal behavior, allowing engineers to identify hotspots and optimize cooling strategies before physical implementation.

Current electrochemical reactor designs incorporate multi-zone temperature control, phase-change cooling materials, and intelligent thermal management algorithms. These innovations have pushed operational capabilities to new heights, yet significant challenges remain in scaling these solutions for industrial throughput requirements.

The primary objective of modern electrochemical reactor heat management is to maintain optimal temperature distributions while accommodating increasing production demands. This involves developing systems capable of handling higher current densities without thermal runaway conditions. Specific technical goals include reducing temperature gradients across electrode surfaces to below 5°C, minimizing energy consumption for cooling processes, and ensuring rapid response to thermal fluctuations during variable load operations.

Another critical objective is the development of predictive thermal models that account for complex electrochemical reactions and their associated heat generation patterns. These models must accurately simulate heat transfer across multiple physical domains and time scales, from millisecond reaction kinetics to hour-long production cycles.

Looking forward, the field aims to achieve autonomous thermal management systems that can self-regulate based on real-time process parameters. This includes adaptive cooling strategies that optimize energy usage while maintaining ideal reaction conditions. Additionally, there is growing emphasis on sustainable cooling technologies that reduce water consumption and utilize waste heat recovery systems, aligning with broader industrial decarbonization efforts.

By the 1970s and 1980s, as industrial applications expanded, more sophisticated thermal management approaches emerged. The introduction of computer-controlled temperature regulation systems allowed for precise thermal profiles across reactor components. This period also witnessed the first comprehensive studies correlating heat distribution patterns with electrochemical performance metrics.

The 1990s through early 2000s saw integration of advanced materials with superior thermal conductivity properties, enabling more efficient heat transfer within reactor systems. Computational fluid dynamics (CFD) modeling became instrumental in predicting thermal behavior, allowing engineers to identify hotspots and optimize cooling strategies before physical implementation.

Current electrochemical reactor designs incorporate multi-zone temperature control, phase-change cooling materials, and intelligent thermal management algorithms. These innovations have pushed operational capabilities to new heights, yet significant challenges remain in scaling these solutions for industrial throughput requirements.

The primary objective of modern electrochemical reactor heat management is to maintain optimal temperature distributions while accommodating increasing production demands. This involves developing systems capable of handling higher current densities without thermal runaway conditions. Specific technical goals include reducing temperature gradients across electrode surfaces to below 5°C, minimizing energy consumption for cooling processes, and ensuring rapid response to thermal fluctuations during variable load operations.

Another critical objective is the development of predictive thermal models that account for complex electrochemical reactions and their associated heat generation patterns. These models must accurately simulate heat transfer across multiple physical domains and time scales, from millisecond reaction kinetics to hour-long production cycles.

Looking forward, the field aims to achieve autonomous thermal management systems that can self-regulate based on real-time process parameters. This includes adaptive cooling strategies that optimize energy usage while maintaining ideal reaction conditions. Additionally, there is growing emphasis on sustainable cooling technologies that reduce water consumption and utilize waste heat recovery systems, aligning with broader industrial decarbonization efforts.

Industrial Market Demand for Advanced Heat Management Solutions

The global market for advanced heat management solutions in electrochemical reactors is experiencing unprecedented growth, driven primarily by the rapid expansion of green hydrogen production, energy storage systems, and industrial electrosynthesis processes. Current market valuations indicate that the thermal management segment within the electrochemical sector reached approximately 3.2 billion USD in 2022, with projections suggesting a compound annual growth rate of 14.7% through 2030.

Industries are increasingly demanding more efficient heat management solutions as they scale up electrochemical processes from laboratory to industrial production levels. This demand stems from the critical relationship between temperature control and process efficiency, where even minor temperature fluctuations can significantly impact reaction rates, selectivity, and overall system performance. For instance, in hydrogen production via water electrolysis, maintaining optimal temperature ranges can improve energy efficiency by up to 25% while extending catalyst lifespan.

Chemical manufacturing corporations are particularly vocal about their need for heat management systems that can handle higher throughput without compromising on precision. The pharmaceutical industry requires solutions that maintain strict temperature uniformity across reactor volumes to ensure product quality and consistency. Meanwhile, metal processing industries seek robust systems capable of managing the intense heat generated during electrowinning and electrorefining operations.

Energy storage manufacturers have identified thermal management as a primary bottleneck in scaling up production of flow batteries and other large-scale electrochemical storage systems. Their requirements focus on solutions that can handle variable load conditions while maintaining stable operating temperatures to prevent degradation of expensive electrolytes and membrane materials.

Geographically, the strongest demand is emerging from regions with aggressive decarbonization targets, particularly the European Union, North America, and East Asia. These markets are characterized by stringent regulatory frameworks that incentivize the adoption of electrochemical processes as alternatives to traditional carbon-intensive manufacturing methods.

The market is also witnessing a shift in customer preferences toward integrated solutions that combine advanced heat exchangers, precise temperature monitoring systems, and intelligent control algorithms. End-users increasingly value systems that offer predictive maintenance capabilities and remote monitoring functionality, reflecting the broader industrial trend toward digitalization and Industry 4.0 principles.

Cost considerations remain paramount, with industries seeking solutions that optimize the balance between capital expenditure and operational efficiency. There is particular interest in heat management technologies that can recover and repurpose waste heat, thereby improving the overall energy economics of electrochemical processes and contributing to sustainability goals.

Industries are increasingly demanding more efficient heat management solutions as they scale up electrochemical processes from laboratory to industrial production levels. This demand stems from the critical relationship between temperature control and process efficiency, where even minor temperature fluctuations can significantly impact reaction rates, selectivity, and overall system performance. For instance, in hydrogen production via water electrolysis, maintaining optimal temperature ranges can improve energy efficiency by up to 25% while extending catalyst lifespan.

Chemical manufacturing corporations are particularly vocal about their need for heat management systems that can handle higher throughput without compromising on precision. The pharmaceutical industry requires solutions that maintain strict temperature uniformity across reactor volumes to ensure product quality and consistency. Meanwhile, metal processing industries seek robust systems capable of managing the intense heat generated during electrowinning and electrorefining operations.

Energy storage manufacturers have identified thermal management as a primary bottleneck in scaling up production of flow batteries and other large-scale electrochemical storage systems. Their requirements focus on solutions that can handle variable load conditions while maintaining stable operating temperatures to prevent degradation of expensive electrolytes and membrane materials.

Geographically, the strongest demand is emerging from regions with aggressive decarbonization targets, particularly the European Union, North America, and East Asia. These markets are characterized by stringent regulatory frameworks that incentivize the adoption of electrochemical processes as alternatives to traditional carbon-intensive manufacturing methods.

The market is also witnessing a shift in customer preferences toward integrated solutions that combine advanced heat exchangers, precise temperature monitoring systems, and intelligent control algorithms. End-users increasingly value systems that offer predictive maintenance capabilities and remote monitoring functionality, reflecting the broader industrial trend toward digitalization and Industry 4.0 principles.

Cost considerations remain paramount, with industries seeking solutions that optimize the balance between capital expenditure and operational efficiency. There is particular interest in heat management technologies that can recover and repurpose waste heat, thereby improving the overall energy economics of electrochemical processes and contributing to sustainability goals.

Current Thermal Control Challenges in Electrochemical Systems

Electrochemical reactors face significant thermal management challenges that directly impact their industrial viability and performance. The primary issue stems from the inherent nature of electrochemical reactions, which often generate substantial heat during operation. This heat generation is non-uniform across reactor components, creating thermal gradients that can lead to material stress, reduced efficiency, and accelerated degradation of critical components.

In large-scale industrial applications, the challenge intensifies as reactor size increases, making heat distribution more uneven and difficult to control. Current cooling systems frequently struggle to maintain optimal temperature profiles throughout the entire reactor volume, particularly in high-throughput operations where reaction rates are maximized for production efficiency.

Temperature fluctuations present another major obstacle, as electrochemical processes typically have narrow optimal temperature windows. Deviations from these ranges can dramatically alter reaction kinetics, selectivity, and yield. For instance, in lithium-ion battery production, temperature variations as small as 5°C can reduce cell capacity by up to 10% and significantly impact cycle life.

Heat removal mechanisms in existing systems often rely on conventional approaches such as liquid cooling channels or heat exchangers. These methods become increasingly inefficient at industrial scales due to limitations in heat transfer coefficients and the physical constraints of reactor design. The trade-off between effective cooling and maintaining compact reactor dimensions represents a significant engineering challenge.

Material limitations further complicate thermal management strategies. Many electrochemical systems utilize components with poor thermal conductivity or temperature-sensitive properties. Polymer electrolyte membranes in fuel cells, for example, require precise humidity and temperature control to maintain proton conductivity while avoiding degradation.

Energy efficiency concerns also plague current thermal control systems. Cooling infrastructure can consume 20-30% of the total energy input in some electrochemical processes, substantially reducing overall system efficiency. This parasitic energy loss undermines the economic and environmental benefits that make electrochemical technologies attractive alternatives to conventional processes.

Monitoring and control systems present additional challenges, as real-time temperature measurement within electrochemical reactors remains difficult due to harsh chemical environments and electromagnetic interference. Without accurate temperature data, implementing effective control strategies becomes problematic, leading to suboptimal performance and increased safety risks.

As industrial applications push toward higher throughput and energy density, these thermal management challenges become increasingly critical bottlenecks that must be addressed through innovative engineering solutions and advanced materials development.

In large-scale industrial applications, the challenge intensifies as reactor size increases, making heat distribution more uneven and difficult to control. Current cooling systems frequently struggle to maintain optimal temperature profiles throughout the entire reactor volume, particularly in high-throughput operations where reaction rates are maximized for production efficiency.

Temperature fluctuations present another major obstacle, as electrochemical processes typically have narrow optimal temperature windows. Deviations from these ranges can dramatically alter reaction kinetics, selectivity, and yield. For instance, in lithium-ion battery production, temperature variations as small as 5°C can reduce cell capacity by up to 10% and significantly impact cycle life.

Heat removal mechanisms in existing systems often rely on conventional approaches such as liquid cooling channels or heat exchangers. These methods become increasingly inefficient at industrial scales due to limitations in heat transfer coefficients and the physical constraints of reactor design. The trade-off between effective cooling and maintaining compact reactor dimensions represents a significant engineering challenge.

Material limitations further complicate thermal management strategies. Many electrochemical systems utilize components with poor thermal conductivity or temperature-sensitive properties. Polymer electrolyte membranes in fuel cells, for example, require precise humidity and temperature control to maintain proton conductivity while avoiding degradation.

Energy efficiency concerns also plague current thermal control systems. Cooling infrastructure can consume 20-30% of the total energy input in some electrochemical processes, substantially reducing overall system efficiency. This parasitic energy loss undermines the economic and environmental benefits that make electrochemical technologies attractive alternatives to conventional processes.

Monitoring and control systems present additional challenges, as real-time temperature measurement within electrochemical reactors remains difficult due to harsh chemical environments and electromagnetic interference. Without accurate temperature data, implementing effective control strategies becomes problematic, leading to suboptimal performance and increased safety risks.

As industrial applications push toward higher throughput and energy density, these thermal management challenges become increasingly critical bottlenecks that must be addressed through innovative engineering solutions and advanced materials development.

Contemporary Thermal Regulation Methodologies

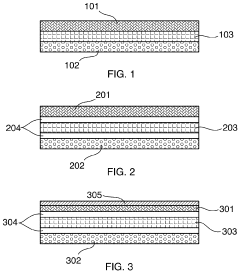

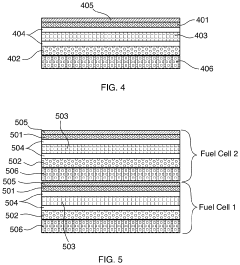

01 Cooling systems for electrochemical reactors

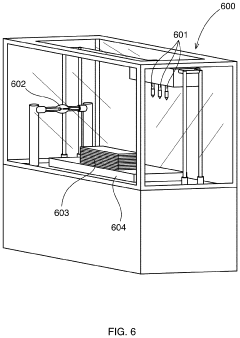

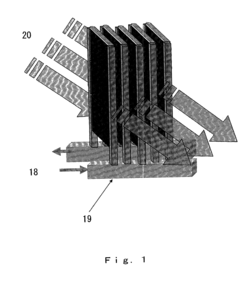

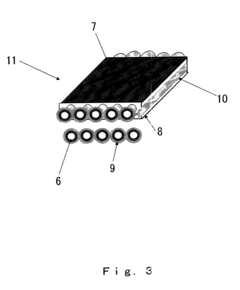

Various cooling systems can be implemented in electrochemical reactors to manage heat generation during operation. These systems include liquid cooling circuits, heat exchangers, and cooling plates that efficiently remove excess heat from the reactor core. Proper thermal management prevents overheating, extends component lifespan, and maintains optimal operating conditions for electrochemical reactions.- Cooling systems for electrochemical reactors: Various cooling systems can be implemented in electrochemical reactors to manage heat generation during operation. These systems include liquid cooling circuits, heat exchangers, and cooling plates that efficiently remove excess heat from the reactor core. Proper thermal management prevents overheating, extends component lifespan, and maintains optimal reaction conditions for electrochemical processes.

- Heat recovery and utilization systems: Heat generated during electrochemical reactions can be recovered and utilized for other purposes, improving overall system efficiency. These systems capture waste heat through specialized heat exchangers and redirect it for space heating, preheating reactants, or powering secondary processes. This approach reduces energy consumption and operational costs while minimizing environmental impact.

- Temperature control in fuel cell systems: Fuel cell systems require precise temperature control to maintain optimal performance and efficiency. This involves integrated cooling channels, thermal management subsystems, and temperature sensors that work together to regulate operating temperatures. Effective heat management in fuel cells prevents membrane degradation, catalyst poisoning, and ensures consistent power output during varying load conditions.

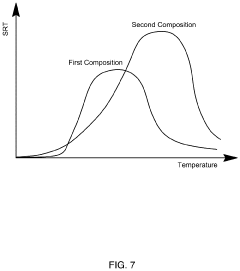

- Phase change materials for thermal regulation: Phase change materials (PCMs) can be incorporated into electrochemical reactor designs to absorb excess heat during operation and release it when needed. These materials undergo phase transitions at specific temperatures, providing passive thermal regulation without additional energy input. PCMs help maintain stable operating temperatures, reduce thermal cycling stress, and can be particularly useful in applications with intermittent operation.

- Advanced thermal management for flow batteries: Flow batteries require specialized thermal management approaches due to their unique architecture and operating principles. These systems often incorporate external cooling loops, heat exchangers integrated with electrolyte tanks, and temperature-controlled electrolyte circulation. Effective thermal management in flow batteries prevents electrolyte degradation, maintains membrane integrity, and ensures consistent performance across varying charge-discharge cycles.

02 Heat recovery and utilization in electrochemical systems

Heat generated during electrochemical reactions can be recovered and utilized for other purposes, improving overall system efficiency. Methods include capturing waste heat for preheating reactants, generating steam, or supporting auxiliary systems. These approaches transform what would otherwise be wasted thermal energy into valuable resources, enhancing the economic and environmental performance of electrochemical reactors.Expand Specific Solutions03 Temperature control strategies for fuel cells

Specialized temperature control strategies are employed in fuel cell systems to maintain optimal operating conditions. These include active thermal management systems, temperature sensors with feedback control loops, and specialized cooling plates integrated into the cell stack design. Precise temperature control ensures consistent electrochemical performance, prevents membrane degradation, and optimizes power output across varying load conditions.Expand Specific Solutions04 Thermal management in flow batteries and electrolyzers

Flow batteries and electrolyzers require specific thermal management approaches due to their unique operational characteristics. Solutions include electrolyte circulation systems that simultaneously manage reactant delivery and heat removal, specialized heat exchanger designs, and thermally conductive bipolar plates. These systems balance the need for uniform temperature distribution while accommodating the flow of electrolytes through the reactor.Expand Specific Solutions05 Advanced materials and designs for thermal regulation

Innovative materials and structural designs enhance thermal regulation in electrochemical reactors. These include thermally conductive composites, phase change materials for passive temperature control, and geometrically optimized flow channels that promote uniform heat distribution. Advanced manufacturing techniques enable the creation of complex internal structures that simultaneously address electrical conductivity, reactant distribution, and thermal management requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions Analysis

Electrochemical reactor heat management for industrial throughput is currently in a growth phase, with the market expected to reach significant scale as industries transition toward more sustainable chemical processing methods. The competitive landscape features established chemical giants like BASF, LG Chem, and Sinopec focusing on large-scale implementation, while specialized players such as NuScale Power and Lydian Labs develop innovative thermal management solutions. Technical maturity varies considerably across applications, with companies like Linde and Shell demonstrating advanced heat integration systems for industrial electrochemical processes, while academic institutions including Zhejiang University and Politecnico di Milano contribute fundamental research. The sector is experiencing accelerated development driven by decarbonization initiatives and efficiency requirements in energy-intensive chemical manufacturing.

BASF Corp.

Technical Solution: BASF has developed advanced thermal management systems for electrochemical reactors that integrate multi-phase cooling technologies with precise temperature control mechanisms. Their approach combines microstructured heat exchangers with specialized cooling fluids to maintain optimal temperature profiles across reactor surfaces. The system employs distributed temperature sensors and adaptive control algorithms that continuously adjust cooling parameters based on reaction kinetics and heat generation patterns. BASF's solution incorporates phase-change materials within reactor walls that absorb excess heat during exothermic peaks and release it during endothermic phases, effectively dampening temperature fluctuations. This technology has demonstrated the ability to maintain temperature variations within ±1.5°C across industrial-scale reactors, enabling consistent product quality and extended catalyst lifetimes.

Strengths: Superior temperature uniformity across large reactor volumes; integrated sensor networks for real-time monitoring; reduced energy consumption compared to conventional cooling systems. Weaknesses: Higher initial capital investment; requires specialized maintenance expertise; system complexity increases vulnerability to component failures.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a comprehensive heat management solution for large-scale electrochemical reactors used in battery material production. Their system employs a dual-circuit cooling architecture with primary and secondary coolant loops that enable precise zonal temperature control. The primary innovation lies in their proprietary heat transfer fluid formulation that maintains optimal viscosity and thermal conductivity across wide temperature ranges. LG's reactors incorporate embedded cooling channels with variable geometry that intensifies heat transfer in high-heat-flux regions while maintaining uniform flow distribution. The system utilizes predictive thermal modeling algorithms that anticipate heat generation patterns based on reaction progress and adjusts cooling parameters proactively rather than reactively. This approach has enabled LG to achieve throughput increases of approximately 40% in their electrode material production facilities while maintaining strict quality parameters.

Strengths: Exceptional scalability for industrial applications; advanced predictive control systems; demonstrated production throughput improvements. Weaknesses: High system complexity requiring specialized engineering support; significant customization needed for different reaction chemistries; higher operational costs compared to simpler cooling systems.

Critical Patents in Electrochemical Reactor Cooling

Heat Exchanger for an Electrochemical Reactor and Method of Making

PatentInactiveUS20200235410A1

Innovation

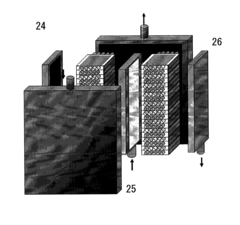

- An electrochemical reactor design incorporating a stack with multiple repeat units separated by interconnects, featuring a heat exchanger in close proximity to the electrodes, and a reformer integrated within the heat exchanger, optimized for compactness and efficiency, using additive manufacturing techniques for layer formation and electromagnetic radiation for sintering.

Electrochemical reactor units and modules and systems composed of them

PatentActiveUS8642229B2

Innovation

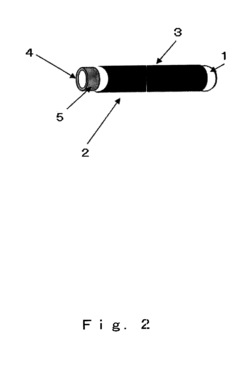

- The development of an electrochemical reactor unit with tube-type cells integrated in a porous material body having heat dissipation and current collection functions, where the cells are arranged in series and connected with a fuel supply system, allowing for efficient heat control and reduced air pressure loss, and the use of a ceramic hollow tube structure with a dense electrolyte layer and a micro-size diameter to facilitate lower operating temperatures.

Energy Recovery Opportunities from Waste Heat

Electrochemical reactors generate significant amounts of waste heat during operation, presenting valuable opportunities for energy recovery that can substantially improve overall system efficiency. The waste heat streams from these reactors typically range from 60°C to over 200°C depending on the specific electrochemical process, creating multiple recovery pathways with varying technical and economic feasibility.

Primary recovery opportunities exist in direct thermal energy utilization, where waste heat can be captured through heat exchangers and redirected to preheat incoming reactants or electrolytes. This approach reduces the energy required for bringing fresh materials to reaction temperature, creating an immediate efficiency gain of 15-25% in many industrial applications. Implementation requires careful integration of heat exchange systems that can withstand the corrosive environments typical of electrochemical processes.

Conversion to electrical power represents another significant recovery pathway, particularly for higher-temperature waste streams. Organic Rankine Cycle (ORC) systems can effectively convert moderate-temperature waste heat (90-200°C) to electricity with efficiencies of 8-15%. For larger industrial installations, these systems can generate sufficient power to offset auxiliary equipment demands, reducing the facility's overall energy footprint.

Thermal storage solutions offer temporal flexibility in waste heat utilization. Phase change materials (PCMs) with melting points matched to waste heat temperatures can store thermal energy during peak production periods and release it during downtimes or when heating demands increase. This approach smooths energy demand curves and provides buffer capacity that enhances system resilience against fluctuations.

Integration with facility heating and cooling requirements presents perhaps the most immediately accessible recovery opportunity. Waste heat from electrochemical reactors can supply space heating, domestic hot water, or absorption cooling systems. Recent case studies demonstrate that such integrations can reduce facility HVAC energy consumption by 30-40% in appropriate climates and configurations.

Cascading heat utilization strategies, where waste heat serves multiple sequential purposes at decreasing temperature thresholds, maximize recovery potential. A well-designed cascade system might first use high-grade heat for power generation, then medium-grade heat for process heating, and finally low-grade heat for space conditioning, achieving overall recovery efficiencies exceeding 60% of available waste heat.

Primary recovery opportunities exist in direct thermal energy utilization, where waste heat can be captured through heat exchangers and redirected to preheat incoming reactants or electrolytes. This approach reduces the energy required for bringing fresh materials to reaction temperature, creating an immediate efficiency gain of 15-25% in many industrial applications. Implementation requires careful integration of heat exchange systems that can withstand the corrosive environments typical of electrochemical processes.

Conversion to electrical power represents another significant recovery pathway, particularly for higher-temperature waste streams. Organic Rankine Cycle (ORC) systems can effectively convert moderate-temperature waste heat (90-200°C) to electricity with efficiencies of 8-15%. For larger industrial installations, these systems can generate sufficient power to offset auxiliary equipment demands, reducing the facility's overall energy footprint.

Thermal storage solutions offer temporal flexibility in waste heat utilization. Phase change materials (PCMs) with melting points matched to waste heat temperatures can store thermal energy during peak production periods and release it during downtimes or when heating demands increase. This approach smooths energy demand curves and provides buffer capacity that enhances system resilience against fluctuations.

Integration with facility heating and cooling requirements presents perhaps the most immediately accessible recovery opportunity. Waste heat from electrochemical reactors can supply space heating, domestic hot water, or absorption cooling systems. Recent case studies demonstrate that such integrations can reduce facility HVAC energy consumption by 30-40% in appropriate climates and configurations.

Cascading heat utilization strategies, where waste heat serves multiple sequential purposes at decreasing temperature thresholds, maximize recovery potential. A well-designed cascade system might first use high-grade heat for power generation, then medium-grade heat for process heating, and finally low-grade heat for space conditioning, achieving overall recovery efficiencies exceeding 60% of available waste heat.

Scaling Considerations for Industrial Implementation

Scaling electrochemical reactor heat management systems from laboratory to industrial scale presents significant engineering challenges that must be addressed systematically. The heat transfer dynamics that function effectively at small scales often encounter limitations when implemented in large-scale industrial operations. Surface-to-volume ratios decrease dramatically with increased reactor size, fundamentally altering thermal behavior and necessitating redesigned heat management approaches.

Industrial implementation requires consideration of spatial heat distribution uniformity across larger reactor volumes. Temperature gradients become more pronounced in scaled-up systems, potentially leading to reaction inconsistencies, reduced product quality, and accelerated catalyst degradation in certain regions. Advanced computational fluid dynamics modeling becomes essential for predicting these thermal patterns before physical implementation.

Material selection criteria shift substantially when scaling to industrial throughput levels. Materials must withstand not only the electrochemical environment but also thermal cycling under continuous operation conditions. Thermal expansion compatibility between different reactor components becomes increasingly critical as dimensions increase, necessitating careful engineering to prevent mechanical failures during thermal fluctuations.

Energy efficiency considerations become paramount at industrial scale, where even small percentage losses translate to significant operational costs. Heat recovery systems that may be optional at laboratory scale become economically essential components of industrial implementations. Integration of waste heat utilization into broader facility thermal management can significantly improve overall process economics.

Control system complexity increases exponentially with scale. Industrial systems require sophisticated sensor networks, predictive algorithms, and redundant safety mechanisms to maintain optimal thermal conditions across larger reactor volumes. Response time to thermal events becomes more challenging as thermal mass increases, requiring anticipatory rather than reactive control strategies.

Maintenance accessibility must be engineered into scaled systems from the outset. Heat management components in industrial electrochemical reactors must be serviceable without complete system shutdown when possible. Modular design approaches allow for sectional maintenance while maintaining partial operational capacity, significantly improving facility uptime metrics.

Cost-benefit analysis of various cooling technologies shifts dramatically at industrial scale. Technologies with high capital costs but superior efficiency or reliability often become economically favorable compared to simpler systems with higher operational expenses or maintenance requirements. The amortization of advanced thermal management systems over larger production volumes frequently justifies more sophisticated approaches than would be practical at smaller scales.

Industrial implementation requires consideration of spatial heat distribution uniformity across larger reactor volumes. Temperature gradients become more pronounced in scaled-up systems, potentially leading to reaction inconsistencies, reduced product quality, and accelerated catalyst degradation in certain regions. Advanced computational fluid dynamics modeling becomes essential for predicting these thermal patterns before physical implementation.

Material selection criteria shift substantially when scaling to industrial throughput levels. Materials must withstand not only the electrochemical environment but also thermal cycling under continuous operation conditions. Thermal expansion compatibility between different reactor components becomes increasingly critical as dimensions increase, necessitating careful engineering to prevent mechanical failures during thermal fluctuations.

Energy efficiency considerations become paramount at industrial scale, where even small percentage losses translate to significant operational costs. Heat recovery systems that may be optional at laboratory scale become economically essential components of industrial implementations. Integration of waste heat utilization into broader facility thermal management can significantly improve overall process economics.

Control system complexity increases exponentially with scale. Industrial systems require sophisticated sensor networks, predictive algorithms, and redundant safety mechanisms to maintain optimal thermal conditions across larger reactor volumes. Response time to thermal events becomes more challenging as thermal mass increases, requiring anticipatory rather than reactive control strategies.

Maintenance accessibility must be engineered into scaled systems from the outset. Heat management components in industrial electrochemical reactors must be serviceable without complete system shutdown when possible. Modular design approaches allow for sectional maintenance while maintaining partial operational capacity, significantly improving facility uptime metrics.

Cost-benefit analysis of various cooling technologies shifts dramatically at industrial scale. Technologies with high capital costs but superior efficiency or reliability often become economically favorable compared to simpler systems with higher operational expenses or maintenance requirements. The amortization of advanced thermal management systems over larger production volumes frequently justifies more sophisticated approaches than would be practical at smaller scales.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!