Electrode Manufacturing Methods For High Current Density Operation

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

High Current Density Electrode Technology Background and Objectives

The evolution of electrode manufacturing has been a critical factor in advancing energy storage and conversion technologies over the past several decades. High current density electrode operation represents a significant frontier in this field, enabling more powerful and efficient energy systems across multiple applications including batteries, fuel cells, and electrolyzers. Historically, electrode manufacturing has progressed from basic hand-crafted approaches to sophisticated industrial processes, with each advancement pushing the boundaries of performance capabilities.

The fundamental challenge in high current density operation lies in managing the increased thermal and electrochemical stresses that occur when electrodes operate at elevated current levels. Traditional electrode designs often suffer from degradation, reduced lifespan, and safety concerns when pushed beyond conventional operating parameters. This has created a technological bottleneck that limits the power density of many energy systems.

Recent technological trends show a convergence of materials science, nanotechnology, and advanced manufacturing techniques to overcome these limitations. The integration of novel materials such as carbon nanotubes, graphene, and advanced metal alloys has opened new possibilities for electrode structures that can withstand higher current densities while maintaining stability and performance.

The primary objectives of high current density electrode technology development include achieving at least a 50% increase in operational current density without compromising electrode longevity, reducing manufacturing costs by 30-40% through process optimization, and enhancing safety profiles to enable widespread commercial adoption across multiple industries.

Another critical goal is the development of scalable manufacturing methods that can transition from laboratory demonstrations to industrial production while maintaining the precise microstructural control necessary for high-performance electrodes. This includes innovations in coating technologies, sintering processes, and quality control methodologies.

Environmental considerations have also become increasingly important, with objectives to reduce toxic materials in electrode manufacturing and decrease energy consumption during production by at least 25% compared to conventional methods. This aligns with broader sustainability goals across the energy sector.

The achievement of these objectives would enable transformative advances in multiple applications, including faster-charging batteries for electric vehicles, more efficient hydrogen production systems, and higher-power density fuel cells for both stationary and mobile applications. The economic impact of such advances is projected to be substantial, potentially reducing energy storage costs by up to 30% while enabling new capabilities in renewable energy integration and grid stabilization.

The fundamental challenge in high current density operation lies in managing the increased thermal and electrochemical stresses that occur when electrodes operate at elevated current levels. Traditional electrode designs often suffer from degradation, reduced lifespan, and safety concerns when pushed beyond conventional operating parameters. This has created a technological bottleneck that limits the power density of many energy systems.

Recent technological trends show a convergence of materials science, nanotechnology, and advanced manufacturing techniques to overcome these limitations. The integration of novel materials such as carbon nanotubes, graphene, and advanced metal alloys has opened new possibilities for electrode structures that can withstand higher current densities while maintaining stability and performance.

The primary objectives of high current density electrode technology development include achieving at least a 50% increase in operational current density without compromising electrode longevity, reducing manufacturing costs by 30-40% through process optimization, and enhancing safety profiles to enable widespread commercial adoption across multiple industries.

Another critical goal is the development of scalable manufacturing methods that can transition from laboratory demonstrations to industrial production while maintaining the precise microstructural control necessary for high-performance electrodes. This includes innovations in coating technologies, sintering processes, and quality control methodologies.

Environmental considerations have also become increasingly important, with objectives to reduce toxic materials in electrode manufacturing and decrease energy consumption during production by at least 25% compared to conventional methods. This aligns with broader sustainability goals across the energy sector.

The achievement of these objectives would enable transformative advances in multiple applications, including faster-charging batteries for electric vehicles, more efficient hydrogen production systems, and higher-power density fuel cells for both stationary and mobile applications. The economic impact of such advances is projected to be substantial, potentially reducing energy storage costs by up to 30% while enabling new capabilities in renewable energy integration and grid stabilization.

Market Analysis for Advanced Electrode Applications

The electrode manufacturing market for high current density applications is experiencing robust growth, driven by increasing demand across multiple sectors including electric vehicles, renewable energy storage systems, and advanced electronics. Current market valuations indicate the global advanced electrode market reached approximately 12 billion USD in 2023, with projections suggesting a compound annual growth rate of 18% through 2030.

Electric vehicle production represents the largest market segment, accounting for nearly 40% of advanced electrode demand. This is primarily due to the push for higher energy density batteries with faster charging capabilities and longer lifespans. The automotive industry's transition toward electrification has created unprecedented demand for electrodes capable of withstanding high current densities while maintaining structural integrity over thousands of charge-discharge cycles.

Energy storage systems form the second largest market segment at 25%, with grid-scale applications requiring electrodes that can handle rapid power fluctuations and maintain performance under variable load conditions. The intermittent nature of renewable energy sources necessitates storage solutions with high power density and rapid response characteristics.

Consumer electronics constitutes approximately 20% of the market, with manufacturers seeking electrodes that enable faster charging times and higher power outputs in increasingly compact devices. The remaining market share is distributed across industrial applications, aerospace, and emerging technologies.

Geographically, Asia-Pacific dominates electrode manufacturing with 45% market share, led by China, South Korea, and Japan. North America follows at 30%, with significant research and production facilities concentrated in the United States. Europe accounts for 20%, with particularly strong growth in countries with established automotive industries transitioning to electric vehicle production.

Market analysis reveals several key customer requirements driving innovation in electrode manufacturing methods: increased energy density (>350 Wh/kg), improved fast-charging capabilities (80% charge in <15 minutes), extended cycle life (>2000 cycles at 80% capacity retention), and reduced production costs. These requirements are pushing manufacturers toward novel electrode designs and manufacturing processes.

The competitive landscape features established battery manufacturers expanding their electrode production capabilities alongside specialized materials science companies developing proprietary manufacturing techniques. Recent market consolidation through strategic acquisitions indicates industry recognition of electrode manufacturing as a critical differentiator in the broader energy storage value chain.

Electric vehicle production represents the largest market segment, accounting for nearly 40% of advanced electrode demand. This is primarily due to the push for higher energy density batteries with faster charging capabilities and longer lifespans. The automotive industry's transition toward electrification has created unprecedented demand for electrodes capable of withstanding high current densities while maintaining structural integrity over thousands of charge-discharge cycles.

Energy storage systems form the second largest market segment at 25%, with grid-scale applications requiring electrodes that can handle rapid power fluctuations and maintain performance under variable load conditions. The intermittent nature of renewable energy sources necessitates storage solutions with high power density and rapid response characteristics.

Consumer electronics constitutes approximately 20% of the market, with manufacturers seeking electrodes that enable faster charging times and higher power outputs in increasingly compact devices. The remaining market share is distributed across industrial applications, aerospace, and emerging technologies.

Geographically, Asia-Pacific dominates electrode manufacturing with 45% market share, led by China, South Korea, and Japan. North America follows at 30%, with significant research and production facilities concentrated in the United States. Europe accounts for 20%, with particularly strong growth in countries with established automotive industries transitioning to electric vehicle production.

Market analysis reveals several key customer requirements driving innovation in electrode manufacturing methods: increased energy density (>350 Wh/kg), improved fast-charging capabilities (80% charge in <15 minutes), extended cycle life (>2000 cycles at 80% capacity retention), and reduced production costs. These requirements are pushing manufacturers toward novel electrode designs and manufacturing processes.

The competitive landscape features established battery manufacturers expanding their electrode production capabilities alongside specialized materials science companies developing proprietary manufacturing techniques. Recent market consolidation through strategic acquisitions indicates industry recognition of electrode manufacturing as a critical differentiator in the broader energy storage value chain.

Current Electrode Manufacturing Challenges and Limitations

Despite significant advancements in electrode manufacturing technologies, several critical challenges persist that limit the achievement of high current density operation in various electrochemical applications. Traditional electrode manufacturing methods often struggle with material uniformity issues, where inconsistent distribution of active materials leads to localized hotspots during operation. These hotspots not only reduce overall efficiency but also accelerate degradation processes, significantly shortening electrode lifespan under high current conditions.

Surface area optimization remains a fundamental limitation in current manufacturing approaches. Conventional coating and calendering processes frequently result in suboptimal active material exposure and restricted ion transport pathways. This becomes particularly problematic at high current densities where rapid ion movement is essential for maintaining performance. The trade-off between mechanical stability and porosity continues to challenge manufacturers seeking to balance structural integrity with electrochemical accessibility.

Interface engineering between electrode components presents another significant hurdle. Poor adhesion between active materials, conductive additives, and current collectors leads to increased contact resistance and potential delamination under thermal and mechanical stress induced by high current operation. Current manufacturing methods often fail to create robust interfaces capable of withstanding the extreme conditions associated with high-power applications.

Scalability issues further complicate the advancement of electrode manufacturing. Laboratory-scale techniques that demonstrate excellent performance for high current density applications frequently encounter significant challenges during scale-up to industrial production. Maintaining precise control over critical parameters such as thickness uniformity, porosity distribution, and material homogeneity becomes increasingly difficult at larger scales, resulting in performance inconsistencies across production batches.

The environmental impact of conventional electrode manufacturing processes also presents growing concerns. Many current methods rely on toxic solvents, energy-intensive drying steps, and generate significant waste materials. These environmental limitations are becoming increasingly restrictive as regulatory frameworks evolve, pushing manufacturers to develop greener alternatives while maintaining or improving electrode performance characteristics.

Cost considerations remain a persistent barrier to implementing advanced manufacturing techniques. Novel approaches that could potentially address many technical limitations often involve expensive equipment, specialized materials, or complex processing steps that significantly increase production costs. This economic constraint frequently forces manufacturers to compromise on performance capabilities, particularly for mass-market applications where price sensitivity is high.

Surface area optimization remains a fundamental limitation in current manufacturing approaches. Conventional coating and calendering processes frequently result in suboptimal active material exposure and restricted ion transport pathways. This becomes particularly problematic at high current densities where rapid ion movement is essential for maintaining performance. The trade-off between mechanical stability and porosity continues to challenge manufacturers seeking to balance structural integrity with electrochemical accessibility.

Interface engineering between electrode components presents another significant hurdle. Poor adhesion between active materials, conductive additives, and current collectors leads to increased contact resistance and potential delamination under thermal and mechanical stress induced by high current operation. Current manufacturing methods often fail to create robust interfaces capable of withstanding the extreme conditions associated with high-power applications.

Scalability issues further complicate the advancement of electrode manufacturing. Laboratory-scale techniques that demonstrate excellent performance for high current density applications frequently encounter significant challenges during scale-up to industrial production. Maintaining precise control over critical parameters such as thickness uniformity, porosity distribution, and material homogeneity becomes increasingly difficult at larger scales, resulting in performance inconsistencies across production batches.

The environmental impact of conventional electrode manufacturing processes also presents growing concerns. Many current methods rely on toxic solvents, energy-intensive drying steps, and generate significant waste materials. These environmental limitations are becoming increasingly restrictive as regulatory frameworks evolve, pushing manufacturers to develop greener alternatives while maintaining or improving electrode performance characteristics.

Cost considerations remain a persistent barrier to implementing advanced manufacturing techniques. Novel approaches that could potentially address many technical limitations often involve expensive equipment, specialized materials, or complex processing steps that significantly increase production costs. This economic constraint frequently forces manufacturers to compromise on performance capabilities, particularly for mass-market applications where price sensitivity is high.

Current Manufacturing Methods for High Current Density Electrodes

01 Electrode design for optimal current density distribution

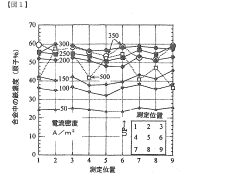

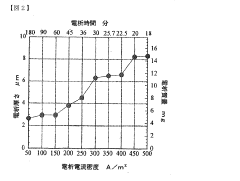

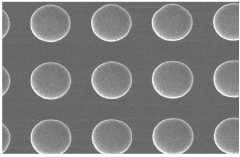

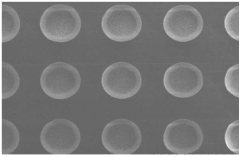

Specific electrode designs can optimize current density distribution across the electrode surface. These designs include shaped electrodes, patterned surfaces, and specialized geometries that help maintain uniform current flow. Such optimized designs are crucial in applications requiring precise control of electrical stimulation or electrochemical reactions, as they prevent hotspots and ensure consistent performance.- Electrode design for optimal current density distribution: Electrode design plays a crucial role in achieving optimal current density distribution. Various geometric configurations, surface treatments, and material selections can be employed to control how current flows through electrodes. Properly designed electrodes can minimize hotspots, ensure uniform current distribution, and enhance overall system efficiency. Advanced electrode designs may incorporate features like graduated surfaces or specialized patterns to direct current flow in desired patterns.

- Current density control in battery and energy storage applications: In battery and energy storage systems, controlling current density is essential for optimizing performance, extending lifespan, and ensuring safety. Techniques include specialized electrode materials, structured electrode surfaces, and advanced electrolyte formulations. Managing current density helps prevent dendrite formation, reduces internal resistance, and improves charge/discharge efficiency. These approaches enable higher energy density while maintaining thermal stability and preventing capacity degradation over multiple cycles.

- Medical and bioelectrical applications of controlled current density: In medical applications, precise control of electrode current density is critical for therapeutic effectiveness and patient safety. Applications include neural stimulation, cardiac pacing, and transcutaneous electrical nerve stimulation. By carefully managing current density, medical devices can deliver targeted stimulation to specific tissues while minimizing damage to surrounding areas. Advanced electrode designs incorporate biocompatible materials and specialized geometries to optimize the interface between electronic devices and biological tissues.

- Semiconductor and microelectronic manufacturing techniques: In semiconductor fabrication, controlling current density during processes like electroplating and etching is fundamental to achieving precise feature dimensions and uniform deposition. Techniques include pulse modulation, auxiliary electrodes, and specialized bath chemistry. These approaches enable the production of high-density interconnects, through-silicon vias, and advanced packaging solutions. Precise current density control allows for the creation of increasingly miniaturized electronic components with reliable performance characteristics.

- Novel materials and structures for enhanced current density handling: Research into novel materials and structures has led to electrodes capable of handling higher current densities without degradation. These innovations include nanostructured surfaces, composite materials, and specialized coatings that improve conductivity and thermal management. Such advances enable more compact designs, faster charging capabilities, and improved performance in high-power applications. These materials often exhibit superior resistance to corrosion, fouling, and mechanical stress under high current density conditions.

02 Materials selection for electrode current density enhancement

The choice of electrode materials significantly impacts current density capabilities. High-conductivity materials like certain metals, alloys, and advanced composites can support higher current densities without degradation. Some materials also feature microstructures that enhance surface area, further improving current density performance while maintaining electrode integrity during operation.Expand Specific Solutions03 Current density control in biomedical electrode applications

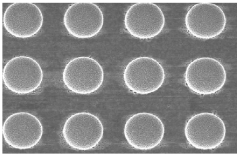

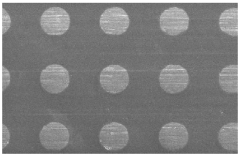

In biomedical applications, precise control of electrode current density is essential for safety and efficacy. Techniques include using specialized electrode configurations, impedance monitoring systems, and adaptive current delivery mechanisms. These approaches help maintain therapeutic current densities while preventing tissue damage, particularly important in neural stimulation, cardiac applications, and transcutaneous electrical nerve stimulation.Expand Specific Solutions04 Electrode surface modifications for current density optimization

Surface modifications can significantly alter electrode current density characteristics. Techniques include nano-texturing, coating with specialized materials, and chemical treatments that increase effective surface area. These modifications enhance charge transfer efficiency, reduce polarization effects, and improve overall electrode performance by creating more active sites for electrochemical reactions.Expand Specific Solutions05 Current density monitoring and control systems

Advanced systems for real-time monitoring and control of electrode current density ensure optimal performance and safety. These systems incorporate sensors, feedback mechanisms, and sophisticated algorithms to adjust current flow based on measured parameters. Such dynamic control is particularly valuable in industrial electrochemical processes, battery technologies, and medical devices where maintaining specific current density ranges is critical.Expand Specific Solutions

Leading Companies in High-Performance Electrode Industry

The electrode manufacturing methods for high current density operation market is currently in a growth phase, with increasing demand driven by electric vehicle adoption and renewable energy storage needs. The market size is expanding rapidly, projected to reach significant scale by 2030. Technologically, the field shows varying maturity levels across different approaches. Toyota Motor Corp. and Nissan lead automotive applications, while specialized players like Sila Nanotechnologies and LG Chem focus on breakthrough electrode technologies. TDK and Panasonic contribute expertise in materials engineering, while research institutions like KERI and Toyota Central R&D Labs advance fundamental innovations. The competitive landscape features both established manufacturers and emerging technology disruptors working to overcome current density limitations through novel materials and manufacturing processes.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive electrode manufacturing approach for high current density applications, particularly focused on electric vehicle applications. Their technology centers on a dry electrode manufacturing process that eliminates traditional NMP solvents, reducing environmental impact and manufacturing costs. Toyota's process incorporates specialized carbon fiber networks within the electrode structure that create dedicated electron pathways, significantly enhancing conductivity at high current loads. Their manufacturing method includes precise control of electrode microstructure through advanced particle engineering and specialized coating techniques that create hierarchical porosity structures. Toyota has also pioneered the use of 3D-structured current collectors with increased surface area that distribute current more effectively across the electrode surface, reducing localized heating and degradation during high-rate operation. The company employs advanced calendering techniques with precise pressure and temperature control to optimize the balance between electronic conductivity and ionic transport pathways.

Strengths: Environmentally friendly manufacturing process; excellent thermal management during high-rate operation; superior mechanical stability preventing electrode delamination. Weaknesses: Requires specialized manufacturing equipment that differs from industry standards; higher initial capital investment; technology still being scaled to mass production levels.

TDK Corp.

Technical Solution: TDK Corporation has developed advanced electrode manufacturing technologies specifically optimized for high current density applications across multiple sectors. Their approach centers on precision-engineered electrode microstructures with controlled porosity gradients that balance electronic conductivity with ionic transport pathways. TDK's manufacturing process incorporates specialized magnetic alignment techniques during electrode fabrication that create oriented conductive networks, significantly enhancing electronic conductivity in the through-plane direction. Their technology includes proprietary slurry formulations with nano-engineered conductive additives that form robust electronic pathways throughout the electrode matrix. TDK employs advanced coating techniques that achieve exceptional thickness uniformity (<1% variation) while maintaining precise control over electrode density. Additionally, they've pioneered specialized surface treatment processes that enhance the electrode-electrolyte interface, reducing interfacial resistance during high-rate operation. TDK's manufacturing also incorporates precision calendering with controlled temperature and pressure profiles that optimize the microstructure for specific high-current applications.

Strengths: Exceptional consistency in electrode properties across large production volumes; superior electronic conductivity networks that maintain performance at extreme current densities; excellent mechanical stability preventing electrode degradation. Weaknesses: Higher manufacturing complexity requiring sophisticated process controls; specialized equipment requirements increase production costs; some proprietary materials face supply chain constraints.

Key Patents and Innovations in Electrode Material Science

Manufacturing method of electrode for water electrolyte

PatentActiveJP2019023349A

Innovation

- Electrodeposition is performed at controlled current densities within specific ranges to ensure uniform alloy composition and enhance durability, using plating solutions with aminocarboxylic acid and boric acid, maintaining a pH of 2 or less, and forming Fe-Co-Ni-C or Ni-Fe-C alloys on appropriate substrates.

A method of low resistance electrode for high capacitor

PatentActiveKR1020130093726A

Innovation

- A method involving screen printing and selective etching on aluminum current collectors to form a stereoscopic pattern, using a chemical-resistant material like chloroprene, enhances the contact area and reduces resistance, thereby improving the effective capacity of ultra-high capacity capacitors.

Environmental Impact of Advanced Electrode Production

The manufacturing of electrodes for high current density applications presents significant environmental challenges that must be addressed as production scales increase. Advanced electrode production processes typically involve energy-intensive steps including material synthesis, coating, drying, and sintering. These processes consume substantial electrical energy, often derived from fossil fuel sources, contributing to greenhouse gas emissions. For instance, high-temperature sintering operations can require temperatures exceeding 1000°C maintained for extended periods, resulting in considerable carbon footprints when powered by non-renewable energy.

Chemical usage in electrode manufacturing poses another environmental concern. The production of high-performance electrodes frequently requires solvents like N-Methyl-2-pyrrolidone (NMP), which is classified as a reproductive toxin and faces increasing regulatory scrutiny. Additionally, binders such as polyvinylidene fluoride (PVDF) can release harmful fluorinated compounds during processing and disposal phases. The environmental persistence of these chemicals necessitates careful management throughout the product lifecycle.

Water consumption represents a third critical environmental factor. Electrode manufacturing processes typically require ultrapure water for mixing slurries and cleaning operations. A single manufacturing facility can consume millions of gallons annually, placing pressure on local water resources. Furthermore, wastewater from these operations often contains metal particulates and processing chemicals requiring specialized treatment before release.

Raw material extraction for advanced electrodes creates significant upstream environmental impacts. Rare earth elements and transition metals essential for high-performance electrodes often involve environmentally destructive mining practices. The extraction of cobalt, nickel, and lithium has been associated with habitat destruction, water pollution, and in some regions, social justice concerns related to mining conditions.

Recent innovations are addressing these environmental challenges through several approaches. Water-based electrode manufacturing processes are replacing solvent-based systems, reducing VOC emissions and hazardous waste. Dry electrode manufacturing techniques pioneered by companies like Tesla eliminate solvents entirely, significantly reducing environmental impact while potentially improving electrode performance for high current density applications.

Energy efficiency improvements in manufacturing equipment, particularly in energy-intensive drying and sintering processes, are reducing the carbon footprint of electrode production. Additionally, closed-loop recycling systems are being implemented to recover valuable materials from production scrap and end-of-life electrodes, reducing the demand for virgin raw materials and associated environmental impacts.

Chemical usage in electrode manufacturing poses another environmental concern. The production of high-performance electrodes frequently requires solvents like N-Methyl-2-pyrrolidone (NMP), which is classified as a reproductive toxin and faces increasing regulatory scrutiny. Additionally, binders such as polyvinylidene fluoride (PVDF) can release harmful fluorinated compounds during processing and disposal phases. The environmental persistence of these chemicals necessitates careful management throughout the product lifecycle.

Water consumption represents a third critical environmental factor. Electrode manufacturing processes typically require ultrapure water for mixing slurries and cleaning operations. A single manufacturing facility can consume millions of gallons annually, placing pressure on local water resources. Furthermore, wastewater from these operations often contains metal particulates and processing chemicals requiring specialized treatment before release.

Raw material extraction for advanced electrodes creates significant upstream environmental impacts. Rare earth elements and transition metals essential for high-performance electrodes often involve environmentally destructive mining practices. The extraction of cobalt, nickel, and lithium has been associated with habitat destruction, water pollution, and in some regions, social justice concerns related to mining conditions.

Recent innovations are addressing these environmental challenges through several approaches. Water-based electrode manufacturing processes are replacing solvent-based systems, reducing VOC emissions and hazardous waste. Dry electrode manufacturing techniques pioneered by companies like Tesla eliminate solvents entirely, significantly reducing environmental impact while potentially improving electrode performance for high current density applications.

Energy efficiency improvements in manufacturing equipment, particularly in energy-intensive drying and sintering processes, are reducing the carbon footprint of electrode production. Additionally, closed-loop recycling systems are being implemented to recover valuable materials from production scrap and end-of-life electrodes, reducing the demand for virgin raw materials and associated environmental impacts.

Scalability and Cost Analysis of Manufacturing Methods

The scalability of electrode manufacturing methods for high current density operation represents a critical factor in the commercial viability of advanced battery and energy storage technologies. Current manufacturing processes face significant challenges when scaled to industrial production levels, particularly when optimized for high current density applications.

Traditional electrode manufacturing techniques such as slurry casting demonstrate reasonable scalability but often compromise performance at high current densities when scaled up. The capital expenditure for establishing large-scale manufacturing facilities utilizing conventional methods ranges from $50-100 million for a production capacity of 1 GWh annually, with economies of scale reducing unit costs by approximately 15-20% for each doubling of production volume.

Advanced manufacturing methods such as direct deposition and 3D-structured electrode fabrication show promising performance characteristics but present more complex scaling challenges. These methods typically require 30-40% higher initial capital investment compared to conventional techniques, though they potentially offer 25-35% reduction in material waste and associated costs.

Energy consumption represents another significant cost factor in electrode manufacturing. Conventional methods require 60-80 kWh per kWh of battery capacity produced, while newer techniques optimized for high current density operation may reduce this to 40-60 kWh through more efficient material utilization and reduced processing steps.

Material costs constitute 50-70% of total manufacturing expenses, with high-performance electrode materials for high current density applications commanding premium prices. Manufacturing methods that reduce material waste or enable the use of lower-cost precursors can significantly impact overall economics. Advanced techniques have demonstrated potential material cost reductions of 15-25% compared to conventional processes.

Labor costs vary significantly by region, representing 5-15% of total manufacturing costs in developed economies and 3-8% in emerging markets. Highly automated manufacturing lines optimized for high current density electrode production typically reduce labor requirements by 40-60% but increase capital equipment costs by 25-35%.

The economic viability threshold for new manufacturing methods appears to be reached when production volumes exceed 500 MWh annually, with full cost competitiveness achieved at the gigawatt-hour scale. Emerging manufacturing techniques must demonstrate at least a 20% improvement in electrode performance at high current densities to justify the 15-25% cost premium typically associated with novel production methods during early adoption phases.

Traditional electrode manufacturing techniques such as slurry casting demonstrate reasonable scalability but often compromise performance at high current densities when scaled up. The capital expenditure for establishing large-scale manufacturing facilities utilizing conventional methods ranges from $50-100 million for a production capacity of 1 GWh annually, with economies of scale reducing unit costs by approximately 15-20% for each doubling of production volume.

Advanced manufacturing methods such as direct deposition and 3D-structured electrode fabrication show promising performance characteristics but present more complex scaling challenges. These methods typically require 30-40% higher initial capital investment compared to conventional techniques, though they potentially offer 25-35% reduction in material waste and associated costs.

Energy consumption represents another significant cost factor in electrode manufacturing. Conventional methods require 60-80 kWh per kWh of battery capacity produced, while newer techniques optimized for high current density operation may reduce this to 40-60 kWh through more efficient material utilization and reduced processing steps.

Material costs constitute 50-70% of total manufacturing expenses, with high-performance electrode materials for high current density applications commanding premium prices. Manufacturing methods that reduce material waste or enable the use of lower-cost precursors can significantly impact overall economics. Advanced techniques have demonstrated potential material cost reductions of 15-25% compared to conventional processes.

Labor costs vary significantly by region, representing 5-15% of total manufacturing costs in developed economies and 3-8% in emerging markets. Highly automated manufacturing lines optimized for high current density electrode production typically reduce labor requirements by 40-60% but increase capital equipment costs by 25-35%.

The economic viability threshold for new manufacturing methods appears to be reached when production volumes exceed 500 MWh annually, with full cost competitiveness achieved at the gigawatt-hour scale. Emerging manufacturing techniques must demonstrate at least a 20% improvement in electrode performance at high current densities to justify the 15-25% cost premium typically associated with novel production methods during early adoption phases.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!