Catalytic Cracking Properties of 2-Methylpentane in Petrochemical Industries

JUL 25, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalytic Cracking Background and Objectives

Catalytic cracking has been a cornerstone technology in the petrochemical industry for decades, playing a crucial role in the conversion of heavy hydrocarbon fractions into more valuable, lighter products. The process, which originated in the 1920s, has undergone significant evolution, driven by the ever-increasing demand for high-quality fuels and petrochemical feedstocks.

The development of catalytic cracking technology has been closely tied to advancements in catalyst design and process engineering. Early catalysts were primarily composed of naturally occurring clay materials, but the introduction of synthetic zeolites in the 1960s revolutionized the field, dramatically improving product yields and selectivity.

In recent years, the focus of catalytic cracking research has shifted towards optimizing the conversion of specific hydrocarbon molecules, such as 2-methylpentane, to meet the changing demands of the petrochemical market. 2-methylpentane, a branched alkane, is of particular interest due to its potential as a high-octane blending component for gasoline and as a precursor for various petrochemical products.

The primary objective of studying the catalytic cracking properties of 2-methylpentane is to enhance the overall efficiency and selectivity of the cracking process. This involves understanding the reaction mechanisms, identifying optimal catalyst compositions, and determining the most favorable operating conditions for maximizing desired product yields while minimizing unwanted byproducts.

Furthermore, the investigation of 2-methylpentane cracking properties aligns with broader industry goals of improving energy efficiency, reducing environmental impact, and adapting to evolving feedstock compositions. As refineries increasingly process unconventional crude oils and seek to maximize the value of each barrel, understanding the behavior of specific hydrocarbon components becomes crucial.

Another key objective is to develop predictive models that can accurately simulate the cracking behavior of 2-methylpentane under various conditions. Such models would enable refiners to optimize their processes in real-time, adjusting operating parameters to respond to changes in feedstock composition or market demands.

The study of 2-methylpentane cracking also has implications for the development of novel catalytic materials. By understanding the molecular interactions between this specific hydrocarbon and various catalyst surfaces, researchers aim to design next-generation catalysts with enhanced activity, selectivity, and stability.

In the broader context of the petrochemical industry's future, this research contributes to the ongoing efforts to diversify product streams and increase the flexibility of refining operations. As the industry faces pressure to reduce its carbon footprint, insights gained from studying specific hydrocarbons like 2-methylpentane could potentially lead to more efficient and environmentally friendly cracking processes.

The development of catalytic cracking technology has been closely tied to advancements in catalyst design and process engineering. Early catalysts were primarily composed of naturally occurring clay materials, but the introduction of synthetic zeolites in the 1960s revolutionized the field, dramatically improving product yields and selectivity.

In recent years, the focus of catalytic cracking research has shifted towards optimizing the conversion of specific hydrocarbon molecules, such as 2-methylpentane, to meet the changing demands of the petrochemical market. 2-methylpentane, a branched alkane, is of particular interest due to its potential as a high-octane blending component for gasoline and as a precursor for various petrochemical products.

The primary objective of studying the catalytic cracking properties of 2-methylpentane is to enhance the overall efficiency and selectivity of the cracking process. This involves understanding the reaction mechanisms, identifying optimal catalyst compositions, and determining the most favorable operating conditions for maximizing desired product yields while minimizing unwanted byproducts.

Furthermore, the investigation of 2-methylpentane cracking properties aligns with broader industry goals of improving energy efficiency, reducing environmental impact, and adapting to evolving feedstock compositions. As refineries increasingly process unconventional crude oils and seek to maximize the value of each barrel, understanding the behavior of specific hydrocarbon components becomes crucial.

Another key objective is to develop predictive models that can accurately simulate the cracking behavior of 2-methylpentane under various conditions. Such models would enable refiners to optimize their processes in real-time, adjusting operating parameters to respond to changes in feedstock composition or market demands.

The study of 2-methylpentane cracking also has implications for the development of novel catalytic materials. By understanding the molecular interactions between this specific hydrocarbon and various catalyst surfaces, researchers aim to design next-generation catalysts with enhanced activity, selectivity, and stability.

In the broader context of the petrochemical industry's future, this research contributes to the ongoing efforts to diversify product streams and increase the flexibility of refining operations. As the industry faces pressure to reduce its carbon footprint, insights gained from studying specific hydrocarbons like 2-methylpentane could potentially lead to more efficient and environmentally friendly cracking processes.

Market Analysis for 2-Methylpentane Cracking

The market for 2-methylpentane cracking in petrochemical industries has shown significant growth potential in recent years. This isomer of hexane plays a crucial role in the production of high-octane gasoline components and various petrochemical products. The global demand for 2-methylpentane is primarily driven by the increasing need for cleaner-burning fuels and the expansion of the petrochemical sector.

In the automotive industry, the push for more efficient and environmentally friendly vehicles has led to a rise in demand for high-octane gasoline blends. 2-Methylpentane, when cracked, produces valuable components that enhance fuel performance and reduce emissions. This trend is expected to continue as governments worldwide implement stricter emission standards and consumers seek more fuel-efficient vehicles.

The petrochemical industry's growth, particularly in emerging economies, has also contributed to the increased demand for 2-methylpentane cracking. As these countries invest in expanding their manufacturing capabilities, the need for various petrochemical products derived from 2-methylpentane has surged. This includes the production of plastics, synthetic rubbers, and other polymer-based materials.

Market analysis indicates that the Asia-Pacific region, led by China and India, is the fastest-growing market for 2-methylpentane cracking. The rapid industrialization and urbanization in these countries have fueled the demand for petrochemical products. North America and Europe, while mature markets, continue to show steady growth due to ongoing technological advancements in catalytic cracking processes.

The market is characterized by intense competition among major petrochemical companies, with a focus on developing more efficient cracking technologies. Investments in research and development are aimed at improving catalyst performance, reducing energy consumption, and minimizing environmental impact. This competitive landscape is driving innovation and creating opportunities for new market entrants with novel cracking solutions.

Environmental regulations and sustainability concerns are shaping the market dynamics for 2-methylpentane cracking. There is a growing emphasis on developing greener cracking processes that minimize waste and reduce carbon emissions. This trend is likely to influence future investments and technological developments in the sector.

The market for 2-methylpentane cracking is closely tied to crude oil prices and overall economic conditions. Fluctuations in oil prices can significantly impact the profitability of cracking operations and influence market growth. However, the diversification of feedstock sources, including the use of shale gas, has helped to mitigate some of these risks and stabilize the market.

In the automotive industry, the push for more efficient and environmentally friendly vehicles has led to a rise in demand for high-octane gasoline blends. 2-Methylpentane, when cracked, produces valuable components that enhance fuel performance and reduce emissions. This trend is expected to continue as governments worldwide implement stricter emission standards and consumers seek more fuel-efficient vehicles.

The petrochemical industry's growth, particularly in emerging economies, has also contributed to the increased demand for 2-methylpentane cracking. As these countries invest in expanding their manufacturing capabilities, the need for various petrochemical products derived from 2-methylpentane has surged. This includes the production of plastics, synthetic rubbers, and other polymer-based materials.

Market analysis indicates that the Asia-Pacific region, led by China and India, is the fastest-growing market for 2-methylpentane cracking. The rapid industrialization and urbanization in these countries have fueled the demand for petrochemical products. North America and Europe, while mature markets, continue to show steady growth due to ongoing technological advancements in catalytic cracking processes.

The market is characterized by intense competition among major petrochemical companies, with a focus on developing more efficient cracking technologies. Investments in research and development are aimed at improving catalyst performance, reducing energy consumption, and minimizing environmental impact. This competitive landscape is driving innovation and creating opportunities for new market entrants with novel cracking solutions.

Environmental regulations and sustainability concerns are shaping the market dynamics for 2-methylpentane cracking. There is a growing emphasis on developing greener cracking processes that minimize waste and reduce carbon emissions. This trend is likely to influence future investments and technological developments in the sector.

The market for 2-methylpentane cracking is closely tied to crude oil prices and overall economic conditions. Fluctuations in oil prices can significantly impact the profitability of cracking operations and influence market growth. However, the diversification of feedstock sources, including the use of shale gas, has helped to mitigate some of these risks and stabilize the market.

Current Challenges in 2-Methylpentane Cracking

The catalytic cracking of 2-methylpentane in petrochemical industries faces several significant challenges that hinder its efficiency and widespread application. One of the primary issues is the high energy requirement for the cracking process. The C-C bond cleavage in 2-methylpentane demands substantial thermal energy input, which translates to increased operational costs and reduced overall process efficiency.

Another challenge lies in the selectivity of the cracking process. Achieving precise control over the product distribution remains difficult, often resulting in a mixture of desired and undesired products. This lack of selectivity not only reduces the yield of valuable products but also complicates downstream separation processes, further impacting the economic viability of the operation.

Catalyst deactivation presents a persistent problem in 2-methylpentane cracking. The formation of coke deposits on the catalyst surface leads to a gradual decline in catalytic activity, necessitating frequent regeneration or replacement. This not only increases operational downtime but also adds to the overall cost of the process.

The presence of impurities in the feedstock poses another significant challenge. Sulfur compounds, in particular, can poison the catalyst, reducing its effectiveness and lifespan. Developing catalysts with improved resistance to sulfur poisoning remains an active area of research in the field.

Environmental concerns also play a crucial role in the challenges faced by 2-methylpentane cracking. The process generates greenhouse gas emissions, contributing to the carbon footprint of petrochemical industries. Stricter environmental regulations are pushing the industry to develop more sustainable cracking technologies with reduced emissions and improved energy efficiency.

Scale-up issues present hurdles in the industrial application of novel cracking technologies. Laboratory-scale successes often face difficulties when translated to commercial-scale operations, particularly in maintaining consistent product quality and process efficiency.

Lastly, the volatility of feedstock prices and the shifting demand for various petrochemical products create economic uncertainties. This market instability challenges the long-term viability of investments in 2-methylpentane cracking technologies, necessitating flexible and adaptable process designs.

Addressing these challenges requires a multifaceted approach, combining advancements in catalyst design, process engineering, and sustainable practices. The development of more efficient, selective, and robust catalysts remains a key focus area for overcoming many of these hurdles in 2-methylpentane cracking.

Another challenge lies in the selectivity of the cracking process. Achieving precise control over the product distribution remains difficult, often resulting in a mixture of desired and undesired products. This lack of selectivity not only reduces the yield of valuable products but also complicates downstream separation processes, further impacting the economic viability of the operation.

Catalyst deactivation presents a persistent problem in 2-methylpentane cracking. The formation of coke deposits on the catalyst surface leads to a gradual decline in catalytic activity, necessitating frequent regeneration or replacement. This not only increases operational downtime but also adds to the overall cost of the process.

The presence of impurities in the feedstock poses another significant challenge. Sulfur compounds, in particular, can poison the catalyst, reducing its effectiveness and lifespan. Developing catalysts with improved resistance to sulfur poisoning remains an active area of research in the field.

Environmental concerns also play a crucial role in the challenges faced by 2-methylpentane cracking. The process generates greenhouse gas emissions, contributing to the carbon footprint of petrochemical industries. Stricter environmental regulations are pushing the industry to develop more sustainable cracking technologies with reduced emissions and improved energy efficiency.

Scale-up issues present hurdles in the industrial application of novel cracking technologies. Laboratory-scale successes often face difficulties when translated to commercial-scale operations, particularly in maintaining consistent product quality and process efficiency.

Lastly, the volatility of feedstock prices and the shifting demand for various petrochemical products create economic uncertainties. This market instability challenges the long-term viability of investments in 2-methylpentane cracking technologies, necessitating flexible and adaptable process designs.

Addressing these challenges requires a multifaceted approach, combining advancements in catalyst design, process engineering, and sustainable practices. The development of more efficient, selective, and robust catalysts remains a key focus area for overcoming many of these hurdles in 2-methylpentane cracking.

Existing Catalytic Solutions for 2-Methylpentane

01 Catalytic cracking process for 2-methylpentane

The catalytic cracking of 2-methylpentane involves the use of specific catalysts and reaction conditions to break down the hydrocarbon molecule into smaller, more valuable products. This process typically occurs at high temperatures and pressures, utilizing zeolite-based catalysts or other specialized materials to facilitate the cracking reaction.- Catalytic cracking of 2-methylpentane: 2-Methylpentane undergoes catalytic cracking to produce lighter hydrocarbons. The process involves breaking down the molecule using catalysts, typically zeolites or other acidic materials, at high temperatures. This reaction is important in petroleum refining for converting heavier hydrocarbons into more valuable lighter products.

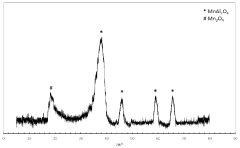

- Catalyst composition for 2-methylpentane cracking: Specific catalyst compositions are developed to optimize the cracking of 2-methylpentane. These catalysts often include zeolites, rare earth elements, and metal oxides. The composition is tailored to enhance selectivity towards desired products while minimizing coke formation and improving catalyst stability.

- Process conditions for 2-methylpentane cracking: Optimal process conditions for catalytic cracking of 2-methylpentane are crucial for maximizing yield and selectivity. Key parameters include temperature, pressure, catalyst-to-oil ratio, and residence time. These conditions are carefully controlled to balance conversion rates with product distribution and catalyst deactivation.

- Product distribution from 2-methylpentane cracking: The catalytic cracking of 2-methylpentane yields a range of products, including lighter alkanes, alkenes, and aromatics. Understanding and predicting this product distribution is essential for process optimization. Factors influencing the distribution include catalyst properties, reaction conditions, and the presence of other hydrocarbons in the feedstock.

- Catalyst regeneration in 2-methylpentane cracking: Catalyst deactivation occurs during the cracking of 2-methylpentane, primarily due to coke deposition. Effective regeneration techniques are crucial for maintaining catalyst activity and process efficiency. This involves controlled burning of coke deposits and may include special treatments to restore catalyst properties and extend its lifespan.

02 Catalyst composition for 2-methylpentane cracking

Specialized catalyst compositions are developed for the efficient cracking of 2-methylpentane. These catalysts often include zeolites, rare earth elements, and other active components that enhance selectivity and conversion rates. The composition is tailored to maximize the yield of desired products while minimizing unwanted byproducts.Expand Specific Solutions03 Reaction conditions optimization

Optimizing reaction conditions is crucial for effective catalytic cracking of 2-methylpentane. This includes controlling parameters such as temperature, pressure, residence time, and catalyst-to-oil ratio. Fine-tuning these conditions helps to achieve the desired product distribution and maximize overall process efficiency.Expand Specific Solutions04 Product distribution and selectivity

The catalytic cracking of 2-methylpentane yields a range of products, including lighter hydrocarbons and olefins. Understanding and controlling the product distribution is essential for maximizing the economic value of the process. Techniques are developed to enhance selectivity towards desired products such as propylene or gasoline-range hydrocarbons.Expand Specific Solutions05 Catalyst regeneration and process improvements

Continuous improvement of the catalytic cracking process for 2-methylpentane involves developing effective catalyst regeneration techniques and implementing process enhancements. This includes methods to remove coke deposits, maintain catalyst activity, and integrate advanced control systems for optimal performance and longevity of the cracking unit.Expand Specific Solutions

Key Players in Petrochemical Catalytic Cracking

The catalytic cracking of 2-methylpentane in petrochemical industries is in a mature stage of development, with a substantial global market size driven by the demand for high-octane gasoline components. The technology's maturity is evident from the involvement of major industry players like China Petroleum & Chemical Corp., ExxonMobil Chemical Patents, Inc., and SABIC Global Technologies BV. These companies have established research institutes and patented technologies, indicating a high level of technical sophistication. The competitive landscape is characterized by ongoing innovation efforts from both established petrochemical giants and specialized research institutions, such as the Shanghai Petrochemical Research Institute and East China University of Science & Technology, focusing on improving catalytic efficiency and selectivity.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed advanced catalytic cracking technologies for 2-methylpentane in petrochemical industries. Their approach involves using shape-selective zeolite catalysts with optimized pore structures to enhance the cracking selectivity of 2-methylpentane[1]. The company has implemented a two-stage reaction system, where the first stage focuses on initial cracking of 2-methylpentane, followed by a second stage that further converts the intermediate products into valuable light olefins[2]. Sinopec has also incorporated rare earth elements into their catalyst formulations to improve the catalyst stability and increase the yield of propylene, a high-value product from 2-methylpentane cracking[3]. Additionally, they have developed a proprietary process control system that adjusts reaction parameters in real-time based on feed composition and desired product distribution, ensuring optimal performance across varying feedstock qualities[4].

Strengths: Extensive experience in refinery operations, access to large-scale testing facilities, and strong R&D capabilities. Weaknesses: Potential over-reliance on traditional fossil fuel-based feedstocks, which may limit adaptability to future sustainable alternatives.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil Chemical Patents, Inc. has pioneered innovative approaches to catalytic cracking of 2-methylpentane. Their technology utilizes a dual-function catalyst system combining acidic and metallic sites to promote both cracking and isomerization reactions[5]. This approach allows for increased flexibility in product slate, enabling the production of both high-octane gasoline components and valuable petrochemical feedstocks. ExxonMobil has also developed a proprietary catalyst regeneration process that significantly extends catalyst lifetime and maintains high activity levels for 2-methylpentane conversion[6]. The company's research has focused on optimizing reaction conditions, including temperature and pressure profiles, to maximize the yield of desired products while minimizing coke formation[7]. Furthermore, ExxonMobil has implemented advanced process modeling and simulation tools to predict and optimize the behavior of 2-methylpentane in complex refinery streams, allowing for more efficient integration of catalytic cracking units within existing petrochemical complexes[8].

Strengths: Strong intellectual property portfolio, global research capabilities, and extensive experience in catalyst development. Weaknesses: Potential challenges in adapting technologies to smaller-scale operations or emerging markets with different regulatory environments.

Core Innovations in 2-Methylpentane Cracking

Method for preparation of ethylene and propylene by catalytic cracking using a fluid-bed catalyst

PatentActiveUS20090137857A1

Innovation

- A fluid-bed catalyst comprising a support such as SiO2, Al2O3, or molecular sieves with a specific chemical composition, including transition metals and rare earth elements, is used for catalytic cracking of naphtha at lower temperatures, enhancing catalyst activity and selectivity for ethylene and propylene production.

Catalytic cracking catalyst, preparation method therefor, and application thereof

PatentPendingSG11202302320VA

Innovation

- A catalytic cracking catalyst comprising a cracking active component, a high specific heat capacity matrix material with at least 5 wt% manganese oxide, a clay, and a binder, where the matrix material has a specific heat capacity of 1.3-2.0 J/(g·K) and contains alumina, manganese oxide, and optionally boron compounds, enhancing resistance to metal contamination and improving heavy oil conversion.

Environmental Impact of Catalytic Cracking Processes

Catalytic cracking processes, while essential in petrochemical industries, have significant environmental implications that require careful consideration. The primary environmental concerns associated with these processes include air pollution, water contamination, and solid waste generation.

Air pollution is a major issue stemming from catalytic cracking operations. The process releases various pollutants into the atmosphere, including sulfur dioxide, nitrogen oxides, carbon monoxide, and particulate matter. These emissions contribute to smog formation, acid rain, and overall air quality degradation in surrounding areas. Additionally, volatile organic compounds (VOCs) released during the cracking process can lead to the formation of ground-level ozone, a key component of photochemical smog.

Water pollution is another critical environmental impact of catalytic cracking. The process generates large volumes of wastewater containing oil residues, suspended solids, and various chemical contaminants. If not properly treated, this wastewater can pose significant risks to aquatic ecosystems and groundwater resources. The presence of phenols, ammonia, and other toxic compounds in the wastewater further exacerbates the potential environmental damage.

Solid waste management is also a challenge in catalytic cracking operations. Spent catalysts, which contain heavy metals and other hazardous materials, require proper disposal or regeneration. Improper handling of these wastes can lead to soil contamination and potential leaching of toxic substances into the environment.

The energy-intensive nature of catalytic cracking processes contributes to increased greenhouse gas emissions, primarily carbon dioxide. This aspect adds to the overall carbon footprint of petrochemical industries and raises concerns about their role in climate change.

To mitigate these environmental impacts, the petrochemical industry has been implementing various strategies. These include the use of advanced emission control technologies, such as flue gas desulfurization units and selective catalytic reduction systems, to reduce air pollutants. Improved wastewater treatment techniques, including biological treatment and advanced oxidation processes, are being employed to minimize water pollution.

Furthermore, efforts are being made to develop more environmentally friendly catalysts and optimize process conditions to reduce waste generation and energy consumption. Research into catalyst regeneration and recycling techniques aims to minimize solid waste and conserve resources.

As environmental regulations become increasingly stringent, the petrochemical industry faces the challenge of balancing production efficiency with environmental stewardship. This has led to increased investment in cleaner technologies and sustainable practices, driving innovation in the field of catalytic cracking and related processes.

Air pollution is a major issue stemming from catalytic cracking operations. The process releases various pollutants into the atmosphere, including sulfur dioxide, nitrogen oxides, carbon monoxide, and particulate matter. These emissions contribute to smog formation, acid rain, and overall air quality degradation in surrounding areas. Additionally, volatile organic compounds (VOCs) released during the cracking process can lead to the formation of ground-level ozone, a key component of photochemical smog.

Water pollution is another critical environmental impact of catalytic cracking. The process generates large volumes of wastewater containing oil residues, suspended solids, and various chemical contaminants. If not properly treated, this wastewater can pose significant risks to aquatic ecosystems and groundwater resources. The presence of phenols, ammonia, and other toxic compounds in the wastewater further exacerbates the potential environmental damage.

Solid waste management is also a challenge in catalytic cracking operations. Spent catalysts, which contain heavy metals and other hazardous materials, require proper disposal or regeneration. Improper handling of these wastes can lead to soil contamination and potential leaching of toxic substances into the environment.

The energy-intensive nature of catalytic cracking processes contributes to increased greenhouse gas emissions, primarily carbon dioxide. This aspect adds to the overall carbon footprint of petrochemical industries and raises concerns about their role in climate change.

To mitigate these environmental impacts, the petrochemical industry has been implementing various strategies. These include the use of advanced emission control technologies, such as flue gas desulfurization units and selective catalytic reduction systems, to reduce air pollutants. Improved wastewater treatment techniques, including biological treatment and advanced oxidation processes, are being employed to minimize water pollution.

Furthermore, efforts are being made to develop more environmentally friendly catalysts and optimize process conditions to reduce waste generation and energy consumption. Research into catalyst regeneration and recycling techniques aims to minimize solid waste and conserve resources.

As environmental regulations become increasingly stringent, the petrochemical industry faces the challenge of balancing production efficiency with environmental stewardship. This has led to increased investment in cleaner technologies and sustainable practices, driving innovation in the field of catalytic cracking and related processes.

Economic Feasibility of 2-Methylpentane Cracking

The economic feasibility of 2-methylpentane cracking in petrochemical industries is a critical consideration for companies looking to optimize their production processes and maximize profitability. This analysis takes into account various factors, including raw material costs, energy consumption, equipment requirements, and market demand for the resulting products.

From a cost perspective, the cracking of 2-methylpentane can be relatively economical due to its availability as a byproduct in petroleum refining processes. This reduces the need for additional raw material procurement, potentially lowering overall production costs. However, the specific catalytic cracking process for 2-methylpentane may require specialized equipment and catalysts, which could entail significant initial capital investment.

Energy consumption is another crucial factor in determining economic viability. The catalytic cracking of 2-methylpentane typically requires high temperatures and pressures, which translate to substantial energy costs. However, advancements in catalyst technology and process optimization have led to more energy-efficient cracking methods, potentially improving the economic outlook for this process.

The market demand for the products of 2-methylpentane cracking plays a pivotal role in its economic feasibility. The primary products, such as propylene and butenes, are valuable feedstocks for various petrochemical processes. The growing demand for these materials in industries like plastics manufacturing and synthetic rubber production contributes positively to the economic viability of the cracking process.

Operational costs, including maintenance, catalyst replacement, and labor, must also be factored into the economic analysis. While these costs can be significant, they can often be offset by the high value of the resulting products and the potential for process integration within existing petrochemical facilities.

The scale of production is another critical aspect affecting economic feasibility. Larger-scale operations typically benefit from economies of scale, reducing per-unit production costs and improving overall profitability. This factor often favors the implementation of 2-methylpentane cracking in large, integrated petrochemical complexes.

Regulatory considerations, such as environmental compliance costs and potential carbon taxes, can impact the economic viability of the process. As environmental regulations become more stringent, investments in cleaner technologies and emission control systems may be necessary, affecting the overall cost structure.

In conclusion, the economic feasibility of 2-methylpentane cracking in petrochemical industries is generally positive, driven by the value of its products and potential for integration with existing processes. However, careful consideration of capital costs, energy efficiency, market demand, and regulatory compliance is essential for accurate assessment and successful implementation.

From a cost perspective, the cracking of 2-methylpentane can be relatively economical due to its availability as a byproduct in petroleum refining processes. This reduces the need for additional raw material procurement, potentially lowering overall production costs. However, the specific catalytic cracking process for 2-methylpentane may require specialized equipment and catalysts, which could entail significant initial capital investment.

Energy consumption is another crucial factor in determining economic viability. The catalytic cracking of 2-methylpentane typically requires high temperatures and pressures, which translate to substantial energy costs. However, advancements in catalyst technology and process optimization have led to more energy-efficient cracking methods, potentially improving the economic outlook for this process.

The market demand for the products of 2-methylpentane cracking plays a pivotal role in its economic feasibility. The primary products, such as propylene and butenes, are valuable feedstocks for various petrochemical processes. The growing demand for these materials in industries like plastics manufacturing and synthetic rubber production contributes positively to the economic viability of the cracking process.

Operational costs, including maintenance, catalyst replacement, and labor, must also be factored into the economic analysis. While these costs can be significant, they can often be offset by the high value of the resulting products and the potential for process integration within existing petrochemical facilities.

The scale of production is another critical aspect affecting economic feasibility. Larger-scale operations typically benefit from economies of scale, reducing per-unit production costs and improving overall profitability. This factor often favors the implementation of 2-methylpentane cracking in large, integrated petrochemical complexes.

Regulatory considerations, such as environmental compliance costs and potential carbon taxes, can impact the economic viability of the process. As environmental regulations become more stringent, investments in cleaner technologies and emission control systems may be necessary, affecting the overall cost structure.

In conclusion, the economic feasibility of 2-methylpentane cracking in petrochemical industries is generally positive, driven by the value of its products and potential for integration with existing processes. However, careful consideration of capital costs, energy efficiency, market demand, and regulatory compliance is essential for accurate assessment and successful implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!