Cellulose Acetate: Key to Sustainable Development Goals

Cellulose Acetate Evolution

Cellulose acetate has undergone a remarkable evolution since its inception in the late 19th century. Initially developed as a substitute for celluloid, it quickly found applications in various industries due to its unique properties. The journey of cellulose acetate began with its discovery by Paul Schützenberger in 1865, but it wasn't until 1894 that Charles Cross and Edward Bevan patented the first commercially viable process for its production.

The early 20th century saw rapid advancements in cellulose acetate technology. In 1904, George Miles developed a method to produce cellulose acetate fibers, paving the way for its use in textiles. This breakthrough led to the creation of acetate silk, which gained popularity in the 1920s as a more affordable alternative to natural silk. The material's versatility became evident as it found applications in photographic film, eyeglass frames, and even aircraft windows during World War I.

The 1930s marked a significant milestone in cellulose acetate's evolution with the development of cellulose acetate plastics. These thermoplastics offered improved moldability and durability compared to earlier cellulose-based materials. This innovation expanded the material's use in consumer goods, including combs, toothbrushes, and decorative items. The advent of cellulose acetate plastics also revolutionized the packaging industry, providing a clear, flexible, and biodegradable alternative to traditional materials.

Post-World War II, cellulose acetate continued to evolve, with researchers focusing on enhancing its properties and developing new applications. The 1950s and 1960s saw improvements in the material's heat resistance and dimensional stability, making it suitable for use in electrical insulation and automotive components. During this period, cellulose acetate also gained prominence in the tobacco industry as a filter material for cigarettes, capitalizing on its ability to effectively remove tar and nicotine.

The late 20th century brought renewed interest in cellulose acetate as environmental concerns grew. Scientists began exploring ways to improve its biodegradability and develop more sustainable production methods. This led to the creation of modified cellulose acetates with enhanced properties, such as increased water resistance and improved mechanical strength. These advancements opened up new possibilities in fields like biomedical engineering and environmental remediation.

In recent years, the evolution of cellulose acetate has been driven by the global push towards sustainability. Researchers are now focusing on developing bio-based production methods, utilizing renewable resources and reducing the environmental impact of manufacturing processes. Additionally, there is growing interest in exploring cellulose acetate's potential in advanced applications, such as drug delivery systems, tissue engineering scaffolds, and smart materials for various industries.

Market Demand Analysis

The market demand for cellulose acetate has been steadily growing, driven by its versatile applications and alignment with sustainable development goals. This biodegradable material, derived from renewable sources, has found increasing use across various industries, particularly in textiles, packaging, and consumer goods.

In the textile sector, cellulose acetate fibers have gained popularity due to their softness, breathability, and moisture-wicking properties. The fashion industry's shift towards more sustainable materials has further boosted demand for cellulose acetate-based fabrics. As consumers become more environmentally conscious, there is a growing preference for clothing and accessories made from biodegradable materials, positioning cellulose acetate as a key player in this market.

The packaging industry has also witnessed a surge in demand for cellulose acetate films and sheets. With increasing pressure on businesses to reduce plastic waste, cellulose acetate offers a viable alternative for food packaging, disposable cutlery, and other single-use items. Its biodegradability and compatibility with food contact make it an attractive option for manufacturers looking to meet stringent environmental regulations and consumer expectations.

In the consumer goods sector, cellulose acetate has found applications in personal care products, such as toothbrush handles and cosmetic packaging. The material's durability, transparency, and ability to mimic the appearance of more resource-intensive materials like plastic have contributed to its adoption in this market segment.

The global cellulose acetate market has shown consistent growth, with projections indicating continued expansion in the coming years. This growth is attributed to the increasing awareness of environmental issues, stricter regulations on plastic use, and the material's alignment with circular economy principles.

Regionally, Asia-Pacific has emerged as a key market for cellulose acetate, driven by rapid industrialization, population growth, and increasing disposable incomes. North America and Europe also maintain significant market shares, primarily due to stringent environmental regulations and consumer preferences for eco-friendly products.

Despite the positive market outlook, challenges remain. The relatively higher production costs of cellulose acetate compared to conventional plastics can be a barrier to widespread adoption. Additionally, the limited availability of raw materials and the need for specialized processing facilities may constrain market growth in some regions.

Overall, the market demand for cellulose acetate is expected to continue its upward trajectory, supported by global sustainability initiatives and the material's diverse applications across industries. As research and development efforts focus on improving production efficiency and expanding applications, cellulose acetate is poised to play a crucial role in achieving sustainable development goals across various sectors.

Technical Challenges

Cellulose acetate, a versatile biopolymer derived from natural sources, faces several technical challenges in its journey towards becoming a key player in sustainable development. One of the primary hurdles is the optimization of the production process to reduce environmental impact and increase efficiency. Current manufacturing methods often involve the use of hazardous chemicals and generate significant waste, which contradicts the material's sustainable potential.

The degradation rate of cellulose acetate presents another significant challenge. While it is biodegradable, the process can take several months to years, depending on environmental conditions. This slow degradation rate limits its applicability in certain single-use products and packaging solutions where rapid decomposition is desired. Researchers are working on developing additives and modifying the polymer structure to enhance biodegradability without compromising its desirable properties.

Mechanical properties of cellulose acetate products often fall short when compared to their petroleum-based counterparts. Improving tensile strength, impact resistance, and flexibility while maintaining biodegradability is a complex task that requires innovative approaches in polymer science. This challenge is particularly evident in applications such as packaging and textiles, where durability and performance are crucial.

Water sensitivity is another technical hurdle for cellulose acetate. Its hydrophilic nature can lead to dimensional instability and reduced mechanical properties in high-humidity environments. This characteristic limits its use in certain applications and necessitates the development of effective moisture barrier coatings or chemical modifications to enhance hydrophobicity.

The scalability of cellulose acetate production poses a significant challenge in meeting the growing demand for sustainable materials. Current production capacities are limited, and scaling up while maintaining product quality and cost-effectiveness requires substantial technological advancements and investment in infrastructure.

Recycling cellulose acetate products presents unique challenges due to the material's biodegradable nature and the presence of additives. Developing efficient recycling processes that can separate and recover cellulose acetate from mixed waste streams is crucial for closing the loop in its lifecycle and achieving true sustainability.

Lastly, the cost of cellulose acetate production remains higher than that of many conventional plastics, hindering its widespread adoption. Reducing production costs through process optimization, utilization of waste biomass as feedstock, and development of more efficient catalysts are areas of ongoing research and development. Overcoming these technical challenges is essential for cellulose acetate to fulfill its potential as a key contributor to sustainable development goals.

Current Solutions

01 Cellulose acetate production methods

Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production for different applications.- Production methods for cellulose acetate: Various methods for producing cellulose acetate are described, including improvements in acetylation processes, solvent systems, and reaction conditions. These methods aim to enhance the efficiency and quality of cellulose acetate production, potentially leading to better material properties for diverse applications.

- Cellulose acetate fibers and films: Innovations in the production and modification of cellulose acetate fibers and films are presented. These developments focus on improving the physical and chemical properties of the materials, such as strength, flexibility, and biodegradability, for use in textiles, packaging, and other industries.

- Cellulose acetate composites and blends: Research on cellulose acetate composites and blends with other materials is discussed. These combinations aim to create new materials with enhanced properties, such as improved mechanical strength, thermal stability, or specific functionalities for targeted applications.

- Modification and functionalization of cellulose acetate: Techniques for modifying and functionalizing cellulose acetate are explored. These methods involve chemical treatments or additions to alter the material's properties, such as hydrophobicity, reactivity, or compatibility with other substances, expanding its potential uses in various fields.

- Applications of cellulose acetate in various industries: The diverse applications of cellulose acetate across different industries are highlighted. These include its use in textiles, packaging, filters, membranes, and biomedical devices. The material's versatility and adaptability to various processing techniques contribute to its wide-ranging industrial applications.

02 Cellulose acetate fiber applications

Cellulose acetate fibers are utilized in diverse applications, including textiles, filters, and composite materials. The properties of these fibers, such as strength, durability, and biodegradability, make them suitable for various industrial and consumer products.Expand Specific Solutions03 Cellulose acetate film and membrane technology

Advancements in cellulose acetate film and membrane technology are presented, focusing on improved manufacturing processes, enhanced properties, and novel applications in areas such as separation, filtration, and packaging.Expand Specific Solutions04 Cellulose acetate modification and derivatives

Research on modifying cellulose acetate and creating new derivatives is discussed, including chemical modifications, blending with other polymers, and developing composite materials to enhance performance characteristics for specific applications.Expand Specific Solutions05 Cellulose acetate in sustainable and biodegradable products

The use of cellulose acetate in environmentally friendly and biodegradable products is explored, highlighting its potential as a sustainable alternative to petroleum-based plastics in various industries, including packaging and consumer goods.Expand Specific Solutions

Industry Leaders

The cellulose acetate market is in a mature stage, with established players like Daicel Corp., Eastman Chemical Co., and BASF Corp. dominating the industry. The market size is substantial, driven by increasing demand for sustainable materials across various sectors. Technologically, cellulose acetate is well-developed, with companies like Nantong Cellulose Fibers Co. Ltd. and Zhuhai Cellulose Fibers Co. Ltd. continuously improving production processes. Research institutions such as the Institute of Process Engineering, Chinese Academy of Sciences, and Guilin University of Technology are advancing the material's properties and applications. The focus on sustainable development goals is propelling innovation, with companies like Sichuan Push Cellulose Acetate Co., Ltd. and Futamura Chemical Co. Ltd. developing eco-friendly variants to meet growing environmental concerns.

Daicel Corp.

Eastman Chemical Co.

Key Innovations

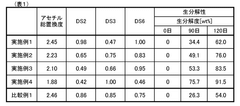

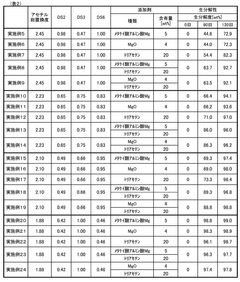

- A cellulose acetate with a total degree of acetyl substitution not greater than 2.7, a specific ratio of acetyl substitution at different positions, and a sulfate component content of 20-400 ppm, along with additives like magnesium oxide and triacetin, enhances biodegradability in seawater.

- Introducing acetyl groups heterogeneously into the 2nd, 3rd, and 6th carbon atoms of the glucose ring in cellulose acetate with a total degree of acetyl substitution between 1.75 and 2.55, and at least one position having a degree of acetyl substitution of 0.7 or less, combined with additives like magnesium oxide and triacetin to enhance biodegradability in seawater.

Environmental Impact

Cellulose acetate, a versatile biopolymer derived from natural sources, plays a significant role in addressing environmental concerns and contributing to sustainable development goals. Its production and use have both positive and negative impacts on the environment, which require careful consideration and management.

The manufacturing process of cellulose acetate involves the acetylation of cellulose, typically sourced from wood pulp or cotton linters. This process generally has a lower environmental footprint compared to the production of petroleum-based plastics. The renewable nature of cellulose as a raw material reduces dependency on fossil fuels and helps mitigate greenhouse gas emissions associated with traditional plastic production.

However, the acetylation process does involve the use of acetic anhydride and other chemicals, which can pose environmental risks if not properly managed. Proper handling, containment, and treatment of these chemicals are essential to prevent air and water pollution. Additionally, the energy consumption during production contributes to the overall carbon footprint of cellulose acetate products.

One of the most significant environmental benefits of cellulose acetate is its biodegradability. Unlike conventional plastics that persist in the environment for hundreds of years, cellulose acetate can decompose within months to a few years under appropriate conditions. This characteristic greatly reduces the long-term environmental impact and helps address the global issue of plastic pollution in terrestrial and marine ecosystems.

The recyclability of cellulose acetate further enhances its environmental profile. Many cellulose acetate products, such as cigarette filters and textile fibers, can be collected and reprocessed into new materials. This circular economy approach conserves resources, reduces waste, and minimizes the need for virgin raw materials.

In terms of end-of-life scenarios, cellulose acetate offers advantages over traditional plastics. When incinerated, it produces fewer toxic emissions compared to many synthetic polymers. If composted in industrial facilities, it can break down into harmless substances that enrich soil quality. However, it is important to note that proper disposal and waste management infrastructure are crucial to realizing these benefits.

The use of cellulose acetate in various applications can also indirectly contribute to environmental protection. For instance, its application in water filtration systems helps improve water quality and reduce the need for chemical treatments. In agriculture, cellulose acetate-based materials used for controlled release of fertilizers and pesticides can minimize chemical runoff and soil contamination.

While cellulose acetate offers numerous environmental advantages, it is not without challenges. The production of raw materials, particularly wood pulp, can lead to deforestation if not managed sustainably. Furthermore, the additives and plasticizers used in some cellulose acetate formulations may have their own environmental impacts that need to be addressed.

Policy and Regulations

The development and implementation of policies and regulations play a crucial role in promoting the sustainable use of cellulose acetate and its contribution to achieving Sustainable Development Goals (SDGs). Governments worldwide are increasingly recognizing the importance of bio-based materials in reducing environmental impact and fostering a circular economy.

Many countries have introduced policies to encourage the use of biodegradable and renewable materials, including cellulose acetate. These policies often include tax incentives, research grants, and preferential procurement practices for products containing sustainable materials. For instance, the European Union's Circular Economy Action Plan emphasizes the importance of bio-based materials and sets targets for their increased use in various sectors.

Regulations surrounding the production and disposal of cellulose acetate products are also evolving. Environmental agencies are implementing stricter guidelines for manufacturing processes to minimize waste and reduce the carbon footprint associated with cellulose acetate production. Additionally, end-of-life regulations are being developed to ensure proper recycling or composting of cellulose acetate products, aligning with SDG 12 (Responsible Consumption and Production).

The United Nations Environment Programme (UNEP) has been instrumental in promoting sustainable practices in the chemical industry, including the production of cellulose acetate. Their initiatives focus on cleaner production techniques, resource efficiency, and the adoption of green chemistry principles. These efforts directly support SDG 9 (Industry, Innovation, and Infrastructure) by encouraging sustainable industrialization.

International standards organizations, such as ISO, have developed specific guidelines for bio-based materials, including cellulose acetate. These standards help ensure product quality, safety, and environmental performance, facilitating global trade and adoption of sustainable materials. Compliance with these standards is increasingly becoming a requirement for market access in many countries.

As awareness of environmental issues grows, consumer protection agencies are also playing a role in shaping regulations. They are advocating for clearer labeling of bio-based products and stricter controls on claims of biodegradability and sustainability. This aligns with SDG 12's target of ensuring that consumers have relevant information for sustainable lifestyles.

Looking ahead, policy makers are exploring innovative regulatory approaches to further promote sustainable materials like cellulose acetate. Extended Producer Responsibility (EPR) schemes are being considered to incentivize manufacturers to design products with improved end-of-life recyclability or compostability. Additionally, there is growing interest in developing harmonized global standards for bio-based materials to facilitate international trade and accelerate the transition to a more sustainable economy.