Challenges in Converting LS Engines for LPG Fuel Use

AUG 12, 20258 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine LPG Conversion Background and Objectives

The conversion of LS engines to run on Liquefied Petroleum Gas (LPG) has gained significant attention in recent years due to the growing emphasis on alternative fuel sources and environmental sustainability. This technological shift represents a convergence of traditional automotive engineering with modern eco-friendly initiatives, aiming to reduce carbon emissions while maintaining high performance standards.

LS engines, originally designed by General Motors, have become renowned for their reliability, power output, and adaptability. These V8 engines have found applications beyond their initial use in GM vehicles, becoming popular choices for engine swaps and custom builds. The challenge of converting these engines to operate on LPG presents an opportunity to leverage their robust design while addressing the need for cleaner fuel alternatives.

The evolution of LPG as a viable fuel source for internal combustion engines dates back several decades. However, the specific application to high-performance engines like the LS series represents a more recent development. This intersection of established engine technology and alternative fuel systems has created a unique set of engineering challenges and opportunities.

The primary objective of LS engine LPG conversion is to maintain or enhance the engine's performance characteristics while significantly reducing its environmental impact. This involves addressing several key areas, including fuel delivery systems, engine management, and materials compatibility. The goal is to create a seamless integration that allows the LS engine to operate efficiently on LPG without compromising its renowned power and reliability.

Another critical objective is to develop conversion solutions that are both cost-effective and widely applicable. This involves creating standardized conversion kits or processes that can be applied across various LS engine models, making the technology accessible to a broader range of vehicle owners and fleet operators.

The technological trajectory of LS engine LPG conversion is closely aligned with broader trends in the automotive industry, including the push for reduced emissions, increased fuel efficiency, and the exploration of alternative energy sources. As such, advancements in this field have the potential to influence future engine designs and fuel system technologies across the automotive sector.

Understanding the background and objectives of LS engine LPG conversion provides a foundation for exploring the specific challenges, current solutions, and future innovations in this field. It sets the stage for a comprehensive analysis of the technical hurdles, market demands, and potential breakthroughs that will shape the future of this technology.

LS engines, originally designed by General Motors, have become renowned for their reliability, power output, and adaptability. These V8 engines have found applications beyond their initial use in GM vehicles, becoming popular choices for engine swaps and custom builds. The challenge of converting these engines to operate on LPG presents an opportunity to leverage their robust design while addressing the need for cleaner fuel alternatives.

The evolution of LPG as a viable fuel source for internal combustion engines dates back several decades. However, the specific application to high-performance engines like the LS series represents a more recent development. This intersection of established engine technology and alternative fuel systems has created a unique set of engineering challenges and opportunities.

The primary objective of LS engine LPG conversion is to maintain or enhance the engine's performance characteristics while significantly reducing its environmental impact. This involves addressing several key areas, including fuel delivery systems, engine management, and materials compatibility. The goal is to create a seamless integration that allows the LS engine to operate efficiently on LPG without compromising its renowned power and reliability.

Another critical objective is to develop conversion solutions that are both cost-effective and widely applicable. This involves creating standardized conversion kits or processes that can be applied across various LS engine models, making the technology accessible to a broader range of vehicle owners and fleet operators.

The technological trajectory of LS engine LPG conversion is closely aligned with broader trends in the automotive industry, including the push for reduced emissions, increased fuel efficiency, and the exploration of alternative energy sources. As such, advancements in this field have the potential to influence future engine designs and fuel system technologies across the automotive sector.

Understanding the background and objectives of LS engine LPG conversion provides a foundation for exploring the specific challenges, current solutions, and future innovations in this field. It sets the stage for a comprehensive analysis of the technical hurdles, market demands, and potential breakthroughs that will shape the future of this technology.

LPG Fuel Market Analysis for LS Engines

The LPG fuel market for LS engines presents a significant opportunity within the automotive industry. As environmental concerns and fuel efficiency demands grow, LPG (Liquefied Petroleum Gas) has emerged as a viable alternative fuel source for traditional gasoline engines. The market for LPG-converted LS engines is driven by several factors, including lower fuel costs, reduced emissions, and government incentives for alternative fuel adoption.

In recent years, the global LPG market has experienced steady growth, with the automotive sector playing a crucial role in this expansion. The increasing number of LPG-powered vehicles on the road has led to a corresponding rise in demand for LPG fuel and conversion technologies. This trend is particularly notable in regions with well-developed LPG infrastructure, such as Europe, Asia-Pacific, and parts of North America.

The LS engine, known for its performance and reliability, has become a popular choice for LPG conversion projects. As a result, the market for LPG fuel systems specifically designed for LS engines has seen substantial growth. This niche market caters to both aftermarket conversions and OEM installations, with a focus on maintaining the engine's performance characteristics while leveraging the benefits of LPG fuel.

Market analysis indicates that the adoption of LPG fuel for LS engines is influenced by several key factors. These include fuel price differentials between LPG and gasoline, government policies promoting alternative fuels, and advancements in LPG conversion technology. The cost-effectiveness of LPG as a fuel source, coupled with its lower environmental impact, has made it an attractive option for fleet operators and individual vehicle owners alike.

The market landscape for LPG fuel systems for LS engines is characterized by a mix of established players and innovative startups. Major automotive component manufacturers have entered this space, offering comprehensive LPG conversion kits tailored for LS engines. Additionally, specialized companies focusing solely on LPG technology have emerged, bringing new solutions to address the unique challenges of converting high-performance engines like the LS series.

Looking ahead, the market for LPG fuel in LS engines is expected to continue its growth trajectory. Factors such as stricter emission regulations, ongoing improvements in LPG technology, and the expansion of LPG refueling infrastructure are likely to drive further adoption. However, challenges such as the initial cost of conversion and competition from other alternative fuel technologies may impact the market's growth rate.

In recent years, the global LPG market has experienced steady growth, with the automotive sector playing a crucial role in this expansion. The increasing number of LPG-powered vehicles on the road has led to a corresponding rise in demand for LPG fuel and conversion technologies. This trend is particularly notable in regions with well-developed LPG infrastructure, such as Europe, Asia-Pacific, and parts of North America.

The LS engine, known for its performance and reliability, has become a popular choice for LPG conversion projects. As a result, the market for LPG fuel systems specifically designed for LS engines has seen substantial growth. This niche market caters to both aftermarket conversions and OEM installations, with a focus on maintaining the engine's performance characteristics while leveraging the benefits of LPG fuel.

Market analysis indicates that the adoption of LPG fuel for LS engines is influenced by several key factors. These include fuel price differentials between LPG and gasoline, government policies promoting alternative fuels, and advancements in LPG conversion technology. The cost-effectiveness of LPG as a fuel source, coupled with its lower environmental impact, has made it an attractive option for fleet operators and individual vehicle owners alike.

The market landscape for LPG fuel systems for LS engines is characterized by a mix of established players and innovative startups. Major automotive component manufacturers have entered this space, offering comprehensive LPG conversion kits tailored for LS engines. Additionally, specialized companies focusing solely on LPG technology have emerged, bringing new solutions to address the unique challenges of converting high-performance engines like the LS series.

Looking ahead, the market for LPG fuel in LS engines is expected to continue its growth trajectory. Factors such as stricter emission regulations, ongoing improvements in LPG technology, and the expansion of LPG refueling infrastructure are likely to drive further adoption. However, challenges such as the initial cost of conversion and competition from other alternative fuel technologies may impact the market's growth rate.

Technical Challenges in LS Engine LPG Conversion

The conversion of LS engines to run on LPG (Liquefied Petroleum Gas) presents several technical challenges that require careful consideration and engineering solutions. One of the primary issues is the need to modify the fuel delivery system to accommodate the different properties of LPG compared to gasoline. This involves replacing the fuel injectors with LPG-compatible units capable of delivering the correct amount of fuel in gaseous form.

Another significant challenge is the adjustment of the engine's compression ratio. LPG has a higher octane rating than gasoline, which allows for higher compression ratios. However, simply increasing the compression ratio can lead to issues with engine durability and reliability. Engineers must find the optimal balance between performance gains and long-term engine health.

The engine management system also requires substantial modifications. The ECU (Engine Control Unit) needs to be reprogrammed or replaced to manage the different fuel characteristics of LPG, including its lower energy density compared to gasoline. This reprogramming must account for changes in fuel pressure, injection timing, and air-fuel mixture ratios to maintain optimal engine performance and efficiency.

Thermal management presents another set of challenges. LPG vaporizes at a much lower temperature than gasoline, which can lead to cold-start issues and potential vapor lock in fuel lines. Implementing effective heating systems for the LPG supply and modifying the engine's cooling system to handle the different heat distribution patterns are crucial steps in the conversion process.

Material compatibility is a critical consideration. LPG can degrade certain types of rubber and plastic components commonly used in gasoline engines. This necessitates the replacement of fuel lines, seals, and gaskets with LPG-resistant materials to prevent leaks and ensure long-term reliability.

Emissions control is another area that requires significant attention. While LPG generally produces lower emissions than gasoline, the conversion must still meet stringent environmental regulations. This may involve redesigning the catalytic converter system and adjusting the engine's air-fuel mixture to optimize emissions performance without sacrificing power output.

Lastly, the integration of LPG storage and delivery systems into the vehicle presents both technical and safety challenges. Proper placement and mounting of LPG tanks, installation of safety valves, and design of fuel lines to withstand the pressures involved in LPG storage and delivery are all critical aspects of the conversion process that demand careful engineering and adherence to safety standards.

Another significant challenge is the adjustment of the engine's compression ratio. LPG has a higher octane rating than gasoline, which allows for higher compression ratios. However, simply increasing the compression ratio can lead to issues with engine durability and reliability. Engineers must find the optimal balance between performance gains and long-term engine health.

The engine management system also requires substantial modifications. The ECU (Engine Control Unit) needs to be reprogrammed or replaced to manage the different fuel characteristics of LPG, including its lower energy density compared to gasoline. This reprogramming must account for changes in fuel pressure, injection timing, and air-fuel mixture ratios to maintain optimal engine performance and efficiency.

Thermal management presents another set of challenges. LPG vaporizes at a much lower temperature than gasoline, which can lead to cold-start issues and potential vapor lock in fuel lines. Implementing effective heating systems for the LPG supply and modifying the engine's cooling system to handle the different heat distribution patterns are crucial steps in the conversion process.

Material compatibility is a critical consideration. LPG can degrade certain types of rubber and plastic components commonly used in gasoline engines. This necessitates the replacement of fuel lines, seals, and gaskets with LPG-resistant materials to prevent leaks and ensure long-term reliability.

Emissions control is another area that requires significant attention. While LPG generally produces lower emissions than gasoline, the conversion must still meet stringent environmental regulations. This may involve redesigning the catalytic converter system and adjusting the engine's air-fuel mixture to optimize emissions performance without sacrificing power output.

Lastly, the integration of LPG storage and delivery systems into the vehicle presents both technical and safety challenges. Proper placement and mounting of LPG tanks, installation of safety valves, and design of fuel lines to withstand the pressures involved in LPG storage and delivery are all critical aspects of the conversion process that demand careful engineering and adherence to safety standards.

Current LS Engine LPG Conversion Solutions

01 LS engine design and improvements

LS engines are a series of small-block V8 automotive engines developed by General Motors. Various improvements have been made to enhance performance, efficiency, and durability. These include advancements in cylinder head design, intake manifold optimization, and the integration of advanced materials for weight reduction and heat management.- LS engine design and improvements: LS engines are a series of small-block V8 automotive engines developed by General Motors. Various improvements and design modifications have been made to enhance performance, efficiency, and reliability. These include advancements in cylinder head design, intake manifold optimization, and combustion chamber improvements.

- Fuel injection systems for LS engines: Advanced fuel injection systems have been developed for LS engines to improve fuel efficiency and power output. These systems include direct injection technology, variable fuel pressure systems, and electronically controlled injectors that optimize fuel delivery based on engine load and operating conditions.

- LS engine control systems and electronics: Modern LS engines incorporate sophisticated control systems and electronics to manage various engine functions. These include engine control units (ECUs) with advanced algorithms, sensor networks for real-time monitoring, and adaptive learning capabilities to optimize performance and emissions.

- LS engine cooling and thermal management: Innovative cooling systems and thermal management solutions have been developed for LS engines to maintain optimal operating temperatures and improve overall efficiency. These include advanced coolant flow designs, electric water pumps, and active thermal management systems that regulate engine temperature based on operating conditions.

- LS engine performance modifications: Aftermarket modifications and performance enhancements have been developed for LS engines to increase power output and improve overall performance. These include high-flow intake and exhaust systems, forced induction solutions such as superchargers and turbochargers, and camshaft upgrades to optimize valve timing and lift.

02 Fuel injection and combustion optimization

Innovations in fuel injection systems and combustion chamber designs have been implemented in LS engines to improve fuel efficiency and power output. These advancements include direct injection technology, variable valve timing, and advanced engine control modules for precise fuel delivery and ignition timing.Expand Specific Solutions03 Forced induction systems for LS engines

Turbocharging and supercharging systems have been developed specifically for LS engines to significantly increase power output. These forced induction systems are designed to work seamlessly with the LS engine architecture, often incorporating intercoolers and specialized intake manifolds to optimize airflow and boost pressure.Expand Specific Solutions04 LS engine cooling and lubrication systems

Advanced cooling and lubrication systems have been engineered for LS engines to improve reliability and performance under high-stress conditions. These include improved water pump designs, oil coolers, and dry-sump lubrication systems for high-performance applications.Expand Specific Solutions05 LS engine electronic control and diagnostics

Sophisticated electronic control systems and diagnostic tools have been developed for LS engines to optimize performance, monitor engine health, and facilitate troubleshooting. These include advanced engine control units (ECUs), onboard diagnostics, and tuning software for customizing engine parameters.Expand Specific Solutions

Key Players in LS Engine LPG Conversion Industry

The market for converting LS engines to LPG fuel use is in a transitional phase, with growing interest driven by environmental concerns and potential cost savings. The global market size for LPG vehicle conversions is expanding, particularly in regions with supportive policies. Technologically, the conversion process is relatively mature, but challenges remain in optimizing performance and efficiency. Key players like Hyundai, Kia, Ford, and GM are investing in LPG-compatible engine technologies, while specialized companies such as TUNAP and AVL List are developing advanced conversion solutions. The competitive landscape is diverse, with both major automakers and niche players contributing to technological advancements in this field.

Ford Global Technologies LLC

Technical Solution: Ford has developed a comprehensive approach to converting LS engines for LPG fuel use. Their system includes a specialized fuel injection system that precisely controls LPG delivery, optimizing combustion efficiency. Ford's technology incorporates advanced engine control modules (ECMs) that dynamically adjust fuel mixture and ignition timing to maintain performance while reducing emissions[1]. The company has also implemented a dual-fuel system, allowing seamless switching between gasoline and LPG, enhancing flexibility for users[2]. Ford's conversion kit includes high-pressure fuel lines, specialized injectors, and a vapor management system to ensure safe and efficient LPG handling. Additionally, they've developed cold-start strategies to overcome LPG's lower energy density, ensuring reliable engine performance in various conditions[3].

Strengths: Comprehensive conversion system, advanced ECM technology, dual-fuel capability. Weaknesses: Potential complexity in installation, higher initial conversion costs compared to simpler systems.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered a sophisticated LPG conversion system for LS engines, focusing on maintaining high performance while reducing emissions. Their approach includes a direct injection LPG system, which allows for precise fuel control and improved combustion efficiency[4]. GM's technology incorporates adaptive learning algorithms in the engine control unit (ECU) to optimize fuel delivery and ignition timing across various operating conditions. The company has also developed specialized piston and cylinder head designs to accommodate the unique combustion characteristics of LPG, ensuring durability and longevity[5]. GM's system features an integrated tank pressure management system, which helps maintain consistent fuel pressure and improves overall system reliability. Additionally, they've implemented advanced catalytic converter technology specifically designed for LPG emissions, further reducing environmental impact[6].

Strengths: High-performance direct injection system, adaptive ECU technology, specialized engine components for LPG use. Weaknesses: Potentially higher costs due to advanced technology, may require more frequent maintenance due to system complexity.

Core Innovations in LS Engine LPG Conversion

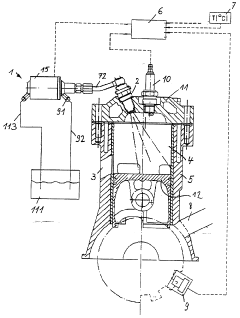

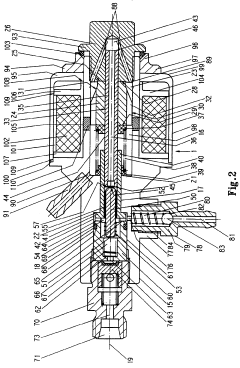

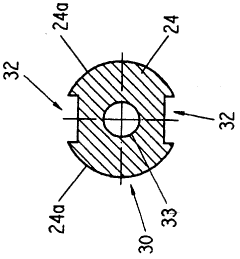

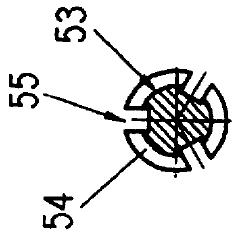

Liquid gas engine

PatentWO1998009060A1

Innovation

- A liquid gas engine with a high-pressure injection device that injects liquefied gas directly into the combustion chamber, where it is atomized and vaporized, preventing icing and ensuring safe operation by controlling the evaporation process within the chamber.

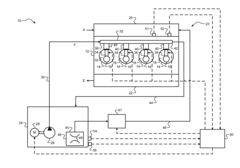

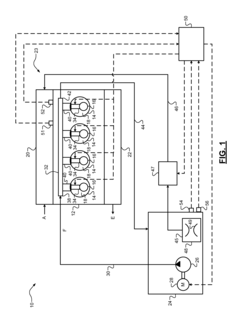

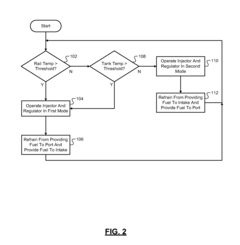

Dual state liquefied petroleum gas engine assembly

PatentInactiveUS20110144886A1

Innovation

- A dual state LPG fuel injection system that includes a liquid LPG fuel injection system communicating with the combustion chamber and a vapor LPG fuel injection system communicating with the intake manifold, utilizing a vaporizer to convert liquid fuel to vapor and a control module to manage fuel delivery based on temperature thresholds, allowing for efficient engine operation and reduced fuel tank pressure.

Environmental Impact of LS Engine LPG Conversion

The conversion of LS engines to LPG fuel use has significant environmental implications, both positive and negative. One of the primary benefits is the reduction in greenhouse gas emissions. LPG, when burned, produces approximately 15% less carbon dioxide compared to gasoline. This reduction in CO2 emissions can contribute to mitigating climate change and improving air quality, especially in urban areas where vehicle emissions are a major concern.

Additionally, LPG combustion results in lower emissions of particulate matter and nitrogen oxides (NOx) compared to traditional gasoline engines. This can lead to improved local air quality and reduced smog formation, which is particularly beneficial in densely populated areas. The lower levels of these pollutants can have positive impacts on public health, potentially reducing respiratory issues and other air pollution-related health problems.

However, the environmental impact of LS engine LPG conversion is not entirely positive. The production and distribution of LPG itself has its own environmental footprint. The extraction, processing, and transportation of LPG require energy and can result in methane leaks, which is a potent greenhouse gas. These factors need to be considered when evaluating the overall environmental impact of LPG conversion.

Furthermore, the conversion process itself may have environmental implications. The manufacturing of conversion kits and the disposal of replaced components can generate waste and consume resources. It is crucial to ensure that the conversion process and the disposal of old parts are carried out in an environmentally responsible manner to minimize negative impacts.

Another consideration is the potential for increased fuel consumption. While LPG has a higher octane rating than gasoline, it has a lower energy density. This means that vehicles converted to LPG may consume more fuel by volume to achieve the same performance as gasoline-powered engines. The increased fuel consumption could partially offset the emissions benefits of LPG, depending on the specific engine and conversion efficiency.

Lastly, the long-term durability and maintenance requirements of converted LS engines may affect their environmental impact. If conversions lead to more frequent engine repairs or shorter engine lifespans, this could result in increased resource consumption and waste generation over time. Therefore, ensuring high-quality conversions and proper maintenance is crucial for maximizing the environmental benefits of LPG use in LS engines.

Additionally, LPG combustion results in lower emissions of particulate matter and nitrogen oxides (NOx) compared to traditional gasoline engines. This can lead to improved local air quality and reduced smog formation, which is particularly beneficial in densely populated areas. The lower levels of these pollutants can have positive impacts on public health, potentially reducing respiratory issues and other air pollution-related health problems.

However, the environmental impact of LS engine LPG conversion is not entirely positive. The production and distribution of LPG itself has its own environmental footprint. The extraction, processing, and transportation of LPG require energy and can result in methane leaks, which is a potent greenhouse gas. These factors need to be considered when evaluating the overall environmental impact of LPG conversion.

Furthermore, the conversion process itself may have environmental implications. The manufacturing of conversion kits and the disposal of replaced components can generate waste and consume resources. It is crucial to ensure that the conversion process and the disposal of old parts are carried out in an environmentally responsible manner to minimize negative impacts.

Another consideration is the potential for increased fuel consumption. While LPG has a higher octane rating than gasoline, it has a lower energy density. This means that vehicles converted to LPG may consume more fuel by volume to achieve the same performance as gasoline-powered engines. The increased fuel consumption could partially offset the emissions benefits of LPG, depending on the specific engine and conversion efficiency.

Lastly, the long-term durability and maintenance requirements of converted LS engines may affect their environmental impact. If conversions lead to more frequent engine repairs or shorter engine lifespans, this could result in increased resource consumption and waste generation over time. Therefore, ensuring high-quality conversions and proper maintenance is crucial for maximizing the environmental benefits of LPG use in LS engines.

Regulatory Framework for LPG Conversion

The regulatory framework for LPG conversion of LS engines is a complex and evolving landscape that significantly impacts the adoption and implementation of this technology. At the federal level in the United States, the Environmental Protection Agency (EPA) plays a crucial role in setting standards and guidelines for vehicle emissions and fuel systems. The EPA's regulations, particularly those outlined in the Clean Air Act, mandate that any modifications to a vehicle's fuel system must not increase emissions beyond the original manufacturer's specifications.

State-level regulations add another layer of complexity to LPG conversion. California, known for its stringent environmental policies, has established the California Air Resources Board (CARB), which often sets standards that exceed federal requirements. CARB certification is necessary for LPG conversion systems to be legally used in California, and many other states follow CARB's lead in adopting these stricter standards.

Safety regulations are equally important in the regulatory framework. The National Fire Protection Association (NFPA) provides guidelines for the safe installation and use of LPG systems in vehicles. These guidelines cover aspects such as tank placement, safety valves, and fuel line specifications. Additionally, the Department of Transportation (DOT) regulates the transportation and storage of LPG, which impacts the design and implementation of conversion systems.

International regulations also play a role, especially for manufacturers and suppliers operating in global markets. The United Nations Economic Commission for Europe (UNECE) has established regulations (such as UNECE R67) that provide standards for LPG systems in vehicles. These regulations are adopted by many countries and serve as a benchmark for safety and performance.

The regulatory landscape is not static, and ongoing changes present challenges for LPG conversion stakeholders. For instance, the push towards zero-emission vehicles in many jurisdictions may impact the long-term viability of LPG conversions. Manufacturers and installers must stay abreast of these regulatory shifts to ensure compliance and adapt their technologies accordingly.

Compliance with these regulations often requires extensive testing and certification processes. This can be time-consuming and costly, potentially acting as a barrier to entry for smaller companies or innovators in the field. However, these processes are essential for ensuring the safety and environmental performance of LPG conversion systems.

State-level regulations add another layer of complexity to LPG conversion. California, known for its stringent environmental policies, has established the California Air Resources Board (CARB), which often sets standards that exceed federal requirements. CARB certification is necessary for LPG conversion systems to be legally used in California, and many other states follow CARB's lead in adopting these stricter standards.

Safety regulations are equally important in the regulatory framework. The National Fire Protection Association (NFPA) provides guidelines for the safe installation and use of LPG systems in vehicles. These guidelines cover aspects such as tank placement, safety valves, and fuel line specifications. Additionally, the Department of Transportation (DOT) regulates the transportation and storage of LPG, which impacts the design and implementation of conversion systems.

International regulations also play a role, especially for manufacturers and suppliers operating in global markets. The United Nations Economic Commission for Europe (UNECE) has established regulations (such as UNECE R67) that provide standards for LPG systems in vehicles. These regulations are adopted by many countries and serve as a benchmark for safety and performance.

The regulatory landscape is not static, and ongoing changes present challenges for LPG conversion stakeholders. For instance, the push towards zero-emission vehicles in many jurisdictions may impact the long-term viability of LPG conversions. Manufacturers and installers must stay abreast of these regulatory shifts to ensure compliance and adapt their technologies accordingly.

Compliance with these regulations often requires extensive testing and certification processes. This can be time-consuming and costly, potentially acting as a barrier to entry for smaller companies or innovators in the field. However, these processes are essential for ensuring the safety and environmental performance of LPG conversion systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!