Challenges in LS Engine Calibration for Seamless Cruise Control

AUG 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

LS Engine Calibration Background and Objectives

Engine calibration for seamless cruise control in LS (Longitudinal Speed) systems has become a critical focus in the automotive industry. This technology has evolved significantly over the past decades, driven by the increasing demand for improved fuel efficiency, reduced emissions, and enhanced driving comfort. The primary objective of LS engine calibration is to optimize the engine's performance while maintaining smooth and consistent vehicle speed during cruise control operation.

The development of LS engine calibration can be traced back to the early 1990s when electronic engine control units (ECUs) became more sophisticated. Initially, the focus was on basic speed maintenance, but as technology progressed, the emphasis shifted towards more refined control strategies. The advent of drive-by-wire systems in the late 1990s marked a significant milestone, allowing for more precise throttle control and paving the way for advanced cruise control functionalities.

In recent years, the integration of adaptive cruise control (ACC) systems has further complicated the calibration process. ACC systems require the engine to respond not only to maintain a set speed but also to adjust based on the distance from vehicles ahead. This has led to the development of more complex algorithms that consider multiple variables simultaneously, including vehicle speed, road gradient, and traffic conditions.

The current technological trend in LS engine calibration is moving towards predictive and learning-based systems. These advanced calibration techniques aim to anticipate changes in driving conditions and adapt the engine's response proactively. Machine learning algorithms are being employed to analyze vast amounts of driving data, allowing for continuous improvement of the calibration parameters over time.

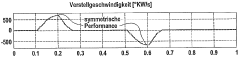

One of the key challenges in LS engine calibration is achieving a balance between performance and comfort. The system must respond quickly to maintain the desired speed, especially on varying road gradients, while avoiding abrupt changes in engine output that could lead to a jerky driving experience. This requires fine-tuning of numerous parameters, including throttle response, gear shifting points, and torque management.

Another significant objective is to optimize fuel efficiency without compromising on performance. This involves developing sophisticated control strategies that can adjust the engine's operating parameters in real-time based on the current driving conditions. The calibration must also account for different driving modes, such as eco, normal, and sport, each requiring a unique set of parameters to meet the driver's expectations.

As environmental regulations become more stringent, a crucial goal of LS engine calibration is to minimize emissions during cruise control operation. This necessitates precise control of the air-fuel mixture and exhaust gas recirculation systems, often requiring complex trade-offs between performance, efficiency, and emissions.

The development of LS engine calibration can be traced back to the early 1990s when electronic engine control units (ECUs) became more sophisticated. Initially, the focus was on basic speed maintenance, but as technology progressed, the emphasis shifted towards more refined control strategies. The advent of drive-by-wire systems in the late 1990s marked a significant milestone, allowing for more precise throttle control and paving the way for advanced cruise control functionalities.

In recent years, the integration of adaptive cruise control (ACC) systems has further complicated the calibration process. ACC systems require the engine to respond not only to maintain a set speed but also to adjust based on the distance from vehicles ahead. This has led to the development of more complex algorithms that consider multiple variables simultaneously, including vehicle speed, road gradient, and traffic conditions.

The current technological trend in LS engine calibration is moving towards predictive and learning-based systems. These advanced calibration techniques aim to anticipate changes in driving conditions and adapt the engine's response proactively. Machine learning algorithms are being employed to analyze vast amounts of driving data, allowing for continuous improvement of the calibration parameters over time.

One of the key challenges in LS engine calibration is achieving a balance between performance and comfort. The system must respond quickly to maintain the desired speed, especially on varying road gradients, while avoiding abrupt changes in engine output that could lead to a jerky driving experience. This requires fine-tuning of numerous parameters, including throttle response, gear shifting points, and torque management.

Another significant objective is to optimize fuel efficiency without compromising on performance. This involves developing sophisticated control strategies that can adjust the engine's operating parameters in real-time based on the current driving conditions. The calibration must also account for different driving modes, such as eco, normal, and sport, each requiring a unique set of parameters to meet the driver's expectations.

As environmental regulations become more stringent, a crucial goal of LS engine calibration is to minimize emissions during cruise control operation. This necessitates precise control of the air-fuel mixture and exhaust gas recirculation systems, often requiring complex trade-offs between performance, efficiency, and emissions.

Market Demand for Advanced Cruise Control Systems

The market demand for advanced cruise control systems has been steadily increasing in recent years, driven by a growing emphasis on vehicle safety, comfort, and fuel efficiency. Consumers are increasingly seeking vehicles equipped with sophisticated driver assistance features, with cruise control being a key component of these systems.

The global market for advanced cruise control systems is experiencing robust growth, with projections indicating a significant expansion over the next decade. This growth is primarily fueled by the automotive industry's shift towards autonomous and semi-autonomous vehicles, where advanced cruise control serves as a stepping stone to full autonomy.

In developed markets such as North America and Europe, there is a strong demand for vehicles with adaptive cruise control (ACC) systems. These systems not only maintain a set speed but also adjust the vehicle's speed to maintain a safe distance from the vehicle ahead. The integration of ACC with other advanced driver assistance systems (ADAS) like lane-keeping assist and automatic emergency braking is becoming increasingly common, further driving market demand.

Emerging markets, particularly in Asia-Pacific, are also showing increased interest in advanced cruise control systems. As disposable incomes rise and awareness of vehicle safety features grows, consumers in these regions are more willing to invest in vehicles equipped with advanced technologies.

The commercial vehicle sector represents another significant area of growth for advanced cruise control systems. Fleet operators are recognizing the benefits of these systems in terms of fuel efficiency, driver fatigue reduction, and overall safety improvements. This has led to increased adoption of advanced cruise control in trucks, buses, and other commercial vehicles.

Environmental concerns and stricter fuel efficiency regulations are also contributing to the demand for advanced cruise control systems. These systems can optimize vehicle speed and acceleration patterns, leading to reduced fuel consumption and lower emissions. As governments worldwide implement more stringent environmental standards, automakers are increasingly turning to advanced cruise control as part of their strategy to meet these requirements.

The ongoing development of vehicle-to-everything (V2X) communication technologies is expected to further enhance the capabilities of cruise control systems. This integration will allow vehicles to communicate with infrastructure and other vehicles, enabling more efficient and safer operation of cruise control systems in complex traffic scenarios.

The global market for advanced cruise control systems is experiencing robust growth, with projections indicating a significant expansion over the next decade. This growth is primarily fueled by the automotive industry's shift towards autonomous and semi-autonomous vehicles, where advanced cruise control serves as a stepping stone to full autonomy.

In developed markets such as North America and Europe, there is a strong demand for vehicles with adaptive cruise control (ACC) systems. These systems not only maintain a set speed but also adjust the vehicle's speed to maintain a safe distance from the vehicle ahead. The integration of ACC with other advanced driver assistance systems (ADAS) like lane-keeping assist and automatic emergency braking is becoming increasingly common, further driving market demand.

Emerging markets, particularly in Asia-Pacific, are also showing increased interest in advanced cruise control systems. As disposable incomes rise and awareness of vehicle safety features grows, consumers in these regions are more willing to invest in vehicles equipped with advanced technologies.

The commercial vehicle sector represents another significant area of growth for advanced cruise control systems. Fleet operators are recognizing the benefits of these systems in terms of fuel efficiency, driver fatigue reduction, and overall safety improvements. This has led to increased adoption of advanced cruise control in trucks, buses, and other commercial vehicles.

Environmental concerns and stricter fuel efficiency regulations are also contributing to the demand for advanced cruise control systems. These systems can optimize vehicle speed and acceleration patterns, leading to reduced fuel consumption and lower emissions. As governments worldwide implement more stringent environmental standards, automakers are increasingly turning to advanced cruise control as part of their strategy to meet these requirements.

The ongoing development of vehicle-to-everything (V2X) communication technologies is expected to further enhance the capabilities of cruise control systems. This integration will allow vehicles to communicate with infrastructure and other vehicles, enabling more efficient and safer operation of cruise control systems in complex traffic scenarios.

Current Challenges in LS Engine Calibration

The calibration of LS (Longitudinal Speed) engines for seamless cruise control presents several significant challenges in the current automotive landscape. One of the primary obstacles is the complexity of modern engine systems, which incorporate numerous sensors, actuators, and control modules. These intricate systems require precise tuning to achieve optimal performance and fuel efficiency while maintaining smooth operation during cruise control.

A major challenge lies in the dynamic nature of driving conditions. Calibrators must account for various factors such as road grade, wind resistance, and vehicle load, which can significantly impact engine performance and fuel consumption. Developing algorithms that can adapt to these changing conditions in real-time without compromising ride comfort or fuel economy is a formidable task.

The integration of advanced driver assistance systems (ADAS) with cruise control functionality adds another layer of complexity to engine calibration. Ensuring seamless coordination between the engine control unit (ECU) and ADAS components, such as radar sensors and camera systems, requires sophisticated software development and extensive testing.

Emissions regulations pose a significant challenge in LS engine calibration. Stricter environmental standards demand that engines operate efficiently across a wide range of speeds and loads while minimizing pollutant emissions. Calibrators must strike a delicate balance between performance, fuel economy, and emissions compliance, often requiring trade-offs and innovative solutions.

The variability in manufacturing tolerances and component wear over time presents another hurdle. Calibration strategies must be robust enough to accommodate these variations without compromising engine performance or cruise control functionality. This necessitates the development of adaptive calibration techniques that can compensate for component aging and manufacturing discrepancies.

Furthermore, the increasing electrification of vehicles introduces new challenges in LS engine calibration. Hybrid powertrains require seamless integration between the internal combustion engine and electric motors, adding complexity to the calibration process. Ensuring smooth transitions between power sources while maintaining consistent cruise control performance is a significant technical challenge.

Lastly, the demand for shorter development cycles in the automotive industry puts pressure on calibration teams to deliver optimized engine performance in less time. This time constraint often conflicts with the need for extensive real-world testing and validation, leading to potential compromises in calibration quality or the adoption of more advanced simulation and modeling techniques to accelerate the process.

A major challenge lies in the dynamic nature of driving conditions. Calibrators must account for various factors such as road grade, wind resistance, and vehicle load, which can significantly impact engine performance and fuel consumption. Developing algorithms that can adapt to these changing conditions in real-time without compromising ride comfort or fuel economy is a formidable task.

The integration of advanced driver assistance systems (ADAS) with cruise control functionality adds another layer of complexity to engine calibration. Ensuring seamless coordination between the engine control unit (ECU) and ADAS components, such as radar sensors and camera systems, requires sophisticated software development and extensive testing.

Emissions regulations pose a significant challenge in LS engine calibration. Stricter environmental standards demand that engines operate efficiently across a wide range of speeds and loads while minimizing pollutant emissions. Calibrators must strike a delicate balance between performance, fuel economy, and emissions compliance, often requiring trade-offs and innovative solutions.

The variability in manufacturing tolerances and component wear over time presents another hurdle. Calibration strategies must be robust enough to accommodate these variations without compromising engine performance or cruise control functionality. This necessitates the development of adaptive calibration techniques that can compensate for component aging and manufacturing discrepancies.

Furthermore, the increasing electrification of vehicles introduces new challenges in LS engine calibration. Hybrid powertrains require seamless integration between the internal combustion engine and electric motors, adding complexity to the calibration process. Ensuring smooth transitions between power sources while maintaining consistent cruise control performance is a significant technical challenge.

Lastly, the demand for shorter development cycles in the automotive industry puts pressure on calibration teams to deliver optimized engine performance in less time. This time constraint often conflicts with the need for extensive real-world testing and validation, leading to potential compromises in calibration quality or the adoption of more advanced simulation and modeling techniques to accelerate the process.

Existing LS Engine Calibration Solutions

01 Engine calibration for seamless cruise control

Advanced engine calibration techniques are employed to ensure smooth and seamless operation of cruise control systems in LS engines. This involves optimizing various engine parameters such as fuel injection, ignition timing, and throttle response to maintain consistent vehicle speed and improve overall driving experience.- Engine calibration for seamless cruise control: Advanced engine calibration techniques are employed to optimize the performance of LS engines during cruise control operation. This involves fine-tuning various engine parameters to ensure smooth transitions between different driving modes, enhancing fuel efficiency and overall driving experience.

- Integration of cruise control with engine management systems: Seamless cruise control in LS engines is achieved through tight integration with the engine management system. This allows for real-time adjustments to engine output based on cruise control demands, road conditions, and vehicle speed, resulting in more precise and responsive control.

- Adaptive cruise control algorithms for LS engines: Advanced algorithms are developed to enable adaptive cruise control functionality in LS engines. These algorithms take into account factors such as traffic conditions, vehicle distance, and speed variations to automatically adjust the engine's performance and maintain desired cruising speeds.

- Torque management for smooth acceleration and deceleration: Specialized torque management strategies are implemented to ensure smooth acceleration and deceleration during cruise control operation. This involves precise control of engine torque output to minimize jerks and provide a seamless driving experience, especially during speed changes or when resuming cruise control.

- Fuel efficiency optimization in cruise control mode: LS engine calibration for cruise control focuses on optimizing fuel efficiency. This is achieved through advanced mapping of engine parameters, such as fuel injection timing and throttle position, to maintain the desired speed while minimizing fuel consumption during steady-state cruising.

02 Integration of cruise control with engine management systems

Seamless cruise control in LS engines is achieved through tight integration with the engine management system. This integration allows for real-time adjustments to engine performance based on cruise control demands, resulting in more precise speed maintenance and improved fuel efficiency.Expand Specific Solutions03 Adaptive cruise control algorithms

Advanced adaptive cruise control algorithms are implemented in LS engine calibration to enhance the seamless operation of cruise control. These algorithms take into account factors such as road conditions, vehicle load, and driver preferences to dynamically adjust engine output and maintain desired speed.Expand Specific Solutions04 Torque management for smooth transitions

LS engine calibration focuses on precise torque management to ensure smooth transitions during cruise control engagement, disengagement, and speed changes. This involves fine-tuning engine response to minimize jerks and maintain passenger comfort while optimizing performance.Expand Specific Solutions05 Sensor integration and data processing

Seamless cruise control in LS engines relies on the integration of various sensors and advanced data processing techniques. This includes the use of speed sensors, accelerometers, and throttle position sensors to gather real-time data, which is then processed to make instantaneous adjustments to engine performance for optimal cruise control operation.Expand Specific Solutions

Key Players in Automotive Calibration Industry

The cruise control calibration for LS engines presents a competitive landscape in a mature yet evolving market. The industry is in a growth phase, with increasing demand for advanced driver assistance systems. The global market for cruise control systems is projected to expand significantly, driven by automotive safety regulations and consumer preferences. Technologically, the field is advancing rapidly, with major players like GM Global Technology Operations, Toyota, Honda, and Volvo Lastvagnar pushing boundaries in adaptive cruise control and autonomous driving features. These companies, along with others like Scania CV and Hitachi Automotive Systems, are investing heavily in R&D to enhance system performance, reliability, and seamless integration with other vehicle functions.

GM Global Technology Operations LLC

Technical Solution: GM has developed an advanced LS Engine Calibration system for seamless cruise control, utilizing machine learning algorithms to optimize engine performance in real-time. Their system employs a combination of predictive modeling and adaptive control strategies to anticipate and respond to changes in driving conditions. The calibration process incorporates data from multiple sensors, including vehicle speed, throttle position, and road gradient, to continuously adjust engine parameters such as fuel injection timing, valve timing, and boost pressure[1]. GM's approach also integrates with the vehicle's transmission control module to ensure smooth gear shifts during cruise control operation[3].

Strengths: Comprehensive integration with vehicle systems, real-time adaptation capabilities. Weaknesses: Potentially high computational requirements, dependency on extensive sensor data.

Toyota Motor Corp.

Technical Solution: Toyota's LS Engine Calibration for cruise control focuses on a hybrid approach, combining traditional lookup tables with dynamic neural network models. Their system utilizes a two-stage calibration process: an offline optimization phase to establish baseline parameters, followed by an online fine-tuning mechanism. Toyota's calibration strategy emphasizes fuel efficiency and emissions reduction while maintaining smooth acceleration and deceleration profiles. The system incorporates a unique "eco-mode" that adjusts engine parameters to prioritize fuel economy during cruise control operation[2]. Additionally, Toyota has implemented a torque-based control strategy that allows for more precise management of engine output during various cruise control scenarios[4].

Strengths: Balance between efficiency and performance, adaptability to different driving modes. Weaknesses: Potential complexity in system integration, may require frequent updates to maintain optimal performance.

Core Innovations in Engine Calibration Technology

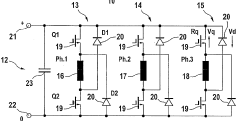

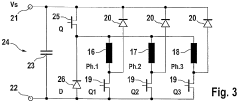

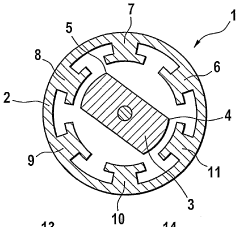

Control device for adjusting the angle of rotation of a camshaft

PatentWO2006111224A1

Innovation

- A control device utilizing a switched reluctance motor (SRM) with a stack of steel laminations as the rotor, which operates without permanent magnetic excitation, allowing for adjustable torque development and high adjustment speeds, and is controlled by a three-phase inverter connected to the vehicle's battery voltage.

Regulatory Framework for Automotive Calibration

The regulatory framework for automotive calibration plays a crucial role in ensuring the safety, efficiency, and environmental compliance of modern vehicles. In the context of LS engine calibration for seamless cruise control, several key regulations and standards must be considered.

At the forefront are the emissions regulations set by various governing bodies worldwide. In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) establish stringent guidelines for vehicle emissions. These regulations dictate the permissible levels of pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. Engine calibration must be optimized to meet these standards while maintaining performance and fuel efficiency.

Safety regulations also significantly impact engine calibration for cruise control systems. The National Highway Traffic Safety Administration (NHTSA) in the U.S. and similar organizations in other countries set standards for vehicle safety features, including those related to cruise control functionality. These regulations ensure that cruise control systems operate reliably and can be safely disengaged when necessary.

Fuel economy standards, such as the Corporate Average Fuel Economy (CAFE) regulations in the U.S., further influence engine calibration strategies. Manufacturers must balance performance requirements with fuel efficiency targets, often leading to complex calibration trade-offs.

International harmonization efforts, like the United Nations Economic Commission for Europe (UNECE) regulations, aim to standardize automotive requirements across different regions. This global approach affects calibration practices, as manufacturers strive to develop engines that comply with diverse regulatory frameworks.

The On-Board Diagnostics (OBD) requirements form another critical aspect of the regulatory landscape. These systems monitor engine performance and emissions control systems, necessitating careful calibration to ensure accurate fault detection and reporting.

Cybersecurity regulations are becoming increasingly important as vehicles become more connected. Calibration processes must incorporate safeguards against unauthorized access or manipulation of engine control systems, particularly in cruise control applications where safety is paramount.

As autonomous driving technologies advance, new regulations are emerging to address the unique challenges posed by self-driving vehicles. These regulations will likely have significant implications for engine calibration in cruise control systems, requiring adaptive strategies that can seamlessly integrate with various levels of autonomous operation.

At the forefront are the emissions regulations set by various governing bodies worldwide. In the United States, the Environmental Protection Agency (EPA) and the California Air Resources Board (CARB) establish stringent guidelines for vehicle emissions. These regulations dictate the permissible levels of pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. Engine calibration must be optimized to meet these standards while maintaining performance and fuel efficiency.

Safety regulations also significantly impact engine calibration for cruise control systems. The National Highway Traffic Safety Administration (NHTSA) in the U.S. and similar organizations in other countries set standards for vehicle safety features, including those related to cruise control functionality. These regulations ensure that cruise control systems operate reliably and can be safely disengaged when necessary.

Fuel economy standards, such as the Corporate Average Fuel Economy (CAFE) regulations in the U.S., further influence engine calibration strategies. Manufacturers must balance performance requirements with fuel efficiency targets, often leading to complex calibration trade-offs.

International harmonization efforts, like the United Nations Economic Commission for Europe (UNECE) regulations, aim to standardize automotive requirements across different regions. This global approach affects calibration practices, as manufacturers strive to develop engines that comply with diverse regulatory frameworks.

The On-Board Diagnostics (OBD) requirements form another critical aspect of the regulatory landscape. These systems monitor engine performance and emissions control systems, necessitating careful calibration to ensure accurate fault detection and reporting.

Cybersecurity regulations are becoming increasingly important as vehicles become more connected. Calibration processes must incorporate safeguards against unauthorized access or manipulation of engine control systems, particularly in cruise control applications where safety is paramount.

As autonomous driving technologies advance, new regulations are emerging to address the unique challenges posed by self-driving vehicles. These regulations will likely have significant implications for engine calibration in cruise control systems, requiring adaptive strategies that can seamlessly integrate with various levels of autonomous operation.

Environmental Impact of Engine Calibration Strategies

Engine calibration strategies play a crucial role in determining the environmental impact of vehicles equipped with LS engines, particularly in the context of cruise control systems. The optimization of these strategies is essential for reducing emissions and improving fuel efficiency, which are key factors in mitigating the automotive industry's contribution to climate change and air pollution.

One of the primary environmental concerns addressed by engine calibration is the reduction of greenhouse gas emissions, particularly carbon dioxide (CO2). By fine-tuning the engine's performance during cruise control operation, calibration engineers can significantly decrease fuel consumption, thereby directly lowering CO2 emissions. This is achieved through precise control of fuel injection timing, air-fuel mixture ratios, and ignition timing, all of which are dynamically adjusted to maintain optimal efficiency across various driving conditions.

Nitrogen oxides (NOx) emissions are another critical focus of engine calibration strategies. LS engines, especially in cruise control scenarios, must balance performance with NOx reduction to comply with increasingly stringent environmental regulations. Advanced calibration techniques, such as exhaust gas recirculation (EGR) optimization and selective catalytic reduction (SCR) system tuning, are employed to minimize NOx formation during steady-state cruising conditions.

Particulate matter (PM) emissions, while less of a concern for gasoline LS engines compared to diesel counterparts, are still addressed through calibration strategies. Fine-tuning of fuel injection parameters and combustion chamber design optimization help reduce PM formation, particularly during transient operations when cruise control is engaged or disengaged.

The challenge of maintaining low emissions while ensuring seamless cruise control operation extends to the management of cold-start emissions. Calibration strategies must account for the rapid warm-up phase of the engine, where emissions are typically highest, and integrate this with cruise control functionality to minimize environmental impact during the initial stages of vehicle operation.

Furthermore, engine calibration strategies for cruise control systems are increasingly incorporating predictive elements to enhance environmental performance. By utilizing GPS data, traffic information, and topographical details, advanced calibration algorithms can anticipate changes in driving conditions and preemptively adjust engine parameters. This proactive approach not only improves the smoothness of cruise control operation but also optimizes fuel efficiency and emissions control over varied terrains and traffic scenarios.

The environmental impact of engine calibration strategies extends beyond direct emissions to include the vehicle's overall lifecycle environmental footprint. Optimized calibration can lead to reduced wear on engine components, potentially extending the engine's lifespan and decreasing the environmental costs associated with manufacturing replacement parts or entire vehicles.

One of the primary environmental concerns addressed by engine calibration is the reduction of greenhouse gas emissions, particularly carbon dioxide (CO2). By fine-tuning the engine's performance during cruise control operation, calibration engineers can significantly decrease fuel consumption, thereby directly lowering CO2 emissions. This is achieved through precise control of fuel injection timing, air-fuel mixture ratios, and ignition timing, all of which are dynamically adjusted to maintain optimal efficiency across various driving conditions.

Nitrogen oxides (NOx) emissions are another critical focus of engine calibration strategies. LS engines, especially in cruise control scenarios, must balance performance with NOx reduction to comply with increasingly stringent environmental regulations. Advanced calibration techniques, such as exhaust gas recirculation (EGR) optimization and selective catalytic reduction (SCR) system tuning, are employed to minimize NOx formation during steady-state cruising conditions.

Particulate matter (PM) emissions, while less of a concern for gasoline LS engines compared to diesel counterparts, are still addressed through calibration strategies. Fine-tuning of fuel injection parameters and combustion chamber design optimization help reduce PM formation, particularly during transient operations when cruise control is engaged or disengaged.

The challenge of maintaining low emissions while ensuring seamless cruise control operation extends to the management of cold-start emissions. Calibration strategies must account for the rapid warm-up phase of the engine, where emissions are typically highest, and integrate this with cruise control functionality to minimize environmental impact during the initial stages of vehicle operation.

Furthermore, engine calibration strategies for cruise control systems are increasingly incorporating predictive elements to enhance environmental performance. By utilizing GPS data, traffic information, and topographical details, advanced calibration algorithms can anticipate changes in driving conditions and preemptively adjust engine parameters. This proactive approach not only improves the smoothness of cruise control operation but also optimizes fuel efficiency and emissions control over varied terrains and traffic scenarios.

The environmental impact of engine calibration strategies extends beyond direct emissions to include the vehicle's overall lifecycle environmental footprint. Optimized calibration can lead to reduced wear on engine components, potentially extending the engine's lifespan and decreasing the environmental costs associated with manufacturing replacement parts or entire vehicles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!