Challenges in Scaling Up Glacial Acetic Acid-based Industrial Processes

AUG 5, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Glacial Acetic Acid Process Evolution and Objectives

Glacial acetic acid has been a cornerstone in industrial processes for decades, with its production and application evolving significantly over time. The journey of glacial acetic acid in industry began in the early 20th century, primarily as a byproduct of wood distillation. However, as demand grew, more efficient synthetic methods were developed, leading to the current dominance of methanol carbonylation processes.

The evolution of glacial acetic acid production has been driven by the need for higher purity, increased yield, and more cost-effective manufacturing methods. Early processes, such as the acetaldehyde oxidation method, gave way to more advanced techniques like the Monsanto process in the 1960s, which utilized methanol carbonylation with a rhodium catalyst. This was later improved upon by the Cativa process, developed by BP Chemicals in the 1990s, which employed an iridium catalyst for enhanced efficiency.

As industrial applications expanded, so did the challenges associated with scaling up glacial acetic acid-based processes. These challenges include maintaining high purity levels at large scales, managing corrosion in equipment due to the acid's aggressive nature, and ensuring worker safety in handling large volumes of this hazardous substance. Additionally, the environmental impact of production and use has become a significant concern, prompting research into more sustainable manufacturing methods and applications.

The objectives of current research and development in glacial acetic acid processes are multifaceted. Firstly, there is a push towards improving process efficiency to reduce energy consumption and raw material usage. This includes optimizing reaction conditions, developing more active and selective catalysts, and enhancing separation and purification techniques. Secondly, there is a focus on developing greener production methods, such as utilizing biomass-derived feedstocks or implementing carbon capture technologies to mitigate environmental impact.

Another key objective is to address the challenges of scaling up glacial acetic acid-based processes in various industries. This involves developing innovative reactor designs that can handle larger volumes while maintaining optimal reaction conditions, as well as implementing advanced process control systems to ensure consistent product quality at industrial scales. Furthermore, there is ongoing research into materials science to create more corrosion-resistant equipment and safer handling systems for large-scale operations.

The future trajectory of glacial acetic acid technology is likely to involve a convergence of traditional chemical engineering with emerging fields such as nanotechnology and artificial intelligence. These advancements may lead to novel catalytic systems, more precise process control, and predictive maintenance capabilities, all contributing to safer, more efficient, and environmentally friendly large-scale glacial acetic acid processes.

The evolution of glacial acetic acid production has been driven by the need for higher purity, increased yield, and more cost-effective manufacturing methods. Early processes, such as the acetaldehyde oxidation method, gave way to more advanced techniques like the Monsanto process in the 1960s, which utilized methanol carbonylation with a rhodium catalyst. This was later improved upon by the Cativa process, developed by BP Chemicals in the 1990s, which employed an iridium catalyst for enhanced efficiency.

As industrial applications expanded, so did the challenges associated with scaling up glacial acetic acid-based processes. These challenges include maintaining high purity levels at large scales, managing corrosion in equipment due to the acid's aggressive nature, and ensuring worker safety in handling large volumes of this hazardous substance. Additionally, the environmental impact of production and use has become a significant concern, prompting research into more sustainable manufacturing methods and applications.

The objectives of current research and development in glacial acetic acid processes are multifaceted. Firstly, there is a push towards improving process efficiency to reduce energy consumption and raw material usage. This includes optimizing reaction conditions, developing more active and selective catalysts, and enhancing separation and purification techniques. Secondly, there is a focus on developing greener production methods, such as utilizing biomass-derived feedstocks or implementing carbon capture technologies to mitigate environmental impact.

Another key objective is to address the challenges of scaling up glacial acetic acid-based processes in various industries. This involves developing innovative reactor designs that can handle larger volumes while maintaining optimal reaction conditions, as well as implementing advanced process control systems to ensure consistent product quality at industrial scales. Furthermore, there is ongoing research into materials science to create more corrosion-resistant equipment and safer handling systems for large-scale operations.

The future trajectory of glacial acetic acid technology is likely to involve a convergence of traditional chemical engineering with emerging fields such as nanotechnology and artificial intelligence. These advancements may lead to novel catalytic systems, more precise process control, and predictive maintenance capabilities, all contributing to safer, more efficient, and environmentally friendly large-scale glacial acetic acid processes.

Industrial Demand Analysis for Glacial Acetic Acid

The global demand for glacial acetic acid has been steadily increasing, driven by its widespread applications across various industries. The chemical sector remains the largest consumer, utilizing glacial acetic acid as a key raw material in the production of vinyl acetate monomer (VAM), purified terephthalic acid (PTA), and acetic anhydride. These derivatives find extensive use in manufacturing adhesives, paints, textiles, and plastics.

In the food industry, glacial acetic acid serves as a crucial ingredient in food preservation and flavor enhancement. Its antimicrobial properties make it an essential component in pickling processes and as a food additive. The pharmaceutical sector also relies heavily on glacial acetic acid for the synthesis of various medications and as a solvent in drug formulations.

The textile industry employs glacial acetic acid in dyeing processes and as a pH regulator. Additionally, it plays a vital role in the production of synthetic fibers such as rayon and cellulose acetate. The electronics industry utilizes glacial acetic acid in the manufacturing of printed circuit boards and as a cleaning agent for electronic components.

Market analysis indicates a growing demand for biodegradable plastics and eco-friendly products, which is expected to further boost the consumption of glacial acetic acid. The compound's role in producing biodegradable polymers aligns with the global shift towards sustainable materials.

Geographically, Asia-Pacific dominates the glacial acetic acid market, with China being the largest producer and consumer. The region's rapid industrialization and expanding manufacturing sector contribute significantly to this trend. North America and Europe follow, with steady demand from established chemical and pharmaceutical industries.

The market is characterized by a few large-scale producers and numerous small to medium-sized manufacturers. Key players are focusing on expanding their production capacities to meet the rising global demand. Technological advancements in production processes are being pursued to improve efficiency and reduce environmental impact.

Despite the positive demand outlook, the glacial acetic acid market faces challenges such as price volatility of raw materials and stringent environmental regulations. The industry is actively exploring bio-based production methods to address sustainability concerns and reduce dependence on fossil fuel-derived feedstocks.

In the food industry, glacial acetic acid serves as a crucial ingredient in food preservation and flavor enhancement. Its antimicrobial properties make it an essential component in pickling processes and as a food additive. The pharmaceutical sector also relies heavily on glacial acetic acid for the synthesis of various medications and as a solvent in drug formulations.

The textile industry employs glacial acetic acid in dyeing processes and as a pH regulator. Additionally, it plays a vital role in the production of synthetic fibers such as rayon and cellulose acetate. The electronics industry utilizes glacial acetic acid in the manufacturing of printed circuit boards and as a cleaning agent for electronic components.

Market analysis indicates a growing demand for biodegradable plastics and eco-friendly products, which is expected to further boost the consumption of glacial acetic acid. The compound's role in producing biodegradable polymers aligns with the global shift towards sustainable materials.

Geographically, Asia-Pacific dominates the glacial acetic acid market, with China being the largest producer and consumer. The region's rapid industrialization and expanding manufacturing sector contribute significantly to this trend. North America and Europe follow, with steady demand from established chemical and pharmaceutical industries.

The market is characterized by a few large-scale producers and numerous small to medium-sized manufacturers. Key players are focusing on expanding their production capacities to meet the rising global demand. Technological advancements in production processes are being pursued to improve efficiency and reduce environmental impact.

Despite the positive demand outlook, the glacial acetic acid market faces challenges such as price volatility of raw materials and stringent environmental regulations. The industry is actively exploring bio-based production methods to address sustainability concerns and reduce dependence on fossil fuel-derived feedstocks.

Current Challenges in Large-Scale Acetic Acid Production

The large-scale production of acetic acid faces several significant challenges that hinder efficiency, sustainability, and cost-effectiveness. One of the primary issues is the corrosive nature of glacial acetic acid, which necessitates the use of specialized materials for equipment and storage. This requirement substantially increases capital and maintenance costs, particularly when scaling up production.

Energy consumption presents another major hurdle in acetic acid production. The process typically involves high-temperature and high-pressure conditions, demanding substantial energy inputs. As production scales up, the energy requirements increase proportionally, leading to higher operational costs and a larger carbon footprint. This challenge is further compounded by the global push for more sustainable and environmentally friendly industrial processes.

Raw material sourcing and supply chain management pose significant challenges in large-scale acetic acid production. The primary feedstocks, such as methanol or ethanol, are subject to price volatility and supply constraints. Ensuring a stable and cost-effective supply of these raw materials becomes increasingly complex as production volumes grow, potentially impacting production consistency and profitability.

Process safety is a critical concern in acetic acid production, particularly at larger scales. The flammable and corrosive nature of the chemicals involved requires stringent safety measures and sophisticated process control systems. Scaling up production amplifies these safety risks, necessitating more advanced monitoring and emergency response capabilities.

Waste management and environmental compliance represent ongoing challenges in acetic acid production. The process generates various byproducts and waste streams that require proper treatment and disposal. As production scales up, the volume of waste increases, demanding more sophisticated and costly waste management solutions to meet increasingly stringent environmental regulations.

Quality control and product consistency become more challenging at larger scales. Maintaining uniform product quality across larger batch sizes or continuous production runs requires advanced process control and analytical techniques. Variations in raw material quality, process conditions, and equipment performance can have more significant impacts on product quality in large-scale operations.

Finally, the optimization of reaction kinetics and catalytic processes presents ongoing challenges in scaling up acetic acid production. Achieving optimal yields and selectivity at industrial scales often requires fine-tuning of reaction conditions and catalyst performance. This optimization becomes more complex and critical as production volumes increase, directly impacting overall process efficiency and economic viability.

Energy consumption presents another major hurdle in acetic acid production. The process typically involves high-temperature and high-pressure conditions, demanding substantial energy inputs. As production scales up, the energy requirements increase proportionally, leading to higher operational costs and a larger carbon footprint. This challenge is further compounded by the global push for more sustainable and environmentally friendly industrial processes.

Raw material sourcing and supply chain management pose significant challenges in large-scale acetic acid production. The primary feedstocks, such as methanol or ethanol, are subject to price volatility and supply constraints. Ensuring a stable and cost-effective supply of these raw materials becomes increasingly complex as production volumes grow, potentially impacting production consistency and profitability.

Process safety is a critical concern in acetic acid production, particularly at larger scales. The flammable and corrosive nature of the chemicals involved requires stringent safety measures and sophisticated process control systems. Scaling up production amplifies these safety risks, necessitating more advanced monitoring and emergency response capabilities.

Waste management and environmental compliance represent ongoing challenges in acetic acid production. The process generates various byproducts and waste streams that require proper treatment and disposal. As production scales up, the volume of waste increases, demanding more sophisticated and costly waste management solutions to meet increasingly stringent environmental regulations.

Quality control and product consistency become more challenging at larger scales. Maintaining uniform product quality across larger batch sizes or continuous production runs requires advanced process control and analytical techniques. Variations in raw material quality, process conditions, and equipment performance can have more significant impacts on product quality in large-scale operations.

Finally, the optimization of reaction kinetics and catalytic processes presents ongoing challenges in scaling up acetic acid production. Achieving optimal yields and selectivity at industrial scales often requires fine-tuning of reaction conditions and catalyst performance. This optimization becomes more complex and critical as production volumes increase, directly impacting overall process efficiency and economic viability.

Existing Solutions for Industrial-Scale Acetic Acid Production

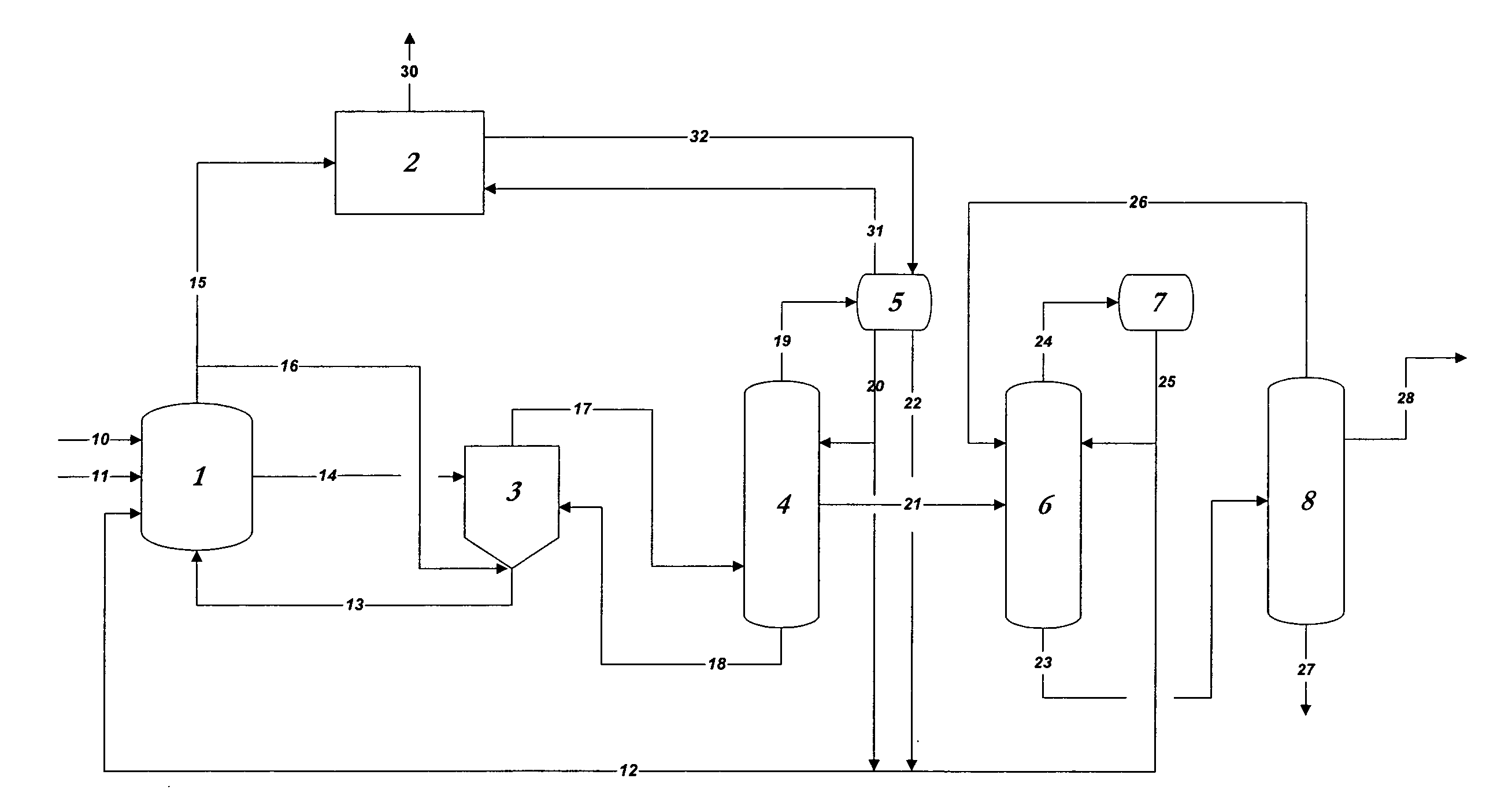

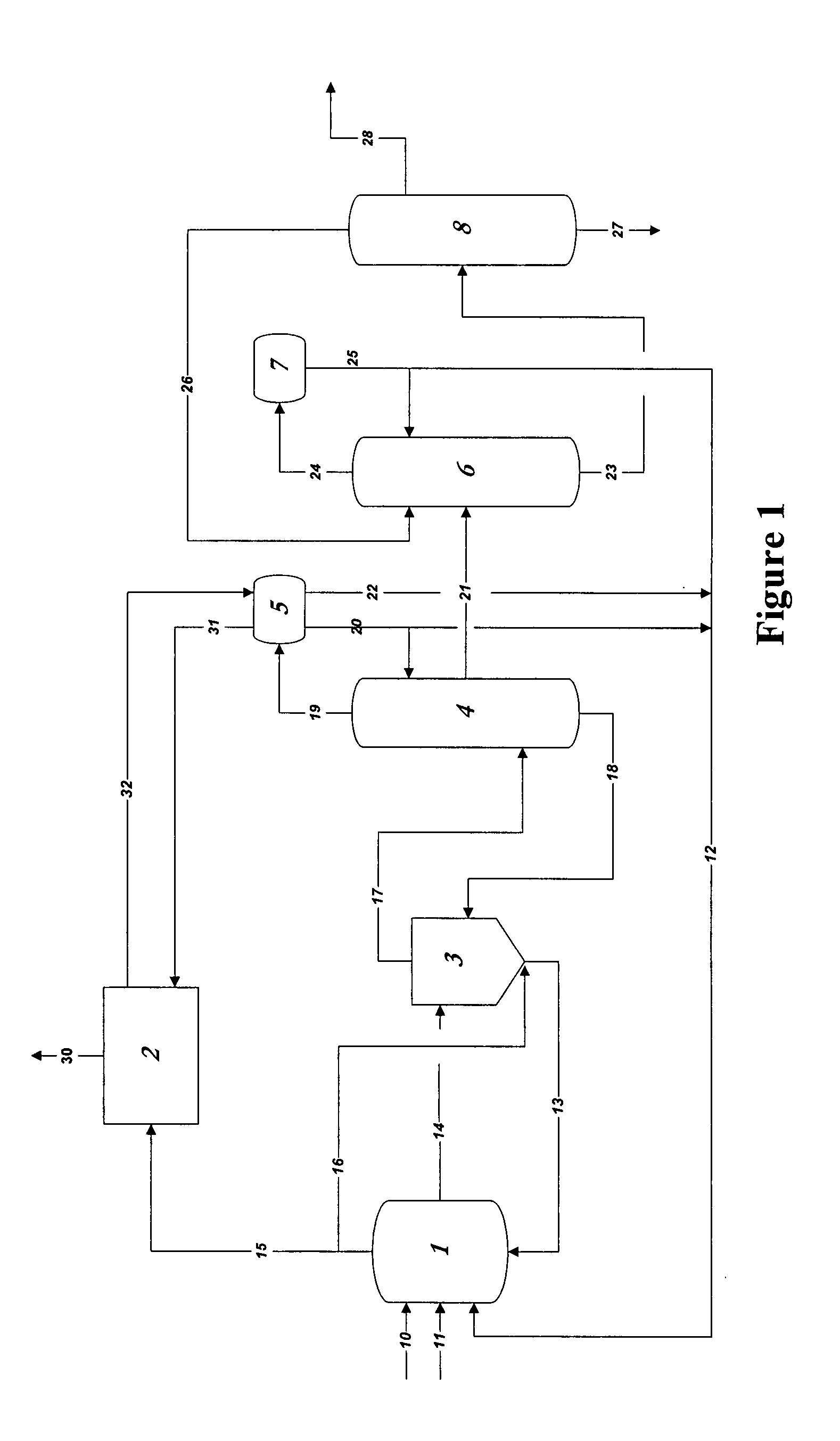

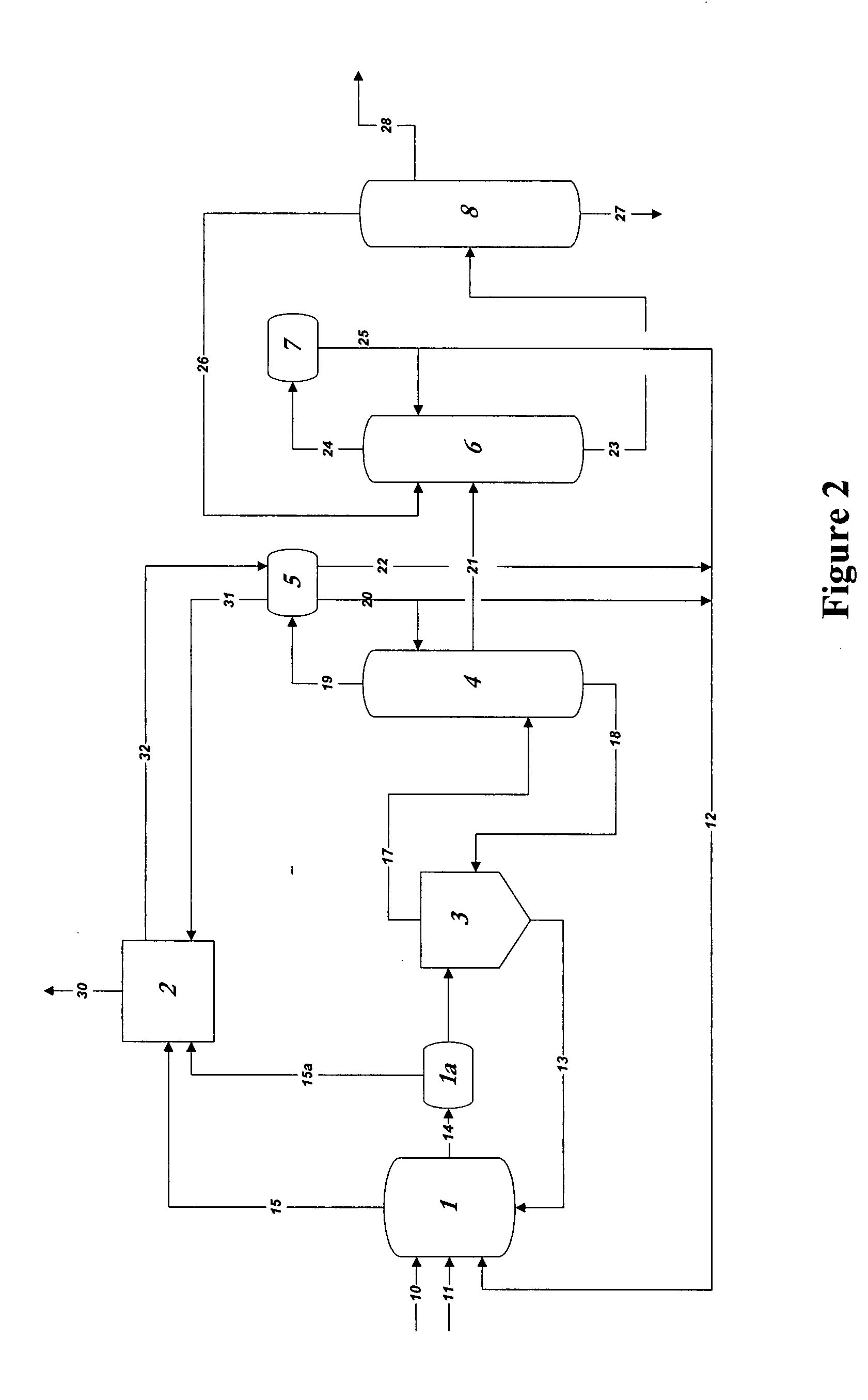

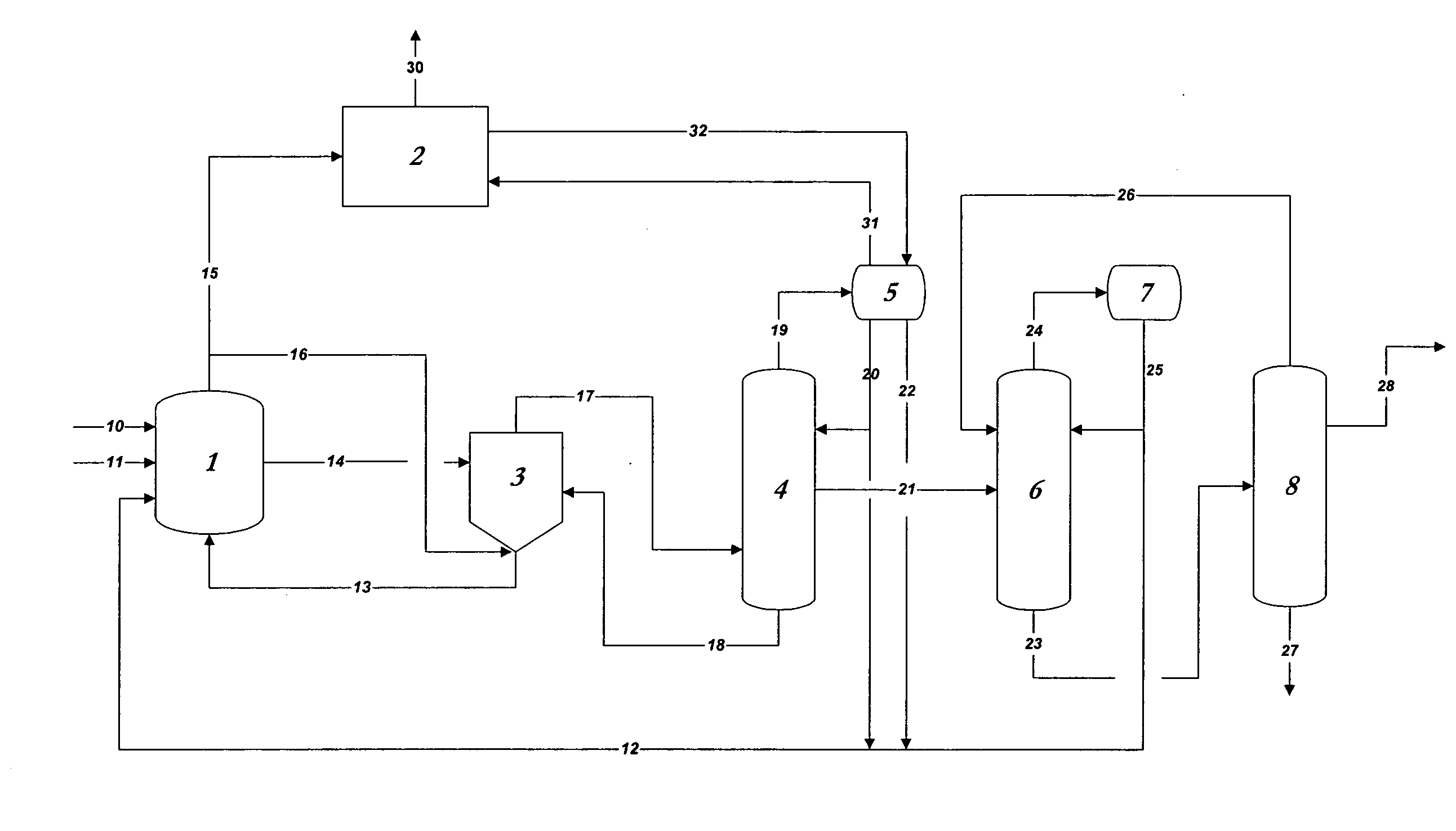

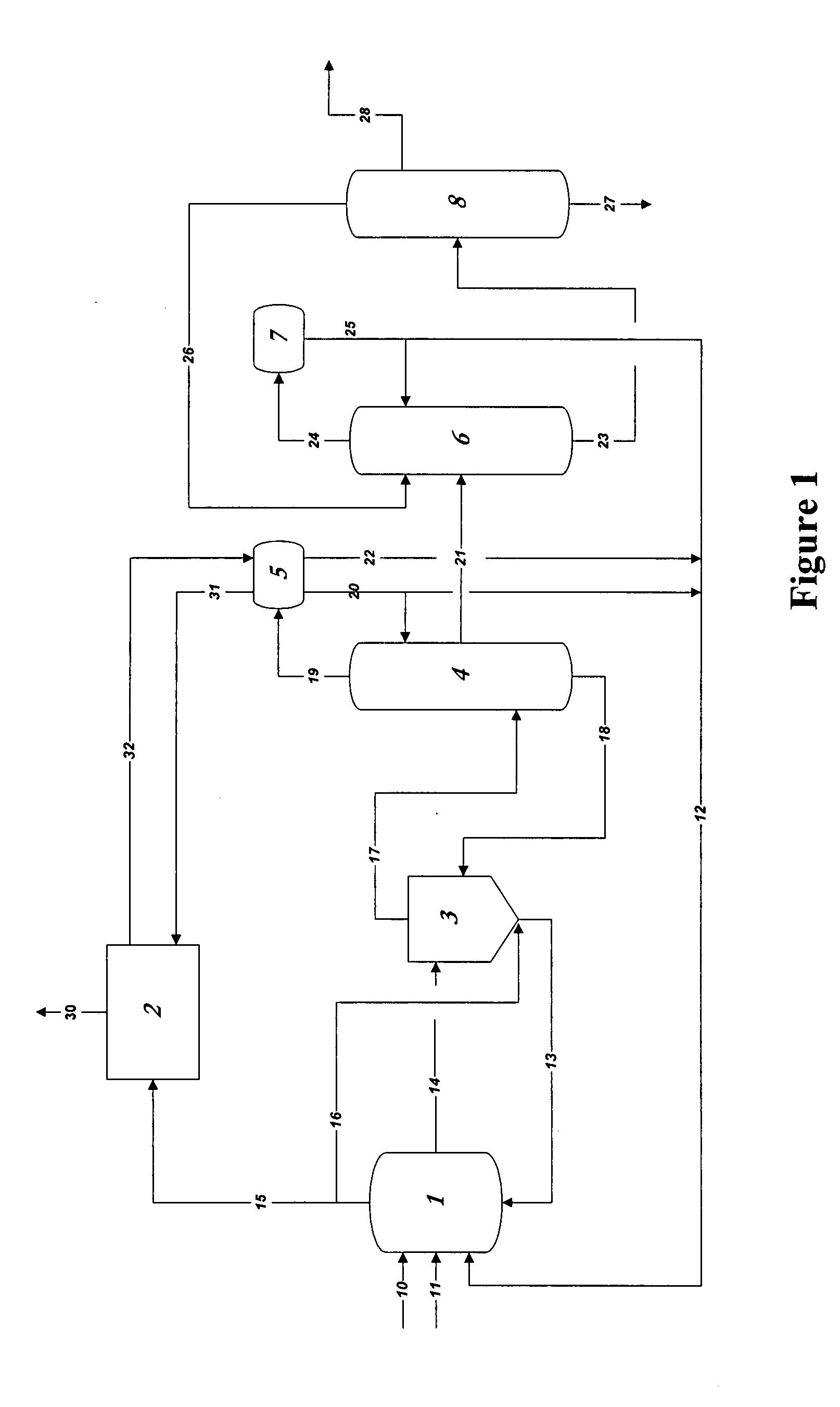

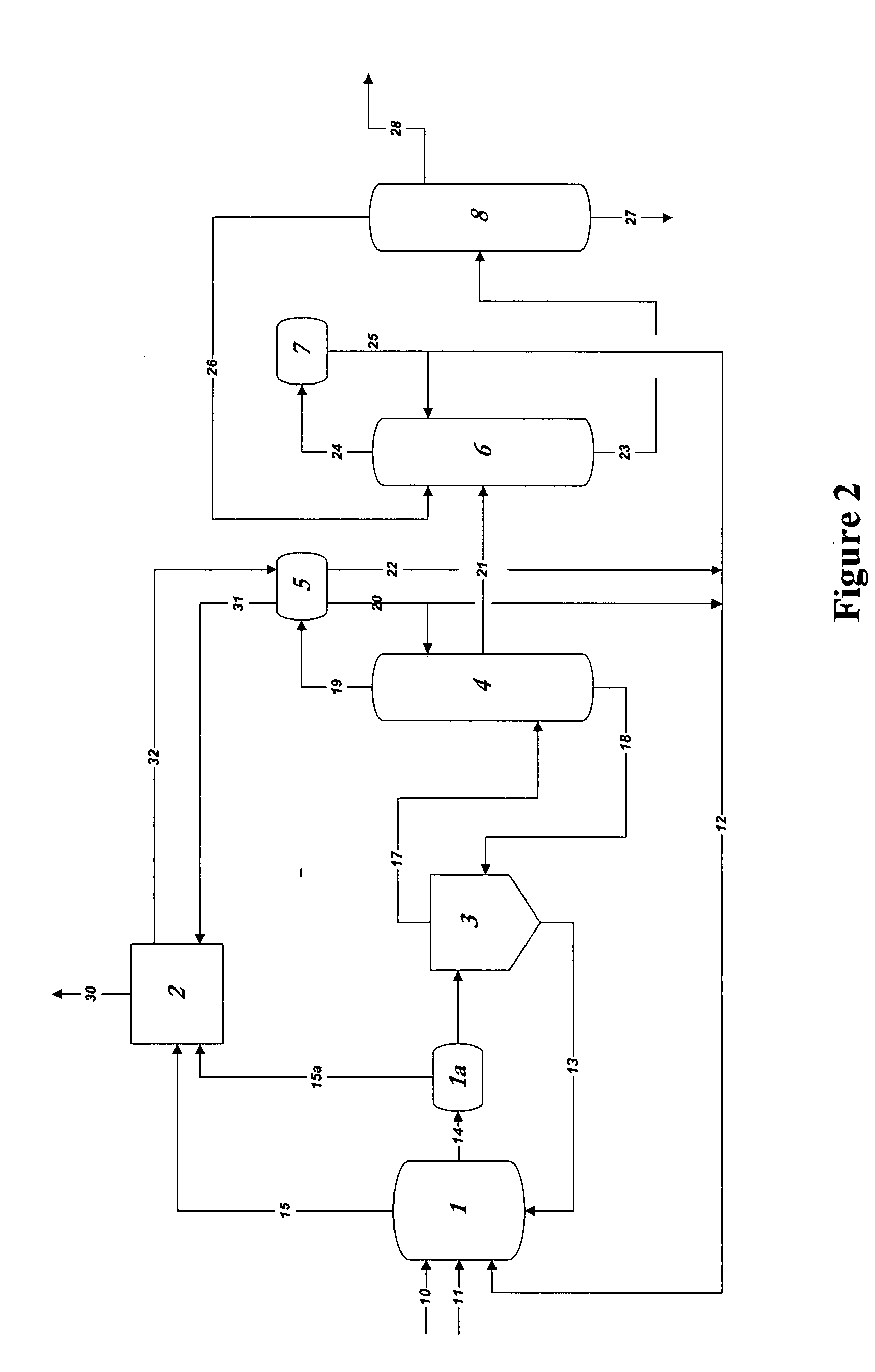

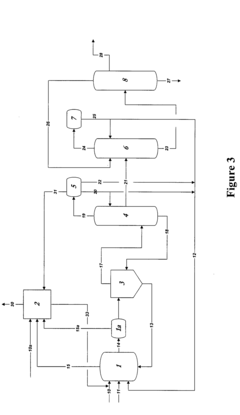

01 Reactor design for glacial acetic acid production

Specialized reactor designs are crucial for scaling up glacial acetic acid production. These reactors often incorporate features such as improved heat exchange systems, corrosion-resistant materials, and optimized mixing mechanisms to handle the increased volume and maintain product quality during large-scale production.- Reactor design for glacial acetic acid production: Specialized reactor designs are crucial for scaling up glacial acetic acid production. These reactors often incorporate features such as improved heat exchange systems, corrosion-resistant materials, and optimized mixing mechanisms to enhance efficiency and product quality at larger scales.

- Purification and concentration techniques: Scaling up glacial acetic acid production requires advanced purification and concentration methods. These may include distillation columns, crystallization processes, and membrane separation technologies to achieve high purity levels and remove impurities efficiently in large-scale operations.

- Process control and automation: Implementing sophisticated process control and automation systems is essential for scaling up glacial acetic acid production. These systems help maintain consistent quality, optimize reaction conditions, and ensure safe operation at industrial scales through real-time monitoring and adjustment of critical parameters.

- Raw material handling and preparation: Efficient handling and preparation of raw materials are crucial for large-scale glacial acetic acid production. This includes developing systems for storage, transportation, and pre-treatment of feedstocks to ensure consistent supply and quality in industrial-scale operations.

- Energy efficiency and heat recovery: Improving energy efficiency and implementing heat recovery systems are important considerations when scaling up glacial acetic acid production. These measures may include the use of heat exchangers, waste heat utilization, and process integration to reduce energy consumption and operational costs in large-scale facilities.

02 Purification and concentration techniques

Scaling up glacial acetic acid production requires advanced purification and concentration methods. These may include distillation columns, crystallization processes, and membrane separation technologies to achieve high purity levels and remove impurities efficiently in large-scale operations.Expand Specific Solutions03 Process control and automation

Implementing sophisticated process control and automation systems is essential for scaling up glacial acetic acid production. These systems help maintain consistent quality, optimize reaction conditions, and ensure safety in large-scale operations through real-time monitoring and adjustment of critical parameters.Expand Specific Solutions04 Raw material handling and storage

Efficient handling and storage of raw materials are crucial for scaled-up glacial acetic acid production. This includes designing large-capacity storage tanks, implementing safety measures for handling corrosive materials, and developing efficient material transfer systems to support continuous production at an industrial scale.Expand Specific Solutions05 Energy efficiency and heat recovery

Improving energy efficiency and implementing heat recovery systems are important considerations when scaling up glacial acetic acid production. This may involve the use of advanced heat exchangers, waste heat utilization, and process integration techniques to minimize energy consumption and reduce operating costs in large-scale operations.Expand Specific Solutions

Key Players in Glacial Acetic Acid Industry

The market for glacial acetic acid-based industrial processes is in a mature stage, with a global market size estimated to exceed $10 billion. The technology is well-established, with major players like China Petroleum & Chemical Corp., BASF Corp., and Resonac Holdings Corp. leading the field. These companies have extensive experience in scaling up production processes. However, challenges remain in improving efficiency and sustainability. Emerging players such as Solugen, Inc. are exploring bio-based alternatives, potentially disrupting the traditional petrochemical-based production methods. The competitive landscape is characterized by a mix of established chemical giants and innovative startups, each addressing the scaling challenges from different technological approaches.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has developed an innovative approach to scaling up glacial acetic acid production using a proprietary catalytic oxidation process. Their method employs a novel rhodium-based catalyst system that enhances selectivity and yield[1]. The process operates at lower temperatures (150-180°C) compared to conventional methods, reducing energy consumption by up to 20%[2]. Sinopec has also implemented advanced process control systems and heat integration techniques to optimize reactor performance and minimize waste. Their scaled-up facilities can produce over 1 million tons of glacial acetic acid annually with a purity exceeding 99.8%[3].

Strengths: High production capacity, improved energy efficiency, and superior product purity. Weaknesses: Potential high costs associated with catalyst materials and specialized equipment requirements.

BASF Corp.

Technical Solution: BASF Corp. has developed a cutting-edge approach to scaling up glacial acetic acid production using a carbonylation process with improved catalysts. Their method utilizes a modified rhodium-iridium bimetallic catalyst system that enhances reaction rates and selectivity[4]. The process operates under milder conditions (150-170°C, 30-40 bar) compared to traditional methods, leading to reduced energy consumption and improved safety profiles[5]. BASF has also implemented advanced process intensification techniques, including microreactor technology and continuous flow systems, to optimize production efficiency. Their scaled-up facilities can achieve production capacities of over 800,000 tons per year with a glacial acetic acid purity of 99.9%[6].

Strengths: Advanced catalyst technology, improved process safety, and high product purity. Weaknesses: Potential complexity in catalyst preparation and handling, and higher initial investment costs for specialized equipment.

Innovative Technologies in Acetic Acid Synthesis

Control of impurities in reaction product of rhodium-catalyzed methanol carbonylation

PatentInactiveUS20080293966A1

Innovation

- A method involving the reaction of methanol, methyl acetate, or dimethyl ether with carbon monoxide in the presence of a rhodium catalyst, maintaining a water concentration of 0.5 to 14 weight percent to control formic acid content in the product acetic acid to 15-160 ppm, and using a silver exchanged cationic ion exchange resin to reduce sulfur levels below 1 ppm.

Control of formic acid impurities in industrial glacial acetic acid

PatentInactiveUS20080293967A1

Innovation

- Controlling the water concentration in the reaction medium during rhodium-catalyzed methanol carbonylation to specific ranges (0.5 to 14 weight percent) effectively inhibits the formation of formic acid impurities in the glacial acetic acid product, achieving low formic acid content below 160 ppm.

Environmental Impact Assessment of Acetic Acid Production

The environmental impact assessment of acetic acid production is a critical component in evaluating the sustainability and ecological footprint of industrial processes involving glacial acetic acid. This assessment encompasses various aspects of the production lifecycle, from raw material extraction to waste management and disposal.

One of the primary environmental concerns associated with acetic acid production is air pollution. The manufacturing process often involves the release of volatile organic compounds (VOCs) and other potentially harmful emissions. These emissions can contribute to smog formation, ozone depletion, and overall air quality degradation in surrounding areas. Implementing advanced air pollution control technologies, such as scrubbers and thermal oxidizers, is essential to mitigate these impacts.

Water pollution is another significant environmental issue related to acetic acid production. Wastewater from the manufacturing process may contain high levels of organic compounds, acids, and other contaminants. If not properly treated, this effluent can harm aquatic ecosystems and potentially contaminate groundwater resources. Implementing robust wastewater treatment systems and adopting water recycling practices are crucial steps in minimizing water pollution.

The production of acetic acid also has implications for energy consumption and greenhouse gas emissions. The process typically requires substantial energy inputs, often derived from fossil fuels, contributing to carbon dioxide emissions and climate change. Improving energy efficiency in production facilities and transitioning to renewable energy sources can help reduce the carbon footprint of acetic acid manufacturing.

Solid waste generation and management are additional environmental concerns. The production process may generate various types of solid waste, including spent catalysts, filter materials, and packaging waste. Proper disposal or recycling of these materials is essential to prevent soil contamination and reduce the overall environmental impact of the industry.

Land use and biodiversity impacts should also be considered in the environmental assessment. The construction and operation of acetic acid production facilities can lead to habitat destruction and fragmentation, potentially affecting local flora and fauna. Careful site selection and implementation of biodiversity conservation measures can help mitigate these impacts.

Furthermore, the transportation of raw materials and finished products contributes to the overall environmental footprint of acetic acid production. Optimizing logistics and exploring more sustainable transportation options can help reduce associated emissions and energy consumption.

In conclusion, a comprehensive environmental impact assessment of acetic acid production must address air and water pollution, energy consumption, greenhouse gas emissions, waste management, land use, and biodiversity impacts. By identifying and addressing these environmental challenges, the industry can work towards more sustainable production practices and minimize its ecological footprint.

One of the primary environmental concerns associated with acetic acid production is air pollution. The manufacturing process often involves the release of volatile organic compounds (VOCs) and other potentially harmful emissions. These emissions can contribute to smog formation, ozone depletion, and overall air quality degradation in surrounding areas. Implementing advanced air pollution control technologies, such as scrubbers and thermal oxidizers, is essential to mitigate these impacts.

Water pollution is another significant environmental issue related to acetic acid production. Wastewater from the manufacturing process may contain high levels of organic compounds, acids, and other contaminants. If not properly treated, this effluent can harm aquatic ecosystems and potentially contaminate groundwater resources. Implementing robust wastewater treatment systems and adopting water recycling practices are crucial steps in minimizing water pollution.

The production of acetic acid also has implications for energy consumption and greenhouse gas emissions. The process typically requires substantial energy inputs, often derived from fossil fuels, contributing to carbon dioxide emissions and climate change. Improving energy efficiency in production facilities and transitioning to renewable energy sources can help reduce the carbon footprint of acetic acid manufacturing.

Solid waste generation and management are additional environmental concerns. The production process may generate various types of solid waste, including spent catalysts, filter materials, and packaging waste. Proper disposal or recycling of these materials is essential to prevent soil contamination and reduce the overall environmental impact of the industry.

Land use and biodiversity impacts should also be considered in the environmental assessment. The construction and operation of acetic acid production facilities can lead to habitat destruction and fragmentation, potentially affecting local flora and fauna. Careful site selection and implementation of biodiversity conservation measures can help mitigate these impacts.

Furthermore, the transportation of raw materials and finished products contributes to the overall environmental footprint of acetic acid production. Optimizing logistics and exploring more sustainable transportation options can help reduce associated emissions and energy consumption.

In conclusion, a comprehensive environmental impact assessment of acetic acid production must address air and water pollution, energy consumption, greenhouse gas emissions, waste management, land use, and biodiversity impacts. By identifying and addressing these environmental challenges, the industry can work towards more sustainable production practices and minimize its ecological footprint.

Safety Considerations in Scaled-Up Acetic Acid Processes

Safety considerations are paramount when scaling up glacial acetic acid-based industrial processes. The corrosive and flammable nature of acetic acid presents significant challenges that must be addressed to ensure worker safety and prevent environmental hazards.

Material selection becomes crucial in large-scale operations. Stainless steel, particularly types 316 and 317, is commonly used for equipment and piping due to its resistance to acetic acid corrosion. However, at higher concentrations and temperatures, even these materials may be susceptible to stress corrosion cracking. Regular inspections and maintenance schedules must be implemented to detect and prevent potential failures.

Proper ventilation systems are essential to mitigate the risks associated with acetic acid vapors. These systems should be designed to handle the increased volume of vapors produced in scaled-up processes. The use of closed systems and vapor recovery units can significantly reduce exposure risks and environmental impact.

Personal protective equipment (PPE) requirements become more stringent in large-scale operations. Workers must be equipped with appropriate acid-resistant clothing, gloves, and eye protection. Respiratory protection may be necessary in areas with potential for high vapor concentrations. Training programs should be enhanced to ensure all personnel are well-versed in safety protocols and emergency procedures.

Emergency response planning must be scaled accordingly. This includes the installation of safety showers and eyewash stations at strategic locations throughout the facility. Spill containment systems should be designed to handle larger volumes, with consideration given to potential domino effects in case of major incidents.

Fire safety is a critical concern due to acetic acid's flammability. Scaled-up processes require more robust fire suppression systems, including specialized foam systems designed for polar solvents. The electrical equipment used in these processes must be explosion-proof to prevent ignition sources.

Environmental considerations become more complex with increased scale. Wastewater treatment systems must be capable of handling larger volumes and potentially higher concentrations of acetic acid. Air quality monitoring should be implemented to ensure emissions comply with regulatory standards.

Risk assessment methodologies, such as Hazard and Operability Studies (HAZOP) and Quantitative Risk Assessment (QRA), should be employed to identify and mitigate potential hazards specific to the scaled-up process. These assessments should be regularly updated to reflect any changes in the process or equipment.

Material selection becomes crucial in large-scale operations. Stainless steel, particularly types 316 and 317, is commonly used for equipment and piping due to its resistance to acetic acid corrosion. However, at higher concentrations and temperatures, even these materials may be susceptible to stress corrosion cracking. Regular inspections and maintenance schedules must be implemented to detect and prevent potential failures.

Proper ventilation systems are essential to mitigate the risks associated with acetic acid vapors. These systems should be designed to handle the increased volume of vapors produced in scaled-up processes. The use of closed systems and vapor recovery units can significantly reduce exposure risks and environmental impact.

Personal protective equipment (PPE) requirements become more stringent in large-scale operations. Workers must be equipped with appropriate acid-resistant clothing, gloves, and eye protection. Respiratory protection may be necessary in areas with potential for high vapor concentrations. Training programs should be enhanced to ensure all personnel are well-versed in safety protocols and emergency procedures.

Emergency response planning must be scaled accordingly. This includes the installation of safety showers and eyewash stations at strategic locations throughout the facility. Spill containment systems should be designed to handle larger volumes, with consideration given to potential domino effects in case of major incidents.

Fire safety is a critical concern due to acetic acid's flammability. Scaled-up processes require more robust fire suppression systems, including specialized foam systems designed for polar solvents. The electrical equipment used in these processes must be explosion-proof to prevent ignition sources.

Environmental considerations become more complex with increased scale. Wastewater treatment systems must be capable of handling larger volumes and potentially higher concentrations of acetic acid. Air quality monitoring should be implemented to ensure emissions comply with regulatory standards.

Risk assessment methodologies, such as Hazard and Operability Studies (HAZOP) and Quantitative Risk Assessment (QRA), should be employed to identify and mitigate potential hazards specific to the scaled-up process. These assessments should be regularly updated to reflect any changes in the process or equipment.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!