Comparative Analysis of Thermal Processes in Synthetic Biology

SEP 19, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Thermal Processes in Synthetic Biology: Background and Objectives

Synthetic biology represents a revolutionary field at the intersection of biology, engineering, and computational science, with thermal processes playing a crucial role in its development and application. The evolution of thermal technologies in synthetic biology can be traced back to the early 2000s when researchers began manipulating biological systems at the molecular level. Initially, thermal processes were primarily used for basic DNA manipulation, but they have since evolved into sophisticated techniques enabling precise control over biological reactions and systems.

The trajectory of thermal processes in synthetic biology has been marked by significant milestones, including the development of polymerase chain reaction (PCR) technologies, thermal cycling systems, and more recently, isothermal amplification methods. These advancements have progressively reduced reaction times, increased precision, and expanded the scope of applications in synthetic biology. The trend is clearly moving toward more energy-efficient, miniaturized, and automated thermal control systems that can operate with greater specificity and reduced environmental impact.

Current research is increasingly focused on integrating thermal processes with other technologies such as microfluidics, nanotechnology, and artificial intelligence to create more comprehensive and efficient synthetic biology platforms. This integration represents a significant shift from isolated thermal techniques to holistic systems that can address complex biological challenges. The convergence of these technologies is creating new possibilities for applications in medicine, agriculture, environmental remediation, and industrial biotechnology.

The primary objective of this technical research is to conduct a comparative analysis of various thermal processes employed in synthetic biology, evaluating their efficiency, scalability, precision, and applicability across different contexts. This analysis aims to identify the most promising thermal technologies and methodologies that can advance the field of synthetic biology and address current limitations in biological engineering.

Additionally, this research seeks to explore emerging thermal technologies that could potentially revolutionize synthetic biology practices, such as spatiotemporal thermal control systems, thermal gradient generators, and thermally responsive biomaterials. By examining these cutting-edge approaches, we aim to forecast future developments and provide strategic insights for research and development initiatives in this rapidly evolving field.

The ultimate goal is to establish a comprehensive understanding of how thermal processes can be optimized and integrated into synthetic biology workflows to enhance the design, construction, and manipulation of biological systems for various applications. This knowledge will be instrumental in guiding future research directions and technological innovations in synthetic biology.

The trajectory of thermal processes in synthetic biology has been marked by significant milestones, including the development of polymerase chain reaction (PCR) technologies, thermal cycling systems, and more recently, isothermal amplification methods. These advancements have progressively reduced reaction times, increased precision, and expanded the scope of applications in synthetic biology. The trend is clearly moving toward more energy-efficient, miniaturized, and automated thermal control systems that can operate with greater specificity and reduced environmental impact.

Current research is increasingly focused on integrating thermal processes with other technologies such as microfluidics, nanotechnology, and artificial intelligence to create more comprehensive and efficient synthetic biology platforms. This integration represents a significant shift from isolated thermal techniques to holistic systems that can address complex biological challenges. The convergence of these technologies is creating new possibilities for applications in medicine, agriculture, environmental remediation, and industrial biotechnology.

The primary objective of this technical research is to conduct a comparative analysis of various thermal processes employed in synthetic biology, evaluating their efficiency, scalability, precision, and applicability across different contexts. This analysis aims to identify the most promising thermal technologies and methodologies that can advance the field of synthetic biology and address current limitations in biological engineering.

Additionally, this research seeks to explore emerging thermal technologies that could potentially revolutionize synthetic biology practices, such as spatiotemporal thermal control systems, thermal gradient generators, and thermally responsive biomaterials. By examining these cutting-edge approaches, we aim to forecast future developments and provide strategic insights for research and development initiatives in this rapidly evolving field.

The ultimate goal is to establish a comprehensive understanding of how thermal processes can be optimized and integrated into synthetic biology workflows to enhance the design, construction, and manipulation of biological systems for various applications. This knowledge will be instrumental in guiding future research directions and technological innovations in synthetic biology.

Market Applications and Demand Analysis for Thermal Bioprocessing

The thermal bioprocessing market is experiencing significant growth driven by the expanding applications of synthetic biology across multiple industries. Current market analysis indicates that the global synthetic biology market, which heavily relies on thermal processes, is projected to reach $30.7 billion by 2026, with thermal bioprocessing technologies representing a substantial segment. This growth is primarily fueled by increasing demand in pharmaceutical development, where thermal processes are essential for protein expression, DNA amplification, and enzyme production.

Healthcare applications dominate the thermal bioprocessing market, accounting for approximately 40% of the total market share. The rising prevalence of chronic diseases and the growing emphasis on personalized medicine have accelerated the demand for precisely controlled thermal processes in drug discovery and development. Biopharmaceutical companies are increasingly investing in advanced thermal control systems that can maintain optimal conditions for sensitive biological reactions, enhancing yield and product quality.

Industrial biotechnology represents another rapidly expanding market segment, with annual growth rates exceeding 15%. Companies in this sector utilize thermal bioprocessing for the production of biofuels, biomaterials, and specialty chemicals. The push toward sustainable manufacturing practices has created substantial demand for energy-efficient thermal bioprocessing technologies that can operate at industrial scales while maintaining precise temperature control.

Agricultural applications of thermal bioprocessing are gaining traction as well, particularly in the development of genetically modified crops and biological pesticides. This sector is expected to grow at a compound annual growth rate of 12.3% through 2028, driven by increasing food security concerns and the need for sustainable agricultural practices. Thermal processes are critical for seed treatment, soil sterilization, and the production of biological agents used in modern agriculture.

Consumer demand trends indicate a growing preference for bio-based products manufactured using environmentally friendly processes. This shift has prompted companies across various industries to adopt thermal bioprocessing technologies that minimize energy consumption and reduce carbon footprints. Market surveys reveal that 67% of consumers are willing to pay premium prices for products developed using sustainable bioprocessing methods.

Regional market analysis shows North America leading the thermal bioprocessing market with approximately 35% market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate due to increasing investments in biotechnology infrastructure and favorable government policies supporting biotech innovations. Countries like China, India, and Singapore are emerging as significant markets for thermal bioprocessing technologies, with domestic demand growing at nearly twice the global average rate.

Healthcare applications dominate the thermal bioprocessing market, accounting for approximately 40% of the total market share. The rising prevalence of chronic diseases and the growing emphasis on personalized medicine have accelerated the demand for precisely controlled thermal processes in drug discovery and development. Biopharmaceutical companies are increasingly investing in advanced thermal control systems that can maintain optimal conditions for sensitive biological reactions, enhancing yield and product quality.

Industrial biotechnology represents another rapidly expanding market segment, with annual growth rates exceeding 15%. Companies in this sector utilize thermal bioprocessing for the production of biofuels, biomaterials, and specialty chemicals. The push toward sustainable manufacturing practices has created substantial demand for energy-efficient thermal bioprocessing technologies that can operate at industrial scales while maintaining precise temperature control.

Agricultural applications of thermal bioprocessing are gaining traction as well, particularly in the development of genetically modified crops and biological pesticides. This sector is expected to grow at a compound annual growth rate of 12.3% through 2028, driven by increasing food security concerns and the need for sustainable agricultural practices. Thermal processes are critical for seed treatment, soil sterilization, and the production of biological agents used in modern agriculture.

Consumer demand trends indicate a growing preference for bio-based products manufactured using environmentally friendly processes. This shift has prompted companies across various industries to adopt thermal bioprocessing technologies that minimize energy consumption and reduce carbon footprints. Market surveys reveal that 67% of consumers are willing to pay premium prices for products developed using sustainable bioprocessing methods.

Regional market analysis shows North America leading the thermal bioprocessing market with approximately 35% market share, followed closely by Europe at 30% and Asia-Pacific at 25%. However, the Asia-Pacific region is experiencing the fastest growth rate due to increasing investments in biotechnology infrastructure and favorable government policies supporting biotech innovations. Countries like China, India, and Singapore are emerging as significant markets for thermal bioprocessing technologies, with domestic demand growing at nearly twice the global average rate.

Current Thermal Technologies and Challenges in Synthetic Biology

Synthetic biology has witnessed significant advancements in thermal technologies over the past decade, with various methodologies being developed to control and manipulate biological systems through temperature regulation. Currently, the field employs several thermal technologies including polymerase chain reaction (PCR), thermal cycling for gene expression control, temperature-responsive biomaterials, and thermally-activated enzyme systems. These technologies have become fundamental tools in synthetic biology laboratories worldwide, enabling precise control over genetic circuits and metabolic pathways.

PCR-based technologies remain the cornerstone of DNA amplification in synthetic biology, with recent innovations focusing on miniaturization and integration with microfluidic platforms. Digital PCR and isothermal amplification methods have emerged as alternatives that offer advantages in certain applications, particularly in resource-limited settings. However, these technologies still face challenges in terms of energy efficiency, speed, and scalability for industrial applications.

Temperature-responsive gene expression systems represent another critical thermal technology in synthetic biology. These systems utilize temperature-sensitive promoters, riboswitches, and protein conformational changes to regulate gene expression. While these systems offer non-invasive control mechanisms, they often suffer from leaky expression, slow response times, and limited dynamic range, constraining their utility in complex synthetic circuits.

Thermal gradients and localized heating technologies have gained prominence for spatial control of biological processes. Techniques such as optothermal manipulation, magnetic nanoparticle-based heating, and microheater arrays enable precise temperature control at microscale resolution. Despite their potential, these approaches face challenges in terms of integration with biological systems, potential cytotoxicity, and difficulties in maintaining stable thermal profiles over extended periods.

A significant challenge across all thermal technologies in synthetic biology is the inherent thermal sensitivity of biological components. Proteins, nucleic acids, and cellular structures can denature or lose functionality under thermal stress, limiting the operational temperature range for many applications. This constraint necessitates careful engineering of thermostable variants or the development of protective strategies to maintain biological activity during thermal processes.

Energy consumption presents another major challenge, particularly for field-deployable or continuous operation systems. Current thermal cycling technologies require substantial power input, making them impractical for certain applications such as point-of-care diagnostics or long-term environmental monitoring. The development of energy-efficient thermal management strategies remains a priority for expanding the application scope of synthetic biology tools.

Standardization and reproducibility issues also plague thermal technologies in synthetic biology. Variations in heating/cooling rates, temperature uniformity, and thermal transfer efficiency across different platforms can lead to inconsistent results, hampering the reliable implementation of synthetic biological systems in diverse settings. Addressing these challenges requires interdisciplinary approaches combining thermal engineering, materials science, and biological design principles.

PCR-based technologies remain the cornerstone of DNA amplification in synthetic biology, with recent innovations focusing on miniaturization and integration with microfluidic platforms. Digital PCR and isothermal amplification methods have emerged as alternatives that offer advantages in certain applications, particularly in resource-limited settings. However, these technologies still face challenges in terms of energy efficiency, speed, and scalability for industrial applications.

Temperature-responsive gene expression systems represent another critical thermal technology in synthetic biology. These systems utilize temperature-sensitive promoters, riboswitches, and protein conformational changes to regulate gene expression. While these systems offer non-invasive control mechanisms, they often suffer from leaky expression, slow response times, and limited dynamic range, constraining their utility in complex synthetic circuits.

Thermal gradients and localized heating technologies have gained prominence for spatial control of biological processes. Techniques such as optothermal manipulation, magnetic nanoparticle-based heating, and microheater arrays enable precise temperature control at microscale resolution. Despite their potential, these approaches face challenges in terms of integration with biological systems, potential cytotoxicity, and difficulties in maintaining stable thermal profiles over extended periods.

A significant challenge across all thermal technologies in synthetic biology is the inherent thermal sensitivity of biological components. Proteins, nucleic acids, and cellular structures can denature or lose functionality under thermal stress, limiting the operational temperature range for many applications. This constraint necessitates careful engineering of thermostable variants or the development of protective strategies to maintain biological activity during thermal processes.

Energy consumption presents another major challenge, particularly for field-deployable or continuous operation systems. Current thermal cycling technologies require substantial power input, making them impractical for certain applications such as point-of-care diagnostics or long-term environmental monitoring. The development of energy-efficient thermal management strategies remains a priority for expanding the application scope of synthetic biology tools.

Standardization and reproducibility issues also plague thermal technologies in synthetic biology. Variations in heating/cooling rates, temperature uniformity, and thermal transfer efficiency across different platforms can lead to inconsistent results, hampering the reliable implementation of synthetic biological systems in diverse settings. Addressing these challenges requires interdisciplinary approaches combining thermal engineering, materials science, and biological design principles.

Comparative Analysis of Current Thermal Process Methodologies

01 Thermally efficient bioreactors for synthetic biology

Advanced bioreactor designs that optimize thermal processes for synthetic biology applications. These systems incorporate innovative heat transfer mechanisms, temperature control systems, and energy recovery methods to maximize thermal efficiency during biological processes. The improved thermal management enables more stable conditions for engineered biological systems, resulting in higher yields and better process control.- Thermally efficient bioreactors for synthetic biology: Advanced bioreactor designs that optimize thermal processes in synthetic biology applications. These systems incorporate precise temperature control mechanisms to maintain optimal conditions for biological processes, enhancing the efficiency of enzymatic reactions and cellular metabolism. The thermal management systems in these bioreactors minimize energy consumption while maximizing biological output, creating more sustainable synthetic biology platforms.

- Heat-responsive genetic circuits: Engineered genetic systems that respond to thermal stimuli, enabling temperature-controlled gene expression in synthetic biology applications. These circuits utilize thermosensitive promoters and regulatory elements that can be activated or deactivated at specific temperature thresholds. This technology allows for precise temporal control of biological processes, improving the thermal efficiency of synthetic biological systems and enabling novel applications in bioproduction and biosensing.

- Thermally optimized enzymatic processes: Methods for enhancing the thermal efficiency of enzymatic reactions in synthetic biology through protein engineering and process optimization. These approaches include the development of thermostable enzymes that maintain activity at elevated temperatures, reducing cooling requirements and increasing reaction rates. Additionally, multi-enzyme cascade systems are designed with compatible thermal profiles to minimize energy input during transitions between reaction steps.

- Thermal energy recovery systems in bioprocessing: Innovative systems that capture and reuse thermal energy in synthetic biology applications, significantly improving overall process efficiency. These technologies incorporate heat exchangers, thermal storage solutions, and integrated process designs that minimize waste heat. By recovering thermal energy from exothermic biological reactions and process equipment, these systems reduce the energy footprint of synthetic biology operations while maintaining optimal conditions for biological activity.

- Computational modeling for thermal optimization: Advanced computational approaches for modeling and optimizing thermal processes in synthetic biology systems. These methods combine thermodynamic principles with biological parameters to predict system behavior under various thermal conditions. Machine learning algorithms analyze complex datasets to identify optimal thermal profiles for specific biological processes, enabling the design of more energy-efficient synthetic biology applications with reduced experimental iterations.

02 Thermal cycling technologies for synthetic biological processes

Specialized thermal cycling technologies designed specifically for synthetic biology applications. These systems provide precise temperature control for processes like PCR, DNA synthesis, and enzyme reactions. The technologies incorporate energy-efficient heating and cooling mechanisms, thermal insulation, and advanced control algorithms to minimize energy consumption while maintaining accurate temperature profiles required for synthetic biological processes.Expand Specific Solutions03 Heat recovery systems in bioprocessing

Innovative heat recovery systems designed to capture and reuse thermal energy in synthetic biology processes. These systems integrate heat exchangers, thermal storage solutions, and energy management controls to minimize waste heat and improve overall thermal efficiency. By recapturing thermal energy that would otherwise be lost, these technologies significantly reduce energy consumption in bioprocessing operations while maintaining optimal conditions for biological systems.Expand Specific Solutions04 AI-optimized thermal management for synthetic biology

Advanced artificial intelligence systems that optimize thermal processes in synthetic biology applications. These technologies use machine learning algorithms to predict, monitor, and control thermal parameters in real-time, adapting to changing conditions and process requirements. The AI systems analyze multiple variables simultaneously to maximize thermal efficiency while maintaining optimal conditions for biological processes, resulting in improved yields and reduced energy consumption.Expand Specific Solutions05 Thermally efficient enzymatic processes

Specialized enzymatic systems engineered for optimal performance under specific thermal conditions. These processes utilize thermostable enzymes, thermal adaptation techniques, and optimized reaction conditions to achieve maximum efficiency at various temperature ranges. The technologies include methods for enzyme stabilization, thermal activation control, and reaction pathway optimization to reduce energy requirements while maintaining or improving process yields in synthetic biology applications.Expand Specific Solutions

Key Industry Players and Research Institutions in Thermal Bioprocessing

The thermal processes in synthetic biology market is currently in a growth phase, characterized by increasing adoption across pharmaceutical, biotechnology, and diagnostic sectors. The global market size is estimated to be expanding at a CAGR of 15-20%, driven by applications in protein engineering, metabolic pathway optimization, and biomanufacturing. Technologically, the field shows moderate maturity with established players like Thermo Fisher Scientific (via Applied Biosystems and Life Technologies) leading innovation in thermal cycling and analysis systems. Companies including DiaSorin, 3M Innovative Properties, and Biognosys are advancing specialized thermal applications, while academic institutions such as ETH Zurich and Carnegie Mellon contribute fundamental research. The integration of AI and automation by players like Tata Consultancy Services is accelerating development, positioning thermal processes as a critical enabler in the synthetic biology revolution.

Applied Biosystems LLC

Technical Solution: Applied Biosystems has developed advanced thermal cycling technologies for synthetic biology applications, particularly their ProFlex™ PCR System which offers precise temperature control (±0.25°C accuracy) for thermal processes. Their thermal management approach incorporates multi-zone temperature optimization allowing researchers to run up to six independent thermal protocols simultaneously. The company has pioneered the integration of rapid ramping technologies (up to 6°C/sec) with proprietary thermal uniformity calibration to ensure consistent results across all sample wells. Their VeriFlex™ technology enables researchers to set up to six different temperatures in the same run, critical for optimizing synthetic biology reactions that require different thermal conditions. Applied Biosystems has also developed specialized thermal management solutions for synthetic DNA assembly, including optimized protocols for Gibson Assembly and Golden Gate cloning that maintain precise thermal control during critical reaction steps.

Strengths: Superior temperature precision and uniformity across reaction vessels; ability to run multiple thermal protocols simultaneously; extensive validation with synthetic biology workflows. Weaknesses: Higher cost compared to standard thermal cyclers; complex systems require more technical expertise; some proprietary technologies limit customization options for specialized applications.

BiognoSYS AG

Technical Solution: BiognoSYS AG has developed innovative thermal process technologies specifically for proteomics applications in synthetic biology. Their Hyper Reaction monitoring (HRM) technology incorporates precise thermal control systems that maintain optimal temperatures during complex protein analysis workflows. The company's thermal management approach focuses on minimizing thermal gradients during sample preparation and analysis, which is crucial for maintaining protein stability and enzymatic activity in synthetic biology applications. Their iRT (indexed Retention Time) technology works in conjunction with controlled thermal environments to ensure reproducible chromatographic separation of peptides. BiognoSYS has also pioneered thermal optimization protocols for their Spectronaut™ platform, which enables precise temperature control during data-independent acquisition mass spectrometry, allowing researchers to analyze synthetic protein constructs with unprecedented accuracy. Their thermal process innovations include specialized temperature-controlled sample preparation workflows that preserve the integrity of synthetic biology constructs throughout the analytical process.

Strengths: Highly specialized thermal control for proteomics applications; excellent reproducibility in temperature-sensitive workflows; comprehensive software integration for thermal process monitoring. Weaknesses: Primarily focused on analytical applications rather than synthesis processes; relatively high cost of implementation; requires specialized training for optimal utilization in synthetic biology contexts.

Critical Patents and Literature on Thermal Control in Synthetic Biology

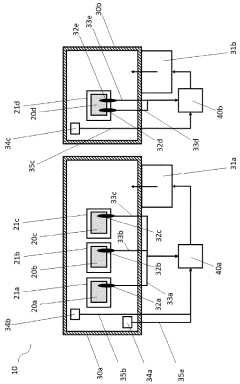

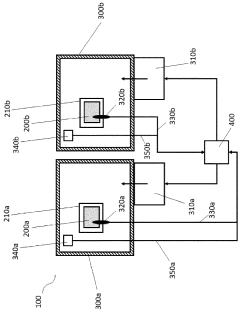

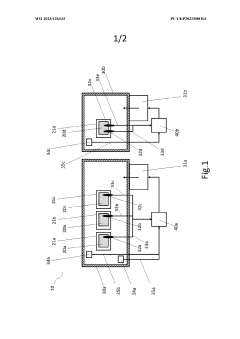

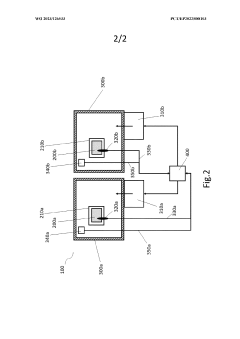

System and method for thermal treatment of cancer cells

PatentWO2023126533A1

Innovation

- A system comprising thermally insulated chambers with biocompatible temperature sensors and a controller that adjusts thermal means based on both sample and air temperature readings to maintain precise temperature control, allowing for accurate thermal treatment protocols and combination with other therapies.

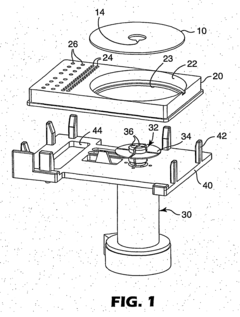

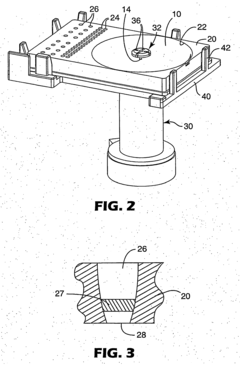

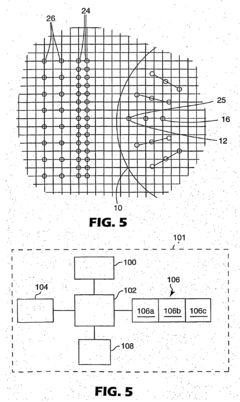

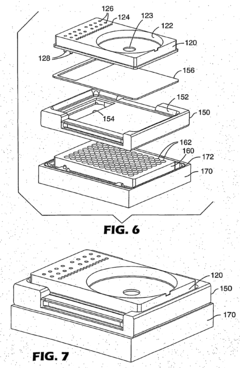

Sample processing apparatus, methods and systems

PatentInactiveEP1322962B1

Innovation

- A system that integrates a standard microtiter plate format with a rotating sample processing device, allowing for simultaneous processing of multiple samples while maintaining the benefits of standard microtiter plates, and enabling automated processing and cleanup.

Regulatory Framework for Synthetic Biology Thermal Applications

The regulatory landscape for thermal processes in synthetic biology is evolving rapidly as this interdisciplinary field continues to advance. Current regulatory frameworks primarily address biosafety, biosecurity, and ethical considerations, but specific regulations for thermal applications remain fragmented across jurisdictions. In the United States, the Coordinated Framework for Regulation of Biotechnology involves multiple agencies including the FDA, EPA, and USDA, each overseeing different aspects of synthetic biology applications based on their intended use rather than the process by which they were created.

The European Union employs a more precautionary approach through the Directive 2001/18/EC on deliberate release of genetically modified organisms, which has implications for thermally-controlled synthetic biology processes. The EU's regulatory framework emphasizes risk assessment and management throughout the product development lifecycle, requiring comprehensive documentation of thermal control parameters when they affect organism behavior or product characteristics.

International harmonization efforts are being led by organizations such as the OECD Working Group on Harmonisation of Regulatory Oversight in Biotechnology, which has published guidance documents addressing risk assessment methodologies applicable to thermally-regulated synthetic biology systems. However, these guidelines lack specificity regarding standardized protocols for thermal process validation.

A significant regulatory gap exists in the classification of novel thermally-induced biological functions. Current frameworks struggle to categorize organisms or products whose properties change substantially at different temperature thresholds, particularly when these changes affect safety profiles or environmental interactions. This regulatory uncertainty has led some companies to implement voluntary standards exceeding minimum requirements to demonstrate commitment to responsible innovation.

Emerging regulatory trends include the development of adaptive regulatory approaches that accommodate rapid technological advancement while maintaining appropriate oversight. Several jurisdictions are exploring regulatory sandboxes that allow controlled testing of thermal synthetic biology applications under close monitoring before full market approval. These initiatives aim to balance innovation with public safety concerns.

Industry stakeholders have identified compliance challenges related to the validation of thermal control systems in production environments. The absence of internationally recognized standards for thermal process monitoring in synthetic biology applications creates barriers to global market access and increases compliance costs for companies operating across multiple regions.

Future regulatory developments will likely focus on establishing clear guidelines for containment strategies specific to thermally-controlled organisms, standardized reporting requirements for thermal process parameters, and harmonized approaches to risk assessment that account for temperature-dependent biological behaviors.

The European Union employs a more precautionary approach through the Directive 2001/18/EC on deliberate release of genetically modified organisms, which has implications for thermally-controlled synthetic biology processes. The EU's regulatory framework emphasizes risk assessment and management throughout the product development lifecycle, requiring comprehensive documentation of thermal control parameters when they affect organism behavior or product characteristics.

International harmonization efforts are being led by organizations such as the OECD Working Group on Harmonisation of Regulatory Oversight in Biotechnology, which has published guidance documents addressing risk assessment methodologies applicable to thermally-regulated synthetic biology systems. However, these guidelines lack specificity regarding standardized protocols for thermal process validation.

A significant regulatory gap exists in the classification of novel thermally-induced biological functions. Current frameworks struggle to categorize organisms or products whose properties change substantially at different temperature thresholds, particularly when these changes affect safety profiles or environmental interactions. This regulatory uncertainty has led some companies to implement voluntary standards exceeding minimum requirements to demonstrate commitment to responsible innovation.

Emerging regulatory trends include the development of adaptive regulatory approaches that accommodate rapid technological advancement while maintaining appropriate oversight. Several jurisdictions are exploring regulatory sandboxes that allow controlled testing of thermal synthetic biology applications under close monitoring before full market approval. These initiatives aim to balance innovation with public safety concerns.

Industry stakeholders have identified compliance challenges related to the validation of thermal control systems in production environments. The absence of internationally recognized standards for thermal process monitoring in synthetic biology applications creates barriers to global market access and increases compliance costs for companies operating across multiple regions.

Future regulatory developments will likely focus on establishing clear guidelines for containment strategies specific to thermally-controlled organisms, standardized reporting requirements for thermal process parameters, and harmonized approaches to risk assessment that account for temperature-dependent biological behaviors.

Sustainability and Energy Efficiency in Thermal Bioprocessing

The thermal processes in synthetic biology present significant opportunities for enhancing sustainability and energy efficiency. Current bioprocessing methods often require substantial energy inputs, particularly for heating and cooling cycles during fermentation, cell culture, and product extraction phases. Analysis of energy consumption patterns across different thermal bioprocesses reveals that temperature control systems account for approximately 30-40% of the total energy expenditure in typical biomanufacturing facilities.

Recent innovations in heat exchange technology have demonstrated potential for reducing energy requirements by 15-25% compared to conventional systems. These advancements include the implementation of regenerative heat exchange networks, where thermal energy from exothermic reactions is captured and redirected to support endothermic processes within the same production system. Such integration minimizes waste heat and reduces the demand for external energy sources.

The application of computational fluid dynamics (CFD) modeling has enabled more precise thermal management in bioreactors, allowing for optimized temperature gradients that maintain ideal conditions while minimizing energy inputs. These models have been particularly valuable in scaling up processes from laboratory to industrial production levels, where thermal inefficiencies typically become more pronounced.

Renewable energy integration represents another frontier in sustainable thermal bioprocessing. Solar thermal collectors coupled with thermal storage systems have been successfully implemented in several pilot facilities, providing stable temperature conditions for continuous bioprocessing operations while reducing dependence on fossil fuel-derived energy. Similarly, geothermal heat pumps have shown promise for maintaining consistent temperatures in large-scale fermentation facilities with significantly lower carbon footprints.

Waste heat recovery systems specifically designed for biological processes have emerged as a critical technology for improving overall energy efficiency. These systems capture low-grade heat from exhaust streams and convert it to useful energy for preheating media, maintaining ambient conditions, or supporting auxiliary processes. Implementation of such systems has demonstrated energy savings of up to 35% in optimized facilities.

Life cycle assessment (LCA) studies comparing traditional and thermally optimized bioprocesses indicate that improvements in thermal efficiency can reduce the overall environmental impact by 20-45%, depending on the specific application and scale. These reductions stem not only from decreased energy consumption but also from associated reductions in cooling water requirements, greenhouse gas emissions, and operational costs, creating a compelling business case for investment in thermally efficient bioprocessing technologies.

Recent innovations in heat exchange technology have demonstrated potential for reducing energy requirements by 15-25% compared to conventional systems. These advancements include the implementation of regenerative heat exchange networks, where thermal energy from exothermic reactions is captured and redirected to support endothermic processes within the same production system. Such integration minimizes waste heat and reduces the demand for external energy sources.

The application of computational fluid dynamics (CFD) modeling has enabled more precise thermal management in bioreactors, allowing for optimized temperature gradients that maintain ideal conditions while minimizing energy inputs. These models have been particularly valuable in scaling up processes from laboratory to industrial production levels, where thermal inefficiencies typically become more pronounced.

Renewable energy integration represents another frontier in sustainable thermal bioprocessing. Solar thermal collectors coupled with thermal storage systems have been successfully implemented in several pilot facilities, providing stable temperature conditions for continuous bioprocessing operations while reducing dependence on fossil fuel-derived energy. Similarly, geothermal heat pumps have shown promise for maintaining consistent temperatures in large-scale fermentation facilities with significantly lower carbon footprints.

Waste heat recovery systems specifically designed for biological processes have emerged as a critical technology for improving overall energy efficiency. These systems capture low-grade heat from exhaust streams and convert it to useful energy for preheating media, maintaining ambient conditions, or supporting auxiliary processes. Implementation of such systems has demonstrated energy savings of up to 35% in optimized facilities.

Life cycle assessment (LCA) studies comparing traditional and thermally optimized bioprocesses indicate that improvements in thermal efficiency can reduce the overall environmental impact by 20-45%, depending on the specific application and scale. These reductions stem not only from decreased energy consumption but also from associated reductions in cooling water requirements, greenhouse gas emissions, and operational costs, creating a compelling business case for investment in thermally efficient bioprocessing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!