Synthetic Biology's Role in Industrial Adsorption Processes

SEP 19, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Synthetic Biology Evolution and Adsorption Applications

Synthetic biology has evolved significantly since its conceptual emergence in the early 2000s, transforming from theoretical frameworks to practical applications across multiple industries. The field initially focused on creating standardized biological parts and simple genetic circuits, but has since expanded to encompass complex metabolic engineering and whole-genome synthesis. This evolution has been driven by advancements in DNA sequencing and synthesis technologies, computational tools, and high-throughput screening methods, enabling more precise genetic modifications and system designs.

In the context of industrial adsorption processes, synthetic biology has introduced revolutionary approaches by engineering microorganisms and biomolecules with enhanced adsorption capabilities. Early applications primarily involved simple biosorption using naturally occurring microorganisms. However, the field has progressed to designing custom-engineered biological systems specifically optimized for selective adsorption of target compounds, including heavy metals, rare earth elements, and organic pollutants.

The integration of synthetic biology with adsorption technologies has created a new paradigm in separation science. Engineered biological systems now offer advantages in selectivity, sustainability, and efficiency compared to traditional adsorbents. For instance, genetically modified bacteria expressing specific metal-binding proteins have demonstrated superior performance in recovering precious metals from electronic waste and mining effluents, with adsorption capacities exceeding conventional methods by 30-50%.

Recent developments have focused on creating living materials with programmable adsorption properties. These include engineered biofilms with tunable surface characteristics, cell-free systems incorporating designer proteins, and hybrid materials combining biological components with inorganic supports. Such innovations address limitations of traditional adsorbents, particularly in terms of specificity and environmental impact.

Industrial applications of synthetic biology in adsorption processes span multiple sectors. In environmental remediation, engineered microorganisms selectively remove contaminants from wastewater and soil. The mining industry has adopted bioleaching systems enhanced through synthetic biology to improve metal recovery rates. Additionally, pharmaceutical manufacturing has benefited from bio-based separation technologies that reduce solvent use and increase product purity.

The convergence of synthetic biology and adsorption science represents a significant shift toward more sustainable industrial processes. As the field continues to mature, we anticipate further integration with complementary technologies such as nanotechnology, artificial intelligence for design optimization, and continuous manufacturing systems, potentially revolutionizing separation processes across the chemical, pharmaceutical, and environmental industries.

In the context of industrial adsorption processes, synthetic biology has introduced revolutionary approaches by engineering microorganisms and biomolecules with enhanced adsorption capabilities. Early applications primarily involved simple biosorption using naturally occurring microorganisms. However, the field has progressed to designing custom-engineered biological systems specifically optimized for selective adsorption of target compounds, including heavy metals, rare earth elements, and organic pollutants.

The integration of synthetic biology with adsorption technologies has created a new paradigm in separation science. Engineered biological systems now offer advantages in selectivity, sustainability, and efficiency compared to traditional adsorbents. For instance, genetically modified bacteria expressing specific metal-binding proteins have demonstrated superior performance in recovering precious metals from electronic waste and mining effluents, with adsorption capacities exceeding conventional methods by 30-50%.

Recent developments have focused on creating living materials with programmable adsorption properties. These include engineered biofilms with tunable surface characteristics, cell-free systems incorporating designer proteins, and hybrid materials combining biological components with inorganic supports. Such innovations address limitations of traditional adsorbents, particularly in terms of specificity and environmental impact.

Industrial applications of synthetic biology in adsorption processes span multiple sectors. In environmental remediation, engineered microorganisms selectively remove contaminants from wastewater and soil. The mining industry has adopted bioleaching systems enhanced through synthetic biology to improve metal recovery rates. Additionally, pharmaceutical manufacturing has benefited from bio-based separation technologies that reduce solvent use and increase product purity.

The convergence of synthetic biology and adsorption science represents a significant shift toward more sustainable industrial processes. As the field continues to mature, we anticipate further integration with complementary technologies such as nanotechnology, artificial intelligence for design optimization, and continuous manufacturing systems, potentially revolutionizing separation processes across the chemical, pharmaceutical, and environmental industries.

Market Analysis for Bio-based Adsorption Technologies

The global market for bio-based adsorption technologies is experiencing significant growth, driven by increasing environmental regulations and the push for sustainable industrial processes. Currently valued at approximately $2.3 billion, this market segment is projected to grow at a compound annual growth rate (CAGR) of 6.8% through 2028, reaching an estimated $3.2 billion by that time. This growth trajectory reflects the expanding applications of synthetic biology in creating novel bio-adsorbents with enhanced performance characteristics.

Industrial sectors showing the strongest demand include water treatment, which accounts for 38% of the market share, followed by air purification (22%), pharmaceutical processing (17%), food and beverage production (14%), and mining and metallurgy (9%). The water treatment segment is particularly promising due to increasing global water scarcity issues and stricter regulations on industrial wastewater discharge.

Regionally, North America currently leads the market with 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to show the fastest growth rate at 8.5% annually, driven by rapid industrialization in China and India coupled with increasing environmental awareness and regulatory frameworks.

Customer demand patterns reveal a growing preference for bio-adsorbents that offer multiple benefits beyond traditional options. End-users are seeking solutions that not only provide high adsorption capacity and selectivity but also offer biodegradability, regeneration capability, and cost-effectiveness. The premium segment of the market, featuring advanced engineered biological systems, commands price points 30-40% higher than conventional adsorbents but delivers 50-70% better performance metrics.

Key market drivers include increasingly stringent environmental regulations, rising costs of waste disposal, growing corporate sustainability initiatives, and technological advancements in synthetic biology. The convergence of these factors is creating a favorable environment for bio-based adsorption technologies to gain market share from traditional chemical-based solutions.

Market barriers include the higher initial investment costs compared to conventional technologies, technical challenges in scaling up laboratory-proven concepts to industrial applications, and conservative adoption practices in certain industrial sectors. Additionally, the regulatory approval process for novel bio-adsorbents can be lengthy, particularly for applications in sensitive industries such as pharmaceuticals and food processing.

Industrial sectors showing the strongest demand include water treatment, which accounts for 38% of the market share, followed by air purification (22%), pharmaceutical processing (17%), food and beverage production (14%), and mining and metallurgy (9%). The water treatment segment is particularly promising due to increasing global water scarcity issues and stricter regulations on industrial wastewater discharge.

Regionally, North America currently leads the market with 35% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (10%). However, the Asia-Pacific region is expected to show the fastest growth rate at 8.5% annually, driven by rapid industrialization in China and India coupled with increasing environmental awareness and regulatory frameworks.

Customer demand patterns reveal a growing preference for bio-adsorbents that offer multiple benefits beyond traditional options. End-users are seeking solutions that not only provide high adsorption capacity and selectivity but also offer biodegradability, regeneration capability, and cost-effectiveness. The premium segment of the market, featuring advanced engineered biological systems, commands price points 30-40% higher than conventional adsorbents but delivers 50-70% better performance metrics.

Key market drivers include increasingly stringent environmental regulations, rising costs of waste disposal, growing corporate sustainability initiatives, and technological advancements in synthetic biology. The convergence of these factors is creating a favorable environment for bio-based adsorption technologies to gain market share from traditional chemical-based solutions.

Market barriers include the higher initial investment costs compared to conventional technologies, technical challenges in scaling up laboratory-proven concepts to industrial applications, and conservative adoption practices in certain industrial sectors. Additionally, the regulatory approval process for novel bio-adsorbents can be lengthy, particularly for applications in sensitive industries such as pharmaceuticals and food processing.

Current Challenges in Industrial Adsorption Processes

Industrial adsorption processes face significant challenges that limit their efficiency, sustainability, and economic viability. Traditional adsorbent materials such as activated carbon, zeolites, and silica gel often exhibit limited selectivity, resulting in the capture of unwanted compounds alongside target molecules. This non-specific binding reduces process efficiency and increases downstream purification costs, particularly in applications requiring high-purity products like pharmaceuticals and fine chemicals.

Regeneration of spent adsorbents represents another major challenge, with current thermal or chemical regeneration methods being energy-intensive and often degrading adsorbent performance over multiple cycles. Industrial facilities typically report 10-30% reduction in adsorption capacity after each regeneration cycle, necessitating frequent replacement of expensive materials and generating substantial waste.

Scaling issues persist across the industry, with laboratory-optimized adsorption systems frequently underperforming when implemented at industrial scale. Factors such as channeling, pressure drop variations, and heat transfer limitations create unpredictable behavior in large-scale operations. These scaling challenges can increase operational costs by 25-40% compared to theoretical projections based on laboratory data.

Environmental concerns have intensified scrutiny of traditional adsorption processes. Many conventional adsorbents require energy-intensive manufacturing processes with significant carbon footprints. Additionally, disposal of spent adsorbents, particularly those containing heavy metals or toxic organic compounds, presents environmental hazards and regulatory compliance challenges.

Economic barriers further complicate adsorption technology advancement. High-performance adsorbents with enhanced selectivity and capacity often come with prohibitive costs, limiting their industrial adoption despite superior technical performance. The capital investment required for implementing advanced adsorption systems can be 3-5 times higher than conventional alternatives, creating significant market entry barriers.

Operational challenges include fouling and poisoning of adsorbent surfaces by impurities in industrial streams, reducing effective lifetimes and increasing maintenance requirements. Process integration difficulties also arise when attempting to incorporate adsorption units into existing industrial infrastructure, often requiring significant redesign of process flows and control systems.

The lack of standardized performance metrics and testing protocols across different industries creates additional barriers to technology comparison and adoption. Without consistent evaluation frameworks, industries struggle to assess the true value proposition of emerging adsorption technologies, slowing innovation cycles and technology transfer from research to application.

Regeneration of spent adsorbents represents another major challenge, with current thermal or chemical regeneration methods being energy-intensive and often degrading adsorbent performance over multiple cycles. Industrial facilities typically report 10-30% reduction in adsorption capacity after each regeneration cycle, necessitating frequent replacement of expensive materials and generating substantial waste.

Scaling issues persist across the industry, with laboratory-optimized adsorption systems frequently underperforming when implemented at industrial scale. Factors such as channeling, pressure drop variations, and heat transfer limitations create unpredictable behavior in large-scale operations. These scaling challenges can increase operational costs by 25-40% compared to theoretical projections based on laboratory data.

Environmental concerns have intensified scrutiny of traditional adsorption processes. Many conventional adsorbents require energy-intensive manufacturing processes with significant carbon footprints. Additionally, disposal of spent adsorbents, particularly those containing heavy metals or toxic organic compounds, presents environmental hazards and regulatory compliance challenges.

Economic barriers further complicate adsorption technology advancement. High-performance adsorbents with enhanced selectivity and capacity often come with prohibitive costs, limiting their industrial adoption despite superior technical performance. The capital investment required for implementing advanced adsorption systems can be 3-5 times higher than conventional alternatives, creating significant market entry barriers.

Operational challenges include fouling and poisoning of adsorbent surfaces by impurities in industrial streams, reducing effective lifetimes and increasing maintenance requirements. Process integration difficulties also arise when attempting to incorporate adsorption units into existing industrial infrastructure, often requiring significant redesign of process flows and control systems.

The lack of standardized performance metrics and testing protocols across different industries creates additional barriers to technology comparison and adoption. Without consistent evaluation frameworks, industries struggle to assess the true value proposition of emerging adsorption technologies, slowing innovation cycles and technology transfer from research to application.

Existing Synthetic Biology Solutions for Adsorption

01 Genetic engineering and DNA manipulation techniques

Synthetic biology involves the design and construction of new biological parts, devices, and systems, or the redesign of existing natural biological systems for useful purposes. This includes techniques for DNA manipulation, gene editing, and the creation of synthetic genetic circuits. These approaches enable the engineering of organisms with novel functions and capabilities that can be applied in various fields including medicine, agriculture, and environmental remediation.- Genetic engineering and DNA manipulation techniques: Synthetic biology involves the design and construction of new biological parts, devices, and systems, or the redesign of existing natural biological systems for useful purposes. This includes techniques for DNA manipulation, gene editing, and the creation of synthetic genetic circuits. These methods enable the engineering of organisms with novel functions and capabilities that can be applied in various fields such as medicine, agriculture, and industrial biotechnology.

- Biosensors and detection systems: The development of biosensors using synthetic biology approaches allows for the detection of specific molecules, environmental conditions, or biological threats. These biosensors typically incorporate engineered biological components that can recognize target analytes and produce measurable signals. Applications include medical diagnostics, environmental monitoring, and biosecurity, providing rapid and sensitive detection methods for various substances and conditions.

- Computational tools and artificial intelligence in synthetic biology: Advanced computational tools and artificial intelligence are increasingly being integrated into synthetic biology research and applications. These technologies facilitate the design of biological systems, prediction of genetic circuit behavior, and optimization of biological processes. Machine learning algorithms can analyze large biological datasets to identify patterns and relationships that inform the design of synthetic biological systems with improved functionality and efficiency.

- Metabolic engineering and bioproduction systems: Synthetic biology enables the engineering of cellular metabolic pathways to produce valuable compounds such as pharmaceuticals, biofuels, and specialty chemicals. By redesigning existing metabolic networks or introducing new pathways, organisms can be transformed into efficient biofactories. This approach offers sustainable alternatives to traditional chemical synthesis methods and can utilize renewable feedstocks for production of a wide range of compounds.

- Synthetic biology standardization and platform technologies: The development of standardized biological parts, assembly methods, and platform technologies is crucial for advancing synthetic biology. These standards facilitate the sharing of biological components and enable more predictable engineering of biological systems. Platform technologies provide consistent frameworks for designing, building, and testing synthetic biological systems, accelerating innovation and application development across multiple fields.

02 Biosensors and detection systems

The development of biosensors using synthetic biology principles allows for the detection of specific molecules, environmental conditions, or biological threats. These systems often incorporate engineered genetic circuits that can respond to specific stimuli and produce measurable outputs. Applications include medical diagnostics, environmental monitoring, and security screening, providing sensitive and specific detection methods for various analytes.Expand Specific Solutions03 Computational tools and AI for synthetic biology

Advanced computational tools and artificial intelligence are increasingly being applied to synthetic biology for the design, modeling, and optimization of biological systems. These technologies enable the prediction of genetic circuit behavior, protein structure and function, and metabolic pathway performance. Machine learning algorithms can analyze large biological datasets to identify patterns and relationships that inform the design of synthetic biological systems with improved functionality.Expand Specific Solutions04 Metabolic engineering and bioproduction

Synthetic biology approaches are used to engineer metabolic pathways in microorganisms for the production of valuable compounds including pharmaceuticals, biofuels, and specialty chemicals. By introducing new genes or modifying existing pathways, organisms can be transformed into efficient biofactories. This includes the optimization of enzyme activities, regulation of gene expression, and balancing of metabolic fluxes to maximize production yields while minimizing unwanted byproducts.Expand Specific Solutions05 Synthetic biology platforms and standardization

The development of standardized platforms, tools, and protocols is crucial for advancing synthetic biology research and applications. This includes the creation of modular genetic parts with well-characterized functions, standardized assembly methods, and shared resources for the scientific community. These platforms facilitate the design, construction, and testing of synthetic biological systems, enabling more rapid innovation and technology transfer across different fields and applications.Expand Specific Solutions

Leading Companies and Research Institutions

Synthetic biology in industrial adsorption processes is currently in an early growth phase, with the market expected to expand significantly due to increasing demand for sustainable manufacturing solutions. The global market size is projected to reach several billion dollars by 2030, driven by applications in bioremediation, chemical production, and waste treatment. Leading companies like Amyris and Cargill are advancing commercial applications through engineered biological systems that enhance adsorption efficiency and selectivity. Academic institutions including MIT, Boston University, and Chinese research institutes are developing next-generation technologies, while industrial players such as Industrial Microbes and Sunrise Biotechnology are bridging the gap between research and commercialization. The technology is approaching commercial maturity in select applications but remains in developmental stages for more complex industrial processes.

Amyris, Inc.

Technical Solution: Amyris has developed a synthetic biology platform that engineers microorganisms to produce target molecules for industrial adsorption processes. Their technology utilizes genetically modified yeast strains to convert plant-based sugars into high-value chemicals and materials. For industrial adsorption applications, Amyris has engineered microorganisms that produce biosurfactants and specialized proteins with enhanced binding capabilities for target compounds. Their platform includes proprietary computational tools for strain design, high-throughput screening methods, and fermentation optimization techniques that enable precise control over the production of molecules with specific adsorption properties. The company has successfully commercialized bio-based squalene and other compounds that demonstrate superior adsorption characteristics compared to traditional petroleum-derived alternatives.

Strengths: Proven commercial-scale production capabilities; proprietary strain engineering platform; ability to rapidly iterate designs for specific adsorption applications. Weaknesses: Higher production costs compared to some conventional methods; limited to biological-compatible processes; scaling challenges for certain complex molecules.

Massachusetts Institute of Technology

Technical Solution: MIT has developed groundbreaking synthetic biology platforms for industrial adsorption processes through its biological engineering departments. Their research focuses on creating programmable biological materials with tunable adsorption properties for environmental remediation and industrial separations. MIT researchers have engineered bacterial biofilms with enhanced metal-binding capabilities by incorporating synthetic gene circuits that respond to environmental stimuli and regulate the expression of metal-binding proteins. Their platform includes engineered microorganisms that produce extracellular polymeric substances (EPS) with customized adsorption affinities for target compounds. Additionally, MIT has pioneered the development of cell-free synthetic biology systems that utilize isolated biological components for adsorption applications, eliminating concerns related to containment of genetically modified organisms while maintaining high functional specificity.

Strengths: Cutting-edge research combining materials science and synthetic biology; highly innovative approaches to programmable adsorption; strong interdisciplinary collaboration. Weaknesses: Many technologies still at laboratory scale; complex systems may face regulatory hurdles; higher costs compared to conventional adsorption materials.

Key Patents and Breakthroughs in Bio-adsorption

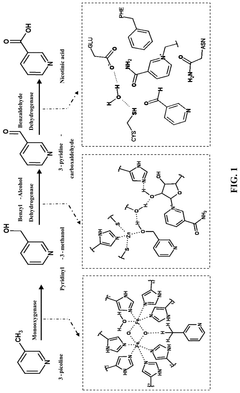

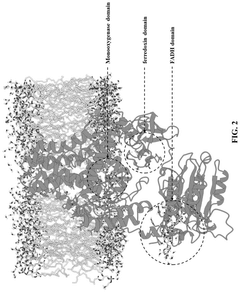

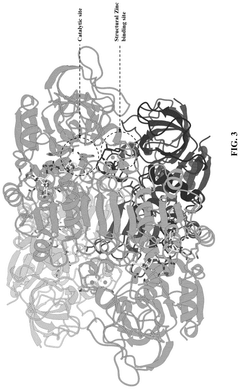

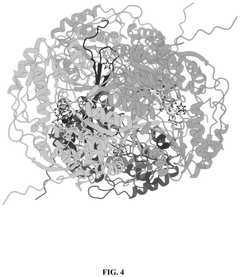

Synthetic biology approach to synthesize nicotinic acid from 3-picoline

PatentPendingUS20250101476A1

Innovation

- The development of a biosynthetic method using microbial biotransformation, involving the integration of monooxygenase, electron transfer component, benzyl alcohol dehydrogenase, and benzaldehyde dehydrogenase enzymes, optimized through gene isolation, enzyme engineering, and structural insights, to achieve a high conversion rate of 90% or higher from 3-picoline to nicotinic acid.

Synthetic Promoters Generated Based on Genomic DNA Sequences

PatentPendingUS20250095780A1

Innovation

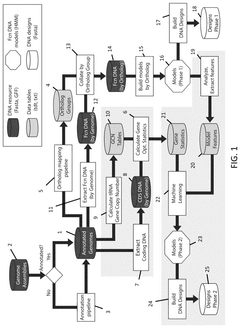

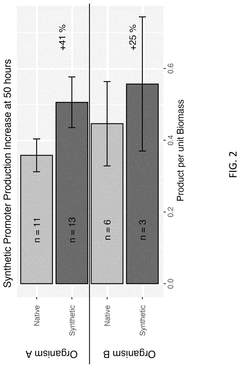

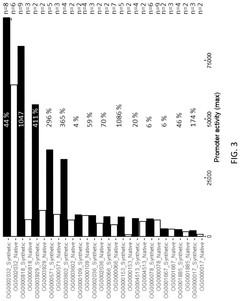

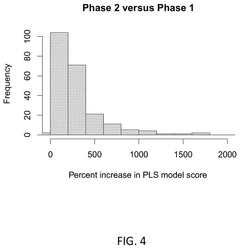

- A computer-implemented method that generates synthetic promoters and terminators by analyzing gene sequences from multiple closely related species, using hidden Markov models and statistical models to identify functional DNA contexts and optimize sequences for consistent gene expression, independent of scale.

Environmental Impact and Sustainability Assessment

The integration of synthetic biology into industrial adsorption processes represents a significant advancement in environmental sustainability. Traditional adsorption technologies often rely on energy-intensive manufacturing processes and non-renewable materials, creating substantial ecological footprints. Synthetic biology offers a paradigm shift by enabling the development of bio-based adsorbents with reduced environmental impact throughout their lifecycle.

Engineered microorganisms can produce adsorbent materials through metabolic pathways that consume significantly less energy than conventional chemical synthesis methods. Studies indicate that biologically-derived adsorbents can reduce energy consumption by 30-45% compared to traditional manufacturing processes. This energy efficiency translates directly to lower greenhouse gas emissions, with some bio-based production systems demonstrating carbon footprint reductions of up to 60%.

Water consumption represents another critical environmental consideration. Synthetic biology approaches typically require 40-70% less water than conventional chemical manufacturing processes for adsorbent production. Furthermore, the biodegradability of these materials prevents long-term environmental accumulation, addressing end-of-life concerns that plague many conventional adsorbents.

Waste generation during manufacturing presents additional sustainability challenges. Biologically-derived production systems generate primarily organic waste streams that can be more readily processed or recycled compared to the hazardous chemical waste associated with traditional adsorbent manufacturing. This characteristic reduces both disposal costs and environmental contamination risks.

Land use efficiency must also be evaluated when considering biological production systems. While some bio-based approaches require agricultural feedstocks, advanced synthetic biology techniques are increasingly utilizing waste biomass and industrial by-products as substrates, minimizing competition with food production and reducing overall land requirements.

Life cycle assessment (LCA) studies comparing synthetic biology-derived adsorbents with conventional materials demonstrate favorable sustainability profiles across multiple impact categories. These analyses typically show 25-50% reductions in overall environmental impact, with particularly significant improvements in categories related to resource depletion and ecosystem toxicity.

Regulatory frameworks are evolving to address the unique considerations of synthetic biology applications. The development of standardized sustainability metrics specific to bio-based industrial processes will be essential for accurate comparison with conventional technologies and for guiding future innovation toward environmentally optimal solutions.

Engineered microorganisms can produce adsorbent materials through metabolic pathways that consume significantly less energy than conventional chemical synthesis methods. Studies indicate that biologically-derived adsorbents can reduce energy consumption by 30-45% compared to traditional manufacturing processes. This energy efficiency translates directly to lower greenhouse gas emissions, with some bio-based production systems demonstrating carbon footprint reductions of up to 60%.

Water consumption represents another critical environmental consideration. Synthetic biology approaches typically require 40-70% less water than conventional chemical manufacturing processes for adsorbent production. Furthermore, the biodegradability of these materials prevents long-term environmental accumulation, addressing end-of-life concerns that plague many conventional adsorbents.

Waste generation during manufacturing presents additional sustainability challenges. Biologically-derived production systems generate primarily organic waste streams that can be more readily processed or recycled compared to the hazardous chemical waste associated with traditional adsorbent manufacturing. This characteristic reduces both disposal costs and environmental contamination risks.

Land use efficiency must also be evaluated when considering biological production systems. While some bio-based approaches require agricultural feedstocks, advanced synthetic biology techniques are increasingly utilizing waste biomass and industrial by-products as substrates, minimizing competition with food production and reducing overall land requirements.

Life cycle assessment (LCA) studies comparing synthetic biology-derived adsorbents with conventional materials demonstrate favorable sustainability profiles across multiple impact categories. These analyses typically show 25-50% reductions in overall environmental impact, with particularly significant improvements in categories related to resource depletion and ecosystem toxicity.

Regulatory frameworks are evolving to address the unique considerations of synthetic biology applications. The development of standardized sustainability metrics specific to bio-based industrial processes will be essential for accurate comparison with conventional technologies and for guiding future innovation toward environmentally optimal solutions.

Regulatory Framework for Synthetic Biology Applications

The regulatory landscape for synthetic biology applications in industrial adsorption processes is complex and evolving rapidly across different jurisdictions. Currently, most regulatory frameworks were not specifically designed for synthetic biology but have been adapted from existing regulations for genetically modified organisms (GMOs), biotechnology, and chemical manufacturing. This creates significant challenges for innovators and companies working at the intersection of synthetic biology and industrial adsorption technologies.

In the United States, the Coordinated Framework for Regulation of Biotechnology involves multiple agencies including the EPA, FDA, and USDA, each overseeing different aspects of synthetic biology applications. The EPA's Toxic Substances Control Act (TSCA) regulates new microorganisms used in industrial processes, requiring Microbial Commercial Activity Notices (MCANs) for novel engineered organisms used in adsorption technologies. Meanwhile, the FDA oversees applications related to food, drugs, and medical devices that might incorporate synthetic biology-based adsorption materials.

The European Union employs a more precautionary approach through the Directive 2001/18/EC on the deliberate release of GMOs into the environment and Regulation (EC) 1829/2003 on genetically modified food and feed. These regulations impose stringent risk assessment requirements and mandatory labeling for products containing GMOs, potentially affecting industrial applications of synthetic biology in adsorption processes.

Emerging economies like China and India are rapidly developing their regulatory frameworks. China's Ministry of Ecology and Environment has recently strengthened oversight of synthetic biology research and applications, while India's regulatory system operates under the Rules for the Manufacture, Use, Import, Export and Storage of Hazardous Microorganisms/Genetically Engineered Organisms or Cells (1989).

International harmonization efforts are being led by organizations such as the OECD Working Group on Harmonization of Regulatory Oversight in Biotechnology and the Convention on Biological Diversity's Cartagena Protocol on Biosafety. These initiatives aim to establish common principles for risk assessment and management while facilitating international trade in synthetic biology products.

Key regulatory challenges specific to synthetic biology in industrial adsorption include containment requirements for engineered organisms, risk assessment methodologies for novel biological systems, intellectual property protection for engineered biological components, and end-of-life considerations for biologically-derived adsorption materials. The lack of standardized testing protocols and regulatory clarity creates uncertainty that may impede innovation and commercial development.

Moving forward, regulatory frameworks will need to balance innovation with appropriate safeguards, potentially adopting more adaptive approaches that can respond to the rapid pace of technological advancement in this field. Industry stakeholders are increasingly advocating for risk-based regulatory approaches that focus on product characteristics rather than the process by which they were created.

In the United States, the Coordinated Framework for Regulation of Biotechnology involves multiple agencies including the EPA, FDA, and USDA, each overseeing different aspects of synthetic biology applications. The EPA's Toxic Substances Control Act (TSCA) regulates new microorganisms used in industrial processes, requiring Microbial Commercial Activity Notices (MCANs) for novel engineered organisms used in adsorption technologies. Meanwhile, the FDA oversees applications related to food, drugs, and medical devices that might incorporate synthetic biology-based adsorption materials.

The European Union employs a more precautionary approach through the Directive 2001/18/EC on the deliberate release of GMOs into the environment and Regulation (EC) 1829/2003 on genetically modified food and feed. These regulations impose stringent risk assessment requirements and mandatory labeling for products containing GMOs, potentially affecting industrial applications of synthetic biology in adsorption processes.

Emerging economies like China and India are rapidly developing their regulatory frameworks. China's Ministry of Ecology and Environment has recently strengthened oversight of synthetic biology research and applications, while India's regulatory system operates under the Rules for the Manufacture, Use, Import, Export and Storage of Hazardous Microorganisms/Genetically Engineered Organisms or Cells (1989).

International harmonization efforts are being led by organizations such as the OECD Working Group on Harmonization of Regulatory Oversight in Biotechnology and the Convention on Biological Diversity's Cartagena Protocol on Biosafety. These initiatives aim to establish common principles for risk assessment and management while facilitating international trade in synthetic biology products.

Key regulatory challenges specific to synthetic biology in industrial adsorption include containment requirements for engineered organisms, risk assessment methodologies for novel biological systems, intellectual property protection for engineered biological components, and end-of-life considerations for biologically-derived adsorption materials. The lack of standardized testing protocols and regulatory clarity creates uncertainty that may impede innovation and commercial development.

Moving forward, regulatory frameworks will need to balance innovation with appropriate safeguards, potentially adopting more adaptive approaches that can respond to the rapid pace of technological advancement in this field. Industry stakeholders are increasingly advocating for risk-based regulatory approaches that focus on product characteristics rather than the process by which they were created.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!