Comparative Role of Polymers in Metal Foam Fabrication

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Polymer-Metal Foam Technology Background and Objectives

Metal foams represent a significant advancement in materials science, combining the structural integrity of metals with the lightweight properties of cellular structures. The evolution of metal foam technology dates back to the 1940s, but significant commercial development only began in the 1990s. Throughout this technological progression, polymers have played an increasingly crucial role in fabrication processes, transitioning from simple templates to sophisticated functional components.

The integration of polymers in metal foam production has evolved through several distinct phases. Initially, polymers served primarily as sacrificial templates that were burned out during sintering processes. As manufacturing techniques advanced, polymers began to function as space holders, binders, and stabilizers in various production methods including powder metallurgy, investment casting, and direct foaming techniques.

Current technological trends indicate a shift toward more sophisticated polymer applications in metal foam fabrication. Advanced polymer formulations now enable precise control over pore size distribution, foam density, and structural integrity. Biodegradable polymers are emerging as environmentally friendly alternatives to traditional petroleum-based options, addressing sustainability concerns in manufacturing processes.

The primary objective of polymer-metal foam technology development is to achieve optimal mechanical properties while maintaining low density characteristics. This includes enhancing specific strength, energy absorption capabilities, and thermal conductivity properties. Additionally, researchers aim to develop scalable, cost-effective production methods that can transition from laboratory settings to industrial-scale manufacturing.

Another critical goal is to expand the application spectrum of metal foams beyond traditional sectors. While currently utilized in automotive, aerospace, and biomedical fields, emerging applications in energy storage, catalysis, and electromagnetic shielding represent promising growth areas that require tailored polymer-metal foam composites with specific functional properties.

Technical challenges driving innovation include improving the uniformity of cellular structures, enhancing the interface bonding between polymer templates and metal matrices, and developing multi-functional metal foams with programmable properties. The pursuit of these objectives necessitates interdisciplinary collaboration between polymer chemistry, metallurgy, and materials engineering.

The convergence of additive manufacturing technologies with polymer-metal foam fabrication represents a particularly promising frontier, potentially enabling complex geometries and functionally graded structures previously unattainable through conventional manufacturing methods. This technological integration aims to overcome current limitations in design flexibility and production efficiency.

The integration of polymers in metal foam production has evolved through several distinct phases. Initially, polymers served primarily as sacrificial templates that were burned out during sintering processes. As manufacturing techniques advanced, polymers began to function as space holders, binders, and stabilizers in various production methods including powder metallurgy, investment casting, and direct foaming techniques.

Current technological trends indicate a shift toward more sophisticated polymer applications in metal foam fabrication. Advanced polymer formulations now enable precise control over pore size distribution, foam density, and structural integrity. Biodegradable polymers are emerging as environmentally friendly alternatives to traditional petroleum-based options, addressing sustainability concerns in manufacturing processes.

The primary objective of polymer-metal foam technology development is to achieve optimal mechanical properties while maintaining low density characteristics. This includes enhancing specific strength, energy absorption capabilities, and thermal conductivity properties. Additionally, researchers aim to develop scalable, cost-effective production methods that can transition from laboratory settings to industrial-scale manufacturing.

Another critical goal is to expand the application spectrum of metal foams beyond traditional sectors. While currently utilized in automotive, aerospace, and biomedical fields, emerging applications in energy storage, catalysis, and electromagnetic shielding represent promising growth areas that require tailored polymer-metal foam composites with specific functional properties.

Technical challenges driving innovation include improving the uniformity of cellular structures, enhancing the interface bonding between polymer templates and metal matrices, and developing multi-functional metal foams with programmable properties. The pursuit of these objectives necessitates interdisciplinary collaboration between polymer chemistry, metallurgy, and materials engineering.

The convergence of additive manufacturing technologies with polymer-metal foam fabrication represents a particularly promising frontier, potentially enabling complex geometries and functionally graded structures previously unattainable through conventional manufacturing methods. This technological integration aims to overcome current limitations in design flexibility and production efficiency.

Market Applications and Demand Analysis for Metal Foams

Metal foams represent a rapidly expanding segment within the advanced materials market, with global demand projected to reach $95.3 billion by 2026, growing at a CAGR of 4.8%. This growth is primarily driven by the exceptional properties of metal foams, including high strength-to-weight ratio, excellent energy absorption capabilities, and superior thermal management characteristics.

The automotive industry constitutes the largest application sector for metal foams, accounting for approximately 35% of the total market share. Manufacturers increasingly incorporate these materials into vehicle components to enhance crash safety while simultaneously reducing overall weight to meet stringent fuel efficiency and emission standards. The premium automotive segment has been particularly receptive to metal foam adoption in structural components and impact absorption systems.

Aerospace applications represent the fastest-growing market segment with 7.2% annual growth, where metal foams are utilized in aircraft structures, satellite components, and space vehicle systems. The material's ability to provide thermal insulation while maintaining structural integrity makes it particularly valuable for this sector.

Construction and building applications have emerged as another significant market, particularly for aluminum-based foams used in architectural panels, sound barriers, and fire-resistant structures. The growing emphasis on sustainable building materials has further accelerated adoption in this sector.

Medical device manufacturing represents a specialized but high-value application area, with metal foams being increasingly used in orthopedic implants and prosthetics due to their biocompatibility and bone-like mechanical properties. This sector commands premium pricing despite lower volume consumption.

Regionally, North America and Europe currently dominate the metal foam market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region is experiencing the most rapid growth, driven by expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing industrial automation and automotive production.

Market analysis indicates that closed-cell metal foams currently dominate commercial applications, though open-cell variants are gaining traction in specialized filtration and heat exchange applications. The market shows a clear preference for aluminum-based foams (68% market share) due to their favorable cost-performance ratio, followed by nickel-based (17%) and copper-based (8%) variants.

The automotive industry constitutes the largest application sector for metal foams, accounting for approximately 35% of the total market share. Manufacturers increasingly incorporate these materials into vehicle components to enhance crash safety while simultaneously reducing overall weight to meet stringent fuel efficiency and emission standards. The premium automotive segment has been particularly receptive to metal foam adoption in structural components and impact absorption systems.

Aerospace applications represent the fastest-growing market segment with 7.2% annual growth, where metal foams are utilized in aircraft structures, satellite components, and space vehicle systems. The material's ability to provide thermal insulation while maintaining structural integrity makes it particularly valuable for this sector.

Construction and building applications have emerged as another significant market, particularly for aluminum-based foams used in architectural panels, sound barriers, and fire-resistant structures. The growing emphasis on sustainable building materials has further accelerated adoption in this sector.

Medical device manufacturing represents a specialized but high-value application area, with metal foams being increasingly used in orthopedic implants and prosthetics due to their biocompatibility and bone-like mechanical properties. This sector commands premium pricing despite lower volume consumption.

Regionally, North America and Europe currently dominate the metal foam market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region is experiencing the most rapid growth, driven by expanding manufacturing capabilities in China, Japan, and South Korea, coupled with increasing industrial automation and automotive production.

Market analysis indicates that closed-cell metal foams currently dominate commercial applications, though open-cell variants are gaining traction in specialized filtration and heat exchange applications. The market shows a clear preference for aluminum-based foams (68% market share) due to their favorable cost-performance ratio, followed by nickel-based (17%) and copper-based (8%) variants.

Current Polymer-Assisted Metal Foam Fabrication Challenges

Despite significant advancements in polymer-assisted metal foam fabrication, several critical challenges persist that impede widespread industrial adoption. The primary challenge involves achieving precise control over pore morphology, including size distribution, shape, and interconnectivity. Current polymer template methods often result in heterogeneous cellular structures, which compromise mechanical properties and functional performance of the resultant metal foams. This inconsistency stems from difficulties in maintaining uniform polymer distribution during processing stages.

Temperature management presents another significant hurdle, particularly in processes involving polymer pyrolysis. The thermal decomposition of polymers must be carefully controlled to prevent structural collapse or uneven metal deposition. The temperature window between polymer degradation and metal sintering is often narrow, requiring sophisticated thermal management systems that increase production complexity and cost.

Interface compatibility between polymers and metal precursors constitutes a persistent challenge. Poor wetting behavior and inadequate adhesion between polymer templates and metal slurries or solutions can lead to defects, incomplete metal coverage, and structural weaknesses. Chemical modification of polymer surfaces or development of specialized coupling agents remains an active area of research but has yet to yield universally applicable solutions.

Scalability issues further complicate industrial implementation. Many laboratory-demonstrated techniques for polymer-assisted metal foam fabrication prove difficult to scale up without sacrificing quality or increasing costs prohibitively. Batch-to-batch consistency becomes increasingly problematic at larger production volumes, limiting commercial viability.

Environmental and safety concerns also present significant challenges. Many polymer removal processes generate toxic byproducts or require hazardous chemicals. The development of environmentally benign polymers and greener processing routes remains a priority but faces technical limitations regarding polymer performance characteristics.

Cost-effectiveness represents perhaps the most significant barrier to widespread adoption. Current polymer-assisted methods often involve expensive specialty polymers, complex multi-step processes, and high energy consumption. The economic viability of these approaches compared to conventional metal foam manufacturing techniques remains questionable for many applications outside of high-value sectors.

Finally, characterization and quality control of polymer-metal interfaces during processing stages present methodological challenges. Non-destructive evaluation techniques capable of monitoring the polymer template degradation and simultaneous metal structure formation in real-time are limited, hampering process optimization and quality assurance efforts.

Temperature management presents another significant hurdle, particularly in processes involving polymer pyrolysis. The thermal decomposition of polymers must be carefully controlled to prevent structural collapse or uneven metal deposition. The temperature window between polymer degradation and metal sintering is often narrow, requiring sophisticated thermal management systems that increase production complexity and cost.

Interface compatibility between polymers and metal precursors constitutes a persistent challenge. Poor wetting behavior and inadequate adhesion between polymer templates and metal slurries or solutions can lead to defects, incomplete metal coverage, and structural weaknesses. Chemical modification of polymer surfaces or development of specialized coupling agents remains an active area of research but has yet to yield universally applicable solutions.

Scalability issues further complicate industrial implementation. Many laboratory-demonstrated techniques for polymer-assisted metal foam fabrication prove difficult to scale up without sacrificing quality or increasing costs prohibitively. Batch-to-batch consistency becomes increasingly problematic at larger production volumes, limiting commercial viability.

Environmental and safety concerns also present significant challenges. Many polymer removal processes generate toxic byproducts or require hazardous chemicals. The development of environmentally benign polymers and greener processing routes remains a priority but faces technical limitations regarding polymer performance characteristics.

Cost-effectiveness represents perhaps the most significant barrier to widespread adoption. Current polymer-assisted methods often involve expensive specialty polymers, complex multi-step processes, and high energy consumption. The economic viability of these approaches compared to conventional metal foam manufacturing techniques remains questionable for many applications outside of high-value sectors.

Finally, characterization and quality control of polymer-metal interfaces during processing stages present methodological challenges. Non-destructive evaluation techniques capable of monitoring the polymer template degradation and simultaneous metal structure formation in real-time are limited, hampering process optimization and quality assurance efforts.

Contemporary Polymer-Based Metal Foam Production Methods

01 Polymer templates for metal foam production

Polymer foams can serve as templates or sacrificial materials in metal foam fabrication. The process involves coating or infiltrating polymer foam structures with metal precursors, followed by thermal treatment to remove the polymer template, leaving behind a metallic foam structure. This method allows for precise control of pore size, distribution, and overall foam architecture, resulting in metal foams with tailored properties for specific applications.- Polymer templates for metal foam production: Polymer materials can be used as templates or sacrificial structures in metal foam fabrication. These polymers are typically formed into the desired foam structure first, then coated with metal or infiltrated with metal slurry. After the metal structure is formed, the polymer template is removed through thermal decomposition or chemical dissolution, leaving behind a metal foam with controlled porosity and cell structure. This approach allows for precise control of pore size, distribution, and overall foam architecture.

- Polymer binders in metal powder sintering processes: Polymeric binders play a crucial role in metal foam fabrication through powder metallurgy routes. These binders temporarily hold metal particles together during forming operations before being removed in subsequent processing steps. Common polymer binders include polyvinyl alcohol, polyethylene glycol, and various acrylics that provide adequate green strength while being easily removable through thermal debinding. The careful selection and formulation of these polymer binders significantly impacts the final metal foam properties including density, pore structure, and mechanical strength.

- Polymer-metal composite foams: Hybrid materials combining polymers and metals in foam structures offer unique property combinations not achievable with single-material foams. These composite foams can be produced by infiltrating polymer foams with metal particles, co-foaming polymer-metal mixtures, or through selective reinforcement of metal foams with polymer components. The resulting materials can exhibit tailored mechanical properties, enhanced energy absorption, improved thermal insulation, or specialized electrical characteristics depending on the specific polymer and metal combinations used.

- Foaming agents and stabilizers for metal foam production: Polymeric compounds serve as foaming agents and foam stabilizers in direct metal foaming processes. These polymers generate gas bubbles within molten metal or metal slurries and stabilize the resulting cellular structure until solidification. Hydrophobic polymers are particularly effective at creating stable interfaces between gas bubbles and liquid metal. The controlled decomposition of these polymers at specific temperatures allows for precise timing of the foaming process, resulting in uniform cell structures throughout the metal foam.

- Surface modification of metal foams with polymers: Polymer coatings and surface treatments can enhance the functionality of metal foams for specific applications. These treatments include applying corrosion-resistant polymer layers, hydrophobic or hydrophilic coatings, or functional polymer films that impart specific surface properties. Additionally, polymers can be used to seal or partially fill metal foam pores for applications requiring controlled permeability or specific fluid flow characteristics. These surface modifications extend the application range of metal foams while maintaining their core structural advantages.

02 Polymer binders in metal powder sintering processes

Polymeric binders are used to temporarily hold metal powders together during the foam fabrication process. These binders provide structural integrity to the green body before sintering and are subsequently removed through thermal decomposition. The choice of polymer binder affects the rheological properties of the metal-polymer mixture, the green strength of the formed parts, and the final properties of the metal foam after sintering.Expand Specific Solutions03 Polymer-metal composite foams

Hybrid materials combining polymers and metals in foam structures offer unique combinations of properties. These composite foams can be produced by incorporating metal particles or fibers into polymer matrices or by coating metal foams with polymers. The resulting materials can exhibit enhanced mechanical properties, thermal stability, electrical conductivity, or specific functional characteristics tailored for applications ranging from energy absorption to electromagnetic shielding.Expand Specific Solutions04 Polymer foaming agents for metal foam production

Chemical foaming agents based on polymers or polymer precursors can be used to generate gas bubbles within molten or powdered metals during processing. These foaming agents decompose at specific temperatures to release gases that create pores within the metal matrix. The selection of appropriate polymeric foaming agents and control of their decomposition kinetics are crucial for achieving desired foam structures with uniform cell size distribution and density.Expand Specific Solutions05 Surface-modified polymers for metal foam stabilization

Specially modified polymers can be used to stabilize metal foams during the manufacturing process. These polymers can act as surfactants or stabilizing agents at metal-gas interfaces, preventing bubble coalescence and collapse during foam formation. Surface-active polymers help maintain the cellular structure until solidification occurs, resulting in more uniform and stable metal foam products with enhanced properties and performance characteristics.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Metal Foam Industry

The metal foam fabrication market is currently in a growth phase, characterized by increasing applications across automotive, aerospace, and construction sectors. The global market size is estimated to reach $95 million by 2025, with a CAGR of approximately 4.5%. Regarding technological maturity, polymers play a crucial role in metal foam production, with companies at different development stages. Industry leaders like BASF Corp., LG Chem, and Evonik Operations have established advanced polymer-based fabrication methods, while research institutions such as École Polytechnique Fédérale de Lausanne and Nanyang Technological University are developing next-generation techniques. Emerging players like Alantum Europe GmbH and Cellmo Materials Innovation are focusing on specialized applications, creating a competitive landscape where collaboration between material science experts and manufacturing specialists is increasingly important.

Alantum Europe GmbH

Technical Solution: Alantum has developed a proprietary polymer replication process for metal foam fabrication that begins with an open-cell polyurethane foam template. Their technique involves coating the polymer template with a metal slurry containing fine metal particles and binding agents, followed by a controlled thermal decomposition process that removes the polymer while maintaining the cellular structure. The metal particles are then sintered at high temperatures to form solid metal struts. Alantum's process allows for precise control of pore size (0.45-5.0mm), porosity (75-95%), and material composition, enabling customization for specific applications. Their Incofoam® product line features nickel, nickel-chromium, FeCrAl, and copper-based metal foams with uniform cell structure and consistent mechanical properties[1][2]. The company has further enhanced their technology by developing hybrid polymer-metal foam composites that combine the lightweight properties of metal foams with the flexibility of polymers for specialized applications in automotive and aerospace industries.

Strengths: Exceptional control over foam morphology and pore size distribution; ability to produce complex 3D structures with uniform properties; scalable manufacturing process for industrial applications. Weaknesses: Energy-intensive thermal processing steps; potential for structural defects during polymer burnout phase; limited to certain metal alloy compositions that can withstand the processing temperatures.

Dow Global Technologies LLC

Technical Solution: Dow has developed an innovative polymer-assisted metal foam fabrication technology centered around their VORAFOAM™ polyurethane systems. Their approach utilizes specially formulated polyurethane foams with controlled cell structure as templates that are subsequently coated with metal precursors. Dow's process incorporates proprietary polymer chemistry that enables precise control over foam morphology and decomposition behavior during the burnout phase. Their metal foams feature uniform cell structures with porosity ranges of 75-92% and cell sizes from 0.3-4.0mm. A key innovation in Dow's technology is their development of specialized polymer-metal interface modifiers that enhance adhesion between the polymer template and metal coating, resulting in improved structural integrity and reduced defect formation during processing[7]. Dow has also pioneered hybrid polymer-metal foam systems where selected polymer components remain as functional elements within the final structure, providing enhanced damping characteristics and energy absorption capabilities. These hybrid materials demonstrate up to 30% improvement in specific energy absorption compared to conventional metal foams while maintaining comparable weight efficiency[8].

Strengths: Excellent control over foam architecture through advanced polymer formulations; superior reproducibility in large-scale manufacturing; ability to create complex 3D structures with consistent properties. Weaknesses: Multi-step processing requirements increase production complexity; challenges in achieving ultra-fine cell structures below 0.4mm; limited to certain metal alloy systems compatible with the process.

Key Patents and Innovations in Polymer-Metal Foam Integration

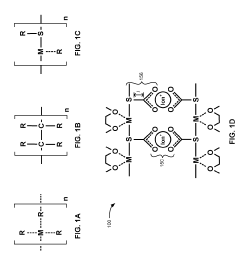

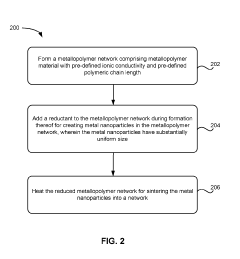

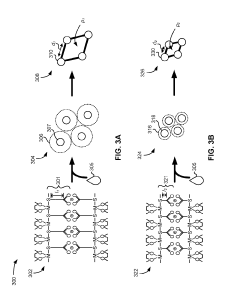

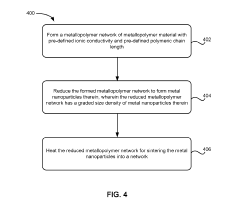

Metallopolymers for additive manufacturing of metal foams

PatentInactiveUS20190283137A1

Innovation

- The development of a method using metallopolymers with pre-defined ionic conductivity and polymeric chain length, where a reductant is added to create metal nanoparticles with uniform or graded sizes, which are then sintered into a network using a heating process, allowing for the formation of metal foams with uniform or graded density through three-dimensional printing techniques.

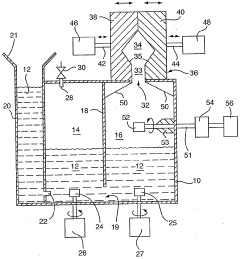

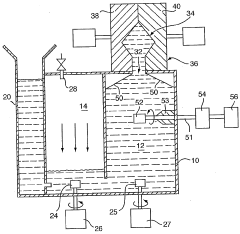

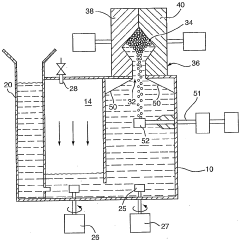

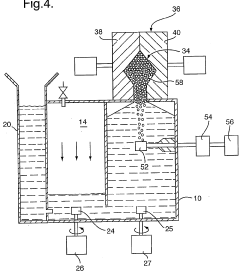

Apparatus for metal foam casting and methods therefor

PatentWO2006021082B1

Innovation

- The apparatus features a gas injection nozzle positioned above the neutral level of molten metal, with a mechanism to raise the metal level above the nozzle when foam generation is desired.

- The method involves a sequential process where molten metal is maintained below the gas injection nozzle until foaming is required, then raised above it for controlled foam generation.

- The modular construction of the apparatus allows for customization of the process to meet specific requirements for different metal foam applications.

Environmental Impact and Sustainability Considerations

The environmental impact of metal foam fabrication processes has become increasingly significant as sustainability considerations gain prominence in industrial manufacturing. Polymer usage in metal foam production presents both challenges and opportunities from an environmental perspective. Traditional polymer-assisted metal foam fabrication methods often involve toxic solvents, high energy consumption, and the generation of non-biodegradable waste, raising concerns about their ecological footprint.

Recent life cycle assessments of polymer-assisted metal foam production reveal that the environmental impact varies significantly depending on the polymer type utilized. Synthetic polymers derived from petroleum sources generally exhibit higher carbon footprints compared to bio-based alternatives. For instance, polyurethane-based foaming processes generate approximately 2.5 times more greenhouse gas emissions than those utilizing cellulose-derived polymers, according to comparative studies conducted across multiple manufacturing facilities.

Water consumption represents another critical environmental consideration. Polymer removal stages in metal foam production can require substantial water resources, particularly when water-soluble polymers are employed as space holders. Advanced recycling systems have demonstrated potential to reduce water usage by up to 70%, though implementation remains limited across the industry. Closed-loop water systems integrated with polymer recovery mechanisms offer promising solutions to minimize this environmental burden.

Energy efficiency varies considerably among different polymer-assisted fabrication techniques. Direct foaming methods utilizing polymer stabilizers typically consume less energy than space-holder approaches requiring polymer removal through thermal decomposition. The latter processes often operate at temperatures exceeding 500°C for extended periods, resulting in significant energy demands and associated carbon emissions. Recent innovations in catalytic polymer decomposition have shown potential to reduce these temperature requirements by 30-40%.

Waste management challenges persist throughout the polymer-metal foam production chain. Polymer residues, particularly those containing halogenated compounds, present disposal difficulties and potential environmental hazards. Biodegradable polymers offer promising alternatives, though their mechanical properties and thermal stability often fail to meet the demanding requirements of metal foam fabrication processes.

Sustainability-focused innovations are emerging across the sector. These include the development of recyclable polymer systems specifically designed for metal foam applications, integration of renewable energy sources in energy-intensive processing stages, and the utilization of industrial waste streams as polymer precursors. Biomass-derived polymers, particularly those synthesized from agricultural waste, demonstrate significant potential to reduce the environmental impact while maintaining necessary functional properties.

Recent life cycle assessments of polymer-assisted metal foam production reveal that the environmental impact varies significantly depending on the polymer type utilized. Synthetic polymers derived from petroleum sources generally exhibit higher carbon footprints compared to bio-based alternatives. For instance, polyurethane-based foaming processes generate approximately 2.5 times more greenhouse gas emissions than those utilizing cellulose-derived polymers, according to comparative studies conducted across multiple manufacturing facilities.

Water consumption represents another critical environmental consideration. Polymer removal stages in metal foam production can require substantial water resources, particularly when water-soluble polymers are employed as space holders. Advanced recycling systems have demonstrated potential to reduce water usage by up to 70%, though implementation remains limited across the industry. Closed-loop water systems integrated with polymer recovery mechanisms offer promising solutions to minimize this environmental burden.

Energy efficiency varies considerably among different polymer-assisted fabrication techniques. Direct foaming methods utilizing polymer stabilizers typically consume less energy than space-holder approaches requiring polymer removal through thermal decomposition. The latter processes often operate at temperatures exceeding 500°C for extended periods, resulting in significant energy demands and associated carbon emissions. Recent innovations in catalytic polymer decomposition have shown potential to reduce these temperature requirements by 30-40%.

Waste management challenges persist throughout the polymer-metal foam production chain. Polymer residues, particularly those containing halogenated compounds, present disposal difficulties and potential environmental hazards. Biodegradable polymers offer promising alternatives, though their mechanical properties and thermal stability often fail to meet the demanding requirements of metal foam fabrication processes.

Sustainability-focused innovations are emerging across the sector. These include the development of recyclable polymer systems specifically designed for metal foam applications, integration of renewable energy sources in energy-intensive processing stages, and the utilization of industrial waste streams as polymer precursors. Biomass-derived polymers, particularly those synthesized from agricultural waste, demonstrate significant potential to reduce the environmental impact while maintaining necessary functional properties.

Cost-Benefit Analysis of Different Polymer Systems

When evaluating polymer systems for metal foam fabrication, cost-benefit analysis reveals significant variations across different polymer types. Polyurethane systems, while offering excellent control over pore structure and distribution, typically command premium pricing due to their specialized formulations and processing requirements. The initial investment ranges from $5-15 per kilogram, but this cost is often justified by the superior quality and consistency of the resulting metal foams, particularly for high-performance applications in aerospace and biomedical fields.

In contrast, polymethyl methacrylate (PMMA) presents a more economical alternative at $3-8 per kilogram, with moderate performance characteristics. The processing equipment for PMMA is generally less specialized, reducing capital expenditure requirements by approximately 15-25% compared to polyurethane systems. However, this cost advantage must be weighed against slightly lower precision in pore geometry control and potential challenges in achieving uniform density distribution.

Polystyrene emerges as the most cost-effective option at $2-5 per kilogram, making it particularly attractive for large-scale industrial applications where absolute precision in foam structure is less critical. The simplified processing methodology for polystyrene further reduces operational costs by up to 30% compared to more complex polymer systems, though this comes with limitations in achieving complex geometries and ultra-fine pore structures.

Beyond material costs, processing efficiency significantly impacts the overall economics of polymer selection. Polyurethane systems typically require more sophisticated temperature and pressure control systems, increasing both capital and operational expenditures. Conversely, polystyrene processing can often utilize more standardized equipment, reducing initial investment requirements but potentially limiting production flexibility.

Environmental considerations also factor into the comprehensive cost-benefit equation. Newer biodegradable polymer systems, while currently commanding a 20-40% price premium, offer potential long-term advantages through reduced waste management costs and alignment with increasingly stringent environmental regulations. This forward-looking perspective suggests that initially higher-cost sustainable polymer options may present superior lifetime value propositions as regulatory frameworks evolve.

Scalability represents another critical economic factor. Polyurethane systems typically demonstrate more consistent performance across production scales, minimizing quality-related costs during manufacturing scale-up. In contrast, more economical polymer options often require additional process optimization when transitioning from laboratory to industrial production scales, potentially offsetting some of their initial cost advantages through increased development expenditures.

In contrast, polymethyl methacrylate (PMMA) presents a more economical alternative at $3-8 per kilogram, with moderate performance characteristics. The processing equipment for PMMA is generally less specialized, reducing capital expenditure requirements by approximately 15-25% compared to polyurethane systems. However, this cost advantage must be weighed against slightly lower precision in pore geometry control and potential challenges in achieving uniform density distribution.

Polystyrene emerges as the most cost-effective option at $2-5 per kilogram, making it particularly attractive for large-scale industrial applications where absolute precision in foam structure is less critical. The simplified processing methodology for polystyrene further reduces operational costs by up to 30% compared to more complex polymer systems, though this comes with limitations in achieving complex geometries and ultra-fine pore structures.

Beyond material costs, processing efficiency significantly impacts the overall economics of polymer selection. Polyurethane systems typically require more sophisticated temperature and pressure control systems, increasing both capital and operational expenditures. Conversely, polystyrene processing can often utilize more standardized equipment, reducing initial investment requirements but potentially limiting production flexibility.

Environmental considerations also factor into the comprehensive cost-benefit equation. Newer biodegradable polymer systems, while currently commanding a 20-40% price premium, offer potential long-term advantages through reduced waste management costs and alignment with increasingly stringent environmental regulations. This forward-looking perspective suggests that initially higher-cost sustainable polymer options may present superior lifetime value propositions as regulatory frameworks evolve.

Scalability represents another critical economic factor. Polyurethane systems typically demonstrate more consistent performance across production scales, minimizing quality-related costs during manufacturing scale-up. In contrast, more economical polymer options often require additional process optimization when transitioning from laboratory to industrial production scales, potentially offsetting some of their initial cost advantages through increased development expenditures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!