How Do Material Properties Affect Metal Foam Fabrication Outcomes?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Technology Background and Objectives

Metal foam technology represents a significant advancement in materials science, emerging in the mid-20th century but gaining substantial research momentum only in the past three decades. These unique cellular structures combine the inherent properties of metals with the architectural advantages of foams, creating materials with exceptional strength-to-weight ratios, energy absorption capabilities, and thermal management characteristics.

The evolution of metal foam technology has followed a trajectory from theoretical conceptualization to practical implementation across multiple industries. Initially developed for specialized aerospace and defense applications, metal foams have progressively expanded into automotive, biomedical, construction, and energy sectors. This expansion reflects both technological maturation and growing recognition of their versatile performance attributes.

Current technological development focuses on enhancing control over foam morphology, including cell size distribution, wall thickness, and overall porosity. These parameters critically influence the mechanical, thermal, and acoustic properties of the resulting materials. The relationship between base material properties and fabrication outcomes represents a central challenge in advancing metal foam technology, as variations in viscosity, surface tension, melting point, and alloy composition significantly impact manufacturing success.

The primary objective of metal foam research is to establish robust correlations between material properties and fabrication outcomes, enabling predictive manufacturing models. This includes understanding how material composition affects foam stability during formation, solidification behavior, and ultimate structural integrity. Researchers aim to develop comprehensive process-structure-property relationships that can guide material selection and processing parameters for targeted applications.

Secondary objectives include expanding the range of metals and alloys suitable for foam production, reducing manufacturing costs, and scaling production techniques for industrial implementation. Particular emphasis is placed on developing sustainable manufacturing methods that minimize material waste and energy consumption while maintaining or enhancing performance characteristics.

The technological trajectory suggests continued refinement of existing fabrication methods alongside exploration of novel approaches. Emerging trends include hybrid metal foams incorporating non-metallic components, functionally graded structures with variable density distributions, and smart metal foams with embedded sensing or responsive capabilities. These developments aim to address specific application challenges while expanding the functional versatility of metal foam materials.

Understanding the fundamental relationship between material properties and fabrication outcomes represents the cornerstone of future advancement in this field, potentially enabling precise engineering of metal foam structures for increasingly specialized applications across diverse industrial sectors.

The evolution of metal foam technology has followed a trajectory from theoretical conceptualization to practical implementation across multiple industries. Initially developed for specialized aerospace and defense applications, metal foams have progressively expanded into automotive, biomedical, construction, and energy sectors. This expansion reflects both technological maturation and growing recognition of their versatile performance attributes.

Current technological development focuses on enhancing control over foam morphology, including cell size distribution, wall thickness, and overall porosity. These parameters critically influence the mechanical, thermal, and acoustic properties of the resulting materials. The relationship between base material properties and fabrication outcomes represents a central challenge in advancing metal foam technology, as variations in viscosity, surface tension, melting point, and alloy composition significantly impact manufacturing success.

The primary objective of metal foam research is to establish robust correlations between material properties and fabrication outcomes, enabling predictive manufacturing models. This includes understanding how material composition affects foam stability during formation, solidification behavior, and ultimate structural integrity. Researchers aim to develop comprehensive process-structure-property relationships that can guide material selection and processing parameters for targeted applications.

Secondary objectives include expanding the range of metals and alloys suitable for foam production, reducing manufacturing costs, and scaling production techniques for industrial implementation. Particular emphasis is placed on developing sustainable manufacturing methods that minimize material waste and energy consumption while maintaining or enhancing performance characteristics.

The technological trajectory suggests continued refinement of existing fabrication methods alongside exploration of novel approaches. Emerging trends include hybrid metal foams incorporating non-metallic components, functionally graded structures with variable density distributions, and smart metal foams with embedded sensing or responsive capabilities. These developments aim to address specific application challenges while expanding the functional versatility of metal foam materials.

Understanding the fundamental relationship between material properties and fabrication outcomes represents the cornerstone of future advancement in this field, potentially enabling precise engineering of metal foam structures for increasingly specialized applications across diverse industrial sectors.

Market Applications and Demand Analysis

Metal foam technology has witnessed significant market growth across multiple industries due to its unique combination of properties including high strength-to-weight ratio, excellent energy absorption capabilities, and thermal management characteristics. The global metal foam market was valued at approximately 85 million USD in 2022 and is projected to reach 115 million USD by 2028, growing at a CAGR of around 5.2% during the forecast period.

The automotive sector represents the largest application segment, accounting for nearly 35% of the total market share. Manufacturers are increasingly incorporating metal foams into vehicle designs to enhance crash safety while reducing overall weight. This trend is particularly pronounced in the electric vehicle segment, where weight reduction directly correlates with improved range performance. BMW, Audi, and Tesla have all implemented metal foam components in their premium vehicle lines.

The aerospace industry constitutes the second-largest market segment, with applications focusing on lightweight structural components and thermal management systems. Boeing and Airbus have both invested in metal foam research for next-generation aircraft designs, aiming to reduce fuel consumption through weight reduction while maintaining structural integrity.

Building and construction applications are experiencing the fastest growth rate among all segments, particularly in regions with stringent fire safety regulations. Metal foams offer superior fire resistance compared to traditional materials, creating significant demand in high-rise buildings and public infrastructure projects.

Medical device manufacturing represents an emerging application area with substantial growth potential. Titanium and tantalum foams are increasingly used in orthopedic implants due to their biocompatibility and bone-mimicking mechanical properties. The global orthopedic implant market utilizing metal foams is expected to grow at 7.8% annually through 2030.

Regional analysis indicates North America currently leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is projected to witness the highest growth rate due to rapid industrialization in China and India, coupled with increasing automotive and aerospace manufacturing activities.

Customer requirements across these markets consistently emphasize the need for reproducible foam structures with predictable mechanical properties. End-users are willing to pay premium prices for metal foams with certified performance characteristics, highlighting the critical importance of understanding how material properties affect fabrication outcomes. This market insight underscores the commercial relevance of advancing process control in metal foam production technologies.

The automotive sector represents the largest application segment, accounting for nearly 35% of the total market share. Manufacturers are increasingly incorporating metal foams into vehicle designs to enhance crash safety while reducing overall weight. This trend is particularly pronounced in the electric vehicle segment, where weight reduction directly correlates with improved range performance. BMW, Audi, and Tesla have all implemented metal foam components in their premium vehicle lines.

The aerospace industry constitutes the second-largest market segment, with applications focusing on lightweight structural components and thermal management systems. Boeing and Airbus have both invested in metal foam research for next-generation aircraft designs, aiming to reduce fuel consumption through weight reduction while maintaining structural integrity.

Building and construction applications are experiencing the fastest growth rate among all segments, particularly in regions with stringent fire safety regulations. Metal foams offer superior fire resistance compared to traditional materials, creating significant demand in high-rise buildings and public infrastructure projects.

Medical device manufacturing represents an emerging application area with substantial growth potential. Titanium and tantalum foams are increasingly used in orthopedic implants due to their biocompatibility and bone-mimicking mechanical properties. The global orthopedic implant market utilizing metal foams is expected to grow at 7.8% annually through 2030.

Regional analysis indicates North America currently leads the market with 38% share, followed by Europe (32%) and Asia-Pacific (24%). However, the Asia-Pacific region is projected to witness the highest growth rate due to rapid industrialization in China and India, coupled with increasing automotive and aerospace manufacturing activities.

Customer requirements across these markets consistently emphasize the need for reproducible foam structures with predictable mechanical properties. End-users are willing to pay premium prices for metal foams with certified performance characteristics, highlighting the critical importance of understanding how material properties affect fabrication outcomes. This market insight underscores the commercial relevance of advancing process control in metal foam production technologies.

Current Challenges in Metal Foam Fabrication

Despite significant advancements in metal foam fabrication technologies, several critical challenges persist that impede optimal production outcomes and widespread industrial adoption. Material property variations represent one of the most significant hurdles in achieving consistent metal foam structures. The chemical composition of base metals, including impurity levels and alloying elements, dramatically affects viscosity, surface tension, and solidification behavior during processing, leading to unpredictable pore formation and distribution.

Temperature control during fabrication presents another substantial challenge, as most metal foam production methods operate within narrow thermal windows. Even minor temperature fluctuations can cause premature solidification or excessive fluidity, resulting in structural defects or collapsed cell walls. This challenge is particularly pronounced in methods requiring precise thermal gradients, such as directional solidification techniques.

Foaming agent selection and integration remains problematic across various fabrication routes. The interaction between foaming agents and molten metals is highly dependent on material properties, with issues of uneven gas evolution, premature decomposition, or insufficient gas generation directly linked to material compatibility issues. These interactions are often difficult to predict theoretically and require extensive empirical testing.

Viscosity management during the foaming process represents another significant challenge. The viscosity of molten metals must be carefully controlled to prevent drainage and cell collapse before solidification. Material additives intended to stabilize foam structures often introduce new variables that complicate processing parameters and may adversely affect final mechanical properties.

Solidification rate control is particularly challenging due to the complex heat transfer mechanisms in cellular metal structures. The thermal conductivity of the base metal, combined with the insulating properties of pores, creates non-uniform cooling patterns that can lead to residual stresses, warping, or cracking in the final product.

Surface oxidation during processing presents additional complications, especially for reactive metals like aluminum and titanium. Oxide formation affects wetting behavior, interfacial energies, and ultimately pore stability. The oxidation kinetics vary significantly between different metal systems, requiring tailored processing environments for each material.

Reproducibility remains perhaps the most persistent challenge in metal foam fabrication. The complex interplay between material properties and processing parameters creates systems highly sensitive to minor variations, making consistent production difficult to achieve at industrial scales. This challenge is compounded by the limited fundamental understanding of how specific material properties influence each stage of the foam formation process.

Temperature control during fabrication presents another substantial challenge, as most metal foam production methods operate within narrow thermal windows. Even minor temperature fluctuations can cause premature solidification or excessive fluidity, resulting in structural defects or collapsed cell walls. This challenge is particularly pronounced in methods requiring precise thermal gradients, such as directional solidification techniques.

Foaming agent selection and integration remains problematic across various fabrication routes. The interaction between foaming agents and molten metals is highly dependent on material properties, with issues of uneven gas evolution, premature decomposition, or insufficient gas generation directly linked to material compatibility issues. These interactions are often difficult to predict theoretically and require extensive empirical testing.

Viscosity management during the foaming process represents another significant challenge. The viscosity of molten metals must be carefully controlled to prevent drainage and cell collapse before solidification. Material additives intended to stabilize foam structures often introduce new variables that complicate processing parameters and may adversely affect final mechanical properties.

Solidification rate control is particularly challenging due to the complex heat transfer mechanisms in cellular metal structures. The thermal conductivity of the base metal, combined with the insulating properties of pores, creates non-uniform cooling patterns that can lead to residual stresses, warping, or cracking in the final product.

Surface oxidation during processing presents additional complications, especially for reactive metals like aluminum and titanium. Oxide formation affects wetting behavior, interfacial energies, and ultimately pore stability. The oxidation kinetics vary significantly between different metal systems, requiring tailored processing environments for each material.

Reproducibility remains perhaps the most persistent challenge in metal foam fabrication. The complex interplay between material properties and processing parameters creates systems highly sensitive to minor variations, making consistent production difficult to achieve at industrial scales. This challenge is compounded by the limited fundamental understanding of how specific material properties influence each stage of the foam formation process.

Material-Process Relationship Analysis

01 Manufacturing methods for metal foams

Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve the introduction of porosity into metal structures through processes such as gas injection, use of space holders, or controlled solidification. The manufacturing approach significantly influences the resulting foam properties, including density, pore size distribution, and mechanical characteristics.- Manufacturing methods for metal foams: Various manufacturing methods are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing techniques. These processes involve the introduction of gas or foaming agents into molten metal or metal powder to create a porous structure. The manufacturing method significantly influences the final properties of the metal foam, such as density, pore size distribution, and mechanical strength.

- Structural properties and mechanical performance: Metal foams exhibit unique structural properties that make them valuable for various applications. These properties include high strength-to-weight ratio, energy absorption capabilities, and thermal insulation. The mechanical performance of metal foams can be tailored by controlling the porosity, cell size, and cell wall thickness during fabrication. Testing methods have been developed to evaluate these properties under different loading conditions.

- Advanced fabrication techniques and process optimization: Advanced fabrication techniques for metal foams include 3D printing, selective laser melting, and electrodeposition. These methods allow for precise control over the foam structure and properties. Process optimization involves adjusting parameters such as temperature, pressure, and cooling rates to achieve desired foam characteristics. Computational modeling and simulation tools are increasingly used to predict and optimize the fabrication outcomes.

- Functional applications and performance outcomes: Metal foams find applications in various industries due to their unique properties. They are used in automotive components for crash energy absorption, in aerospace for lightweight structures, in biomedical implants, and in thermal management systems. The performance outcomes in these applications depend on the specific properties of the metal foam, such as porosity, cell structure, and base metal composition.

- Surface treatments and post-processing techniques: Various surface treatments and post-processing techniques are applied to metal foams to enhance their properties and performance. These include coating applications, heat treatments, and surface functionalization. Post-processing can improve corrosion resistance, wear resistance, and biocompatibility of metal foams. Additionally, joining techniques have been developed to integrate metal foams with other materials in composite structures.

02 Structural properties and mechanical performance

Metal foams exhibit unique structural properties that result in distinctive mechanical performance. These materials combine lightweight characteristics with relatively high strength, energy absorption capabilities, and impact resistance. The cellular structure of metal foams provides advantages in applications requiring weight reduction while maintaining structural integrity. The relationship between foam density, cell structure, and mechanical properties can be tailored for specific applications.Expand Specific Solutions03 Advanced applications in engineering and industry

Metal foams find applications across various engineering fields due to their unique combination of properties. They are utilized in automotive components for crash energy absorption, aerospace structures for weight reduction, thermal management systems, filtration devices, and acoustic dampening solutions. The multifunctional nature of metal foams makes them valuable in industries requiring materials with combined thermal, mechanical, and acoustic performance.Expand Specific Solutions04 Optimization and modeling of foam structures

Computational modeling and simulation techniques are employed to optimize metal foam structures for specific applications. These approaches allow for prediction of mechanical behavior, thermal properties, and fluid flow characteristics through foam structures. Advanced algorithms and design methodologies enable the creation of tailored foam architectures with gradient porosity or anisotropic properties to meet specific performance requirements.Expand Specific Solutions05 Novel compositions and functional enhancements

Research in metal foam technology has led to the development of novel compositions and functional enhancements. These include multi-material foams, composite structures, surface-modified foams, and foams with embedded functionality. By incorporating additional elements or phases, or through post-processing treatments, metal foams can be engineered to possess enhanced properties such as improved corrosion resistance, electrical conductivity, or catalytic activity.Expand Specific Solutions

Key Industry Players and Competition Landscape

The metal foam fabrication market is currently in a growth phase, characterized by increasing applications across automotive, aerospace, and energy sectors. The market size is estimated to reach $95-100 million by 2025, with a CAGR of approximately 4.5%. Technical maturity varies significantly across fabrication methods, with companies demonstrating different specialization levels. Leading players like Fraunhofer-Gesellschaft and ALANTUM Corp. have established advanced manufacturing capabilities, while academic institutions such as North Carolina State University and Tongji University contribute significant research innovations. LG Chem and Infineon Technologies are leveraging metal foams for specialized applications, while smaller players like Yuhuan Degu and Cellmo Materials focus on niche material properties optimization. The competitive landscape shows a blend of established industrial manufacturers and emerging technology-focused enterprises working to overcome material property challenges.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed comprehensive research on metal foam fabrication focusing on the relationship between material properties and manufacturing outcomes. Their approach encompasses multiple production methods including powder metallurgy, investment casting, and direct foaming techniques. Their research has established quantitative correlations between starting material characteristics (particle size distribution, oxide content, alloying elements) and resulting foam properties. For aluminum foams, they've demonstrated that controlling the Ca and Ti stabilizer content (typically 1-2 wt%) is critical for achieving uniform pore structures, with their optimized formulations achieving up to 95% porosity while maintaining structural integrity. Fraunhofer's work has mapped the influence of processing parameters (temperature profiles, pressure conditions, cooling rates) on cell morphology, showing that controlled cooling rates of 10-15°C/min produce the most uniform cell structures in aluminum-silicon alloy foams. Their research extends to hybrid metal foams, where they've pioneered techniques to create functionally graded materials with density variations of 0.4-0.8 g/cm³ within a single component.

Strengths: Exceptional versatility across multiple metal foam production technologies; strong scientific understanding of process-structure-property relationships; ability to create application-specific foam structures with tailored properties. Weaknesses: Some processes remain laboratory-scale and face challenges in industrial scaling; higher production costs for specialized foam variants; energy-intensive production methods for certain foam types.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics has conducted extensive research on metal foam fabrication with particular emphasis on aluminum and titanium-based foams for aerospace applications. Their approach focuses on understanding the fundamental relationships between material composition, processing parameters, and resulting foam properties. The university has developed innovative space-holder methods using carbamide particles as temporary fillers, allowing precise control of pore size (0.5-5mm) and distribution. Their research demonstrates that the wettability between molten metal and space holder materials critically affects cell wall integrity, with optimized surface treatments improving wetting angles by up to 30%. They've established correlations between sintering temperature profiles and resulting mechanical properties, showing that controlled sintering at 630-650°C for aluminum alloys produces optimal strength-to-weight ratios. Their work includes comprehensive mapping of how alloying elements (particularly Mg, Si, and Cu in aluminum systems) affect foam stability and mechanical performance, with their optimized Al-Mg-Si foams achieving compressive strengths of 15-25 MPa at relative densities of 15-25%.

Strengths: Excellent control over pore morphology and size distribution; strong fundamental understanding of metallurgical factors affecting foam properties; ability to create lightweight structures with superior energy absorption characteristics. Weaknesses: Some processes have limited scalability for industrial production; higher production costs compared to conventional manufacturing; challenges in achieving consistent properties in large-volume production.

Critical Material Property Influence Mechanisms

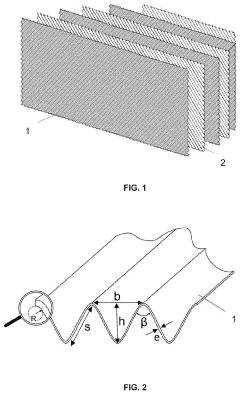

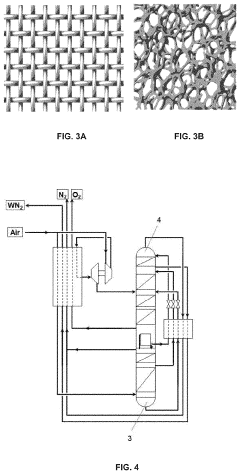

Cross-corrugated packing made from metal foam

PatentActiveUS20220219134A1

Innovation

- The use of open-pore metal foam with a specific surface area greater than 500 m2/m3, and a leaf thickness less than 2 mm before shaping, allows for enhanced capillary action and reduced drying-out, increasing the effective surface area for gas-liquid contact without compromising gas passage, particularly suited for low liquid reflux conditions.

Sustainability and Environmental Considerations

Metal foam production processes have significant environmental implications that must be considered in the context of sustainable manufacturing. The energy consumption during metal foam fabrication varies considerably depending on the base material properties and chosen manufacturing method. Aluminum foams typically require less energy to produce than titanium or nickel-based foams due to their lower melting points, making them relatively more environmentally friendly options. However, the overall carbon footprint extends beyond just the production phase to include raw material extraction and processing.

The recyclability of metal foams presents a notable sustainability advantage. Most metal foam structures can be recycled multiple times without significant degradation of material properties, particularly aluminum-based foams which maintain up to 95% of their original properties through recycling processes. This circular economy potential significantly reduces the environmental impact compared to non-recyclable materials used in similar applications.

Material selection directly influences the environmental footprint of metal foam products throughout their lifecycle. Foams manufactured from recycled metals demonstrate substantially lower environmental impact than those produced from virgin materials. Research indicates that using recycled aluminum in foam production can reduce energy consumption by approximately 95% compared to using primary aluminum, with corresponding reductions in greenhouse gas emissions.

Manufacturing process selection based on material properties also affects sustainability metrics. Powder metallurgy approaches typically consume less energy than melt-based processes for high-melting-point metals like titanium. Additionally, additive manufacturing techniques for metal foam production can reduce material waste by up to 40% compared to traditional subtractive manufacturing methods, though they may require more specialized equipment and energy during the fabrication process.

The durability and longevity of metal foams, determined largely by their base material properties and structural integrity, contribute significantly to their sustainability profile. Corrosion-resistant alloys in foam structures extend service life, reducing replacement frequency and associated environmental impacts. For instance, nickel-based metal foams demonstrate superior longevity in harsh environments compared to aluminum alternatives, potentially offsetting their higher initial environmental production cost through extended use phases.

Emerging research focuses on developing bio-inspired metal foam structures that optimize material distribution based on natural principles, potentially reducing material usage by 15-30% while maintaining mechanical performance. These developments represent promising directions for enhancing the sustainability of metal foam applications across industries from automotive to aerospace and construction.

The recyclability of metal foams presents a notable sustainability advantage. Most metal foam structures can be recycled multiple times without significant degradation of material properties, particularly aluminum-based foams which maintain up to 95% of their original properties through recycling processes. This circular economy potential significantly reduces the environmental impact compared to non-recyclable materials used in similar applications.

Material selection directly influences the environmental footprint of metal foam products throughout their lifecycle. Foams manufactured from recycled metals demonstrate substantially lower environmental impact than those produced from virgin materials. Research indicates that using recycled aluminum in foam production can reduce energy consumption by approximately 95% compared to using primary aluminum, with corresponding reductions in greenhouse gas emissions.

Manufacturing process selection based on material properties also affects sustainability metrics. Powder metallurgy approaches typically consume less energy than melt-based processes for high-melting-point metals like titanium. Additionally, additive manufacturing techniques for metal foam production can reduce material waste by up to 40% compared to traditional subtractive manufacturing methods, though they may require more specialized equipment and energy during the fabrication process.

The durability and longevity of metal foams, determined largely by their base material properties and structural integrity, contribute significantly to their sustainability profile. Corrosion-resistant alloys in foam structures extend service life, reducing replacement frequency and associated environmental impacts. For instance, nickel-based metal foams demonstrate superior longevity in harsh environments compared to aluminum alternatives, potentially offsetting their higher initial environmental production cost through extended use phases.

Emerging research focuses on developing bio-inspired metal foam structures that optimize material distribution based on natural principles, potentially reducing material usage by 15-30% while maintaining mechanical performance. These developments represent promising directions for enhancing the sustainability of metal foam applications across industries from automotive to aerospace and construction.

Quality Control and Standardization Requirements

Quality control in metal foam fabrication presents unique challenges due to the complex relationship between material properties and final product characteristics. The inherent variability in raw materials significantly impacts the consistency of metal foam structures, necessitating robust standardization frameworks. Currently, the industry faces a critical gap in universally accepted quality standards specific to metal foam production, with most manufacturers relying on adapted standards from traditional metallurgy or custom internal specifications.

Material composition analysis must be rigorously controlled through techniques such as X-ray fluorescence spectroscopy and inductively coupled plasma mass spectrometry to ensure precise alloy formulations. These methods enable manufacturers to verify that input materials meet the required specifications before entering the production process, thereby reducing variability in final foam properties.

Mechanical property testing represents another essential component of quality control protocols. Compression testing, fatigue resistance evaluation, and impact absorption measurements must be standardized to enable meaningful comparison between different metal foam products. The development of non-destructive testing methodologies specifically calibrated for cellular metal structures remains a priority research area, as conventional techniques often prove inadequate for these heterogeneous materials.

Dimensional accuracy and structural uniformity assessment require specialized imaging techniques such as micro-computed tomography and scanning electron microscopy. These methods allow for detailed characterization of cell size distribution, wall thickness variations, and void fraction—parameters directly influenced by material properties during fabrication. Statistical process control methods must be adapted to accommodate the inherently variable nature of foam structures while maintaining meaningful quality thresholds.

International standardization efforts are gradually emerging through organizations like ASTM International and ISO, which have begun developing specific test methods and classification systems for metal foams. Standard ASTM E2736, which addresses terminology for cellular metals, represents an initial step toward comprehensive standardization. However, material-specific standards that account for the unique behavior of different metal alloys in foam fabrication processes remain underdeveloped.

Traceability systems linking raw material properties to process parameters and final product characteristics are increasingly recognized as essential for quality assurance. Digital manufacturing platforms incorporating machine learning algorithms show promise in predicting how variations in material properties will affect foam quality, potentially enabling real-time process adjustments to maintain consistent outcomes despite input material fluctuations.

Material composition analysis must be rigorously controlled through techniques such as X-ray fluorescence spectroscopy and inductively coupled plasma mass spectrometry to ensure precise alloy formulations. These methods enable manufacturers to verify that input materials meet the required specifications before entering the production process, thereby reducing variability in final foam properties.

Mechanical property testing represents another essential component of quality control protocols. Compression testing, fatigue resistance evaluation, and impact absorption measurements must be standardized to enable meaningful comparison between different metal foam products. The development of non-destructive testing methodologies specifically calibrated for cellular metal structures remains a priority research area, as conventional techniques often prove inadequate for these heterogeneous materials.

Dimensional accuracy and structural uniformity assessment require specialized imaging techniques such as micro-computed tomography and scanning electron microscopy. These methods allow for detailed characterization of cell size distribution, wall thickness variations, and void fraction—parameters directly influenced by material properties during fabrication. Statistical process control methods must be adapted to accommodate the inherently variable nature of foam structures while maintaining meaningful quality thresholds.

International standardization efforts are gradually emerging through organizations like ASTM International and ISO, which have begun developing specific test methods and classification systems for metal foams. Standard ASTM E2736, which addresses terminology for cellular metals, represents an initial step toward comprehensive standardization. However, material-specific standards that account for the unique behavior of different metal alloys in foam fabrication processes remain underdeveloped.

Traceability systems linking raw material properties to process parameters and final product characteristics are increasingly recognized as essential for quality assurance. Digital manufacturing platforms incorporating machine learning algorithms show promise in predicting how variations in material properties will affect foam quality, potentially enabling real-time process adjustments to maintain consistent outcomes despite input material fluctuations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!