What Are the Key Innovations in Metal Foam Fabrication?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Technology Background and Objectives

Metal foam technology represents a significant advancement in materials science, combining the structural benefits of metals with the unique properties of cellular structures. Since its emergence in the mid-20th century, metal foams have evolved from laboratory curiosities to engineered materials with diverse applications across industries. The development trajectory has been marked by continuous improvements in manufacturing techniques, material compositions, and structural control.

The evolution of metal foam fabrication has progressed through several distinct phases. Initial production methods relied on gas injection into molten metals, which offered limited control over pore size and distribution. Subsequent advancements introduced powder metallurgy approaches, allowing for more precise manipulation of foam characteristics. Recent innovations have focused on achieving greater homogeneity in cellular structure while expanding the range of base metals and alloys that can be successfully foamed.

Current technological objectives in metal foam fabrication center on addressing several persistent challenges. These include reducing production costs to enable broader commercial adoption, enhancing mechanical properties through structural optimization, and developing scalable manufacturing processes that maintain consistent quality across larger production volumes. Additionally, there is significant interest in creating multi-functional metal foams that combine mechanical performance with other properties such as thermal management, acoustic dampening, or electromagnetic shielding.

The global research landscape shows accelerating interest in metal foam technology, with notable contributions from research institutions in North America, Europe, and East Asia. Publication trends indicate growing focus on application-specific foam designs, where cellular structures are tailored to meet particular performance requirements rather than general-purpose solutions.

Looking forward, the technology roadmap for metal foam fabrication is increasingly oriented toward sustainability considerations. This includes developing energy-efficient production methods, incorporating recycled materials into foam production, and designing foams for end-of-life recyclability. These objectives align with broader industrial trends toward circular economy principles and reduced environmental footprints.

The convergence of advanced computational modeling, additive manufacturing capabilities, and materials science is expected to drive the next generation of innovations in metal foam fabrication. These developments aim to transition metal foams from specialized applications to mainstream engineering materials with predictable properties and cost-effective production pathways.

The evolution of metal foam fabrication has progressed through several distinct phases. Initial production methods relied on gas injection into molten metals, which offered limited control over pore size and distribution. Subsequent advancements introduced powder metallurgy approaches, allowing for more precise manipulation of foam characteristics. Recent innovations have focused on achieving greater homogeneity in cellular structure while expanding the range of base metals and alloys that can be successfully foamed.

Current technological objectives in metal foam fabrication center on addressing several persistent challenges. These include reducing production costs to enable broader commercial adoption, enhancing mechanical properties through structural optimization, and developing scalable manufacturing processes that maintain consistent quality across larger production volumes. Additionally, there is significant interest in creating multi-functional metal foams that combine mechanical performance with other properties such as thermal management, acoustic dampening, or electromagnetic shielding.

The global research landscape shows accelerating interest in metal foam technology, with notable contributions from research institutions in North America, Europe, and East Asia. Publication trends indicate growing focus on application-specific foam designs, where cellular structures are tailored to meet particular performance requirements rather than general-purpose solutions.

Looking forward, the technology roadmap for metal foam fabrication is increasingly oriented toward sustainability considerations. This includes developing energy-efficient production methods, incorporating recycled materials into foam production, and designing foams for end-of-life recyclability. These objectives align with broader industrial trends toward circular economy principles and reduced environmental footprints.

The convergence of advanced computational modeling, additive manufacturing capabilities, and materials science is expected to drive the next generation of innovations in metal foam fabrication. These developments aim to transition metal foams from specialized applications to mainstream engineering materials with predictable properties and cost-effective production pathways.

Market Applications and Demand Analysis

The global market for metal foam applications has witnessed substantial growth in recent years, driven by increasing demand across multiple industries. The unique properties of metal foams - including high strength-to-weight ratio, excellent energy absorption capabilities, thermal conductivity control, and acoustic damping - have positioned them as valuable materials in advanced engineering applications.

The automotive sector represents one of the largest markets for metal foam applications, with an expanding focus on lightweight materials to improve fuel efficiency and meet stringent emissions regulations. Metal foams are increasingly incorporated into crash absorption zones, structural components, and heat shields. The electric vehicle segment particularly values metal foams for battery protection systems and thermal management solutions.

Aerospace and defense industries demonstrate growing demand for metal foams in structural components, vibration damping systems, and blast protection applications. The material's ability to absorb impact energy while maintaining structural integrity makes it particularly valuable for military applications and aircraft components where weight reduction is critical.

The building and construction sector utilizes metal foams for architectural panels, fire-resistant structures, and sound absorption systems. The material's aesthetic appeal combined with functional properties has created new design possibilities for modern architecture, particularly in high-end commercial buildings and public infrastructure.

Healthcare applications represent an emerging market segment, with metal foams being developed for orthopedic implants and prosthetics. The porous structure allows for bone ingrowth and better integration with human tissue, while maintaining necessary mechanical strength. This application area shows significant growth potential as manufacturing techniques improve.

Energy sector applications include heat exchangers, catalytic supports, and filtration systems. The controllable porosity and surface area characteristics make metal foams particularly effective in these applications, with growing implementation in renewable energy systems and industrial processes.

Market analysis indicates regional variations in adoption rates, with North America and Europe leading in high-value applications, while Asia-Pacific demonstrates the fastest growth rate due to expanding manufacturing capabilities and increasing industrial demand. The global metal foam market is projected to continue its upward trajectory as manufacturing costs decrease and awareness of application benefits increases across industries.

Challenges to market expansion include relatively high production costs compared to conventional materials, standardization issues, and limited awareness among potential end-users. However, ongoing innovations in fabrication techniques are gradually addressing these barriers, particularly through improved process control and scalability.

The automotive sector represents one of the largest markets for metal foam applications, with an expanding focus on lightweight materials to improve fuel efficiency and meet stringent emissions regulations. Metal foams are increasingly incorporated into crash absorption zones, structural components, and heat shields. The electric vehicle segment particularly values metal foams for battery protection systems and thermal management solutions.

Aerospace and defense industries demonstrate growing demand for metal foams in structural components, vibration damping systems, and blast protection applications. The material's ability to absorb impact energy while maintaining structural integrity makes it particularly valuable for military applications and aircraft components where weight reduction is critical.

The building and construction sector utilizes metal foams for architectural panels, fire-resistant structures, and sound absorption systems. The material's aesthetic appeal combined with functional properties has created new design possibilities for modern architecture, particularly in high-end commercial buildings and public infrastructure.

Healthcare applications represent an emerging market segment, with metal foams being developed for orthopedic implants and prosthetics. The porous structure allows for bone ingrowth and better integration with human tissue, while maintaining necessary mechanical strength. This application area shows significant growth potential as manufacturing techniques improve.

Energy sector applications include heat exchangers, catalytic supports, and filtration systems. The controllable porosity and surface area characteristics make metal foams particularly effective in these applications, with growing implementation in renewable energy systems and industrial processes.

Market analysis indicates regional variations in adoption rates, with North America and Europe leading in high-value applications, while Asia-Pacific demonstrates the fastest growth rate due to expanding manufacturing capabilities and increasing industrial demand. The global metal foam market is projected to continue its upward trajectory as manufacturing costs decrease and awareness of application benefits increases across industries.

Challenges to market expansion include relatively high production costs compared to conventional materials, standardization issues, and limited awareness among potential end-users. However, ongoing innovations in fabrication techniques are gradually addressing these barriers, particularly through improved process control and scalability.

Current Fabrication Challenges and Limitations

Despite significant advancements in metal foam fabrication technologies, several critical challenges continue to impede widespread industrial adoption and commercialization. The primary limitation remains cost-effectiveness, as current manufacturing processes require substantial capital investment and operational expenses. Production-scale metal foam fabrication often involves specialized equipment, precise control systems, and expensive raw materials, resulting in final products that are prohibitively expensive for many potential applications.

Process consistency and reproducibility present another major hurdle. Manufacturing metal foams with uniform cellular structures, consistent pore size distribution, and predictable mechanical properties across large batches remains difficult. This variability significantly impacts quality control and hampers the development of standardized specifications necessary for engineering applications.

Dimensional limitations also restrict the potential applications of metal foams. Current technologies struggle to produce large-scale metal foam components while maintaining structural integrity and uniform properties throughout the material. This constraint particularly affects industries requiring substantial metal foam panels or complex three-dimensional structures.

The control of pore morphology represents a sophisticated technical challenge. While applications demand specific pore characteristics—including size, shape, distribution, and interconnectivity—existing fabrication methods offer limited precision in controlling these parameters. This limitation directly affects the functional properties of metal foams, including thermal conductivity, acoustic absorption, and mechanical strength.

Material compatibility issues further restrict innovation in this field. Not all metals and alloys are equally suitable for foam production using current technologies. High-melting-point metals and certain alloys present particular difficulties, limiting material selection and potential applications. Additionally, many fabrication methods introduce impurities or structural defects that compromise the mechanical integrity and corrosion resistance of the final product.

Energy consumption during production poses both economic and environmental concerns. Many metal foam fabrication processes require high temperatures, extended processing times, or energy-intensive steps that increase carbon footprint and production costs. This energy inefficiency contradicts the sustainability benefits that metal foams potentially offer in their applications.

Finally, the integration of metal foams into existing manufacturing workflows presents significant challenges. Current joining techniques for connecting metal foams to conventional materials often compromise the integrity of the foam structure or create weak points at interfaces. This integration difficulty limits the adoption of metal foams in complex assemblies and hybrid material systems.

Process consistency and reproducibility present another major hurdle. Manufacturing metal foams with uniform cellular structures, consistent pore size distribution, and predictable mechanical properties across large batches remains difficult. This variability significantly impacts quality control and hampers the development of standardized specifications necessary for engineering applications.

Dimensional limitations also restrict the potential applications of metal foams. Current technologies struggle to produce large-scale metal foam components while maintaining structural integrity and uniform properties throughout the material. This constraint particularly affects industries requiring substantial metal foam panels or complex three-dimensional structures.

The control of pore morphology represents a sophisticated technical challenge. While applications demand specific pore characteristics—including size, shape, distribution, and interconnectivity—existing fabrication methods offer limited precision in controlling these parameters. This limitation directly affects the functional properties of metal foams, including thermal conductivity, acoustic absorption, and mechanical strength.

Material compatibility issues further restrict innovation in this field. Not all metals and alloys are equally suitable for foam production using current technologies. High-melting-point metals and certain alloys present particular difficulties, limiting material selection and potential applications. Additionally, many fabrication methods introduce impurities or structural defects that compromise the mechanical integrity and corrosion resistance of the final product.

Energy consumption during production poses both economic and environmental concerns. Many metal foam fabrication processes require high temperatures, extended processing times, or energy-intensive steps that increase carbon footprint and production costs. This energy inefficiency contradicts the sustainability benefits that metal foams potentially offer in their applications.

Finally, the integration of metal foams into existing manufacturing workflows presents significant challenges. Current joining techniques for connecting metal foams to conventional materials often compromise the integrity of the foam structure or create weak points at interfaces. This integration difficulty limits the adoption of metal foams in complex assemblies and hybrid material systems.

State-of-the-Art Fabrication Methods

01 Powder metallurgy techniques for metal foam production

Powder metallurgy approaches involve mixing metal powders with foaming agents or space holders that create pores when removed. These techniques allow for precise control of porosity, pore size, and distribution. Advanced powder metallurgy methods include hot isostatic pressing, sintering, and space holder techniques where sacrificial materials are removed through thermal or chemical processes to create controlled pore structures in the metal foam.- Advanced metal foam manufacturing processes: Recent innovations in metal foam fabrication include advanced manufacturing processes that enhance the structural integrity and performance characteristics of the final product. These processes involve precise control of parameters such as temperature, pressure, and material composition to create metal foams with optimized properties. The techniques allow for the production of metal foams with uniform cell structures, controlled density, and improved mechanical properties, making them suitable for various industrial applications.

- Powder metallurgy techniques for metal foam production: Powder metallurgy approaches have been developed for the fabrication of metal foams, offering advantages in terms of material versatility and process control. These techniques involve the mixing of metal powders with foaming agents, followed by compaction and sintering processes. The resulting metal foams exhibit tailored porosity, density, and mechanical properties. Innovations in this area focus on optimizing powder characteristics, binding mechanisms, and thermal processing parameters to achieve desired foam structures.

- Additive manufacturing of metal foams: Additive manufacturing technologies have revolutionized metal foam fabrication by enabling the creation of complex, customized foam structures with precise control over cell architecture. These processes involve layer-by-layer construction of metal foams using techniques such as selective laser melting, electron beam melting, or direct metal deposition. The innovations in this field focus on optimizing printing parameters, developing specialized metal powders, and creating novel lattice designs to achieve metal foams with superior mechanical, thermal, and acoustic properties.

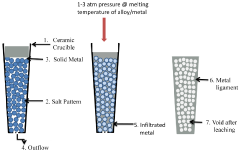

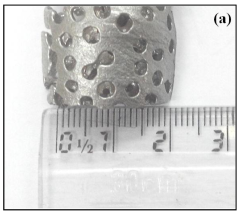

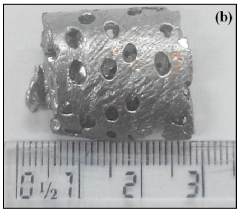

- Casting and infiltration methods for metal foam production: Advanced casting and infiltration techniques have been developed for metal foam fabrication, offering scalable production methods for various applications. These processes involve the creation of a template or preform that is subsequently infiltrated with molten metal or metal alloys. Innovations in this area include the development of novel template materials, improved infiltration processes, and techniques for controlling solidification dynamics. These methods enable the production of metal foams with tailored pore structures, density gradients, and functional properties.

- Hybrid and composite metal foam systems: Recent innovations focus on the development of hybrid and composite metal foam systems that combine multiple materials or fabrication techniques to achieve enhanced performance characteristics. These approaches involve the integration of different metals, alloys, ceramics, or polymers within the foam structure, creating multifunctional materials with superior properties. The fabrication methods include co-sintering, infiltration of secondary phases, or sequential processing steps. The resulting hybrid metal foams exhibit combinations of properties such as high strength-to-weight ratio, enhanced energy absorption, improved thermal management, and superior corrosion resistance.

02 Melt-based fabrication methods

Melt-based methods involve introducing gas or foaming agents into molten metal to create bubbles that solidify into a porous structure. Innovations include direct gas injection, gas-releasing particle decomposition, and eutectic solidification techniques. These approaches allow for the production of closed-cell metal foams with controlled density and mechanical properties, suitable for structural applications requiring lightweight materials with good energy absorption capabilities.Expand Specific Solutions03 Additive manufacturing for complex metal foam structures

Additive manufacturing technologies enable the fabrication of metal foams with precisely controlled architectures and complex geometries that would be impossible with traditional methods. Selective laser melting, electron beam melting, and direct metal laser sintering allow for layer-by-layer construction of intricate lattice structures and gradient porosity. These techniques offer unprecedented design freedom for creating application-specific metal foams with optimized properties.Expand Specific Solutions04 Electrochemical and chemical deposition techniques

Electrochemical and chemical deposition methods involve the formation of metal foams through processes like electrodeposition onto templates, dealloying, or chemical vapor deposition. These techniques can produce nanoporous metal foams with extremely high surface areas and unique properties. Recent innovations include template-assisted electrodeposition where metal is deposited onto a sacrificial template that is subsequently removed to create the porous structure.Expand Specific Solutions05 Hybrid and composite metal foam fabrication

Hybrid approaches combine multiple fabrication techniques to create metal foams with enhanced properties or multifunctional characteristics. These include metal-ceramic composites, functionally graded metal foams, and sandwich structures. Innovations in this area focus on creating synergistic combinations of materials and processes to achieve properties that cannot be obtained through single-material or single-process approaches, such as improved strength-to-weight ratios or thermal management capabilities.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The metal foam fabrication industry is currently in a growth phase, characterized by increasing market adoption across automotive, aerospace, and construction sectors. The global market size is estimated to reach $95 million by 2025, with a CAGR of approximately 4.5%. Regarding technological maturity, academic institutions like Tsinghua University, North Carolina State University, and Shanghai University are driving fundamental research, while commercial players demonstrate varying levels of implementation capability. Companies like ALANTUM Corp. and LG Chem have achieved commercial-scale production, whereas Fraunhofer-Gesellschaft and Korea Institute of Industrial Technology focus on process optimization. Emerging players such as Yuhuan Degu New Material Technology are introducing novel fabrication methods, while established manufacturers like Magna International and Rolls Royce are integrating metal foams into high-performance applications, indicating the technology's transition from research to industrial implementation.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has pioneered several metal foam fabrication techniques, with their powder metallurgy approach being particularly innovative. Their process involves mixing metal powders with foaming agents (typically titanium hydride) that release gas when heated. The mixture is compacted into semi-finished products and then foamed in a controlled heating process where the released hydrogen creates the cellular structure. Fraunhofer has also developed advanced investment casting methods for open-cell metal foams using polyurethane templates that are coated with ceramic slurry, burned out, and replaced with molten metal. Their recent innovations include hybrid metal foams with engineered density gradients and specialized surface treatments to enhance corrosion resistance while maintaining the foam's functional properties.

Strengths: Exceptional precision in controlling pore size distribution and density gradients; strong industrial scalability of their processes; extensive experience in customizing foams for specific applications. Weaknesses: Higher production costs compared to some competing methods; energy-intensive manufacturing process; some techniques require specialized equipment limiting widespread adoption.

Institute of Metal Research Chinese Academy of Sciences

Technical Solution: The Institute of Metal Research (IMR) has developed several innovative approaches to metal foam fabrication, with particular emphasis on space-holder methods and melt foaming techniques. Their researchers have pioneered a salt-based space-holder process where NaCl particles of controlled size are mixed with metal powders, compacted, sintered, and then dissolved to create precise pore architectures. IMR has also made significant advances in lotus-type metal foams, created through unidirectional solidification under hydrogen pressure, resulting in cylindrical pores aligned in one direction. Their recent innovations include functionally graded metal foams with controlled porosity gradients and novel titanium-based foams with biocompatible coatings for medical implants. The institute has also developed advanced characterization techniques specifically for metal foams, including 3D X-ray tomography methods that provide unprecedented insights into foam microstructure and deformation mechanisms.

Strengths: Exceptional control over pore morphology and distribution; strong capabilities in developing biomedical-grade metal foams; advanced research facilities enabling rapid prototyping and testing. Weaknesses: Some processes remain difficult to scale to industrial production; higher costs for specialized biomedical applications; certain techniques require rare or expensive raw materials.

Critical Patents and Technical Breakthroughs

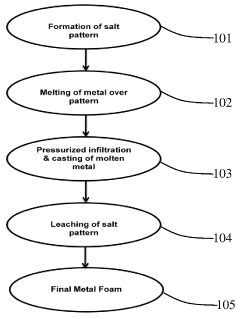

Process for synthesizing metallic foams having controlled shape, size and uniform distribution of the pores

PatentInactiveIN742DEL2015A

Innovation

- A process involving pressurized infiltration and casting of molten metallic materials over custom-made salt patterns, followed by leaching out the salt to produce metallic foams with controlled shape, size, and uniform distribution of open cells, using an inert atmosphere and specific crucible materials.

Process for producing metal foam and metal body produced using this process

PatentInactiveUS6915834B2

Innovation

- A process involving the introduction of a solid, gas-releasing blowing agent into a metal melt within a die-casting machine, where the metal melt is foamed in a closed die cavity, allowing for the production of integral, gradient metal foams with a closed outer skin and near net shape in a single step, using commercially available die-casting machines.

Material Science Advancements

Material science has undergone significant transformations in recent decades, particularly in the realm of metal foam fabrication. The development of advanced manufacturing techniques has revolutionized how metal foams are produced, enhancing their structural integrity and functional properties. Traditional methods such as powder metallurgy and casting have evolved into more sophisticated approaches including direct foaming, investment casting with polymer templates, and additive manufacturing technologies.

The emergence of nano-engineering has enabled unprecedented control over metal foam microstructures, allowing for precise manipulation of pore size, distribution, and interconnectivity. This level of control has dramatically improved mechanical properties such as strength-to-weight ratio, energy absorption capacity, and thermal conductivity. Researchers have successfully developed metal foams with density reductions of up to 95% while maintaining critical structural properties, representing a remarkable achievement in materials engineering.

Surface modification technologies have further expanded the functionality of metal foams. Techniques such as plasma treatment, chemical etching, and coating applications have enhanced corrosion resistance, biocompatibility, and catalytic properties. These advancements have broadened the application spectrum of metal foams beyond traditional structural uses into biomedical implants, chemical reactors, and environmental remediation systems.

Computational modeling and simulation tools have become instrumental in predicting and optimizing metal foam properties. Finite element analysis, computational fluid dynamics, and molecular dynamics simulations now allow engineers to design metal foams with tailored characteristics for specific applications before physical prototyping begins. This predictive capability has significantly reduced development cycles and improved performance outcomes.

Hybrid and composite metal foams represent another frontier in material science advancement. By combining different metals or incorporating ceramic, polymer, or carbon-based materials into metal foam structures, researchers have created multifunctional materials with synergistic properties. These hybrids exhibit enhanced performance characteristics such as improved damping capacity, self-healing capabilities, and multiphysics responses that were previously unattainable in single-material systems.

The integration of smart materials technology with metal foams has led to the development of responsive structures capable of adapting to environmental stimuli. Shape memory alloy foams, for instance, can undergo reversible deformation in response to temperature changes, while piezoelectric-integrated foams can convert mechanical energy to electrical signals, opening new possibilities for sensing and actuation applications.

The emergence of nano-engineering has enabled unprecedented control over metal foam microstructures, allowing for precise manipulation of pore size, distribution, and interconnectivity. This level of control has dramatically improved mechanical properties such as strength-to-weight ratio, energy absorption capacity, and thermal conductivity. Researchers have successfully developed metal foams with density reductions of up to 95% while maintaining critical structural properties, representing a remarkable achievement in materials engineering.

Surface modification technologies have further expanded the functionality of metal foams. Techniques such as plasma treatment, chemical etching, and coating applications have enhanced corrosion resistance, biocompatibility, and catalytic properties. These advancements have broadened the application spectrum of metal foams beyond traditional structural uses into biomedical implants, chemical reactors, and environmental remediation systems.

Computational modeling and simulation tools have become instrumental in predicting and optimizing metal foam properties. Finite element analysis, computational fluid dynamics, and molecular dynamics simulations now allow engineers to design metal foams with tailored characteristics for specific applications before physical prototyping begins. This predictive capability has significantly reduced development cycles and improved performance outcomes.

Hybrid and composite metal foams represent another frontier in material science advancement. By combining different metals or incorporating ceramic, polymer, or carbon-based materials into metal foam structures, researchers have created multifunctional materials with synergistic properties. These hybrids exhibit enhanced performance characteristics such as improved damping capacity, self-healing capabilities, and multiphysics responses that were previously unattainable in single-material systems.

The integration of smart materials technology with metal foams has led to the development of responsive structures capable of adapting to environmental stimuli. Shape memory alloy foams, for instance, can undergo reversible deformation in response to temperature changes, while piezoelectric-integrated foams can convert mechanical energy to electrical signals, opening new possibilities for sensing and actuation applications.

Sustainability and Recycling Considerations

Metal foam fabrication processes have significant environmental implications that must be addressed as this technology advances. The sustainability of metal foam production begins with raw material selection, where recycled metals can substantially reduce the environmental footprint. Aluminum, titanium, and copper foams can all incorporate recycled content, decreasing primary resource extraction demands and associated environmental impacts. This approach aligns with circular economy principles and reduces energy consumption by up to 95% compared to virgin material processing.

Manufacturing processes themselves present varying sustainability profiles. Powder metallurgy routes typically consume less energy than melt-based methods, though this advantage may be offset by the energy-intensive powder production phase. Gas injection methods, while efficient for large-scale production, often utilize environmentally problematic foaming agents that require careful management and potential substitution with more eco-friendly alternatives.

End-of-life considerations for metal foams present both challenges and opportunities. The cellular structure that provides beneficial properties also complicates recycling processes. However, the homogeneous composition of most metal foams facilitates material recovery compared to composite materials. Research indicates that aluminum foams can be recycled with approximately 85-90% material recovery rates when appropriate separation techniques are employed.

Life cycle assessment (LCA) studies reveal that the environmental benefits of metal foams during their use phase—particularly in lightweight transportation applications where they reduce fuel consumption—can outweigh production impacts. For instance, aluminum foam components in vehicles can achieve carbon payback within 2-3 years of operation through weight reduction and consequent fuel savings.

Emerging sustainable practices include developing biodegradable foaming agents, implementing closed-loop water systems in production facilities, and utilizing renewable energy sources for energy-intensive processes. Some manufacturers have pioneered zero-waste initiatives where production scraps are immediately reincorporated into new batches, achieving material utilization rates exceeding 98%.

Future research directions should focus on developing standardized recycling protocols specific to different metal foam types, improving separation technologies for multi-material foam systems, and further reducing process emissions. Additionally, design-for-disassembly approaches could significantly enhance end-of-life recovery rates by facilitating the separation of foam components from complex assemblies.

Manufacturing processes themselves present varying sustainability profiles. Powder metallurgy routes typically consume less energy than melt-based methods, though this advantage may be offset by the energy-intensive powder production phase. Gas injection methods, while efficient for large-scale production, often utilize environmentally problematic foaming agents that require careful management and potential substitution with more eco-friendly alternatives.

End-of-life considerations for metal foams present both challenges and opportunities. The cellular structure that provides beneficial properties also complicates recycling processes. However, the homogeneous composition of most metal foams facilitates material recovery compared to composite materials. Research indicates that aluminum foams can be recycled with approximately 85-90% material recovery rates when appropriate separation techniques are employed.

Life cycle assessment (LCA) studies reveal that the environmental benefits of metal foams during their use phase—particularly in lightweight transportation applications where they reduce fuel consumption—can outweigh production impacts. For instance, aluminum foam components in vehicles can achieve carbon payback within 2-3 years of operation through weight reduction and consequent fuel savings.

Emerging sustainable practices include developing biodegradable foaming agents, implementing closed-loop water systems in production facilities, and utilizing renewable energy sources for energy-intensive processes. Some manufacturers have pioneered zero-waste initiatives where production scraps are immediately reincorporated into new batches, achieving material utilization rates exceeding 98%.

Future research directions should focus on developing standardized recycling protocols specific to different metal foam types, improving separation technologies for multi-material foam systems, and further reducing process emissions. Additionally, design-for-disassembly approaches could significantly enhance end-of-life recovery rates by facilitating the separation of foam components from complex assemblies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!