Metallurgical Science in Metal Foam Fabrication for the Aerospace Industry

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Technology Background and Objectives

Metal foam technology has evolved significantly over the past several decades, transitioning from laboratory curiosities to engineered materials with specific applications. The development of metal foams dates back to the 1940s, but significant advancements in metallurgical understanding and manufacturing techniques have accelerated since the 1990s. These cellular metallic structures combine the inherent properties of metals with the architectural advantages of foams, creating materials with exceptional strength-to-weight ratios, energy absorption capabilities, and thermal management characteristics.

The aerospace industry has emerged as a prime beneficiary of metal foam technology due to its constant pursuit of weight reduction without compromising structural integrity. Early applications focused primarily on aluminum-based foams, but research has expanded to include titanium, nickel, and various alloys specifically engineered for extreme aerospace environments. The evolution of manufacturing processes has paralleled material development, moving from rudimentary powder metallurgy approaches to sophisticated techniques including investment casting, direct foaming, and additive manufacturing.

Current technological trends indicate a shift toward multi-functional metal foams that simultaneously address multiple aerospace requirements. These include structures that provide both thermal protection and load-bearing capabilities, or components that offer electromagnetic shielding while maintaining lightweight properties. The integration of nanotechnology into metal foam fabrication represents another significant trend, enabling unprecedented control over cell structure, size distribution, and wall thickness.

The primary technical objectives in metal foam development for aerospace applications center on achieving precise control over foam architecture at multiple scales. This includes optimizing pore size distribution, cell wall thickness uniformity, and overall density gradients to meet specific performance requirements. Additionally, there is a focused effort to develop reliable, scalable manufacturing processes that can produce consistent metal foam components with predictable properties at industrial scales.

Another critical objective involves enhancing the fundamental understanding of metallurgical phenomena unique to metal foam structures, particularly regarding fatigue behavior, corrosion resistance in aerospace environments, and performance under extreme temperature fluctuations. Research aims to establish comprehensive material models that accurately predict long-term performance and degradation mechanisms specific to porous metallic structures.

The convergence of computational modeling with experimental metallurgy represents a key enabler for future advancements. Simulation tools that accurately predict foam formation, solidification behavior, and resultant mechanical properties are becoming essential for designing application-specific metal foams. The ultimate goal is to develop a comprehensive metallurgical science framework that enables "design for performance" approaches to metal foam fabrication specifically tailored for aerospace requirements.

The aerospace industry has emerged as a prime beneficiary of metal foam technology due to its constant pursuit of weight reduction without compromising structural integrity. Early applications focused primarily on aluminum-based foams, but research has expanded to include titanium, nickel, and various alloys specifically engineered for extreme aerospace environments. The evolution of manufacturing processes has paralleled material development, moving from rudimentary powder metallurgy approaches to sophisticated techniques including investment casting, direct foaming, and additive manufacturing.

Current technological trends indicate a shift toward multi-functional metal foams that simultaneously address multiple aerospace requirements. These include structures that provide both thermal protection and load-bearing capabilities, or components that offer electromagnetic shielding while maintaining lightweight properties. The integration of nanotechnology into metal foam fabrication represents another significant trend, enabling unprecedented control over cell structure, size distribution, and wall thickness.

The primary technical objectives in metal foam development for aerospace applications center on achieving precise control over foam architecture at multiple scales. This includes optimizing pore size distribution, cell wall thickness uniformity, and overall density gradients to meet specific performance requirements. Additionally, there is a focused effort to develop reliable, scalable manufacturing processes that can produce consistent metal foam components with predictable properties at industrial scales.

Another critical objective involves enhancing the fundamental understanding of metallurgical phenomena unique to metal foam structures, particularly regarding fatigue behavior, corrosion resistance in aerospace environments, and performance under extreme temperature fluctuations. Research aims to establish comprehensive material models that accurately predict long-term performance and degradation mechanisms specific to porous metallic structures.

The convergence of computational modeling with experimental metallurgy represents a key enabler for future advancements. Simulation tools that accurately predict foam formation, solidification behavior, and resultant mechanical properties are becoming essential for designing application-specific metal foams. The ultimate goal is to develop a comprehensive metallurgical science framework that enables "design for performance" approaches to metal foam fabrication specifically tailored for aerospace requirements.

Aerospace Industry Demand Analysis

The aerospace industry's demand for advanced materials with superior performance characteristics has been steadily increasing over the past decade. Metal foams represent a critical innovation area, offering exceptional strength-to-weight ratios that directly address the industry's primary challenge of weight reduction while maintaining structural integrity. Current market analysis indicates that aerospace manufacturers are actively seeking materials that can reduce aircraft weight by 15-20% without compromising safety standards, positioning metal foams as an ideal candidate for this application.

The global aerospace market, valued at approximately 298 billion USD in 2022, is projected to grow at a compound annual growth rate of 7.2% through 2030. Within this expanding market, the demand for specialized materials like metal foams is growing even faster, with estimates suggesting a 9.5% annual growth rate for advanced aerospace materials. This accelerated growth is driven by both commercial aviation's push for fuel efficiency and defense sector requirements for enhanced performance capabilities.

Metal foams are particularly sought after for specific aerospace applications including acoustic and vibration damping components, impact absorption structures, heat exchangers, and lightweight structural elements. The commercial aviation segment represents the largest market share for these materials, with approximately 60% of current demand, followed by military applications at 25% and space systems at 15%. This distribution reflects the varying requirements across aerospace subsectors, with commercial aviation prioritizing fuel efficiency and operational cost reduction.

Regional analysis reveals that North America currently leads the demand for aerospace metal foams, accounting for 42% of the global market, followed by Europe at 31% and Asia-Pacific at 22%. However, the fastest growth is occurring in the Asia-Pacific region, where rapid expansion of aerospace manufacturing capabilities in China, Japan, and India is creating new market opportunities for advanced materials suppliers.

Industry surveys indicate that aerospace engineers and designers are increasingly incorporating metal foams into their specifications, with 78% of major aerospace manufacturers now including metal foam components in their development roadmaps for next-generation aircraft. This trend is reinforced by regulatory pressures to improve fuel efficiency and reduce emissions, creating a favorable environment for lightweight material adoption.

The economic value proposition for metal foams in aerospace applications is compelling, with lifecycle cost analyses demonstrating potential savings of 12-18% compared to traditional materials when accounting for reduced fuel consumption, maintenance requirements, and extended service life. This economic advantage, combined with superior technical performance, is driving accelerated adoption across multiple aerospace platforms and applications.

The global aerospace market, valued at approximately 298 billion USD in 2022, is projected to grow at a compound annual growth rate of 7.2% through 2030. Within this expanding market, the demand for specialized materials like metal foams is growing even faster, with estimates suggesting a 9.5% annual growth rate for advanced aerospace materials. This accelerated growth is driven by both commercial aviation's push for fuel efficiency and defense sector requirements for enhanced performance capabilities.

Metal foams are particularly sought after for specific aerospace applications including acoustic and vibration damping components, impact absorption structures, heat exchangers, and lightweight structural elements. The commercial aviation segment represents the largest market share for these materials, with approximately 60% of current demand, followed by military applications at 25% and space systems at 15%. This distribution reflects the varying requirements across aerospace subsectors, with commercial aviation prioritizing fuel efficiency and operational cost reduction.

Regional analysis reveals that North America currently leads the demand for aerospace metal foams, accounting for 42% of the global market, followed by Europe at 31% and Asia-Pacific at 22%. However, the fastest growth is occurring in the Asia-Pacific region, where rapid expansion of aerospace manufacturing capabilities in China, Japan, and India is creating new market opportunities for advanced materials suppliers.

Industry surveys indicate that aerospace engineers and designers are increasingly incorporating metal foams into their specifications, with 78% of major aerospace manufacturers now including metal foam components in their development roadmaps for next-generation aircraft. This trend is reinforced by regulatory pressures to improve fuel efficiency and reduce emissions, creating a favorable environment for lightweight material adoption.

The economic value proposition for metal foams in aerospace applications is compelling, with lifecycle cost analyses demonstrating potential savings of 12-18% compared to traditional materials when accounting for reduced fuel consumption, maintenance requirements, and extended service life. This economic advantage, combined with superior technical performance, is driving accelerated adoption across multiple aerospace platforms and applications.

Current State and Challenges in Metal Foam Fabrication

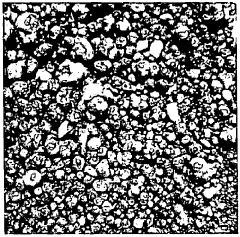

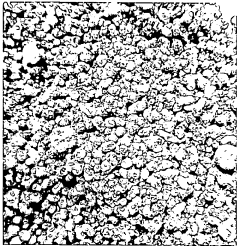

Metal foam fabrication for aerospace applications has witnessed significant advancements globally, with research centers in North America, Europe, and Asia leading innovation efforts. Currently, several manufacturing methods dominate the industry: powder metallurgy, melt gas injection, investment casting with space holders, and additive manufacturing techniques. Each method presents unique advantages and limitations in terms of foam structure control, mechanical properties, and production scalability.

The powder metallurgy approach remains the most established technique, offering good control over pore size distribution but facing challenges in producing complex geometries. Recent improvements in sintering processes have enhanced the structural integrity of foams produced through this method, though limitations in density control persist.

Melt gas injection techniques have advanced considerably, with improved gas dispersion systems allowing for more uniform cell structures. However, this method continues to struggle with precise control of pore morphology and distribution, particularly for aerospace applications requiring highly specific mechanical properties.

Investment casting with space holders has gained traction for producing near-net-shape components with controlled porosity. The primary challenge lies in the removal of space holder materials without compromising the integrity of the metal foam structure, especially for high-temperature aerospace alloys like titanium and nickel-based superalloys.

Additive manufacturing represents the newest frontier, with selective laser melting and electron beam melting showing promise for creating tailored metal foam structures. These technologies enable unprecedented design freedom but face significant hurdles in process parameter optimization, build size limitations, and post-processing requirements.

A critical technical challenge across all fabrication methods is achieving consistent mechanical properties while maintaining low density. Aerospace applications demand exceptional specific strength, fatigue resistance, and thermal stability—properties that remain difficult to predict and control in metal foam structures due to their inherent structural complexity.

Material compatibility presents another significant obstacle, particularly for high-temperature applications. While aluminum foams have reached commercial maturity, titanium, nickel, and refractory metal foams still face considerable metallurgical challenges related to oxidation resistance, phase stability, and interfacial bonding in composite structures.

Quality control and non-destructive testing methodologies lag behind manufacturing capabilities, creating a bottleneck in certification processes for aerospace components. Current inspection techniques struggle to detect internal defects and structural inconsistencies without damaging the foam structure.

Cost-effectiveness remains a persistent barrier to widespread adoption, with current production methods requiring significant capital investment and specialized expertise. The aerospace industry's stringent certification requirements further compound these challenges, necessitating extensive testing and validation protocols that increase development timelines and costs.

The powder metallurgy approach remains the most established technique, offering good control over pore size distribution but facing challenges in producing complex geometries. Recent improvements in sintering processes have enhanced the structural integrity of foams produced through this method, though limitations in density control persist.

Melt gas injection techniques have advanced considerably, with improved gas dispersion systems allowing for more uniform cell structures. However, this method continues to struggle with precise control of pore morphology and distribution, particularly for aerospace applications requiring highly specific mechanical properties.

Investment casting with space holders has gained traction for producing near-net-shape components with controlled porosity. The primary challenge lies in the removal of space holder materials without compromising the integrity of the metal foam structure, especially for high-temperature aerospace alloys like titanium and nickel-based superalloys.

Additive manufacturing represents the newest frontier, with selective laser melting and electron beam melting showing promise for creating tailored metal foam structures. These technologies enable unprecedented design freedom but face significant hurdles in process parameter optimization, build size limitations, and post-processing requirements.

A critical technical challenge across all fabrication methods is achieving consistent mechanical properties while maintaining low density. Aerospace applications demand exceptional specific strength, fatigue resistance, and thermal stability—properties that remain difficult to predict and control in metal foam structures due to their inherent structural complexity.

Material compatibility presents another significant obstacle, particularly for high-temperature applications. While aluminum foams have reached commercial maturity, titanium, nickel, and refractory metal foams still face considerable metallurgical challenges related to oxidation resistance, phase stability, and interfacial bonding in composite structures.

Quality control and non-destructive testing methodologies lag behind manufacturing capabilities, creating a bottleneck in certification processes for aerospace components. Current inspection techniques struggle to detect internal defects and structural inconsistencies without damaging the foam structure.

Cost-effectiveness remains a persistent barrier to widespread adoption, with current production methods requiring significant capital investment and specialized expertise. The aerospace industry's stringent certification requirements further compound these challenges, necessitating extensive testing and validation protocols that increase development timelines and costs.

Current Metal Foam Manufacturing Techniques

01 Manufacturing methods for metal foam

Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, casting processes, and gas injection methods. These processes involve creating porous structures by introducing gas bubbles or space-holding materials into molten metal or metal powder mixtures. The manufacturing methods significantly influence the final properties of the metal foam, such as density, pore size distribution, and mechanical strength.- Manufacturing methods for metal foam: Various techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve creating porous structures by introducing gas bubbles into molten metal, using space-holder materials that are later removed, or direct 3D printing of cellular structures. The manufacturing process significantly influences the resulting foam's properties such as density, pore size distribution, and mechanical characteristics.

- Structural applications of metal foam: Metal foams are utilized in structural applications due to their high strength-to-weight ratio and energy absorption capabilities. They are particularly valuable in automotive, aerospace, and construction industries where lightweight yet strong materials are required. These foams can be designed with gradient porosity or as sandwich structures to optimize performance for specific load-bearing applications while maintaining minimal weight.

- Thermal and acoustic properties of metal foam: Metal foams exhibit excellent thermal management capabilities due to their high surface area and porous structure, making them effective heat exchangers and thermal insulators. Additionally, their cellular structure provides significant sound absorption properties, dampening vibrations and reducing noise transmission. These characteristics make metal foams suitable for applications requiring thermal regulation or acoustic insulation.

- Composite metal foams: Composite metal foams combine different materials to enhance specific properties beyond what single-metal foams can achieve. These may include metal-ceramic composites, multi-metal systems, or metal foams reinforced with particles or fibers. The resulting hybrid materials can offer improved mechanical strength, corrosion resistance, or functional properties such as electromagnetic shielding while maintaining the lightweight benefits of traditional metal foams.

- Functional applications of metal foam: Beyond structural uses, metal foams serve in various functional applications including filtration systems, catalytic supports, battery electrodes, and biomedical implants. Their high surface area, controllable pore structure, and customizable surface properties make them ideal for processes requiring fluid flow, chemical reactions, or biological integration. These specialized applications leverage the unique combination of metallic properties with porous architecture.

02 Structural applications of metal foam

Metal foams are utilized in various structural applications due to their unique combination of lightweight properties and mechanical strength. These materials are particularly valuable in automotive, aerospace, and construction industries where weight reduction without compromising structural integrity is crucial. Metal foams provide excellent energy absorption capabilities, making them ideal for impact protection and crash safety components.Expand Specific Solutions03 Thermal management applications

Metal foams exhibit exceptional thermal management properties due to their high surface area-to-volume ratio and thermal conductivity. These materials are employed in heat exchangers, cooling systems, and thermal insulation applications. The porous structure allows for efficient heat transfer while maintaining structural integrity at high temperatures, making them suitable for demanding thermal environments in electronics cooling and industrial processes.Expand Specific Solutions04 Composite metal foams

Composite metal foams combine different metals or incorporate non-metallic materials to enhance specific properties. These hybrid structures can offer improved mechanical strength, corrosion resistance, or functional characteristics compared to single-metal foams. By integrating multiple materials, composite metal foams can be tailored for specialized applications requiring unique combinations of properties, such as radiation shielding, sound absorption, or electromagnetic interference protection.Expand Specific Solutions05 Functional properties and surface treatments

Metal foams can be engineered with specific functional properties through surface treatments and modifications. These treatments can enhance characteristics such as corrosion resistance, catalytic activity, or biocompatibility. Surface functionalization techniques include coating, anodizing, or chemical modification of the metal foam structure. These treatments extend the application range of metal foams to fields such as filtration, catalysis, biomedical implants, and electrochemical devices.Expand Specific Solutions

Key Players in Aerospace Metal Foam Industry

The metal foam fabrication market for aerospace applications is currently in a growth phase, characterized by increasing demand for lightweight, high-strength materials. The global market size is expanding steadily, driven by aerospace industry requirements for fuel efficiency and performance optimization. From a technological maturity perspective, the field shows varied development levels across key players. Research institutions like Naval Research Laboratory and École Polytechnique Fédérale de Lausanne are advancing fundamental metallurgical science, while specialized companies such as Cellmobility, Inc. have established production capabilities with innovative metal foam technologies. Major industrial players including United Technologies Corp., ExxonMobil Technology & Engineering, and LG Chem are leveraging their R&D infrastructure to develop proprietary metal foam applications, indicating the technology's transition from experimental to commercial implementation in aerospace components.

École Polytechnique Fédérale de Lausanne

Technical Solution: École Polytechnique Fédérale de Lausanne (EPFL) has developed innovative metallurgical approaches to metal foam fabrication for aerospace applications through their advanced materials research program. Their primary technology involves a novel freeze-casting process combined with controlled sintering to create highly ordered cellular metal structures with unprecedented control over pore morphology and distribution. EPFL's metallurgical innovation includes the development of specialized precursor materials that enable the creation of hierarchical pore structures spanning from nano to macro scales within the same component. Their process employs precisely controlled directional solidification techniques that create aligned, elongated pores that can be oriented to match load paths in aerospace structures. EPFL has pioneered advanced characterization methods that provide real-time feedback during foam formation, allowing for adaptive process control and enhanced reproducibility. Their metal foams exhibit exceptional specific stiffness, with values up to 40% higher than randomly structured foams of equivalent density. Recent developments include bio-inspired structural designs that mimic natural cellular materials like bone and wood, resulting in optimized mechanical performance with minimal material usage. EPFL has also developed computational models that accurately predict the mechanical behavior of complex foam architectures under aerospace loading conditions.

Strengths: Exceptional control over foam architecture at multiple length scales; superior specific mechanical properties; advanced characterization capabilities; innovative bio-inspired design approaches. Weaknesses: Currently limited to laboratory and small-batch production scales; higher complexity in manufacturing process control; challenges in scaling to industrial production volumes.

United Technologies Corp.

Technical Solution: United Technologies Corporation has developed a comprehensive metallurgical approach to metal foam fabrication specifically engineered for aerospace applications. Their proprietary process combines direct foaming techniques with advanced powder metallurgy to create high-performance aluminum, titanium, and nickel-based foams. UTC's technology utilizes precisely controlled gas injection into molten metal with specialized stabilizing agents to achieve uniform cell structure and density. Their metallurgical innovation includes tailored alloy compositions that optimize both mechanical properties and processing characteristics during foam formation. The corporation has implemented advanced solidification control systems that manage cooling rates to enhance cell wall integrity and overall structural performance. UTC has also developed specialized post-processing treatments including heat treatment cycles and surface modifications that significantly improve fatigue resistance and corrosion protection in aerospace environments. Their metal foams demonstrate exceptional vibration damping capabilities, with up to 10 times higher damping capacity than solid metals while maintaining 70-80% weight reduction. Recent advancements include functionally graded foams that provide optimized performance across thermal and mechanical load paths in aircraft components.

Strengths: Extensive industrial-scale production capabilities; comprehensive quality control systems; integrated design approach that considers manufacturing constraints; proven track record in aerospace applications with certified materials. Weaknesses: Higher production costs compared to conventional materials; longer development cycles for new foam compositions; challenges in non-destructive testing of internal foam structures.

Critical Metallurgical Innovations in Metal Foam

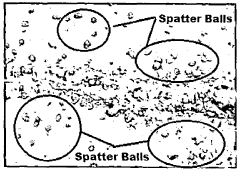

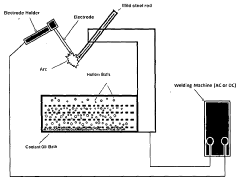

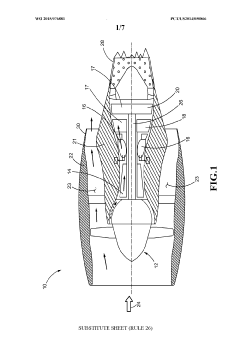

A method for the manufacture of composite metal foams with hollow spheres obtained by arc welding

PatentActiveIN202241003450A

Innovation

- The method involves generating hardened hollow spheres through arc welding technology utilizing the reverse Leidenfrost effect, which are then arranged with interstitial spaces filled with aluminum or stainless steel powders, compacted under high pressure, and heated to specific temperatures to create closed cell composite metal foams with enhanced mechanical properties.

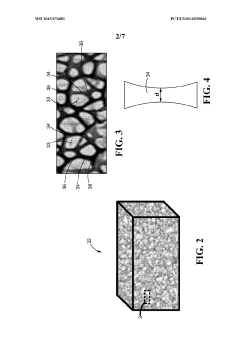

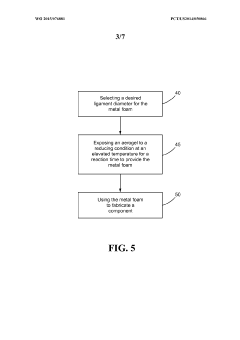

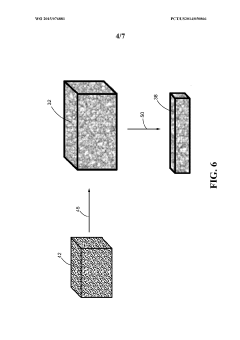

Method for fabricating metal foams having ligament diameters below one micron

PatentWO2015076881A1

Innovation

- A method involving an aerogel containing a polymer and nanoparticles is exposed to a reducing condition at an elevated temperature for a controlled reaction time to produce metal foams with ligament diameters below one micron, using hydrogen gas in an inert atmosphere, and pyrolyzing the polymer while partially reducing the nanoparticles.

Material Certification and Standards for Aerospace Applications

The aerospace industry imposes stringent requirements on materials used in aircraft and spacecraft components, necessitating comprehensive certification and standardization processes for metal foams. These specialized materials must meet or exceed industry-specific standards established by regulatory bodies such as the Federal Aviation Administration (FAA), European Union Aviation Safety Agency (EASA), and the International Organization for Standardization (ISO).

Metal foams intended for aerospace applications undergo rigorous testing protocols outlined in standards like ASTM F3122 for cellular metals and AMS 4365 for aluminum foam materials. These standards specify minimum requirements for mechanical properties, including compressive strength, shear resistance, and fatigue performance under cyclic loading conditions representative of aerospace environments.

Certification processes typically involve multi-stage testing regimes that evaluate material consistency across production batches. This includes microstructural analysis to verify cell size distribution, wall thickness uniformity, and density gradients. Manufacturers must demonstrate statistical process control and maintain detailed documentation of production parameters to achieve material qualification status.

Thermal stability certification is particularly critical for metal foams in aerospace applications, requiring materials to maintain structural integrity across temperature ranges from -65°C to over 200°C. Standards like RTCA DO-160 establish environmental testing protocols that simulate operational conditions, including thermal cycling, humidity exposure, and altitude effects.

Fire resistance certification follows standards such as FAR 25.853, which mandates specific flame propagation limits and smoke emission thresholds. Metal foams must demonstrate self-extinguishing properties and minimal toxic gas generation during combustion testing to receive airworthiness certification.

Quality assurance systems for aerospace-grade metal foams typically adhere to AS9100 standards, the aerospace-specific extension of ISO 9001. These systems require comprehensive material traceability from raw material sourcing through manufacturing to final installation, with each production batch assigned unique identifiers for lifecycle tracking.

Non-destructive evaluation techniques, standardized under ASTM E2580 for cellular materials, play a crucial role in certification processes. Methods including X-ray computed tomography, ultrasonic testing, and infrared thermography enable inspection of internal foam structures without compromising material integrity, ensuring detection of defects that could compromise performance in service.

Recent developments in certification standards have begun addressing advanced manufacturing techniques for metal foams, including additive manufacturing processes that enable complex geometries previously unachievable through conventional methods. These emerging standards focus on process validation rather than solely on end-product testing, recognizing the unique challenges posed by novel fabrication approaches.

Metal foams intended for aerospace applications undergo rigorous testing protocols outlined in standards like ASTM F3122 for cellular metals and AMS 4365 for aluminum foam materials. These standards specify minimum requirements for mechanical properties, including compressive strength, shear resistance, and fatigue performance under cyclic loading conditions representative of aerospace environments.

Certification processes typically involve multi-stage testing regimes that evaluate material consistency across production batches. This includes microstructural analysis to verify cell size distribution, wall thickness uniformity, and density gradients. Manufacturers must demonstrate statistical process control and maintain detailed documentation of production parameters to achieve material qualification status.

Thermal stability certification is particularly critical for metal foams in aerospace applications, requiring materials to maintain structural integrity across temperature ranges from -65°C to over 200°C. Standards like RTCA DO-160 establish environmental testing protocols that simulate operational conditions, including thermal cycling, humidity exposure, and altitude effects.

Fire resistance certification follows standards such as FAR 25.853, which mandates specific flame propagation limits and smoke emission thresholds. Metal foams must demonstrate self-extinguishing properties and minimal toxic gas generation during combustion testing to receive airworthiness certification.

Quality assurance systems for aerospace-grade metal foams typically adhere to AS9100 standards, the aerospace-specific extension of ISO 9001. These systems require comprehensive material traceability from raw material sourcing through manufacturing to final installation, with each production batch assigned unique identifiers for lifecycle tracking.

Non-destructive evaluation techniques, standardized under ASTM E2580 for cellular materials, play a crucial role in certification processes. Methods including X-ray computed tomography, ultrasonic testing, and infrared thermography enable inspection of internal foam structures without compromising material integrity, ensuring detection of defects that could compromise performance in service.

Recent developments in certification standards have begun addressing advanced manufacturing techniques for metal foams, including additive manufacturing processes that enable complex geometries previously unachievable through conventional methods. These emerging standards focus on process validation rather than solely on end-product testing, recognizing the unique challenges posed by novel fabrication approaches.

Environmental Impact and Sustainability Considerations

The aerospace industry's adoption of metal foam fabrication technologies necessitates a thorough examination of environmental impacts and sustainability considerations. Metal foam production processes typically involve significant energy consumption, particularly during the melting and casting phases. Traditional manufacturing methods can release substantial greenhouse gas emissions, with estimates suggesting that aluminum foam production generates approximately 9.5 kg CO2 equivalent per kilogram of material—considerably higher than conventional aluminum processing.

Water usage presents another critical environmental concern, as metal foam fabrication often requires substantial quantities for cooling and cleaning operations. Advanced facilities implementing closed-loop water systems have demonstrated potential reductions in freshwater consumption by up to 85%, representing a significant improvement in resource efficiency.

Material waste generation during metal foam manufacturing varies considerably depending on the production technique employed. Powder metallurgy approaches typically yield waste rates of 15-20%, while investment casting methods may generate up to 30% waste material. Recent innovations in additive manufacturing for metal foams have shown promise in reducing waste to below 10%, though these technologies remain in developmental stages for aerospace-grade applications.

The recyclability of metal foams presents a notable sustainability advantage. Research indicates that aluminum and titanium foams can be recycled with approximately 95% and 85% material recovery rates respectively, significantly reducing the environmental footprint across the product lifecycle. This characteristic aligns well with aerospace industry sustainability initiatives and circular economy principles.

Chemical usage in metal foam production, particularly in processes involving foaming agents and stabilizers, introduces potential environmental hazards. Traditional foaming agents like titanium hydride release hydrogen during decomposition, while newer organic-based foaming agents offer reduced toxicity profiles but may present different environmental challenges regarding biodegradability and aquatic toxicity.

Regulatory frameworks governing metal foam manufacturing are evolving rapidly, with the European Union's REACH regulations and the Aerospace Environmental Technical Operating Procedures (AETOPs) establishing increasingly stringent requirements for chemical management and emissions control. Compliance necessitates substantial investment in pollution control technologies, with modern scrubber systems and thermal oxidizers capable of reducing harmful emissions by 90-95%.

Life cycle assessment studies comparing metal foams to traditional aerospace materials demonstrate that despite higher initial environmental impacts during production, the lightweight properties of metal foams can yield net environmental benefits through fuel savings during aircraft operation. Research indicates that a 10% weight reduction in aircraft components can translate to approximately 6-8% reduction in fuel consumption over the vehicle's operational lifetime.

Water usage presents another critical environmental concern, as metal foam fabrication often requires substantial quantities for cooling and cleaning operations. Advanced facilities implementing closed-loop water systems have demonstrated potential reductions in freshwater consumption by up to 85%, representing a significant improvement in resource efficiency.

Material waste generation during metal foam manufacturing varies considerably depending on the production technique employed. Powder metallurgy approaches typically yield waste rates of 15-20%, while investment casting methods may generate up to 30% waste material. Recent innovations in additive manufacturing for metal foams have shown promise in reducing waste to below 10%, though these technologies remain in developmental stages for aerospace-grade applications.

The recyclability of metal foams presents a notable sustainability advantage. Research indicates that aluminum and titanium foams can be recycled with approximately 95% and 85% material recovery rates respectively, significantly reducing the environmental footprint across the product lifecycle. This characteristic aligns well with aerospace industry sustainability initiatives and circular economy principles.

Chemical usage in metal foam production, particularly in processes involving foaming agents and stabilizers, introduces potential environmental hazards. Traditional foaming agents like titanium hydride release hydrogen during decomposition, while newer organic-based foaming agents offer reduced toxicity profiles but may present different environmental challenges regarding biodegradability and aquatic toxicity.

Regulatory frameworks governing metal foam manufacturing are evolving rapidly, with the European Union's REACH regulations and the Aerospace Environmental Technical Operating Procedures (AETOPs) establishing increasingly stringent requirements for chemical management and emissions control. Compliance necessitates substantial investment in pollution control technologies, with modern scrubber systems and thermal oxidizers capable of reducing harmful emissions by 90-95%.

Life cycle assessment studies comparing metal foams to traditional aerospace materials demonstrate that despite higher initial environmental impacts during production, the lightweight properties of metal foams can yield net environmental benefits through fuel savings during aircraft operation. Research indicates that a 10% weight reduction in aircraft components can translate to approximately 6-8% reduction in fuel consumption over the vehicle's operational lifetime.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!