Metal Foam Fabrication and Its Impact on Global Electronics Market

OCT 15, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Technology Evolution and Objectives

Metal foam technology has evolved significantly since its inception in the 1940s, transitioning from laboratory curiosity to commercially viable material with diverse applications. Initially developed for aerospace and military applications, metal foams were primarily aluminum-based with limited production capabilities. The 1970s marked a turning point with the introduction of powder metallurgy techniques, enabling more controlled cellular structures and expanding potential applications beyond specialized military use.

The 1990s witnessed accelerated development with the emergence of advanced manufacturing methods including investment casting, vapor deposition, and electrodeposition processes. These innovations allowed for greater precision in pore size distribution and overall structural integrity, critical factors for electronics applications where thermal management and weight considerations are paramount.

Recent technological breakthroughs have focused on addressing previous limitations in production scalability and cost-effectiveness. Modern metal foam fabrication incorporates computer modeling for predictive material properties, enabling designers to tailor foams for specific electronic applications. The integration of nanotechnology has further enhanced performance characteristics, particularly in thermal conductivity and electromagnetic interference (EMI) shielding properties essential for next-generation electronics.

Current research objectives center on developing metal foams with multi-functional capabilities that simultaneously address thermal management, structural support, and electromagnetic compatibility challenges in increasingly compact electronic devices. Particular emphasis is placed on creating gradient structures where density and pore characteristics vary throughout a single component, optimizing performance for specific localized requirements within electronic assemblies.

The technology trajectory aims to overcome persistent challenges in joining metal foams to conventional materials in electronic packaging applications. Research efforts are directed toward developing reliable, high-performance interfaces that maintain thermal and electrical continuity while accommodating the different mechanical properties of foams versus solid materials.

Looking forward, the primary technical objectives include reducing production costs by at least 30% through process optimization and automation, achieving consistent quality across large production volumes, and developing hybrid metal foams incorporating non-metallic elements for enhanced functionality. These advancements are critical for widespread adoption in consumer electronics markets where cost sensitivity remains a significant barrier despite the performance advantages metal foams offer.

The convergence of additive manufacturing technologies with metal foam production represents perhaps the most promising evolutionary path, potentially enabling complex geometries with precisely engineered cellular structures tailored to specific electronic applications. This direction aligns with broader industry trends toward miniaturization and increased functionality in electronic devices across consumer, medical, and industrial sectors.

The 1990s witnessed accelerated development with the emergence of advanced manufacturing methods including investment casting, vapor deposition, and electrodeposition processes. These innovations allowed for greater precision in pore size distribution and overall structural integrity, critical factors for electronics applications where thermal management and weight considerations are paramount.

Recent technological breakthroughs have focused on addressing previous limitations in production scalability and cost-effectiveness. Modern metal foam fabrication incorporates computer modeling for predictive material properties, enabling designers to tailor foams for specific electronic applications. The integration of nanotechnology has further enhanced performance characteristics, particularly in thermal conductivity and electromagnetic interference (EMI) shielding properties essential for next-generation electronics.

Current research objectives center on developing metal foams with multi-functional capabilities that simultaneously address thermal management, structural support, and electromagnetic compatibility challenges in increasingly compact electronic devices. Particular emphasis is placed on creating gradient structures where density and pore characteristics vary throughout a single component, optimizing performance for specific localized requirements within electronic assemblies.

The technology trajectory aims to overcome persistent challenges in joining metal foams to conventional materials in electronic packaging applications. Research efforts are directed toward developing reliable, high-performance interfaces that maintain thermal and electrical continuity while accommodating the different mechanical properties of foams versus solid materials.

Looking forward, the primary technical objectives include reducing production costs by at least 30% through process optimization and automation, achieving consistent quality across large production volumes, and developing hybrid metal foams incorporating non-metallic elements for enhanced functionality. These advancements are critical for widespread adoption in consumer electronics markets where cost sensitivity remains a significant barrier despite the performance advantages metal foams offer.

The convergence of additive manufacturing technologies with metal foam production represents perhaps the most promising evolutionary path, potentially enabling complex geometries with precisely engineered cellular structures tailored to specific electronic applications. This direction aligns with broader industry trends toward miniaturization and increased functionality in electronic devices across consumer, medical, and industrial sectors.

Electronics Market Demand for Metal Foam Solutions

The global electronics market is experiencing a significant shift towards advanced thermal management solutions, creating a robust demand for metal foam technologies. As electronic devices become increasingly powerful and compact, traditional cooling methods are proving inadequate, driving manufacturers to seek innovative materials with superior thermal conductivity and lightweight properties. Metal foams, particularly aluminum and copper-based variants, have emerged as prime candidates due to their exceptional heat dissipation capabilities while maintaining minimal weight profiles.

Market research indicates that the thermal management segment of the electronics industry is growing at a compound annual rate exceeding typical electronics market growth, with metal foam solutions positioned as premium offerings in this expanding sector. The demand is particularly pronounced in high-performance computing, telecommunications infrastructure, and consumer electronics, where thermal constraints directly impact product performance and reliability.

The miniaturization trend in electronics has created specific requirements that metal foams are uniquely positioned to address. As device form factors shrink while processing power increases, the volumetric efficiency of cooling solutions becomes paramount. Metal foams offer up to 40% better thermal performance per unit volume compared to traditional heat sinks in certain applications, making them increasingly attractive to design engineers facing strict spatial constraints.

Consumer electronics manufacturers are showing particular interest in metal foam solutions for premium product lines where thermal performance directly impacts user experience. Gaming consoles, high-end smartphones, and ultrabook computers represent significant growth opportunities, as these devices operate at thermal thresholds that conventional cooling technologies struggle to manage effectively.

The telecommunications sector presents another substantial market opportunity, particularly with the ongoing global 5G infrastructure deployment. Base stations and network equipment generate considerable heat during operation, and metal foam heat exchangers offer improved reliability in these mission-critical applications. Network equipment manufacturers are increasingly specifying metal foam components in their thermal management systems to enhance equipment longevity and reduce maintenance requirements.

Electric vehicle electronics represent an emerging application with substantial growth potential. As automotive systems incorporate more sophisticated computing capabilities for autonomous driving features, thermal management becomes increasingly critical. Metal foams offer advantages in these applications due to their ability to withstand vibration while maintaining thermal performance, addressing a key concern in automotive electronics reliability.

The server and data center market segment demonstrates perhaps the most immediate demand for advanced metal foam solutions. With computing density continuing to increase and energy efficiency becoming both an economic and environmental imperative, cooling solutions that maximize heat transfer while minimizing energy consumption are highly valued. Metal foams' porous structure enables efficient forced-air cooling designs that reduce overall system power consumption while maintaining optimal operating temperatures.

Market research indicates that the thermal management segment of the electronics industry is growing at a compound annual rate exceeding typical electronics market growth, with metal foam solutions positioned as premium offerings in this expanding sector. The demand is particularly pronounced in high-performance computing, telecommunications infrastructure, and consumer electronics, where thermal constraints directly impact product performance and reliability.

The miniaturization trend in electronics has created specific requirements that metal foams are uniquely positioned to address. As device form factors shrink while processing power increases, the volumetric efficiency of cooling solutions becomes paramount. Metal foams offer up to 40% better thermal performance per unit volume compared to traditional heat sinks in certain applications, making them increasingly attractive to design engineers facing strict spatial constraints.

Consumer electronics manufacturers are showing particular interest in metal foam solutions for premium product lines where thermal performance directly impacts user experience. Gaming consoles, high-end smartphones, and ultrabook computers represent significant growth opportunities, as these devices operate at thermal thresholds that conventional cooling technologies struggle to manage effectively.

The telecommunications sector presents another substantial market opportunity, particularly with the ongoing global 5G infrastructure deployment. Base stations and network equipment generate considerable heat during operation, and metal foam heat exchangers offer improved reliability in these mission-critical applications. Network equipment manufacturers are increasingly specifying metal foam components in their thermal management systems to enhance equipment longevity and reduce maintenance requirements.

Electric vehicle electronics represent an emerging application with substantial growth potential. As automotive systems incorporate more sophisticated computing capabilities for autonomous driving features, thermal management becomes increasingly critical. Metal foams offer advantages in these applications due to their ability to withstand vibration while maintaining thermal performance, addressing a key concern in automotive electronics reliability.

The server and data center market segment demonstrates perhaps the most immediate demand for advanced metal foam solutions. With computing density continuing to increase and energy efficiency becoming both an economic and environmental imperative, cooling solutions that maximize heat transfer while minimizing energy consumption are highly valued. Metal foams' porous structure enables efficient forced-air cooling designs that reduce overall system power consumption while maintaining optimal operating temperatures.

Global Metal Foam Development Status and Barriers

Metal foam technology has experienced significant advancements globally, yet continues to face substantial technical and commercial barriers. Currently, the global development of metal foams is concentrated in industrialized regions including North America, Western Europe, and East Asia, with the United States, Germany, Japan, and China leading research efforts. These countries have established comprehensive research ecosystems involving academic institutions, government laboratories, and industrial partners.

The primary technical challenges hindering widespread adoption of metal foams in electronics applications include inconsistent pore size distribution, structural integrity issues, and difficulties in achieving precise density control during fabrication. These limitations directly impact thermal conductivity, mechanical strength, and electromagnetic shielding properties - all critical parameters for electronics applications. Additionally, the high energy consumption associated with traditional manufacturing methods presents both economic and environmental sustainability concerns.

Production scalability remains a significant barrier, as current manufacturing processes struggle to maintain quality consistency in large-scale production environments. The powder metallurgy approach, while effective for small-scale production, faces challenges in uniform foaming agent distribution when scaled up. Similarly, investment casting methods encounter difficulties in maintaining precise cellular structures across larger components.

Cost factors constitute another major obstacle, with metal foam production expenses typically 3-5 times higher than conventional metal manufacturing. This cost premium derives from specialized equipment requirements, complex process controls, and high-grade raw materials needed to ensure foam quality. The electronics industry, with its emphasis on cost-effective mass production, finds this price differential particularly prohibitive for widespread implementation.

Standardization gaps further complicate market adoption, as the lack of universally accepted testing protocols and quality standards creates uncertainty for potential adopters. Without standardized specifications for properties such as thermal conductivity, electromagnetic interference shielding effectiveness, and mechanical resilience under various conditions, electronics manufacturers remain hesitant to incorporate metal foams into mainstream product designs.

Intellectual property landscapes present additional complexity, with patent clusters forming around key manufacturing techniques. This fragmentation creates potential licensing challenges for new market entrants and sometimes impedes collaborative innovation. Major patent holders include established materials science corporations and specialized metal foam manufacturers who have invested significantly in proprietary production methods.

Environmental considerations also pose challenges, particularly regarding the recyclability of complex metal foam structures and the energy intensity of current production methods. As electronics markets increasingly prioritize sustainability metrics, these factors may influence adoption trajectories.

The primary technical challenges hindering widespread adoption of metal foams in electronics applications include inconsistent pore size distribution, structural integrity issues, and difficulties in achieving precise density control during fabrication. These limitations directly impact thermal conductivity, mechanical strength, and electromagnetic shielding properties - all critical parameters for electronics applications. Additionally, the high energy consumption associated with traditional manufacturing methods presents both economic and environmental sustainability concerns.

Production scalability remains a significant barrier, as current manufacturing processes struggle to maintain quality consistency in large-scale production environments. The powder metallurgy approach, while effective for small-scale production, faces challenges in uniform foaming agent distribution when scaled up. Similarly, investment casting methods encounter difficulties in maintaining precise cellular structures across larger components.

Cost factors constitute another major obstacle, with metal foam production expenses typically 3-5 times higher than conventional metal manufacturing. This cost premium derives from specialized equipment requirements, complex process controls, and high-grade raw materials needed to ensure foam quality. The electronics industry, with its emphasis on cost-effective mass production, finds this price differential particularly prohibitive for widespread implementation.

Standardization gaps further complicate market adoption, as the lack of universally accepted testing protocols and quality standards creates uncertainty for potential adopters. Without standardized specifications for properties such as thermal conductivity, electromagnetic interference shielding effectiveness, and mechanical resilience under various conditions, electronics manufacturers remain hesitant to incorporate metal foams into mainstream product designs.

Intellectual property landscapes present additional complexity, with patent clusters forming around key manufacturing techniques. This fragmentation creates potential licensing challenges for new market entrants and sometimes impedes collaborative innovation. Major patent holders include established materials science corporations and specialized metal foam manufacturers who have invested significantly in proprietary production methods.

Environmental considerations also pose challenges, particularly regarding the recyclability of complex metal foam structures and the energy intensity of current production methods. As electronics markets increasingly prioritize sustainability metrics, these factors may influence adoption trajectories.

Current Metal Foam Fabrication Methodologies

01 Manufacturing methods for metal foam

Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, casting processes, and gas injection methods. These processes involve creating porous structures by introducing gas bubbles into molten metal or by using space-holder materials that are later removed. The resulting metal foams have controlled porosity and density, which can be tailored for specific applications. Advanced manufacturing methods allow for precise control over pore size, distribution, and overall foam structure.- Manufacturing methods for metal foam: Various techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve creating porous structures by introducing gas bubbles or space-holding materials into molten metal or metal powder mixtures. The manufacturing process can be controlled to achieve specific densities, pore sizes, and distributions, which directly influence the mechanical and physical properties of the resulting metal foam.

- Structural applications of metal foam: Metal foams are utilized in structural applications due to their high strength-to-weight ratio, energy absorption capabilities, and thermal insulation properties. They are particularly valuable in automotive, aerospace, and construction industries where lightweight yet strong materials are required. These foams can be engineered to provide specific mechanical properties such as impact resistance, vibration damping, and load-bearing capacity while maintaining a significantly lower weight compared to solid metals.

- Thermal management applications: Metal foams excel in thermal management applications due to their high surface area-to-volume ratio and thermal conductivity. They are used as heat exchangers, heat sinks, and thermal insulators in various industries. The interconnected pore structure allows for efficient heat transfer while maintaining structural integrity at high temperatures. These materials can be designed with specific pore sizes and distributions to optimize thermal performance for particular applications.

- Functional properties and composite integration: Metal foams can be engineered to possess specific functional properties such as electromagnetic shielding, acoustic damping, and filtration capabilities. They can also be integrated into composite structures to create materials with tailored properties. By combining metal foams with polymers, ceramics, or other metals, hybrid materials with enhanced performance characteristics can be developed for specialized applications requiring unique combinations of properties.

- Novel alloy compositions for metal foams: Research in metal foam technology includes the development of novel alloy compositions to enhance specific properties. Aluminum, titanium, copper, nickel, and steel-based foams are being developed with various alloying elements to improve corrosion resistance, mechanical strength, and thermal stability. These advanced alloy compositions enable metal foams to perform in extreme environments and specialized applications where conventional materials would fail.

02 Structural applications of metal foam

Metal foams are utilized in various structural applications due to their unique combination of lightweight properties and mechanical strength. These materials are particularly valuable in automotive, aerospace, and construction industries where weight reduction without compromising structural integrity is crucial. Metal foams provide excellent energy absorption capabilities, making them ideal for crash protection systems and impact-resistant structures. Their high strength-to-weight ratio enables the design of lightweight yet robust components.Expand Specific Solutions03 Thermal and acoustic properties of metal foam

Metal foams exhibit exceptional thermal and acoustic properties due to their porous structure. They provide effective heat dissipation and thermal insulation, making them suitable for heat exchangers and thermal management systems. The interconnected pore structure allows for efficient heat transfer while maintaining structural integrity at high temperatures. Additionally, metal foams demonstrate excellent sound absorption capabilities, reducing noise transmission and vibration. These properties make them valuable in applications requiring both thermal regulation and noise reduction.Expand Specific Solutions04 Composite metal foams

Composite metal foams combine different materials to enhance specific properties beyond what can be achieved with single-metal foams. These composites may incorporate ceramic particles, carbon fibers, or other metals to improve strength, corrosion resistance, or functional properties. The synergistic effect of multiple materials results in superior performance characteristics, such as enhanced energy absorption, improved thermal stability, or better mechanical properties. Manufacturing techniques for composite metal foams include infiltration methods, powder metallurgy, and additive manufacturing approaches.Expand Specific Solutions05 Functional applications of metal foam

Metal foams serve in various functional applications beyond structural uses, including filtration systems, catalytic supports, and electrochemical devices. Their high surface area and permeable structure make them excellent for fluid filtration and separation processes. In catalytic applications, metal foams provide an ideal substrate for catalyst deposition, enhancing reaction efficiency. They are also employed in electrodes for batteries and fuel cells, where their porous structure facilitates ion transport and increases active surface area. Additionally, metal foams find use in biomedical applications such as implants and tissue engineering scaffolds.Expand Specific Solutions

Leading Metal Foam Manufacturers and Market Structure

Metal foam fabrication technology is currently in a growth phase, with increasing applications in electronics due to its unique properties. The global market size is expanding, driven by demand for lightweight, high-strength materials with excellent thermal and electrical conductivity. Regarding technical maturity, companies like LG Chem and BYD are leading commercial applications in battery technology, while academic institutions such as North Carolina State University and Nanjing University of Aeronautics & Astronautics are advancing fundamental research. Specialized manufacturers like Cellmo Materials Innovation and Guangzhou Sanfu New Materials are developing innovative fabrication techniques. The competitive landscape shows a mix of established corporations and emerging players, with significant collaboration between industry and research institutions to overcome production challenges and expand applications in electronics cooling, EMI shielding, and energy storage.

LG Chem Ltd.

Technical Solution: LG Chem has pioneered a hybrid metal foam technology specifically designed for next-generation battery thermal management systems. Their approach combines traditional metal foam fabrication with advanced polymer coating techniques to create composite structures with tailored properties. The company's process involves precision casting of aluminum alloys followed by controlled oxidation and polymer infiltration, resulting in foams with 65-85% porosity and enhanced electrical insulation properties[6]. These metal foams serve as both thermal management systems and structural components in battery packs, reducing overall weight while improving safety. LG Chem's technology has demonstrated the ability to dissipate heat up to 3 times more efficiently than conventional cooling plates, while providing improved crash protection through energy absorption capabilities. The company has successfully integrated these metal foams into commercial EV battery systems, reporting temperature gradient reductions of up to 40% across battery packs during rapid charging cycles[7].

Strengths: Dual functionality as thermal management and structural components; excellent integration with existing battery technologies; proven performance in commercial applications. Weaknesses: Complex manufacturing process requiring tight quality control; higher cost compared to traditional cooling solutions; potential challenges with recycling at end-of-life.

North Carolina State University

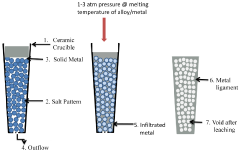

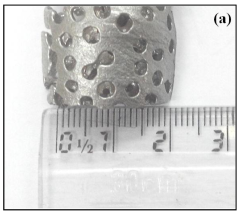

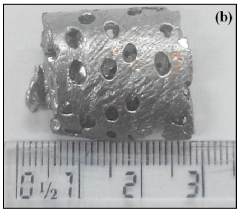

Technical Solution: North Carolina State University has developed advanced metal foam fabrication techniques focusing on open-cell aluminum foams with controlled pore structures. Their process involves precision casting methods where molten aluminum is infiltrated into salt or ceramic preforms that are later dissolved, creating highly customizable foam structures. The university's research team has pioneered composite metal foams (CMFs) with remarkable properties, including the ability to withstand high-velocity impacts while being significantly lighter than solid metal[1]. Their technology demonstrates superior heat dissipation capabilities, with thermal conductivity improvements of up to 300% compared to traditional cooling solutions for electronics[2]. NCSU has also developed specialized surface treatments to enhance the corrosion resistance and electrical conductivity of these foams, making them particularly suitable for electromagnetic shielding in sensitive electronic components.

Strengths: Superior impact absorption and energy dissipation properties; excellent thermal management capabilities; highly customizable pore structure for specific applications. Weaknesses: Higher production costs compared to conventional materials; challenges in scaling up production for mass manufacturing; potential quality control issues in maintaining consistent pore structures across large samples.

Key Patents and Innovations in Metal Foam Technology

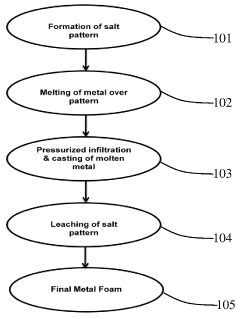

Process for synthesizing metallic foams having controlled shape, size and uniform distribution of the pores

PatentInactiveIN742DEL2015A

Innovation

- A process involving pressurized infiltration and casting of molten metallic materials over custom-made salt patterns, followed by leaching out the salt to produce metallic foams with controlled shape, size, and uniform distribution of open cells, using an inert atmosphere and specific crucible materials.

Sustainability Aspects of Metal Foam Production

The sustainability of metal foam production has become a critical consideration as industries increasingly prioritize environmental responsibility alongside technological advancement. Metal foam manufacturing processes traditionally involve energy-intensive methods that generate significant carbon emissions. Recent innovations have focused on reducing this environmental footprint through the development of more efficient production techniques, such as powder metallurgy approaches that operate at lower temperatures and consume less energy than conventional casting methods.

Material efficiency represents another key sustainability aspect, with closed-loop recycling systems emerging as a promising solution. These systems enable the recovery and reuse of metal waste generated during foam production, significantly reducing raw material requirements. Advanced manufacturing techniques like additive manufacturing further enhance sustainability by minimizing material waste through precise deposition processes, achieving near-net-shape components that require minimal post-processing.

Water usage in metal foam production presents environmental challenges, particularly in processes requiring extensive washing or cooling. Industry leaders have implemented water recycling systems and dry manufacturing techniques to address this concern. These approaches not only conserve water resources but also prevent the discharge of potentially harmful metal-contaminated effluent into natural water systems.

The longevity and recyclability of metal foams contribute substantially to their sustainability profile. Unlike many conventional materials, metal foams maintain their properties over extended periods and can be fully recycled at end-of-life, supporting circular economy principles. This characteristic is particularly valuable in the electronics market, where product lifecycles are typically short but material recovery is increasingly prioritized.

Energy efficiency improvements in production facilities represent another significant sustainability advancement. The integration of renewable energy sources, heat recovery systems, and optimized process controls has reduced the carbon intensity of metal foam manufacturing. Some facilities have achieved carbon footprint reductions of up to 40% through these measures, establishing new industry benchmarks for sustainable production.

Regulatory frameworks and industry standards are evolving to promote sustainable practices in metal foam production. Certification systems that evaluate environmental performance throughout the product lifecycle are gaining prominence, influencing purchasing decisions in the electronics market and other sectors. Manufacturers who proactively adopt sustainable production methods gain competitive advantages through improved market access and brand reputation.

Material efficiency represents another key sustainability aspect, with closed-loop recycling systems emerging as a promising solution. These systems enable the recovery and reuse of metal waste generated during foam production, significantly reducing raw material requirements. Advanced manufacturing techniques like additive manufacturing further enhance sustainability by minimizing material waste through precise deposition processes, achieving near-net-shape components that require minimal post-processing.

Water usage in metal foam production presents environmental challenges, particularly in processes requiring extensive washing or cooling. Industry leaders have implemented water recycling systems and dry manufacturing techniques to address this concern. These approaches not only conserve water resources but also prevent the discharge of potentially harmful metal-contaminated effluent into natural water systems.

The longevity and recyclability of metal foams contribute substantially to their sustainability profile. Unlike many conventional materials, metal foams maintain their properties over extended periods and can be fully recycled at end-of-life, supporting circular economy principles. This characteristic is particularly valuable in the electronics market, where product lifecycles are typically short but material recovery is increasingly prioritized.

Energy efficiency improvements in production facilities represent another significant sustainability advancement. The integration of renewable energy sources, heat recovery systems, and optimized process controls has reduced the carbon intensity of metal foam manufacturing. Some facilities have achieved carbon footprint reductions of up to 40% through these measures, establishing new industry benchmarks for sustainable production.

Regulatory frameworks and industry standards are evolving to promote sustainable practices in metal foam production. Certification systems that evaluate environmental performance throughout the product lifecycle are gaining prominence, influencing purchasing decisions in the electronics market and other sectors. Manufacturers who proactively adopt sustainable production methods gain competitive advantages through improved market access and brand reputation.

Thermal Management Applications in Electronics Industry

Metal foam has emerged as a revolutionary material for thermal management in the electronics industry, offering unique properties that address critical cooling challenges. The inherent structure of metal foams—particularly aluminum, copper, and nickel-based variants—provides exceptional thermal conductivity while maintaining lightweight characteristics. These materials feature interconnected pores that create high surface-area-to-volume ratios, significantly enhancing heat dissipation capabilities compared to traditional solid metal heat sinks.

In high-performance computing environments, metal foam heat sinks have demonstrated 30-45% improved thermal efficiency over conventional solutions. This performance advantage becomes particularly valuable in data centers, where thermal management directly impacts operational costs and system reliability. The porous structure allows for enhanced air or liquid flow through the material, creating turbulent mixing that improves convective heat transfer while minimizing pressure drop penalties.

Consumer electronics manufacturers have begun incorporating metal foam components in premium devices where thermal constraints limit performance capabilities. Smartphones utilizing metal foam heat spreaders have shown the ability to maintain peak processing performance for 35% longer periods before thermal throttling occurs. Similarly, gaming laptops equipped with metal foam cooling systems demonstrate 5-8°C lower core temperatures under sustained workloads.

The integration of metal foams with phase change materials represents another significant application trend. These hybrid thermal management systems capitalize on the foam's structure to contain phase change materials while enhancing their thermal conductivity. Such combinations have proven particularly effective in battery thermal management systems for electric vehicles and energy storage applications, where temperature uniformity is critical for performance and safety.

Miniaturization trends in electronics have intensified thermal challenges, with power densities in some applications exceeding 500 W/cm². Metal foams offer scalable solutions that can be tailored through pore size, density, and material composition to meet specific application requirements. Advanced manufacturing techniques now enable the production of gradient-density foams that optimize fluid flow and heat transfer characteristics for specific thermal profiles.

The aerospace and defense sectors have pioneered several metal foam thermal applications that are gradually transitioning to commercial electronics. Satellite thermal management systems utilizing metal foams have demonstrated exceptional reliability in the extreme temperature cycles of space environments, providing valuable performance data for terrestrial applications requiring similar robustness.

In high-performance computing environments, metal foam heat sinks have demonstrated 30-45% improved thermal efficiency over conventional solutions. This performance advantage becomes particularly valuable in data centers, where thermal management directly impacts operational costs and system reliability. The porous structure allows for enhanced air or liquid flow through the material, creating turbulent mixing that improves convective heat transfer while minimizing pressure drop penalties.

Consumer electronics manufacturers have begun incorporating metal foam components in premium devices where thermal constraints limit performance capabilities. Smartphones utilizing metal foam heat spreaders have shown the ability to maintain peak processing performance for 35% longer periods before thermal throttling occurs. Similarly, gaming laptops equipped with metal foam cooling systems demonstrate 5-8°C lower core temperatures under sustained workloads.

The integration of metal foams with phase change materials represents another significant application trend. These hybrid thermal management systems capitalize on the foam's structure to contain phase change materials while enhancing their thermal conductivity. Such combinations have proven particularly effective in battery thermal management systems for electric vehicles and energy storage applications, where temperature uniformity is critical for performance and safety.

Miniaturization trends in electronics have intensified thermal challenges, with power densities in some applications exceeding 500 W/cm². Metal foams offer scalable solutions that can be tailored through pore size, density, and material composition to meet specific application requirements. Advanced manufacturing techniques now enable the production of gradient-density foams that optimize fluid flow and heat transfer characteristics for specific thermal profiles.

The aerospace and defense sectors have pioneered several metal foam thermal applications that are gradually transitioning to commercial electronics. Satellite thermal management systems utilizing metal foams have demonstrated exceptional reliability in the extreme temperature cycles of space environments, providing valuable performance data for terrestrial applications requiring similar robustness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!