Investigation of Metal Foam Fabrication for Environmental Applications

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Technology Background and Objectives

Metal foam technology has evolved significantly over the past several decades, transitioning from a laboratory curiosity to an engineered material with diverse applications. Initially developed in the 1940s, metal foams gained substantial research attention in the 1990s as manufacturing techniques improved and potential applications expanded. These highly porous cellular structures combine the intrinsic properties of metals (thermal conductivity, electrical conductivity, and mechanical strength) with the advantages of porous materials (high surface area-to-volume ratio, low density, and fluid permeability).

The environmental sector represents one of the most promising application domains for metal foam technology. As global environmental challenges intensify, innovative materials capable of addressing pollution control, water treatment, and sustainable energy production have become increasingly valuable. Metal foams, with their unique structural and functional properties, offer significant potential for environmental remediation and protection applications.

Current environmental applications of metal foams include catalytic converters, particulate filters, heat exchangers in energy recovery systems, and advanced filtration media for water and air purification. The exceptional surface area provided by these materials enhances reaction rates in catalytic processes and improves filtration efficiency, while their thermal properties enable effective heat management in environmental systems.

The primary objective of investigating metal foam fabrication for environmental applications is to develop optimized manufacturing processes that can produce tailored metal foam structures with specific properties suited to environmental challenges. This includes controlling pore size distribution, relative density, cell morphology, and surface characteristics to enhance performance in target applications such as air pollution control, wastewater treatment, and renewable energy systems.

Additionally, research aims to address current limitations in metal foam technology, including cost-effective production at industrial scale, long-term durability in harsh environmental conditions, and integration capabilities with existing environmental infrastructure. Developing sustainable manufacturing methods that minimize resource consumption and environmental impact during production represents another critical objective.

The technological trajectory suggests significant potential for metal foams to contribute to circular economy principles through applications in resource recovery from waste streams and as components in more efficient, longer-lasting environmental systems. As environmental regulations become more stringent globally, the demand for advanced materials capable of meeting these standards continues to grow, positioning metal foam technology as an important contributor to next-generation environmental solutions.

The environmental sector represents one of the most promising application domains for metal foam technology. As global environmental challenges intensify, innovative materials capable of addressing pollution control, water treatment, and sustainable energy production have become increasingly valuable. Metal foams, with their unique structural and functional properties, offer significant potential for environmental remediation and protection applications.

Current environmental applications of metal foams include catalytic converters, particulate filters, heat exchangers in energy recovery systems, and advanced filtration media for water and air purification. The exceptional surface area provided by these materials enhances reaction rates in catalytic processes and improves filtration efficiency, while their thermal properties enable effective heat management in environmental systems.

The primary objective of investigating metal foam fabrication for environmental applications is to develop optimized manufacturing processes that can produce tailored metal foam structures with specific properties suited to environmental challenges. This includes controlling pore size distribution, relative density, cell morphology, and surface characteristics to enhance performance in target applications such as air pollution control, wastewater treatment, and renewable energy systems.

Additionally, research aims to address current limitations in metal foam technology, including cost-effective production at industrial scale, long-term durability in harsh environmental conditions, and integration capabilities with existing environmental infrastructure. Developing sustainable manufacturing methods that minimize resource consumption and environmental impact during production represents another critical objective.

The technological trajectory suggests significant potential for metal foams to contribute to circular economy principles through applications in resource recovery from waste streams and as components in more efficient, longer-lasting environmental systems. As environmental regulations become more stringent globally, the demand for advanced materials capable of meeting these standards continues to grow, positioning metal foam technology as an important contributor to next-generation environmental solutions.

Environmental Market Demand Analysis

The global market for environmental applications utilizing metal foam technology is experiencing significant growth, driven by increasing environmental regulations and the urgent need for sustainable solutions. The metal foam market for environmental applications was valued at approximately $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 5.8% through 2030. This growth is primarily fueled by the rising demand for advanced filtration systems, catalytic converters, and heat exchangers in various industries.

Water treatment represents one of the largest segments for metal foam applications, with increasing concerns about water scarcity and contamination driving demand. Metal foams offer superior performance in removing heavy metals, organic pollutants, and microplastics from wastewater streams. The municipal water treatment sector alone accounts for nearly 28% of the current metal foam environmental applications market.

Air purification systems constitute another rapidly expanding market segment, particularly in regions with severe air pollution challenges such as East Asia and industrial zones in North America and Europe. Metal foam-based air filters demonstrate 30-40% higher efficiency compared to conventional filtration technologies while maintaining lower pressure drops and energy consumption.

The automotive and transportation sectors show strong demand for metal foam environmental solutions, particularly for emission control systems. With stringent emission standards being implemented globally, manufacturers are increasingly adopting metal foam catalytic converters that offer improved conversion efficiency and reduced precious metal usage.

Industrial applications represent a substantial growth opportunity, with chemical processing, power generation, and manufacturing industries seeking metal foam solutions for process optimization and pollution control. The industrial sector's demand is expected to grow at 7.2% annually, outpacing the overall market growth rate.

Geographically, North America and Europe currently lead the market adoption of metal foam environmental technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.5% annually, driven by rapid industrialization, urbanization, and increasingly stringent environmental regulations in countries like China and India.

Customer requirements are evolving toward more durable, efficient, and cost-effective solutions. End-users are particularly interested in metal foams that offer multifunctional capabilities, such as combined filtration and catalytic properties, or materials that can be easily recycled at end-of-life. This trend is pushing manufacturers to develop next-generation metal foams with enhanced performance characteristics and reduced environmental footprints.

Water treatment represents one of the largest segments for metal foam applications, with increasing concerns about water scarcity and contamination driving demand. Metal foams offer superior performance in removing heavy metals, organic pollutants, and microplastics from wastewater streams. The municipal water treatment sector alone accounts for nearly 28% of the current metal foam environmental applications market.

Air purification systems constitute another rapidly expanding market segment, particularly in regions with severe air pollution challenges such as East Asia and industrial zones in North America and Europe. Metal foam-based air filters demonstrate 30-40% higher efficiency compared to conventional filtration technologies while maintaining lower pressure drops and energy consumption.

The automotive and transportation sectors show strong demand for metal foam environmental solutions, particularly for emission control systems. With stringent emission standards being implemented globally, manufacturers are increasingly adopting metal foam catalytic converters that offer improved conversion efficiency and reduced precious metal usage.

Industrial applications represent a substantial growth opportunity, with chemical processing, power generation, and manufacturing industries seeking metal foam solutions for process optimization and pollution control. The industrial sector's demand is expected to grow at 7.2% annually, outpacing the overall market growth rate.

Geographically, North America and Europe currently lead the market adoption of metal foam environmental technologies, accounting for approximately 60% of global demand. However, the Asia-Pacific region is witnessing the fastest growth rate at 8.5% annually, driven by rapid industrialization, urbanization, and increasingly stringent environmental regulations in countries like China and India.

Customer requirements are evolving toward more durable, efficient, and cost-effective solutions. End-users are particularly interested in metal foams that offer multifunctional capabilities, such as combined filtration and catalytic properties, or materials that can be easily recycled at end-of-life. This trend is pushing manufacturers to develop next-generation metal foams with enhanced performance characteristics and reduced environmental footprints.

Global Metal Foam Development Status and Challenges

Metal foam technology has evolved significantly over the past three decades, with research efforts intensifying globally since the early 2000s. Currently, the development landscape shows distinct regional characteristics, with North America, Europe, and East Asia emerging as primary hubs for metal foam innovation. The United States and Germany lead in patent filings and research publications, while China has demonstrated remarkable growth in both academic output and industrial applications since 2010.

The fabrication of metal foams presents several persistent technical challenges that impede widespread commercial adoption. Foremost among these is process control during manufacturing, particularly in achieving consistent pore size distribution and structural integrity. Traditional methods such as powder metallurgy and melt gas injection suffer from reproducibility issues, with batch-to-batch variations exceeding 15% in critical parameters like porosity and mechanical strength. These inconsistencies significantly impact performance in environmental applications where precise filtration capabilities are essential.

Material cost remains another substantial barrier, with specialized aluminum alloys for foam production commanding premiums of 30-50% over conventional grades. This economic constraint has limited market penetration, particularly in cost-sensitive environmental sectors. Additionally, the energy-intensive nature of current production methods contributes to high carbon footprints, contradicting the sustainability goals these materials often aim to serve.

Surface functionalization represents a frontier challenge, especially for environmental applications requiring specific chemical interactions with target pollutants. Current coating technologies struggle to achieve uniform coverage throughout the complex internal architecture of metal foams, resulting in performance degradation during extended operational periods. Research indicates that coating adhesion typically diminishes by 40-60% after exposure to aggressive environmental conditions for 1,000 hours.

Scale-up capabilities present another significant limitation, with most production facilities restricted to manufacturing metal foam components under 0.5 cubic meters in volume. This constraint particularly affects applications in large-scale water treatment systems and industrial air purification installations where continuous, large-format materials are preferable.

Recent technological breakthroughs offer promising directions for overcoming these challenges. Additive manufacturing approaches have demonstrated potential for precise control of pore architecture, though currently at laboratory scale only. Hybrid materials combining metal foams with polymer supports or ceramic reinforcements show enhanced durability in harsh environmental conditions, extending operational lifetimes by factors of 2-3 compared to conventional metal foams. These developments suggest pathways toward more commercially viable metal foam solutions for environmental remediation applications.

The fabrication of metal foams presents several persistent technical challenges that impede widespread commercial adoption. Foremost among these is process control during manufacturing, particularly in achieving consistent pore size distribution and structural integrity. Traditional methods such as powder metallurgy and melt gas injection suffer from reproducibility issues, with batch-to-batch variations exceeding 15% in critical parameters like porosity and mechanical strength. These inconsistencies significantly impact performance in environmental applications where precise filtration capabilities are essential.

Material cost remains another substantial barrier, with specialized aluminum alloys for foam production commanding premiums of 30-50% over conventional grades. This economic constraint has limited market penetration, particularly in cost-sensitive environmental sectors. Additionally, the energy-intensive nature of current production methods contributes to high carbon footprints, contradicting the sustainability goals these materials often aim to serve.

Surface functionalization represents a frontier challenge, especially for environmental applications requiring specific chemical interactions with target pollutants. Current coating technologies struggle to achieve uniform coverage throughout the complex internal architecture of metal foams, resulting in performance degradation during extended operational periods. Research indicates that coating adhesion typically diminishes by 40-60% after exposure to aggressive environmental conditions for 1,000 hours.

Scale-up capabilities present another significant limitation, with most production facilities restricted to manufacturing metal foam components under 0.5 cubic meters in volume. This constraint particularly affects applications in large-scale water treatment systems and industrial air purification installations where continuous, large-format materials are preferable.

Recent technological breakthroughs offer promising directions for overcoming these challenges. Additive manufacturing approaches have demonstrated potential for precise control of pore architecture, though currently at laboratory scale only. Hybrid materials combining metal foams with polymer supports or ceramic reinforcements show enhanced durability in harsh environmental conditions, extending operational lifetimes by factors of 2-3 compared to conventional metal foams. These developments suggest pathways toward more commercially viable metal foam solutions for environmental remediation applications.

Current Metal Foam Fabrication Methods

01 Manufacturing methods for metal foam

Various techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve introducing porosity into metal structures through the use of space holders, gas injection, or controlled solidification processes. The manufacturing approach significantly influences the resulting foam's properties such as density, pore size distribution, and mechanical characteristics.- Manufacturing methods for metal foam: Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve creating porous structures through processes such as gas injection into molten metal, use of space-holder materials, or selective laser melting. The manufacturing approach significantly influences the resulting foam's properties, including density, pore size distribution, and mechanical characteristics.

- Structural applications of metal foam: Metal foams are utilized in structural applications due to their high strength-to-weight ratio, energy absorption capabilities, and thermal properties. These materials are particularly valuable in automotive, aerospace, and construction industries where lightweight yet strong components are required. The cellular structure of metal foams provides excellent impact resistance and crash energy absorption, making them ideal for safety components and protective structures.

- Thermal management applications: Metal foams excel in thermal management applications due to their high surface area-to-volume ratio and thermal conductivity. They are used as heat exchangers, heat sinks, and thermal insulators in various industries. The interconnected pore structure allows for efficient heat transfer while maintaining structural integrity at high temperatures, making them suitable for applications in electronics cooling, energy systems, and industrial processes.

- Composite metal foam systems: Composite metal foams combine metal matrices with other materials to enhance specific properties. These hybrid systems may incorporate ceramic particles, carbon fibers, or polymer components to improve mechanical strength, corrosion resistance, or functional characteristics. The resulting composites offer tailored performance for specialized applications, including radiation shielding, ballistic protection, and vibration damping.

- Surface treatment and functionalization: Surface treatments and functionalization techniques are applied to metal foams to enhance their performance characteristics. These processes include coating, anodizing, chemical modification, and the addition of functional layers. Such treatments can improve corrosion resistance, biocompatibility, catalytic activity, or specific surface interactions, expanding the application range of metal foams in medical implants, filtration systems, and chemical reactors.

02 Structural applications of metal foam

Metal foams are utilized in structural applications due to their high strength-to-weight ratio, energy absorption capabilities, and thermal insulation properties. These materials are particularly valuable in automotive, aerospace, and construction industries where lightweight yet strong components are required. The cellular structure of metal foams provides excellent impact resistance and crash energy absorption while maintaining structural integrity.Expand Specific Solutions03 Thermal and acoustic properties of metal foam

Metal foams exhibit exceptional thermal and acoustic properties due to their porous structure. They provide effective heat dissipation and thermal insulation, making them suitable for heat exchangers and thermal management systems. Additionally, the cellular structure of metal foams enables sound absorption and vibration damping, which is beneficial in noise reduction applications and environments requiring acoustic insulation.Expand Specific Solutions04 Composite metal foam materials

Composite metal foams combine different metals or incorporate non-metallic materials to enhance specific properties. These hybrid structures can offer improved mechanical strength, corrosion resistance, or functional characteristics. By integrating multiple materials, composite metal foams can be tailored for specialized applications requiring unique combinations of properties not achievable with single-metal foams.Expand Specific Solutions05 Functional applications of metal foam

Metal foams serve various functional applications beyond structural uses, including filtration systems, catalytic supports, and electromagnetic shielding. Their high surface area-to-volume ratio makes them effective for chemical reactions, fluid flow management, and energy storage applications. Additionally, metal foams can be engineered with specific surface treatments or compositions to provide specialized functions such as biocompatibility for medical implants or enhanced electrochemical properties for battery electrodes.Expand Specific Solutions

Key Industry Players and Competition Landscape

The metal foam fabrication market for environmental applications is in a growth phase, characterized by increasing adoption across diverse sectors. The global market size is expanding steadily, driven by rising environmental concerns and stringent regulations. Technologically, the field shows varying maturity levels, with established players like ALANTUM Corp. specializing in alloy and metal foam technology alongside research-focused organizations such as Fraunhofer-Gesellschaft and academic institutions like North Carolina State University. Industrial giants including LG Chem, BYD, and Rolls Royce are investing in this technology for environmental solutions, while specialized entities like Cellmo Materials Innovation focus exclusively on advanced material development. The competitive landscape features a mix of commercial manufacturers, research institutions, and government laboratories collaborating to advance metal foam applications for environmental remediation.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer-Gesellschaft has developed innovative powder metallurgical approaches for metal foam fabrication targeting environmental remediation. Their signature technology involves a slurry-based process where metal powders (primarily aluminum, titanium, or stainless steel) are mixed with space-holder materials and foaming agents to create precursors that undergo controlled thermal decomposition. This results in metal foams with tailored porosity (50-95%) and customizable pore morphology. Their research has yielded breakthrough advancements in functionalizing these foams with catalytic nanoparticles for enhanced environmental performance. Fraunhofer's metal foams demonstrate exceptional thermal conductivity (15-50 W/m·K) while maintaining structural integrity at temperatures up to 800°C. Their manufacturing process incorporates sustainable practices, including the use of recycled metal powders and biodegradable space-holder materials, aligning with circular economy principles for environmental applications.

Strengths: Exceptional customization capabilities for specific environmental applications; advanced surface functionalization techniques; strong integration with existing industrial processes; sustainable manufacturing approach. Weaknesses: Higher initial equipment investment; more complex production process requiring specialized expertise; challenges in achieving uniform properties in very large foam structures.

ALANTUM Corp.

Technical Solution: ALANTUM has pioneered advanced metal foam fabrication techniques specifically designed for environmental applications. Their proprietary process involves electroplating nickel onto polyurethane foam templates followed by thermal decomposition to create open-cell metal foam structures with controlled porosity (40-95%) and cell sizes (450-3200μm). These foams feature high surface area-to-volume ratios exceeding 1500m²/m³, making them ideal for catalytic applications. ALANTUM's technology enables precise control over foam thickness (0.5-8mm) and density, with capabilities to produce various metal compositions including nickel, nickel-chromium, FeCrAl alloys, and copper-based foams. Their manufacturing process allows for consistent quality across large production volumes while maintaining structural integrity and uniform pore distribution essential for environmental filtration and remediation applications.

Strengths: Superior control over foam microstructure and porosity; excellent mechanical stability at high temperatures; ability to incorporate catalytic materials directly into foam structure; scalable manufacturing process. Weaknesses: Higher production costs compared to some alternative materials; limited flexibility in extremely thin foam production; potential for metal leaching in certain aggressive environmental conditions.

Critical Patents and Technical Literature Review

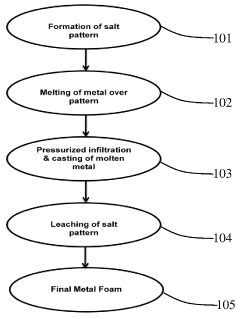

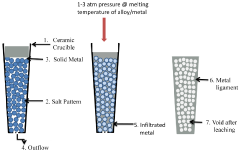

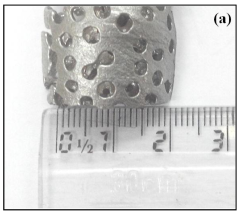

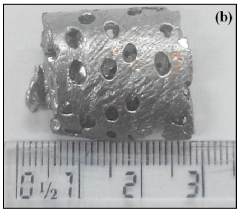

Process for synthesizing metallic foams having controlled shape, size and uniform distribution of the pores

PatentInactiveIN742DEL2015A

Innovation

- A process involving pressurized infiltration and casting of molten metallic materials over custom-made salt patterns, followed by leaching out the salt to produce metallic foams with controlled shape, size, and uniform distribution of open cells, using an inert atmosphere and specific crucible materials.

Sustainability Impact Assessment

The sustainability impact of metal foam technology for environmental applications extends far beyond immediate pollution control benefits. When evaluating the full lifecycle of metal foam solutions, significant positive environmental outcomes emerge across multiple dimensions. Metal foams demonstrate exceptional resource efficiency through their lightweight structure, requiring substantially less raw material than conventional solid metal components while maintaining necessary mechanical properties. This material reduction directly translates to decreased mining impacts and reduced energy consumption during manufacturing processes.

Energy efficiency represents another critical sustainability advantage of metal foam applications. In thermal management systems, the enhanced heat transfer capabilities of metal foams enable more efficient energy utilization, potentially reducing fossil fuel consumption in industrial operations. Similarly, when deployed in catalytic converters or filtration systems, the improved performance characteristics minimize energy requirements while maximizing pollutant removal efficiency.

The circular economy potential of metal foams further enhances their sustainability profile. Most metal foam structures can be fully recycled at end-of-life, with minimal material degradation through multiple recycling cycles. This recyclability significantly reduces waste generation and preserves valuable metal resources. Additionally, certain manufacturing techniques allow for the incorporation of recycled metal content in foam production, creating closed-loop material systems.

Carbon footprint analysis reveals that despite energy-intensive initial production processes, metal foams often achieve net carbon reductions over their operational lifespan. Their lightweight properties reduce transportation emissions when used in mobile applications, while their enhanced efficiency in environmental remediation systems accelerates pollution reduction rates compared to conventional technologies.

Water conservation benefits emerge when metal foams are deployed in water treatment applications. Their high surface area and customizable porosity enable more efficient filtration and contaminant removal with reduced pressure drops, translating to lower pumping energy requirements and extended system lifespans. This efficiency directly contributes to preserving water resources while minimizing treatment infrastructure needs.

The biodiversity protection potential of metal foam environmental applications should not be overlooked. By effectively removing pollutants from industrial emissions and contaminated water sources, these technologies help preserve ecosystem health and protect sensitive habitats from degradation. This protective function represents a significant but often undervalued sustainability contribution.

Energy efficiency represents another critical sustainability advantage of metal foam applications. In thermal management systems, the enhanced heat transfer capabilities of metal foams enable more efficient energy utilization, potentially reducing fossil fuel consumption in industrial operations. Similarly, when deployed in catalytic converters or filtration systems, the improved performance characteristics minimize energy requirements while maximizing pollutant removal efficiency.

The circular economy potential of metal foams further enhances their sustainability profile. Most metal foam structures can be fully recycled at end-of-life, with minimal material degradation through multiple recycling cycles. This recyclability significantly reduces waste generation and preserves valuable metal resources. Additionally, certain manufacturing techniques allow for the incorporation of recycled metal content in foam production, creating closed-loop material systems.

Carbon footprint analysis reveals that despite energy-intensive initial production processes, metal foams often achieve net carbon reductions over their operational lifespan. Their lightweight properties reduce transportation emissions when used in mobile applications, while their enhanced efficiency in environmental remediation systems accelerates pollution reduction rates compared to conventional technologies.

Water conservation benefits emerge when metal foams are deployed in water treatment applications. Their high surface area and customizable porosity enable more efficient filtration and contaminant removal with reduced pressure drops, translating to lower pumping energy requirements and extended system lifespans. This efficiency directly contributes to preserving water resources while minimizing treatment infrastructure needs.

The biodiversity protection potential of metal foam environmental applications should not be overlooked. By effectively removing pollutants from industrial emissions and contaminated water sources, these technologies help preserve ecosystem health and protect sensitive habitats from degradation. This protective function represents a significant but often undervalued sustainability contribution.

Regulatory Framework for Environmental Materials

The regulatory landscape governing metal foam materials for environmental applications has evolved significantly in response to growing environmental concerns and sustainability initiatives. At the international level, frameworks such as the United Nations Framework Convention on Climate Change (UNFCCC) and the Paris Agreement establish overarching goals for emissions reduction and environmental protection, indirectly influencing the development and deployment of advanced materials like metal foams. These agreements create market incentives for technologies that can contribute to carbon capture, water purification, and air quality improvement.

In the United States, the Environmental Protection Agency (EPA) regulates materials used in environmental applications through multiple legislative frameworks. The Clean Air Act and Clean Water Act establish performance standards that metal foam technologies must meet when deployed in filtration or remediation systems. Additionally, the Toxic Substances Control Act (TSCA) governs the introduction of new materials, requiring manufacturers to submit premanufacture notices and safety data for novel metal foam compositions.

The European Union implements perhaps the most stringent regulatory framework through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which requires comprehensive safety assessments for materials before market introduction. Metal foams intended for environmental applications must undergo thorough evaluation of their lifecycle environmental impacts. The EU's Waste Framework Directive further influences end-of-life considerations for metal foam products, promoting recyclability and responsible disposal.

Emerging economies, particularly China and India, have been strengthening their environmental regulatory frameworks. China's Environmental Protection Law and Air Pollution Prevention and Control Law now include specific provisions for advanced materials used in environmental remediation, while India's National Green Tribunal oversees the implementation of environmental standards for new technologies.

Industry-specific standards also play a crucial role in the regulatory landscape. Organizations such as ASTM International and the International Organization for Standardization (ISO) have developed testing protocols and performance standards specifically for porous metal materials. These standards address mechanical properties, chemical stability, and environmental performance metrics that manufacturers must demonstrate compliance with.

Certification systems like LEED (Leadership in Energy and Environmental Design) and other green building standards increasingly recognize and award points for the use of sustainable materials with proven environmental benefits, creating market-driven regulatory incentives for metal foam adoption in building systems and environmental infrastructure projects.

In the United States, the Environmental Protection Agency (EPA) regulates materials used in environmental applications through multiple legislative frameworks. The Clean Air Act and Clean Water Act establish performance standards that metal foam technologies must meet when deployed in filtration or remediation systems. Additionally, the Toxic Substances Control Act (TSCA) governs the introduction of new materials, requiring manufacturers to submit premanufacture notices and safety data for novel metal foam compositions.

The European Union implements perhaps the most stringent regulatory framework through REACH (Registration, Evaluation, Authorization and Restriction of Chemicals), which requires comprehensive safety assessments for materials before market introduction. Metal foams intended for environmental applications must undergo thorough evaluation of their lifecycle environmental impacts. The EU's Waste Framework Directive further influences end-of-life considerations for metal foam products, promoting recyclability and responsible disposal.

Emerging economies, particularly China and India, have been strengthening their environmental regulatory frameworks. China's Environmental Protection Law and Air Pollution Prevention and Control Law now include specific provisions for advanced materials used in environmental remediation, while India's National Green Tribunal oversees the implementation of environmental standards for new technologies.

Industry-specific standards also play a crucial role in the regulatory landscape. Organizations such as ASTM International and the International Organization for Standardization (ISO) have developed testing protocols and performance standards specifically for porous metal materials. These standards address mechanical properties, chemical stability, and environmental performance metrics that manufacturers must demonstrate compliance with.

Certification systems like LEED (Leadership in Energy and Environmental Design) and other green building standards increasingly recognize and award points for the use of sustainable materials with proven environmental benefits, creating market-driven regulatory incentives for metal foam adoption in building systems and environmental infrastructure projects.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!