Metal Foam Fabrication: Innovations in Thermal Management

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Evolution and Objectives

Metal foam technology has evolved significantly since its inception in the early 20th century, with the first patents for metal foam production appearing in the 1940s. Initially developed for specialized military and aerospace applications, metal foams remained largely experimental until the 1990s when manufacturing techniques began to mature. The evolution of metal foam fabrication has been characterized by continuous improvements in production methods, moving from rudimentary powder metallurgy approaches to sophisticated techniques including investment casting, direct foaming, and additive manufacturing processes.

The thermal management capabilities of metal foams represent one of their most promising attributes. With their unique combination of high thermal conductivity derived from their metal matrix and enhanced surface area from their porous structure, metal foams offer exceptional heat transfer efficiency. This characteristic has positioned them as increasingly valuable materials in an era where thermal management challenges are intensifying across multiple industries, from electronics to energy systems.

Current objectives in metal foam fabrication research center on several key areas. First, enhancing production consistency and reliability remains paramount, as variations in pore size, distribution, and interconnectivity significantly impact thermal performance. Researchers aim to develop manufacturing methods that deliver predictable, uniform foam structures with precisely controlled porosity parameters. Second, cost reduction represents a critical objective, as current production expenses limit widespread commercial adoption despite the material's technical advantages.

Another significant objective involves tailoring metal foam properties for specific thermal management applications. This includes developing gradient porosity structures where density varies throughout the material to optimize heat transfer in specific directions or regions. Additionally, researchers are exploring hybrid metal foams incorporating multiple metals or alloys to combine the beneficial properties of different materials, such as copper's thermal conductivity with aluminum's lightweight characteristics.

The integration of computational modeling with fabrication processes constitutes another important objective. Advanced simulation tools enable researchers to predict thermal behavior based on foam microstructure, allowing for design optimization before physical production. This approach significantly reduces development cycles and enables application-specific customization of metal foam properties.

Environmental sustainability has also emerged as a key objective in metal foam evolution. Researchers are investigating more energy-efficient production methods and exploring the use of recycled metals as feedstock materials. Additionally, the potential for metal foams to improve energy efficiency in various applications aligns with global sustainability goals, driving further interest in their development and implementation in thermal management systems.

The thermal management capabilities of metal foams represent one of their most promising attributes. With their unique combination of high thermal conductivity derived from their metal matrix and enhanced surface area from their porous structure, metal foams offer exceptional heat transfer efficiency. This characteristic has positioned them as increasingly valuable materials in an era where thermal management challenges are intensifying across multiple industries, from electronics to energy systems.

Current objectives in metal foam fabrication research center on several key areas. First, enhancing production consistency and reliability remains paramount, as variations in pore size, distribution, and interconnectivity significantly impact thermal performance. Researchers aim to develop manufacturing methods that deliver predictable, uniform foam structures with precisely controlled porosity parameters. Second, cost reduction represents a critical objective, as current production expenses limit widespread commercial adoption despite the material's technical advantages.

Another significant objective involves tailoring metal foam properties for specific thermal management applications. This includes developing gradient porosity structures where density varies throughout the material to optimize heat transfer in specific directions or regions. Additionally, researchers are exploring hybrid metal foams incorporating multiple metals or alloys to combine the beneficial properties of different materials, such as copper's thermal conductivity with aluminum's lightweight characteristics.

The integration of computational modeling with fabrication processes constitutes another important objective. Advanced simulation tools enable researchers to predict thermal behavior based on foam microstructure, allowing for design optimization before physical production. This approach significantly reduces development cycles and enables application-specific customization of metal foam properties.

Environmental sustainability has also emerged as a key objective in metal foam evolution. Researchers are investigating more energy-efficient production methods and exploring the use of recycled metals as feedstock materials. Additionally, the potential for metal foams to improve energy efficiency in various applications aligns with global sustainability goals, driving further interest in their development and implementation in thermal management systems.

Thermal Management Market Analysis

The thermal management market has experienced substantial growth in recent years, driven primarily by increasing heat dissipation requirements across multiple industries. The global thermal management market was valued at approximately $12.3 billion in 2022 and is projected to reach $19.1 billion by 2028, representing a compound annual growth rate (CAGR) of 7.6%. This growth trajectory is particularly evident in sectors such as electronics, automotive, aerospace, and industrial manufacturing.

Electronics and semiconductor industries remain the dominant consumers of thermal management solutions, accounting for nearly 35% of the total market share. This dominance stems from the continuous miniaturization of electronic components and the increasing power densities in modern devices, which generate significant heat that must be efficiently dissipated to maintain performance and reliability.

The automotive sector represents another rapidly expanding segment, particularly with the rise of electric vehicles (EVs) and hybrid electric vehicles (HEVs). These vehicles require sophisticated thermal management systems for battery packs, power electronics, and electric motors. Market analysis indicates that the automotive thermal management segment is growing at a CAGR of 8.9%, outpacing the overall market average.

Geographically, Asia-Pacific leads the thermal management market with approximately 40% share, driven by the region's robust electronics manufacturing ecosystem and automotive production capabilities. North America and Europe follow with 28% and 24% market shares respectively, with significant contributions from aerospace, defense, and high-performance computing sectors.

Metal foam-based thermal management solutions currently represent a niche but rapidly growing segment within this broader market. While traditional thermal management technologies like heat sinks, heat pipes, and liquid cooling systems dominate with over 75% market share, metal foams are gaining traction due to their superior thermal conductivity, lightweight properties, and customizable porosity.

Market research indicates that metal foam thermal solutions are experiencing a growth rate of approximately 12.3% annually, significantly higher than conventional technologies. This accelerated adoption is particularly notable in high-value applications where performance advantages outweigh cost considerations, such as aerospace components, high-performance computing, and specialized industrial equipment.

Customer demand patterns show increasing preference for integrated thermal solutions that combine multiple technologies, with metal foams often serving as a critical component in these hybrid systems. Industry surveys reveal that 68% of thermal management engineers are considering metal foam incorporation in next-generation designs, highlighting the growing market acceptance of this innovative material.

Electronics and semiconductor industries remain the dominant consumers of thermal management solutions, accounting for nearly 35% of the total market share. This dominance stems from the continuous miniaturization of electronic components and the increasing power densities in modern devices, which generate significant heat that must be efficiently dissipated to maintain performance and reliability.

The automotive sector represents another rapidly expanding segment, particularly with the rise of electric vehicles (EVs) and hybrid electric vehicles (HEVs). These vehicles require sophisticated thermal management systems for battery packs, power electronics, and electric motors. Market analysis indicates that the automotive thermal management segment is growing at a CAGR of 8.9%, outpacing the overall market average.

Geographically, Asia-Pacific leads the thermal management market with approximately 40% share, driven by the region's robust electronics manufacturing ecosystem and automotive production capabilities. North America and Europe follow with 28% and 24% market shares respectively, with significant contributions from aerospace, defense, and high-performance computing sectors.

Metal foam-based thermal management solutions currently represent a niche but rapidly growing segment within this broader market. While traditional thermal management technologies like heat sinks, heat pipes, and liquid cooling systems dominate with over 75% market share, metal foams are gaining traction due to their superior thermal conductivity, lightweight properties, and customizable porosity.

Market research indicates that metal foam thermal solutions are experiencing a growth rate of approximately 12.3% annually, significantly higher than conventional technologies. This accelerated adoption is particularly notable in high-value applications where performance advantages outweigh cost considerations, such as aerospace components, high-performance computing, and specialized industrial equipment.

Customer demand patterns show increasing preference for integrated thermal solutions that combine multiple technologies, with metal foams often serving as a critical component in these hybrid systems. Industry surveys reveal that 68% of thermal management engineers are considering metal foam incorporation in next-generation designs, highlighting the growing market acceptance of this innovative material.

Metal Foam Technology Status and Barriers

Metal foam technology has witnessed significant advancements globally, yet faces several technical barriers that limit its widespread adoption in thermal management applications. Currently, the most established production methods include powder metallurgy, investment casting, and direct foaming techniques. These methods have reached commercial viability for aluminum, copper, and nickel-based foams, with porosity ranges typically between 60-95% and pore sizes from 0.5-5mm being achievable with reasonable consistency.

The primary technical challenges in metal foam fabrication center around precise control of pore morphology and distribution. Conventional manufacturing processes often produce foams with inconsistent cell structures, leading to unpredictable thermal-mechanical properties. This variability significantly impacts thermal conductivity pathways, creating reliability issues in critical thermal management applications. Research indicates that property variations of up to 30% can occur within the same production batch, making quality control exceptionally difficult.

Cost-effectiveness remains another substantial barrier. Current production methods require specialized equipment and complex processing steps, resulting in manufacturing costs approximately 3-5 times higher than conventional heat sink materials. The energy-intensive nature of metal foam production also contributes to its high carbon footprint, contradicting sustainability goals in modern manufacturing.

Scalability presents additional challenges, particularly for applications requiring large-format metal foams with uniform properties. Most current technologies are optimized for smaller components, with production volumes limited by batch processing constraints. Continuous manufacturing methods are still in early development stages, with significant technical hurdles remaining before industrial-scale implementation becomes feasible.

Material compatibility issues further complicate metal foam advancement. While aluminum foams have reached relative maturity, high-performance copper and nickel-based foams still face challenges in achieving optimal microstructural characteristics. Additionally, joining metal foams to solid substrates without compromising thermal interfaces remains problematic, with current bonding techniques often creating thermal resistance at critical junctions.

Geographically, metal foam technology development shows distinct patterns. North America and Europe lead in fundamental research and patent activity, while Asian manufacturers, particularly in China and Japan, dominate production capacity. This distribution creates knowledge transfer challenges between research institutions and manufacturing facilities, slowing technological advancement and commercial implementation.

Recent developments in additive manufacturing show promise for overcoming some of these barriers, particularly in controlling pore architecture. However, these approaches currently face limitations in build volume, production speed, and material options, restricting their immediate industrial applicability for thermal management solutions.

The primary technical challenges in metal foam fabrication center around precise control of pore morphology and distribution. Conventional manufacturing processes often produce foams with inconsistent cell structures, leading to unpredictable thermal-mechanical properties. This variability significantly impacts thermal conductivity pathways, creating reliability issues in critical thermal management applications. Research indicates that property variations of up to 30% can occur within the same production batch, making quality control exceptionally difficult.

Cost-effectiveness remains another substantial barrier. Current production methods require specialized equipment and complex processing steps, resulting in manufacturing costs approximately 3-5 times higher than conventional heat sink materials. The energy-intensive nature of metal foam production also contributes to its high carbon footprint, contradicting sustainability goals in modern manufacturing.

Scalability presents additional challenges, particularly for applications requiring large-format metal foams with uniform properties. Most current technologies are optimized for smaller components, with production volumes limited by batch processing constraints. Continuous manufacturing methods are still in early development stages, with significant technical hurdles remaining before industrial-scale implementation becomes feasible.

Material compatibility issues further complicate metal foam advancement. While aluminum foams have reached relative maturity, high-performance copper and nickel-based foams still face challenges in achieving optimal microstructural characteristics. Additionally, joining metal foams to solid substrates without compromising thermal interfaces remains problematic, with current bonding techniques often creating thermal resistance at critical junctions.

Geographically, metal foam technology development shows distinct patterns. North America and Europe lead in fundamental research and patent activity, while Asian manufacturers, particularly in China and Japan, dominate production capacity. This distribution creates knowledge transfer challenges between research institutions and manufacturing facilities, slowing technological advancement and commercial implementation.

Recent developments in additive manufacturing show promise for overcoming some of these barriers, particularly in controlling pore architecture. However, these approaches currently face limitations in build volume, production speed, and material options, restricting their immediate industrial applicability for thermal management solutions.

Current Metal Foam Fabrication Methods

01 Metal foam heat exchangers for electronic devices

Metal foam structures are used in heat exchangers for electronic devices to enhance thermal management. The porous nature of metal foams provides increased surface area for heat dissipation while maintaining lightweight properties. These structures can be integrated into cooling systems for semiconductors, processors, and other electronic components to efficiently transfer heat away from critical components, preventing overheating and improving device performance and reliability.- Metal foam heat exchangers for electronic devices: Metal foam structures are used in heat exchangers for electronic devices to enhance thermal management. The porous nature of metal foams provides a large surface area for heat dissipation while maintaining lightweight properties. These heat exchangers can be integrated into various electronic components such as processors, power modules, and LED lighting systems to efficiently remove heat and prevent overheating, thereby extending the lifespan and improving the performance of electronic devices.

- Automotive thermal management using metal foams: Metal foams are implemented in automotive thermal management systems to improve heat dissipation in various vehicle components. These foams can be used in engine cooling systems, battery thermal management for electric vehicles, and exhaust heat recovery systems. The high thermal conductivity and lightweight nature of metal foams make them ideal for automotive applications where weight reduction and efficient thermal management are critical for improving fuel efficiency and vehicle performance.

- Metal foam composites for enhanced thermal conductivity: Composite materials incorporating metal foams are developed to enhance thermal conductivity for various applications. These composites combine metal foams with other materials such as polymers, ceramics, or phase change materials to create structures with tailored thermal properties. The resulting composites offer improved heat transfer capabilities while maintaining mechanical strength and can be customized for specific thermal management requirements in industries ranging from aerospace to consumer electronics.

- Manufacturing methods for metal foam thermal management systems: Various manufacturing techniques are employed to produce metal foam structures optimized for thermal management applications. These methods include powder metallurgy, investment casting, direct foaming, and additive manufacturing processes. Each technique offers different advantages in terms of foam structure control, pore size distribution, and material composition, allowing for the creation of customized metal foam components with specific thermal conductivity, mechanical strength, and weight characteristics tailored to particular thermal management requirements.

- Metal foam heat sinks with integrated cooling channels: Advanced heat sink designs incorporate metal foams with integrated cooling channels to maximize thermal management efficiency. These structures combine the high surface area of metal foams with strategically placed fluid channels that allow for enhanced convective heat transfer. The cooling fluid, which can be air, water, or other coolants, flows through these channels and efficiently absorbs heat from the metal foam structure. This design approach is particularly effective for high-power density applications where traditional cooling methods are insufficient.

02 Automotive thermal management using metal foams

Metal foams are implemented in automotive applications for thermal management, including engine cooling systems, battery thermal regulation in electric vehicles, and exhaust heat recovery. The high thermal conductivity and large surface area of metal foams enable efficient heat transfer while their lightweight nature contributes to overall vehicle weight reduction. These materials can be customized with varying porosity and density to meet specific automotive thermal management requirements.Expand Specific Solutions03 Manufacturing methods for metal foam thermal solutions

Various manufacturing techniques are employed to produce metal foams for thermal management applications. These include powder metallurgy, investment casting, direct foaming, and additive manufacturing processes. Each method offers different advantages in terms of controlling pore size, distribution, and overall structure. Advanced manufacturing approaches allow for the creation of tailored metal foam structures with optimized thermal conductivity, mechanical strength, and fluid flow characteristics for specific cooling requirements.Expand Specific Solutions04 Phase change material integration with metal foams

Metal foams can be combined with phase change materials (PCMs) to create hybrid thermal management systems. The metal foam provides structural support and enhances thermal conductivity, while the PCM absorbs and releases thermal energy during phase transitions. This combination is particularly effective for applications requiring thermal buffering or temperature stabilization. The metal foam structure helps overcome the inherently low thermal conductivity of many PCMs, resulting in more efficient heat absorption and distribution.Expand Specific Solutions05 Metal foam cooling for high-power industrial applications

Metal foams are utilized in cooling systems for high-power industrial equipment and processes. Their open-cell structure allows for efficient forced convection cooling when integrated with fluid circulation systems. Applications include power electronics cooling, industrial furnace insulation, and thermal management in renewable energy systems. The combination of high thermal conductivity, large surface area, and customizable porosity makes metal foams particularly suitable for managing extreme heat loads in industrial environments.Expand Specific Solutions

Industry Leaders in Metal Foam Manufacturing

Metal foam fabrication for thermal management is in a growth phase, with the market expanding due to increasing demand for lightweight, thermally efficient materials. The global market is projected to reach significant scale as industries adopt these solutions for heat dissipation challenges. Technologically, the field shows varying maturity levels across different manufacturing approaches. Leading players like LG Chem, Parker-Hannifin, and BASF are advancing commercial applications, while specialized companies such as HAVEL metal foam GmbH and Aspen Aerogels focus on innovative fabrication techniques. Academic institutions including Shanghai Jiao Tong University and Taiyuan University of Technology are contributing fundamental research, creating a competitive landscape balanced between established industrial players and emerging technology specialists.

HAVEL metal foam GmbH

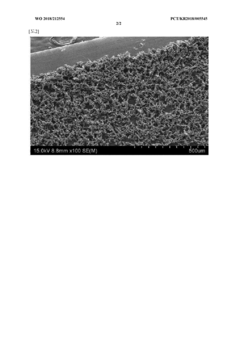

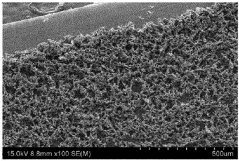

Technical Solution: HAVEL metal foam GmbH has developed proprietary manufacturing processes for open-cell aluminum metal foams specifically designed for thermal management applications. Their technology involves precision-controlled gas injection into molten aluminum alloys followed by controlled solidification to create uniform pore structures. The company's metal foams feature highly interconnected pore networks with 10-40 pores per inch (PPI) and relative densities between 8-15%, optimized for maximum heat transfer efficiency. HAVEL's manufacturing process allows for the integration of their metal foams directly into heat exchangers and cooling systems, creating monolithic structures that eliminate thermal contact resistance issues. Their foams can be manufactured with functional gradients in porosity to address specific thermal management challenges, and they've developed specialized surface treatments to enhance wettability and corrosion resistance for liquid cooling applications[1][2].

Strengths: Superior thermal conductivity compared to polymer-based solutions; excellent surface-area-to-volume ratio enhancing heat transfer; ability to create custom geometries for specific applications; reduced weight compared to solid metal heat sinks. Weaknesses: Higher manufacturing costs than conventional cooling solutions; potential for corrosion in certain environments; mechanical strength limitations compared to solid structures; challenges in achieving perfectly uniform pore distribution at scale.

3M Innovative Properties Co.

Technical Solution: 3M Innovative Properties Co. has pioneered advanced metal foam fabrication techniques focused on thermal management applications. Their proprietary process combines powder metallurgy with controlled foaming agents to create metal foams with tailored properties. The company's technology utilizes specialized binding agents mixed with metal powders (primarily aluminum, copper, or nickel alloys) that decompose during sintering to create precisely controlled pore structures. 3M's metal foams achieve thermal conductivities of 15-40 W/m·K while maintaining porosity levels of 60-85%. Their manufacturing process allows for the creation of composite metal foams with gradient structures that can be optimized for specific thermal pathways. The company has also developed specialized coating technologies that enhance the corrosion resistance and surface properties of their metal foams, making them suitable for harsh operating environments. 3M's metal foams can be integrated into heat exchangers, electronic cooling systems, and thermal energy storage devices with complex geometries that would be impossible to achieve with traditional manufacturing methods[3][4].

Strengths: Exceptional customization capabilities for specific thermal applications; established manufacturing infrastructure allowing for scale production; ability to create multi-material composite foams with enhanced properties; extensive intellectual property portfolio. Weaknesses: Higher production costs compared to some competitors; challenges in achieving ultra-high thermal conductivity needed for certain applications; potential limitations in maximum foam thickness; some designs require post-processing steps that add to manufacturing complexity.

Key Patents in Metal Foam Thermal Solutions

Method for manufacturing metal foam

PatentWO2018212554A1

Innovation

- A method involving the formation of a metal foam precursor using a slurry with metal powder, dispersant, and binder, followed by sintering, which allows for the creation of metal foams with adjustable porosity and mechanical strength, and integration with metal substrates for enhanced adhesion and mechanical properties.

methods of foaming metal with thermal contact

PatentInactiveDE102017121512A1

Innovation

- A method involving direct heat transfer through solid contact conduction using a heatable solid body to foam a semi-finished product containing a metal and a propellant, ensuring homogeneous foaming without the need for protective gases, allowing the process to be performed in ambient air.

Sustainability Aspects of Metal Foam Production

The sustainability of metal foam production has become increasingly important as industries seek to balance technological advancement with environmental responsibility. Metal foam manufacturing processes traditionally involve energy-intensive methods and potentially hazardous materials, raising significant environmental concerns. However, recent innovations are addressing these challenges through more sustainable approaches.

Energy consumption represents one of the primary sustainability concerns in metal foam production. Conventional manufacturing methods such as powder metallurgy and melt gas injection require high temperatures and prolonged processing times, resulting in substantial carbon footprints. New developments in low-temperature processing techniques and energy-efficient furnace designs have demonstrated potential energy savings of 20-30% compared to traditional methods.

Material utilization efficiency has also seen marked improvement. Advanced recycling systems now enable the recovery and reuse of metal powders and foaming agents that would otherwise be discarded. Closed-loop manufacturing systems have been implemented by leading producers, reducing raw material requirements by up to 40% while minimizing waste generation.

Water usage in metal foam production presents another environmental challenge, particularly in processes requiring extensive washing and cleaning steps. Water-conserving technologies, including advanced filtration systems and water recirculation loops, have been integrated into newer production facilities, reducing freshwater consumption by 50-70% compared to older manufacturing plants.

The environmental impact of foaming agents deserves particular attention. Traditional chemical foaming agents often contain environmentally persistent compounds with high global warming potential. Research into bio-derived foaming agents and physical foaming methods has yielded promising alternatives with significantly reduced environmental impacts. Several manufacturers have successfully implemented calcium carbonate-based foaming systems that decompose into environmentally benign byproducts.

Life cycle assessment (LCA) studies of metal foam products reveal that despite energy-intensive production, their lightweight properties and thermal efficiency can result in net environmental benefits over product lifetimes. For thermal management applications specifically, the extended operational efficiency and reduced material requirements often offset initial production impacts within 3-5 years of deployment.

Regulatory frameworks are increasingly influencing production methods, with stricter emissions standards and waste management requirements driving innovation in cleaner manufacturing processes. Companies investing in sustainable production technologies have reported improved regulatory compliance and reduced environmental liability, creating additional business incentives beyond direct operational cost savings.

Energy consumption represents one of the primary sustainability concerns in metal foam production. Conventional manufacturing methods such as powder metallurgy and melt gas injection require high temperatures and prolonged processing times, resulting in substantial carbon footprints. New developments in low-temperature processing techniques and energy-efficient furnace designs have demonstrated potential energy savings of 20-30% compared to traditional methods.

Material utilization efficiency has also seen marked improvement. Advanced recycling systems now enable the recovery and reuse of metal powders and foaming agents that would otherwise be discarded. Closed-loop manufacturing systems have been implemented by leading producers, reducing raw material requirements by up to 40% while minimizing waste generation.

Water usage in metal foam production presents another environmental challenge, particularly in processes requiring extensive washing and cleaning steps. Water-conserving technologies, including advanced filtration systems and water recirculation loops, have been integrated into newer production facilities, reducing freshwater consumption by 50-70% compared to older manufacturing plants.

The environmental impact of foaming agents deserves particular attention. Traditional chemical foaming agents often contain environmentally persistent compounds with high global warming potential. Research into bio-derived foaming agents and physical foaming methods has yielded promising alternatives with significantly reduced environmental impacts. Several manufacturers have successfully implemented calcium carbonate-based foaming systems that decompose into environmentally benign byproducts.

Life cycle assessment (LCA) studies of metal foam products reveal that despite energy-intensive production, their lightweight properties and thermal efficiency can result in net environmental benefits over product lifetimes. For thermal management applications specifically, the extended operational efficiency and reduced material requirements often offset initial production impacts within 3-5 years of deployment.

Regulatory frameworks are increasingly influencing production methods, with stricter emissions standards and waste management requirements driving innovation in cleaner manufacturing processes. Companies investing in sustainable production technologies have reported improved regulatory compliance and reduced environmental liability, creating additional business incentives beyond direct operational cost savings.

Performance Metrics and Testing Standards

Standardized performance evaluation frameworks are essential for the advancement and industrial adoption of metal foam thermal management solutions. The industry currently employs several key metrics to quantify thermal performance, including thermal conductivity (W/m·K), thermal diffusivity (m²/s), and heat transfer coefficient (W/m²·K). These parameters provide fundamental insights into how efficiently metal foams can transfer heat in various applications. Additionally, specific heat capacity (J/kg·K) and thermal resistance (K/W) measurements offer complementary data points for comprehensive performance assessment.

Testing methodologies for metal foams have evolved significantly, with the steady-state method and transient plane source technique emerging as industry standards. The ASTM E1461 standard for thermal diffusivity measurement using the flash method has been adapted specifically for porous metal structures. Similarly, ISO 22007-2 provides guidelines for thermal conductivity determination in cellular metals. These standardized approaches ensure reproducibility and comparability of results across different research institutions and manufacturing facilities.

Mechanical performance metrics are equally important in thermal management applications, as metal foams must maintain structural integrity under thermal cycling and mechanical stress. Compression strength, fatigue resistance, and deformation under thermal load are routinely evaluated using modified versions of ASTM C365 and ISO 844 standards. The correlation between mechanical properties and thermal performance represents a critical area of investigation, particularly for applications in aerospace and automotive industries.

Environmental testing standards have gained prominence as metal foams find applications in increasingly harsh conditions. Corrosion resistance testing (ASTM G31), thermal cycling endurance (ASTM B553), and thermal shock resistance (ASTM C1171) provide valuable data on long-term reliability. These tests typically subject metal foam samples to accelerated aging conditions, simulating years of operational stress within compressed timeframes.

Quality control metrics for manufacturing consistency include porosity distribution analysis, cell size uniformity, and ligament thickness variation. Advanced imaging techniques such as X-ray microtomography enable non-destructive evaluation against these metrics, with data processing algorithms quantifying structural homogeneity. The industry is moving toward implementing statistical process control methodologies specifically tailored for metal foam production, ensuring batch-to-batch consistency.

Comparative benchmarking frameworks have emerged to position metal foam thermal solutions against conventional heat exchangers and emerging alternatives. These frameworks typically evaluate performance-to-weight ratios, performance-to-cost indices, and lifecycle environmental impact assessments. Such holistic evaluation approaches are increasingly important as industries seek to balance thermal efficiency with sustainability considerations and economic viability.

Testing methodologies for metal foams have evolved significantly, with the steady-state method and transient plane source technique emerging as industry standards. The ASTM E1461 standard for thermal diffusivity measurement using the flash method has been adapted specifically for porous metal structures. Similarly, ISO 22007-2 provides guidelines for thermal conductivity determination in cellular metals. These standardized approaches ensure reproducibility and comparability of results across different research institutions and manufacturing facilities.

Mechanical performance metrics are equally important in thermal management applications, as metal foams must maintain structural integrity under thermal cycling and mechanical stress. Compression strength, fatigue resistance, and deformation under thermal load are routinely evaluated using modified versions of ASTM C365 and ISO 844 standards. The correlation between mechanical properties and thermal performance represents a critical area of investigation, particularly for applications in aerospace and automotive industries.

Environmental testing standards have gained prominence as metal foams find applications in increasingly harsh conditions. Corrosion resistance testing (ASTM G31), thermal cycling endurance (ASTM B553), and thermal shock resistance (ASTM C1171) provide valuable data on long-term reliability. These tests typically subject metal foam samples to accelerated aging conditions, simulating years of operational stress within compressed timeframes.

Quality control metrics for manufacturing consistency include porosity distribution analysis, cell size uniformity, and ligament thickness variation. Advanced imaging techniques such as X-ray microtomography enable non-destructive evaluation against these metrics, with data processing algorithms quantifying structural homogeneity. The industry is moving toward implementing statistical process control methodologies specifically tailored for metal foam production, ensuring batch-to-batch consistency.

Comparative benchmarking frameworks have emerged to position metal foam thermal solutions against conventional heat exchangers and emerging alternatives. These frameworks typically evaluate performance-to-weight ratios, performance-to-cost indices, and lifecycle environmental impact assessments. Such holistic evaluation approaches are increasingly important as industries seek to balance thermal efficiency with sustainability considerations and economic viability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!