Examination of Metal Foam Fabrication in Energy Storage Solutions

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Energy Storage Background and Objectives

Metal foam technology represents a significant advancement in materials science, emerging as a promising solution for energy storage applications due to its unique structural and functional properties. The evolution of metal foam technology can be traced back to the 1940s, but it has gained substantial momentum in the energy sector only in the past two decades. This acceleration is primarily driven by the growing demand for more efficient, lightweight, and sustainable energy storage solutions in response to global energy challenges and climate change concerns.

The development trajectory of metal foam technology has been characterized by progressive improvements in manufacturing techniques, material compositions, and structural designs. Initially limited to aerospace and defense applications, metal foam technology has gradually expanded into various energy storage domains, including batteries, fuel cells, thermal energy storage, and hydrogen storage systems. This expansion has been facilitated by advancements in fabrication methods such as powder metallurgy, investment casting, and additive manufacturing, which have enabled the production of metal foams with tailored properties.

Current technological trends in metal foam fabrication are moving toward more precise control of pore size, distribution, and connectivity, as well as the development of hybrid and composite metal foams that combine the advantages of different materials. These innovations aim to enhance the performance metrics critical for energy storage applications, such as energy density, power density, cycle life, and thermal management capabilities.

The primary objective of this technical research is to comprehensively examine the state-of-the-art in metal foam fabrication techniques specifically for energy storage applications. This includes evaluating the effectiveness of various manufacturing methods, identifying key material properties that influence energy storage performance, and assessing the scalability and cost-effectiveness of different production approaches.

Additionally, this research aims to explore the potential of novel metal foam architectures and compositions to address existing limitations in energy storage technologies, such as limited energy density, poor cycle stability, and inadequate thermal management. By understanding the relationship between manufacturing parameters and resultant foam properties, we seek to establish design principles for optimizing metal foams for specific energy storage applications.

Furthermore, this investigation intends to identify emerging opportunities for metal foam technology in next-generation energy storage systems, including solid-state batteries, advanced hydrogen storage, and high-temperature thermal energy storage. The ultimate goal is to provide a roadmap for future research and development efforts that can accelerate the commercial adoption of metal foam-based energy storage solutions.

The development trajectory of metal foam technology has been characterized by progressive improvements in manufacturing techniques, material compositions, and structural designs. Initially limited to aerospace and defense applications, metal foam technology has gradually expanded into various energy storage domains, including batteries, fuel cells, thermal energy storage, and hydrogen storage systems. This expansion has been facilitated by advancements in fabrication methods such as powder metallurgy, investment casting, and additive manufacturing, which have enabled the production of metal foams with tailored properties.

Current technological trends in metal foam fabrication are moving toward more precise control of pore size, distribution, and connectivity, as well as the development of hybrid and composite metal foams that combine the advantages of different materials. These innovations aim to enhance the performance metrics critical for energy storage applications, such as energy density, power density, cycle life, and thermal management capabilities.

The primary objective of this technical research is to comprehensively examine the state-of-the-art in metal foam fabrication techniques specifically for energy storage applications. This includes evaluating the effectiveness of various manufacturing methods, identifying key material properties that influence energy storage performance, and assessing the scalability and cost-effectiveness of different production approaches.

Additionally, this research aims to explore the potential of novel metal foam architectures and compositions to address existing limitations in energy storage technologies, such as limited energy density, poor cycle stability, and inadequate thermal management. By understanding the relationship between manufacturing parameters and resultant foam properties, we seek to establish design principles for optimizing metal foams for specific energy storage applications.

Furthermore, this investigation intends to identify emerging opportunities for metal foam technology in next-generation energy storage systems, including solid-state batteries, advanced hydrogen storage, and high-temperature thermal energy storage. The ultimate goal is to provide a roadmap for future research and development efforts that can accelerate the commercial adoption of metal foam-based energy storage solutions.

Market Analysis for Metal Foam Energy Storage Applications

The global market for metal foam energy storage applications is experiencing significant growth, driven by the increasing demand for efficient and sustainable energy storage solutions. Metal foams, particularly those made from aluminum, nickel, copper, and titanium, offer unique properties that make them highly suitable for various energy storage applications, including batteries, fuel cells, and thermal energy storage systems.

The energy storage market is projected to reach $546 billion by 2035, with a compound annual growth rate of approximately 12% between 2023 and 2035. Within this broader market, metal foam applications are gaining traction due to their superior performance characteristics compared to traditional materials. The metal foam segment for energy storage applications specifically is estimated to grow at a rate of 15-18% annually over the next decade.

Battery technologies represent the largest application segment for metal foam materials, accounting for approximately 45% of the total metal foam energy storage market. The electric vehicle industry serves as a primary driver, with automotive manufacturers increasingly adopting metal foam electrodes and current collectors to enhance battery performance and safety. The stationary energy storage sector follows closely, representing about 30% of market share.

Geographically, Asia-Pacific dominates the market with over 40% share, led by China, Japan, and South Korea, where substantial investments in renewable energy infrastructure and electric vehicle production are creating robust demand. North America and Europe collectively account for approximately 45% of the market, with particularly strong growth in countries prioritizing green energy transitions.

Consumer electronics represents another rapidly expanding application area, with metal foam components being integrated into next-generation portable devices to improve energy density and thermal management. This segment is expected to grow at 20% annually, outpacing the overall market average.

Key market challenges include high production costs and scalability issues, which currently limit widespread adoption. The average cost premium for metal foam components remains 30-40% higher than conventional alternatives, though this gap is narrowing as manufacturing processes improve and economies of scale develop.

Market analysts identify significant growth opportunities in emerging economies, where expanding energy infrastructure and increasing environmental regulations are creating favorable conditions for advanced energy storage solutions. Additionally, the integration of metal foams with renewable energy systems presents a substantial market opportunity, with solar and wind energy storage applications projected to grow at 25% annually through 2030.

The energy storage market is projected to reach $546 billion by 2035, with a compound annual growth rate of approximately 12% between 2023 and 2035. Within this broader market, metal foam applications are gaining traction due to their superior performance characteristics compared to traditional materials. The metal foam segment for energy storage applications specifically is estimated to grow at a rate of 15-18% annually over the next decade.

Battery technologies represent the largest application segment for metal foam materials, accounting for approximately 45% of the total metal foam energy storage market. The electric vehicle industry serves as a primary driver, with automotive manufacturers increasingly adopting metal foam electrodes and current collectors to enhance battery performance and safety. The stationary energy storage sector follows closely, representing about 30% of market share.

Geographically, Asia-Pacific dominates the market with over 40% share, led by China, Japan, and South Korea, where substantial investments in renewable energy infrastructure and electric vehicle production are creating robust demand. North America and Europe collectively account for approximately 45% of the market, with particularly strong growth in countries prioritizing green energy transitions.

Consumer electronics represents another rapidly expanding application area, with metal foam components being integrated into next-generation portable devices to improve energy density and thermal management. This segment is expected to grow at 20% annually, outpacing the overall market average.

Key market challenges include high production costs and scalability issues, which currently limit widespread adoption. The average cost premium for metal foam components remains 30-40% higher than conventional alternatives, though this gap is narrowing as manufacturing processes improve and economies of scale develop.

Market analysts identify significant growth opportunities in emerging economies, where expanding energy infrastructure and increasing environmental regulations are creating favorable conditions for advanced energy storage solutions. Additionally, the integration of metal foams with renewable energy systems presents a substantial market opportunity, with solar and wind energy storage applications projected to grow at 25% annually through 2030.

Technical Challenges in Metal Foam Fabrication

Despite significant advancements in metal foam fabrication techniques, several technical challenges persist that impede widespread industrial adoption for energy storage applications. The primary challenge lies in achieving consistent and reproducible pore structures across large-scale production. Current manufacturing processes often result in heterogeneous cellular architectures with variations in pore size, distribution, and interconnectivity, which directly impacts the electrochemical performance and mechanical stability of energy storage devices.

Material selection presents another significant hurdle, as the base metals must simultaneously satisfy multiple requirements: excellent electrical conductivity, electrochemical stability, corrosion resistance, and mechanical strength. Additionally, these materials must be compatible with the specific electrolytes used in various energy storage systems while maintaining structural integrity during charge-discharge cycles.

Process control during fabrication remains problematic, particularly in methods involving gas evolution or template removal. Precise temperature control, pressure regulation, and reaction kinetics management are essential for creating optimal foam structures. Small deviations in these parameters can lead to structural defects, closed-cell formations, or inadequate mechanical properties that compromise energy storage performance.

Cost-effectiveness represents a substantial barrier to commercialization. Current high-precision manufacturing techniques for metal foams often involve expensive equipment, specialized facilities, and complex multi-step processes. The economic viability of metal foam energy storage solutions depends on developing more efficient, scalable production methods that reduce material waste and energy consumption while maintaining quality standards.

Surface functionalization of metal foams presents technical difficulties in achieving uniform coating or modification across the entire three-dimensional structure. Ensuring complete coverage of internal surfaces with catalysts, active materials, or protective layers is challenging due to the complex geometry and limited accessibility of internal pore networks.

Integration challenges arise when incorporating metal foams into complete energy storage systems. Interface engineering between the foam structure and other components (electrodes, separators, current collectors) requires precise control to minimize contact resistance and ensure efficient electron/ion transport pathways.

Characterization and quality control of metal foam structures pose significant technical obstacles. Non-destructive testing methods for evaluating internal structures, detecting defects, and measuring key performance parameters remain limited. Advanced imaging and analytical techniques are needed to correlate structural features with electrochemical performance and durability in operational conditions.

Material selection presents another significant hurdle, as the base metals must simultaneously satisfy multiple requirements: excellent electrical conductivity, electrochemical stability, corrosion resistance, and mechanical strength. Additionally, these materials must be compatible with the specific electrolytes used in various energy storage systems while maintaining structural integrity during charge-discharge cycles.

Process control during fabrication remains problematic, particularly in methods involving gas evolution or template removal. Precise temperature control, pressure regulation, and reaction kinetics management are essential for creating optimal foam structures. Small deviations in these parameters can lead to structural defects, closed-cell formations, or inadequate mechanical properties that compromise energy storage performance.

Cost-effectiveness represents a substantial barrier to commercialization. Current high-precision manufacturing techniques for metal foams often involve expensive equipment, specialized facilities, and complex multi-step processes. The economic viability of metal foam energy storage solutions depends on developing more efficient, scalable production methods that reduce material waste and energy consumption while maintaining quality standards.

Surface functionalization of metal foams presents technical difficulties in achieving uniform coating or modification across the entire three-dimensional structure. Ensuring complete coverage of internal surfaces with catalysts, active materials, or protective layers is challenging due to the complex geometry and limited accessibility of internal pore networks.

Integration challenges arise when incorporating metal foams into complete energy storage systems. Interface engineering between the foam structure and other components (electrodes, separators, current collectors) requires precise control to minimize contact resistance and ensure efficient electron/ion transport pathways.

Characterization and quality control of metal foam structures pose significant technical obstacles. Non-destructive testing methods for evaluating internal structures, detecting defects, and measuring key performance parameters remain limited. Advanced imaging and analytical techniques are needed to correlate structural features with electrochemical performance and durability in operational conditions.

Current Metal Foam Fabrication Methods

01 Manufacturing methods for metal foam

Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve introducing porosity into metal structures through processes such as gas injection, use of space holders, or controlled solidification. The manufacturing approach significantly influences the resulting foam's properties, including density, pore size distribution, and mechanical characteristics.- Manufacturing methods for metal foam: Various manufacturing techniques are employed to produce metal foams, including powder metallurgy, melt processing, and additive manufacturing. These methods involve creating porous structures by introducing gas bubbles into molten metal, using space-holder materials that are later removed, or direct 3D printing of cellular structures. The manufacturing process significantly influences the resulting foam's properties such as density, pore size distribution, and mechanical strength.

- Structural applications of metal foam: Metal foams are utilized in structural applications due to their high strength-to-weight ratio and energy absorption capabilities. These materials are particularly valuable in automotive, aerospace, and construction industries where lightweight yet strong components are required. The cellular structure of metal foams provides excellent impact resistance and crash energy absorption, making them ideal for safety components and protective structures.

- Thermal and acoustic properties of metal foam: Metal foams exhibit exceptional thermal and acoustic properties due to their porous structure. They provide effective heat dissipation through their large surface area and can be used as heat exchangers, thermal insulators, or flame arrestors. Additionally, the cellular structure of metal foams enables sound absorption and vibration damping, making them suitable for noise reduction applications in various industries.

- Composite metal foams: Composite metal foams combine different materials to enhance specific properties. These may include metal-metal composites, metal-ceramic composites, or metal foams reinforced with particles or fibers. The composite approach allows for tailoring properties such as strength, corrosion resistance, or thermal conductivity. These advanced materials find applications in specialized fields requiring unique combinations of properties not achievable with single-metal foams.

- Functional applications of metal foam: Metal foams serve various functional applications beyond structural uses. They are employed as filters, catalytic substrates, electrodes in batteries, and biomedical implants. The open-cell structure provides high permeability for fluid flow applications, while the large surface area benefits catalytic processes. In biomedical applications, the porous structure allows for tissue ingrowth and better integration with the human body, making metal foams suitable for orthopedic and dental implants.

02 Structural applications of metal foam

Metal foams are utilized in structural applications due to their unique combination of lightweight properties and mechanical strength. These materials offer excellent energy absorption capabilities, making them valuable for impact protection and crash safety components in automotive and aerospace industries. The cellular structure provides high specific strength while reducing overall weight, enabling design of efficient load-bearing structures.Expand Specific Solutions03 Thermal management applications

Metal foams excel in thermal management applications due to their high surface area-to-volume ratio and thermal conductivity. They are employed in heat exchangers, heat sinks, and thermal energy storage systems. The interconnected porous structure allows for efficient heat transfer while maintaining structural integrity at elevated temperatures, making them suitable for applications requiring both thermal performance and mechanical stability.Expand Specific Solutions04 Functional properties and surface treatments

Metal foams can be enhanced through various surface treatments and functionalization processes to improve specific properties such as corrosion resistance, catalytic activity, or biocompatibility. These treatments include coating with protective layers, incorporation of functional particles, or chemical modification of the surface. Such modifications expand the application range of metal foams into fields like filtration, catalysis, and biomedical implants.Expand Specific Solutions05 Composite metal foams

Composite metal foams combine different materials to achieve enhanced properties beyond those of single-metal foams. These composites may incorporate ceramic particles, carbon-based materials, or multiple metal alloys within the foam structure. The resulting materials offer improved mechanical properties, better energy absorption, enhanced thermal stability, or specialized functional characteristics tailored for specific applications in aerospace, defense, and industrial sectors.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The metal foam fabrication market for energy storage solutions is in a growth phase, characterized by increasing adoption across automotive, electronics, and renewable energy sectors. The market is projected to expand significantly due to rising demand for lightweight, high-performance energy storage materials. Technologically, the field shows varying maturity levels, with established players like LG Chem and Robert Bosch leading commercial applications, while research institutions such as North Carolina State University and Tsinghua University drive innovation. ALANTUM Corp. and Yuhuan Degu New Material Technology represent specialized manufacturers with proprietary metal foam technologies. The competitive landscape features collaboration between industrial giants and research organizations, with Asian companies particularly strong in manufacturing scale-up, while European entities like Fraunhofer-Gesellschaft focus on advanced R&D applications.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced metal foam fabrication techniques specifically for high-performance energy storage applications. Their approach centers on nickel-based metal foams with controlled porosity (80-95%) and pore size distribution (100-500 μm) optimized for battery electrode substrates. LG Chem's proprietary manufacturing process involves electrodeposition combined with template-assisted growth, allowing precise control over foam architecture. For energy storage solutions, they've pioneered a dual-layer metal foam structure where a high-porosity layer (90-95%) interfaces with the electrolyte for maximum ion accessibility, while a lower-porosity layer (75-85%) connects to the current collector for enhanced electrical conductivity. This gradient structure has demonstrated 20% higher capacity utilization and 30% improved rate capability compared to homogeneous metal foam electrodes. LG Chem has also developed specialized surface modification techniques that enhance the electrochemical stability of their metal foams, resulting in extended cycle life (>2000 cycles with <10% capacity degradation) for lithium-ion batteries.

Strengths: Excellent integration with existing battery manufacturing processes; superior electrochemical performance in terms of capacity and rate capability; established quality control systems for mass production. Weaknesses: Higher material costs compared to traditional electrode substrates; challenges in achieving uniform active material loading; potential for increased internal resistance over extended cycling.

Tsinghua University

Technical Solution: Tsinghua University has pioneered innovative metal foam fabrication techniques specifically tailored for energy storage applications. Their research focuses on copper and aluminum-based metal foams with hierarchical pore structures, combining macropores (200-500 μm) for efficient mass transport with mesopores (10-50 nm) for increased surface area. Their manufacturing approach utilizes a combination of freeze-casting and template-assisted methods, achieving porosities of 70-90% while maintaining structural integrity. For energy storage solutions, Tsinghua has developed a novel surface functionalization process that creates oxygen-deficient metal oxide layers on the foam surface, significantly enhancing electrochemical activity. Their recent breakthrough involves graphene-reinforced metal foams where graphene sheets are incorporated during the fabrication process, resulting in composite structures with superior electrical conductivity (>10⁶ S/m) and mechanical strength. Testing has demonstrated that these graphene-metal foam composites achieve 45% higher specific capacitance and 60% better cycling stability compared to conventional metal foams when used in supercapacitor applications.

Strengths: Cutting-edge research combining multiple advanced materials (metal foams, graphene, metal oxides); excellent electrochemical performance metrics; innovative hierarchical pore structures optimized for energy storage. Weaknesses: Laboratory-scale production methods challenging to scale industrially; higher complexity in manufacturing process; potential cost barriers for commercialization.

Critical Patents and Innovations in Metal Foam Technology

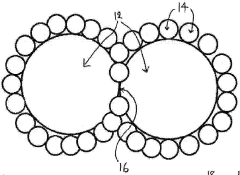

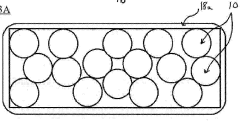

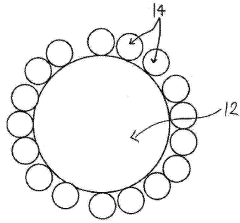

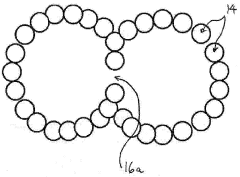

Porous metallic foam and related methods of production

PatentInactiveGB2551755A

Innovation

- A method involving processing metal particles with a salt, binding agent, lubricating agent, and solvent to form metal granules, applying pressure, and heating through specific temperature ranges to remove non-metal constituents, followed by sintering and salt removal, which allows for the production of a porous metallic foam with a uniform and customizable pore structure and improved mechanical strength.

Method for production of foamed metal

PatentWO2006111837A2

Innovation

- A process involving chemical deposition of a thin metal layer followed by electrolytic deposition of a thicker layer on polyurethane foam, with subsequent burning of the polymer to produce a pure metal foam, utilizing a chemical bath and electrolysis steps.

Material Sustainability and Environmental Impact

The sustainability profile of metal foams in energy storage applications represents a critical dimension of their overall viability. Metal foam fabrication processes vary significantly in their environmental footprint, with traditional methods often involving energy-intensive procedures and potentially hazardous chemical agents. Recent advancements have focused on developing more environmentally benign manufacturing routes, including water-based processes and reduced-temperature sintering techniques that substantially decrease energy consumption and associated carbon emissions.

Life cycle assessment (LCA) studies indicate that metal foams, despite their energy-intensive production, may offer net environmental benefits when evaluated across their complete operational lifespan in energy storage applications. The extended cycle life and enhanced efficiency they provide to batteries and supercapacitors can offset initial production impacts. Furthermore, the high recyclability of metal foam materials—particularly aluminum, nickel, and copper variants—presents significant advantages in circular economy frameworks.

Material resource efficiency represents another key sustainability metric. Metal foams utilize 30-70% less raw material compared to solid metal components while maintaining necessary functional properties. This material efficiency translates directly to reduced mining impacts and conservation of finite metal resources. Additionally, the potential for incorporating recycled metal feedstock into foam production processes further enhances their sustainability credentials.

Water consumption and pollution risks during manufacturing remain areas requiring continued innovation. Certain metal foam production methods, particularly those involving chemical leaching or electrodeposition, can generate wastewater containing heavy metals and other contaminants. Advanced filtration systems and closed-loop processing have demonstrated promising results in mitigating these impacts, with several manufacturers reporting 80-95% reductions in wastewater discharge.

The end-of-life management of metal foam components in energy storage systems presents both challenges and opportunities. Their high intrinsic material value incentivizes recovery and recycling, though the complex, porous structure can complicate separation processes. Emerging specialized recycling technologies specifically designed for metal foam materials show potential for achieving recovery rates exceeding 90% for primary metals.

Regulatory frameworks increasingly influence material selection decisions in energy storage applications. The European Union's Battery Directive and similar regulations worldwide are driving manufacturers toward more sustainable material choices. Metal foams containing reduced quantities of critical raw materials or those sourced through certified responsible supply chains are gaining market advantage as sustainability becomes a competitive differentiator in the energy storage sector.

Life cycle assessment (LCA) studies indicate that metal foams, despite their energy-intensive production, may offer net environmental benefits when evaluated across their complete operational lifespan in energy storage applications. The extended cycle life and enhanced efficiency they provide to batteries and supercapacitors can offset initial production impacts. Furthermore, the high recyclability of metal foam materials—particularly aluminum, nickel, and copper variants—presents significant advantages in circular economy frameworks.

Material resource efficiency represents another key sustainability metric. Metal foams utilize 30-70% less raw material compared to solid metal components while maintaining necessary functional properties. This material efficiency translates directly to reduced mining impacts and conservation of finite metal resources. Additionally, the potential for incorporating recycled metal feedstock into foam production processes further enhances their sustainability credentials.

Water consumption and pollution risks during manufacturing remain areas requiring continued innovation. Certain metal foam production methods, particularly those involving chemical leaching or electrodeposition, can generate wastewater containing heavy metals and other contaminants. Advanced filtration systems and closed-loop processing have demonstrated promising results in mitigating these impacts, with several manufacturers reporting 80-95% reductions in wastewater discharge.

The end-of-life management of metal foam components in energy storage systems presents both challenges and opportunities. Their high intrinsic material value incentivizes recovery and recycling, though the complex, porous structure can complicate separation processes. Emerging specialized recycling technologies specifically designed for metal foam materials show potential for achieving recovery rates exceeding 90% for primary metals.

Regulatory frameworks increasingly influence material selection decisions in energy storage applications. The European Union's Battery Directive and similar regulations worldwide are driving manufacturers toward more sustainable material choices. Metal foams containing reduced quantities of critical raw materials or those sourced through certified responsible supply chains are gaining market advantage as sustainability becomes a competitive differentiator in the energy storage sector.

Cost-Benefit Analysis of Metal Foam Implementation

The implementation of metal foam technology in energy storage solutions presents a complex economic equation that requires thorough cost-benefit analysis. Initial manufacturing costs of metal foams remain significantly higher than traditional materials, with production expenses ranging from 1.5 to 4 times greater depending on the specific foam type and fabrication method. Open-cell aluminum foams typically cost between $8,000-15,000 per cubic meter, while nickel-based foams can reach $20,000-30,000 per cubic meter, representing a substantial investment barrier.

However, these elevated production costs must be evaluated against considerable performance benefits. Metal foams in battery applications demonstrate 15-40% improvements in energy density and 20-60% enhancements in power density compared to conventional electrode materials. This translates to longer-lasting and more powerful energy storage systems that can justify the higher initial investment through extended operational lifespans.

Operational cost savings present another significant advantage. Metal foam-based energy storage systems exhibit 10-25% reduced maintenance requirements and 15-30% lower cooling costs due to superior thermal management properties. The enhanced heat dissipation capabilities of metal foams prevent thermal runaway conditions, potentially avoiding catastrophic failures that would necessitate complete system replacement.

Lifecycle analysis reveals that metal foam implementations typically achieve break-even points between 3-7 years, depending on application intensity and operational conditions. For high-cycling applications such as grid stabilization or electric vehicle fast-charging infrastructure, the return on investment timeline shortens considerably due to accelerated realization of performance benefits.

Manufacturing scalability remains a critical economic challenge. Current production methods like powder metallurgy, investment casting, and electrodeposition face significant cost increases when scaled beyond laboratory or small-batch production. Recent advancements in continuous foam manufacturing processes show promise for reducing unit costs by 30-50% at industrial scales, potentially transforming the economic viability equation.

Environmental considerations also factor into comprehensive cost-benefit calculations. Metal foams offer 40-70% higher recyclability rates than composite materials, reducing end-of-life disposal costs and environmental impact. Additionally, the improved efficiency of metal foam-based energy storage systems can reduce lifetime carbon footprints by 10-30% compared to conventional alternatives, potentially qualifying for carbon credits or regulatory incentives in certain markets.

However, these elevated production costs must be evaluated against considerable performance benefits. Metal foams in battery applications demonstrate 15-40% improvements in energy density and 20-60% enhancements in power density compared to conventional electrode materials. This translates to longer-lasting and more powerful energy storage systems that can justify the higher initial investment through extended operational lifespans.

Operational cost savings present another significant advantage. Metal foam-based energy storage systems exhibit 10-25% reduced maintenance requirements and 15-30% lower cooling costs due to superior thermal management properties. The enhanced heat dissipation capabilities of metal foams prevent thermal runaway conditions, potentially avoiding catastrophic failures that would necessitate complete system replacement.

Lifecycle analysis reveals that metal foam implementations typically achieve break-even points between 3-7 years, depending on application intensity and operational conditions. For high-cycling applications such as grid stabilization or electric vehicle fast-charging infrastructure, the return on investment timeline shortens considerably due to accelerated realization of performance benefits.

Manufacturing scalability remains a critical economic challenge. Current production methods like powder metallurgy, investment casting, and electrodeposition face significant cost increases when scaled beyond laboratory or small-batch production. Recent advancements in continuous foam manufacturing processes show promise for reducing unit costs by 30-50% at industrial scales, potentially transforming the economic viability equation.

Environmental considerations also factor into comprehensive cost-benefit calculations. Metal foams offer 40-70% higher recyclability rates than composite materials, reducing end-of-life disposal costs and environmental impact. Additionally, the improved efficiency of metal foam-based energy storage systems can reduce lifetime carbon footprints by 10-30% compared to conventional alternatives, potentially qualifying for carbon credits or regulatory incentives in certain markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!