Metal Foam Fabrication and Its Impact on Catalytic Systems

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Technology Background and Objectives

Metal foam technology has evolved significantly over the past several decades, transitioning from a laboratory curiosity to an advanced material with diverse industrial applications. Initially developed in the 1940s, metal foams gained substantial research attention in the 1990s when manufacturing processes became more refined and commercially viable. These unique materials combine the structural properties of metals with the lightweight characteristics of cellular structures, offering exceptional strength-to-weight ratios, high surface area, and excellent energy absorption capabilities.

The evolution of metal foam fabrication techniques has followed several distinct pathways, including powder metallurgy, melt gas injection, investment casting, and more recently, additive manufacturing approaches. Each method presents unique advantages and limitations regarding pore size control, density regulation, and structural integrity. The technological trajectory has consistently moved toward achieving greater precision in cellular architecture while reducing production costs and enhancing scalability.

Current research focuses on developing metal foams with tailored properties for specific applications, particularly in catalytic systems where surface area, thermal conductivity, and fluid flow characteristics are paramount. The integration of metal foams as catalyst supports represents a significant advancement over traditional pellet or monolith structures, offering improved mass transfer, reduced pressure drop, and enhanced thermal management.

The primary objectives in metal foam technology development for catalytic applications include optimizing pore morphology for maximum surface area while maintaining structural integrity, developing cost-effective fabrication methods suitable for industrial scale production, and enhancing the durability of metal foams under harsh reaction conditions. Additionally, researchers aim to improve methods for uniform catalyst deposition throughout the foam structure and develop techniques for precise control of foam composition to enhance catalytic performance.

Another critical goal is understanding the complex relationship between foam architecture and catalytic efficiency. This includes investigating how pore size distribution, strut thickness, and overall porosity affect parameters such as residence time distribution, heat transfer rates, and reaction kinetics. Computational fluid dynamics modeling has become increasingly important in predicting these relationships and guiding design optimization.

Looking forward, the field is moving toward multi-functional metal foams that can simultaneously serve as structural supports, heat exchangers, and catalytic substrates. This integration of functions could revolutionize reactor design across numerous chemical processes, from petroleum refining to environmental remediation and renewable energy applications. The ultimate technological objective remains developing sustainable, efficient, and economically viable metal foam-based catalytic systems that outperform conventional technologies across multiple performance metrics.

The evolution of metal foam fabrication techniques has followed several distinct pathways, including powder metallurgy, melt gas injection, investment casting, and more recently, additive manufacturing approaches. Each method presents unique advantages and limitations regarding pore size control, density regulation, and structural integrity. The technological trajectory has consistently moved toward achieving greater precision in cellular architecture while reducing production costs and enhancing scalability.

Current research focuses on developing metal foams with tailored properties for specific applications, particularly in catalytic systems where surface area, thermal conductivity, and fluid flow characteristics are paramount. The integration of metal foams as catalyst supports represents a significant advancement over traditional pellet or monolith structures, offering improved mass transfer, reduced pressure drop, and enhanced thermal management.

The primary objectives in metal foam technology development for catalytic applications include optimizing pore morphology for maximum surface area while maintaining structural integrity, developing cost-effective fabrication methods suitable for industrial scale production, and enhancing the durability of metal foams under harsh reaction conditions. Additionally, researchers aim to improve methods for uniform catalyst deposition throughout the foam structure and develop techniques for precise control of foam composition to enhance catalytic performance.

Another critical goal is understanding the complex relationship between foam architecture and catalytic efficiency. This includes investigating how pore size distribution, strut thickness, and overall porosity affect parameters such as residence time distribution, heat transfer rates, and reaction kinetics. Computational fluid dynamics modeling has become increasingly important in predicting these relationships and guiding design optimization.

Looking forward, the field is moving toward multi-functional metal foams that can simultaneously serve as structural supports, heat exchangers, and catalytic substrates. This integration of functions could revolutionize reactor design across numerous chemical processes, from petroleum refining to environmental remediation and renewable energy applications. The ultimate technological objective remains developing sustainable, efficient, and economically viable metal foam-based catalytic systems that outperform conventional technologies across multiple performance metrics.

Catalytic Applications Market Analysis

The global catalytic applications market is experiencing robust growth, driven by increasing demand across various industries including petrochemicals, automotive, and environmental sectors. Metal foam catalysts represent a significant innovation in this space, offering enhanced surface area and improved mass transfer properties compared to traditional catalytic systems. The market for catalytic applications was valued at approximately $24.6 billion in 2020 and is projected to reach $38.2 billion by 2027, growing at a CAGR of 6.5%.

The automotive sector remains a dominant consumer of catalytic technologies, particularly for emission control systems. With stringent environmental regulations being implemented worldwide, the demand for more efficient catalytic converters continues to rise. Metal foam-based catalytic systems are gaining traction in this segment due to their superior performance in reducing harmful emissions while using less precious metal content.

Petrochemical processing represents another substantial market segment, where catalysts are essential for refining operations and chemical synthesis. The enhanced mass transfer properties of metal foam catalysts make them particularly valuable for reactions involving multiple phases, potentially reducing energy requirements and improving yield rates by 15-20% compared to conventional packed bed reactors.

Environmental applications constitute the fastest-growing segment within the catalytic market, expanding at approximately 8.7% annually. This includes water treatment, air purification, and industrial waste processing. Metal foam catalysts show particular promise in these applications due to their high porosity and excellent fluid permeability, allowing for more efficient contaminant removal with lower pressure drops across treatment systems.

Regional analysis indicates that Asia-Pacific dominates the catalytic applications market with a 38% share, followed by North America (27%) and Europe (24%). China and India are experiencing the most rapid growth rates due to expanding industrial bases and increasing environmental regulations. The adoption of metal foam catalytic technologies is most advanced in developed economies, though emerging markets are showing accelerated uptake as manufacturing capabilities improve.

Key market drivers include increasingly stringent environmental regulations, growing industrial production, and the push for greater energy efficiency. The premium pricing of metal foam catalytic systems remains a constraint, with costs typically 30-40% higher than conventional alternatives. However, this premium is gradually decreasing as manufacturing techniques improve and production scales increase.

The automotive sector remains a dominant consumer of catalytic technologies, particularly for emission control systems. With stringent environmental regulations being implemented worldwide, the demand for more efficient catalytic converters continues to rise. Metal foam-based catalytic systems are gaining traction in this segment due to their superior performance in reducing harmful emissions while using less precious metal content.

Petrochemical processing represents another substantial market segment, where catalysts are essential for refining operations and chemical synthesis. The enhanced mass transfer properties of metal foam catalysts make them particularly valuable for reactions involving multiple phases, potentially reducing energy requirements and improving yield rates by 15-20% compared to conventional packed bed reactors.

Environmental applications constitute the fastest-growing segment within the catalytic market, expanding at approximately 8.7% annually. This includes water treatment, air purification, and industrial waste processing. Metal foam catalysts show particular promise in these applications due to their high porosity and excellent fluid permeability, allowing for more efficient contaminant removal with lower pressure drops across treatment systems.

Regional analysis indicates that Asia-Pacific dominates the catalytic applications market with a 38% share, followed by North America (27%) and Europe (24%). China and India are experiencing the most rapid growth rates due to expanding industrial bases and increasing environmental regulations. The adoption of metal foam catalytic technologies is most advanced in developed economies, though emerging markets are showing accelerated uptake as manufacturing capabilities improve.

Key market drivers include increasingly stringent environmental regulations, growing industrial production, and the push for greater energy efficiency. The premium pricing of metal foam catalytic systems remains a constraint, with costs typically 30-40% higher than conventional alternatives. However, this premium is gradually decreasing as manufacturing techniques improve and production scales increase.

Current Fabrication Methods and Technical Barriers

Metal foam fabrication has evolved significantly over the past few decades, with several established methods now dominating industrial production. Powder metallurgy remains one of the most widely employed techniques, involving the mixing of metal powders with foaming agents, followed by compaction and sintering. This method offers good control over pore size distribution but often struggles with achieving uniform cellular structures throughout larger samples.

Investment casting represents another prominent approach, where polymer foams are coated with ceramic slurry, dried, and then subjected to burnout processes to create a negative template for metal infiltration. While this technique produces high-quality open-cell structures ideal for catalytic applications, it faces limitations in terms of scalability and production costs.

Direct foaming methods have gained traction in recent years, involving the introduction of gas bubbles directly into molten metal or metal slurries. These techniques offer advantages in production speed but present significant challenges in stabilizing the foam structure before solidification occurs, often resulting in inconsistent pore morphology.

Additive manufacturing has emerged as a promising frontier for metal foam fabrication, enabling unprecedented control over structural parameters. However, current limitations in build volume, production speed, and material compatibility restrict its widespread industrial adoption for catalytic applications.

Despite these advances, several technical barriers persist across fabrication methods. Achieving precise control over pore size, distribution, and interconnectivity remains challenging, particularly when scaling to industrial production volumes. This variability directly impacts catalytic performance by affecting surface area availability and flow dynamics.

Material limitations constitute another significant barrier, as not all metals and alloys are equally amenable to foaming processes. Noble metals and specialized alloys critical for certain catalytic reactions often present processing difficulties due to high melting points or oxidation susceptibility.

Cost-effectiveness represents a persistent challenge, with many advanced fabrication techniques requiring expensive equipment, specialized expertise, or time-intensive processing steps. This economic barrier has slowed adoption in price-sensitive applications despite the performance advantages metal foams offer.

Surface functionalization of metal foams for catalytic applications presents additional technical hurdles, as conventional coating methods often struggle to achieve uniform catalyst deposition throughout complex three-dimensional structures. This challenge is particularly pronounced in hierarchical foam structures with multi-scale porosity.

Investment casting represents another prominent approach, where polymer foams are coated with ceramic slurry, dried, and then subjected to burnout processes to create a negative template for metal infiltration. While this technique produces high-quality open-cell structures ideal for catalytic applications, it faces limitations in terms of scalability and production costs.

Direct foaming methods have gained traction in recent years, involving the introduction of gas bubbles directly into molten metal or metal slurries. These techniques offer advantages in production speed but present significant challenges in stabilizing the foam structure before solidification occurs, often resulting in inconsistent pore morphology.

Additive manufacturing has emerged as a promising frontier for metal foam fabrication, enabling unprecedented control over structural parameters. However, current limitations in build volume, production speed, and material compatibility restrict its widespread industrial adoption for catalytic applications.

Despite these advances, several technical barriers persist across fabrication methods. Achieving precise control over pore size, distribution, and interconnectivity remains challenging, particularly when scaling to industrial production volumes. This variability directly impacts catalytic performance by affecting surface area availability and flow dynamics.

Material limitations constitute another significant barrier, as not all metals and alloys are equally amenable to foaming processes. Noble metals and specialized alloys critical for certain catalytic reactions often present processing difficulties due to high melting points or oxidation susceptibility.

Cost-effectiveness represents a persistent challenge, with many advanced fabrication techniques requiring expensive equipment, specialized expertise, or time-intensive processing steps. This economic barrier has slowed adoption in price-sensitive applications despite the performance advantages metal foams offer.

Surface functionalization of metal foams for catalytic applications presents additional technical hurdles, as conventional coating methods often struggle to achieve uniform catalyst deposition throughout complex three-dimensional structures. This challenge is particularly pronounced in hierarchical foam structures with multi-scale porosity.

State-of-the-Art Fabrication Techniques

01 Metal foam catalysts for emission control

Metal foams can be used as catalytic substrates for emission control systems, particularly in automotive applications. These foams provide high surface area and excellent heat transfer properties, enhancing catalytic performance for the reduction of harmful exhaust gases. The open-cell structure of metal foams allows for efficient gas flow and contact with catalytic materials, resulting in improved conversion efficiency of pollutants such as NOx, CO, and hydrocarbons.- Metal foam catalysts for emission control: Metal foams can be used as catalytic substrates for emission control systems, particularly in automotive applications. These foams provide high surface area and excellent heat transfer properties, making them effective for catalytic converters. The open-cell structure allows for efficient gas flow while maintaining good contact between exhaust gases and catalytic materials, resulting in improved conversion efficiency of harmful emissions to less harmful substances.

- Metal foam catalyst preparation methods: Various methods are employed to prepare metal foam catalysts with enhanced catalytic performance. These include impregnation techniques, electrodeposition, sol-gel methods, and direct growth of catalytic materials on foam structures. The preparation methods significantly influence the dispersion of active components, adhesion strength, and overall catalytic efficiency. Advanced preparation techniques can create hierarchical structures with optimized pore distribution for specific catalytic applications.

- Metal foam catalysts for energy applications: Metal foams serve as effective catalytic materials in various energy applications, including fuel cells, hydrogen production, and energy storage systems. Their three-dimensional structure provides excellent mass transfer properties and electrical conductivity. When functionalized with appropriate catalytic materials, these foams can enhance reaction rates and efficiency in energy conversion processes, making them valuable components in sustainable energy technologies.

- Enhanced catalytic performance through structural modifications: The catalytic performance of metal foams can be significantly enhanced through structural modifications such as pore size optimization, surface roughening, and creation of hierarchical structures. These modifications increase the specific surface area, improve mass transfer, and create more active sites for catalytic reactions. Advanced manufacturing techniques allow for precise control over foam architecture, enabling tailored designs for specific catalytic applications.

- Novel metal foam composite catalysts: Composite catalysts combining metal foams with other materials such as ceramics, carbon structures, or additional metal components demonstrate superior catalytic performance. These hybrid structures leverage the advantages of each component, resulting in synergistic effects that enhance activity, selectivity, and stability. The integration of nanomaterials with metal foam structures creates multifunctional catalysts with improved performance across various reaction conditions and applications.

02 Noble metal catalysts supported on metal foams

Noble metals such as platinum, palladium, and rhodium can be deposited on metal foam substrates to create high-performance catalysts. The combination of the porous foam structure with noble metal catalysts provides enhanced catalytic activity due to increased active sites and improved mass transfer. These catalysts exhibit excellent durability and resistance to thermal degradation, making them suitable for high-temperature catalytic reactions in various industrial processes.Expand Specific Solutions03 Metal foam catalysts for fuel cell applications

Metal foams serve as effective catalyst supports in fuel cell systems, offering advantages such as high electrical conductivity, mechanical stability, and enhanced mass transport. The three-dimensional structure of metal foams facilitates efficient distribution of reactant gases and removal of reaction products, improving overall fuel cell performance. These catalysts demonstrate superior durability under the operating conditions of fuel cells, contributing to extended service life and consistent power output.Expand Specific Solutions04 Manufacturing methods for metal foam catalysts

Various manufacturing techniques have been developed to produce metal foam catalysts with optimized properties for specific applications. These methods include powder metallurgy, electrodeposition, chemical vapor deposition, and sol-gel processes. The manufacturing approach significantly influences the foam's structural characteristics, such as pore size distribution, porosity, and specific surface area, which in turn affect catalytic performance. Advanced manufacturing techniques enable precise control over these parameters to tailor the catalyst properties for maximum efficiency.Expand Specific Solutions05 Metal foam catalysts for chemical processing

Metal foam-based catalysts offer significant advantages in chemical processing applications, including hydrogenation, oxidation, and reforming reactions. The high thermal conductivity of metal foams helps to dissipate heat effectively, preventing hot spots and improving reaction selectivity. The open-cell structure minimizes pressure drop while maximizing contact between reactants and catalytic sites. These catalysts demonstrate enhanced activity, selectivity, and stability compared to conventional catalyst supports, leading to improved process efficiency and product yield.Expand Specific Solutions

Industry Leaders and Competitive Landscape

Metal foam fabrication technology is currently in a growth phase, with the global market expected to expand significantly due to increasing applications in catalytic systems. The technology maturity varies across players, with established chemical companies like Evonik Operations GmbH, LG Chem, and Air Liquide leading commercial development. Research institutions such as Fraunhofer-Gesellschaft, Tsinghua University, and North Carolina State University are advancing fundamental innovations. ALANTUM Corp. and its European subsidiary have specialized expertise in metal foam manufacturing, while companies like Sinopec and BYD are exploring catalytic applications for energy and automotive sectors. The integration of metal foams in catalytic systems represents a convergent technology trend with significant potential for efficiency improvements in chemical processes, emissions control, and energy applications.

Evonik Operations GmbH

Technical Solution: Evonik has developed advanced metal foam fabrication techniques focusing on high-performance catalytic applications. Their proprietary SEPURAN® technology incorporates metal foams as structural supports for catalysts, enabling enhanced mass transfer and reaction efficiency. The company utilizes precision electrodeposition methods to create open-cell metal foams with controlled pore sizes (typically 0.5-5mm) and porosities exceeding 90%. These structures are then functionalized with noble metal catalysts through specialized coating processes that ensure uniform distribution and strong adhesion. Evonik's metal foams feature hierarchical structures that combine macro, meso, and micropores to maximize surface area while maintaining mechanical stability and thermal conductivity. This approach has demonstrated up to 40% higher catalytic efficiency compared to conventional pellet catalysts in industrial chemical processes.

Strengths: Superior control over pore architecture and distribution; excellent thermal management properties; enhanced catalyst utilization efficiency. Weaknesses: Higher production costs compared to traditional catalyst supports; potential for metal leaching in certain chemical environments; challenges in scaling up production while maintaining structural uniformity.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced metal foam technologies primarily focused on energy storage and catalytic applications. Their proprietary process combines powder metallurgy with controlled foaming agents to create aluminum and nickel-based foams with porosities ranging from 85-95%. For catalytic applications, LG Chem employs a specialized electrochemical deposition technique that creates nanoscale catalyst coatings on the foam surfaces, achieving catalyst loadings of 0.1-5.0 mg/cm² depending on application requirements. Their metal foams feature gradient porosity structures that optimize flow distribution and reaction kinetics. LG Chem's recent innovations include incorporating rare earth elements into the foam matrix to enhance catalytic performance and stability, particularly for hydrogen production and fuel cell applications. Their metal foam catalysts have demonstrated up to 30% reduction in precious metal loading while maintaining equivalent performance to conventional systems.

Strengths: Excellent mass production capabilities; strong integration with existing chemical manufacturing processes; advanced surface modification techniques. Weaknesses: Less specialized in ultra-high temperature applications; relatively new entrant to specialized catalytic foam market; some dependency on rare earth materials that face supply chain challenges.

Key Patents in Metal Foam Catalytic Systems

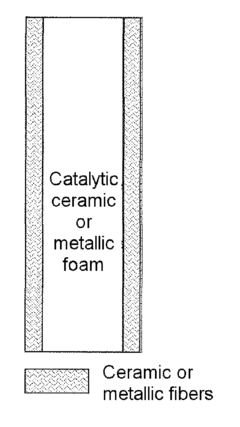

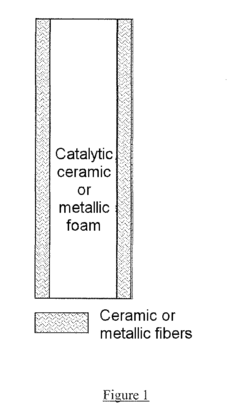

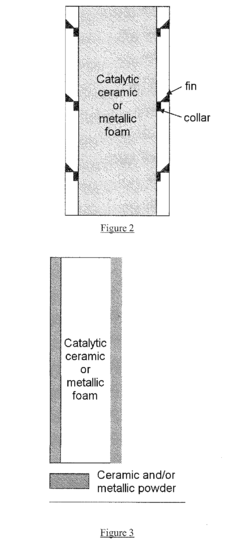

Catalytic Reactor Including a Cell-Like Structure and Elements Optimizing the Contact Thereof with the Inner Wall of the Reactor

PatentActiveUS20120235096A1

Innovation

- Incorporating a second structure in the annular space between the cellular architectures and the reaction chamber wall, such as a fibrous structure, a metal collar with fins, or metallic/ceramic powder, to enhance contact and adapt to dimensional variations, improving heat transfer and flow distribution.

Patent

Innovation

- Development of hierarchical metal foam structures with controlled porosity at multiple scales, enhancing both mechanical stability and catalytic surface area for improved reaction efficiency.

- Novel surface functionalization methods for metal foams that enable selective catalyst deposition and enhanced catalyst-support interactions, leading to improved catalytic activity and selectivity.

- Implementation of bimetallic or multi-metallic foam compositions that combine structural support properties with intrinsic catalytic activity, reducing the need for additional catalyst loading.

Environmental Impact and Sustainability Factors

Metal foam fabrication processes have significant environmental implications that must be considered in their development and application within catalytic systems. Traditional manufacturing methods for metal foams often involve energy-intensive processes and potentially hazardous materials, resulting in considerable carbon footprints. However, recent advancements in production techniques have demonstrated promising reductions in environmental impact through optimized energy consumption and material utilization.

The sustainability profile of metal foams in catalytic applications presents a complex balance of benefits and challenges. On the positive side, metal foam catalysts typically require less precious metal loading than conventional catalysts while maintaining equivalent or superior performance. This reduction in rare metal usage contributes to resource conservation and mitigates environmental degradation associated with mining activities.

Metal foam catalysts also demonstrate extended operational lifespans compared to traditional catalytic systems, reducing replacement frequency and associated waste generation. Their enhanced durability stems from superior mechanical properties and resistance to thermal cycling, which translates to fewer disposal issues and decreased material consumption over time.

Recycling potential represents another significant sustainability advantage of metal foam catalytic systems. The monolithic structure of metal foams facilitates easier recovery and recycling of precious metals compared to powder-based catalysts. Advanced recovery techniques can reclaim up to 95% of precious metals from spent metal foam catalysts, creating a more circular material economy.

Energy efficiency improvements in catalytic processes utilizing metal foams contribute substantially to their environmental benefits. The enhanced mass and heat transfer properties of metal foams enable reactions to proceed at lower temperatures or with reduced energy inputs, potentially decreasing greenhouse gas emissions from industrial processes by 15-30% in certain applications.

Water usage considerations also favor metal foam catalysts in many scenarios. Their open-cell structure allows for more efficient liquid-phase reactions with reduced pressure drops, minimizing pumping energy requirements and associated water consumption in continuous flow processes.

Despite these advantages, challenges remain in achieving truly sustainable metal foam production. Current fabrication methods still generate waste streams containing potentially harmful chemical agents. Research into green chemistry approaches and bio-inspired manufacturing techniques shows promise for developing environmentally benign production pathways that maintain the exceptional properties of metal foams while eliminating toxic precursors and byproducts.

The sustainability profile of metal foams in catalytic applications presents a complex balance of benefits and challenges. On the positive side, metal foam catalysts typically require less precious metal loading than conventional catalysts while maintaining equivalent or superior performance. This reduction in rare metal usage contributes to resource conservation and mitigates environmental degradation associated with mining activities.

Metal foam catalysts also demonstrate extended operational lifespans compared to traditional catalytic systems, reducing replacement frequency and associated waste generation. Their enhanced durability stems from superior mechanical properties and resistance to thermal cycling, which translates to fewer disposal issues and decreased material consumption over time.

Recycling potential represents another significant sustainability advantage of metal foam catalytic systems. The monolithic structure of metal foams facilitates easier recovery and recycling of precious metals compared to powder-based catalysts. Advanced recovery techniques can reclaim up to 95% of precious metals from spent metal foam catalysts, creating a more circular material economy.

Energy efficiency improvements in catalytic processes utilizing metal foams contribute substantially to their environmental benefits. The enhanced mass and heat transfer properties of metal foams enable reactions to proceed at lower temperatures or with reduced energy inputs, potentially decreasing greenhouse gas emissions from industrial processes by 15-30% in certain applications.

Water usage considerations also favor metal foam catalysts in many scenarios. Their open-cell structure allows for more efficient liquid-phase reactions with reduced pressure drops, minimizing pumping energy requirements and associated water consumption in continuous flow processes.

Despite these advantages, challenges remain in achieving truly sustainable metal foam production. Current fabrication methods still generate waste streams containing potentially harmful chemical agents. Research into green chemistry approaches and bio-inspired manufacturing techniques shows promise for developing environmentally benign production pathways that maintain the exceptional properties of metal foams while eliminating toxic precursors and byproducts.

Scale-up Challenges and Industrial Implementation

The transition from laboratory-scale production to industrial implementation of metal foam catalytic systems presents significant challenges that must be addressed for commercial viability. Current manufacturing processes for metal foams, including powder metallurgy, investment casting, and electrodeposition methods, face considerable difficulties when scaled to industrial volumes. These challenges primarily stem from maintaining consistent structural properties, such as porosity distribution, pore size, and interconnectivity across larger dimensions.

Production consistency represents a major hurdle, as variations in foam structure can lead to unpredictable catalytic performance. Industrial-scale metal foam production requires precise control over processing parameters including temperature gradients, gas flow rates, and solidification conditions. Even minor deviations can result in structural defects that compromise the foam's mechanical integrity and catalytic efficiency.

Cost considerations also significantly impact industrial implementation. The raw materials for high-performance metal foams, particularly those incorporating noble metals as catalysts, involve substantial investment. Manufacturing equipment for large-scale production requires specialized facilities capable of handling molten metals, controlled atmospheres, and precise thermal management systems, further increasing capital expenditure requirements.

Quality control methodologies present another challenge, as conventional testing procedures developed for solid materials often prove inadequate for characterizing metal foams. Non-destructive evaluation techniques must be adapted or newly developed to assess internal structural features without compromising the foam's integrity. This includes advanced imaging technologies such as industrial CT scanning and specialized mechanical testing protocols.

Environmental and safety regulations add complexity to industrial implementation. Metal foam production processes often involve hazardous materials, high temperatures, and potentially toxic byproducts. Scaling up requires comprehensive environmental management systems and worker safety protocols that comply with increasingly stringent regulations across different jurisdictions.

Integration with existing manufacturing infrastructure presents practical challenges. Many catalytic applications require metal foams to be incorporated into complex systems or devices, necessitating compatible connection methods, sealing technologies, and assembly processes. The development of standardized interfaces and joining techniques remains an active area of research critical to widespread adoption.

Despite these challenges, several companies have made significant progress in commercializing metal foam catalytic systems. These early adopters have developed proprietary solutions to address scale-up issues, often through iterative process optimization and substantial R&D investment. Their experiences demonstrate that while difficult, industrial implementation is achievable with appropriate technical expertise and capital resources.

Production consistency represents a major hurdle, as variations in foam structure can lead to unpredictable catalytic performance. Industrial-scale metal foam production requires precise control over processing parameters including temperature gradients, gas flow rates, and solidification conditions. Even minor deviations can result in structural defects that compromise the foam's mechanical integrity and catalytic efficiency.

Cost considerations also significantly impact industrial implementation. The raw materials for high-performance metal foams, particularly those incorporating noble metals as catalysts, involve substantial investment. Manufacturing equipment for large-scale production requires specialized facilities capable of handling molten metals, controlled atmospheres, and precise thermal management systems, further increasing capital expenditure requirements.

Quality control methodologies present another challenge, as conventional testing procedures developed for solid materials often prove inadequate for characterizing metal foams. Non-destructive evaluation techniques must be adapted or newly developed to assess internal structural features without compromising the foam's integrity. This includes advanced imaging technologies such as industrial CT scanning and specialized mechanical testing protocols.

Environmental and safety regulations add complexity to industrial implementation. Metal foam production processes often involve hazardous materials, high temperatures, and potentially toxic byproducts. Scaling up requires comprehensive environmental management systems and worker safety protocols that comply with increasingly stringent regulations across different jurisdictions.

Integration with existing manufacturing infrastructure presents practical challenges. Many catalytic applications require metal foams to be incorporated into complex systems or devices, necessitating compatible connection methods, sealing technologies, and assembly processes. The development of standardized interfaces and joining techniques remains an active area of research critical to widespread adoption.

Despite these challenges, several companies have made significant progress in commercializing metal foam catalytic systems. These early adopters have developed proprietary solutions to address scale-up issues, often through iterative process optimization and substantial R&D investment. Their experiences demonstrate that while difficult, industrial implementation is achievable with appropriate technical expertise and capital resources.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!