How Do Coating Technologies Integrate with Metal Foam Fabrication?

OCT 15, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Metal Foam Coating Background & Objectives

Metal foam technology has evolved significantly since its inception in the 1940s, transitioning from laboratory curiosity to engineered material with diverse industrial applications. The integration of coating technologies with metal foam fabrication represents a critical advancement in enhancing the performance characteristics and application scope of these unique cellular materials. Metal foams, characterized by their high porosity (typically 75-95%) and distinctive cellular structure, offer exceptional properties including high specific strength, excellent energy absorption, and superior thermal management capabilities.

The evolution of metal foam coating technologies has been driven by increasing demands for materials that can withstand extreme environments while maintaining structural integrity. Early developments focused primarily on basic protective coatings, while contemporary research explores multifunctional surface treatments that can simultaneously address multiple performance requirements such as corrosion resistance, wear protection, catalytic activity, and biocompatibility.

The primary objective of integrating coating technologies with metal foam fabrication is to overcome inherent limitations of base metal foams, particularly their susceptibility to corrosion, oxidation, and mechanical degradation in aggressive environments. Additionally, coatings aim to impart specialized functionalities that expand application possibilities across aerospace, automotive, biomedical, energy, and environmental sectors.

Current technological objectives include developing seamless integration methods that preserve the foam's porous architecture while ensuring uniform coating distribution throughout the complex three-dimensional structure. This presents significant challenges due to the intricate geometry and variable pore sizes characteristic of metal foams. Research efforts are focused on optimizing coating methodologies that can penetrate the internal structure without blocking pores or compromising the foam's beneficial properties.

Another critical goal is establishing scalable and economically viable coating processes suitable for industrial implementation. While laboratory-scale coating techniques have demonstrated promising results, translating these approaches to commercial production remains challenging. The development of cost-effective coating solutions that can be applied during or post-foam fabrication represents a key technological target.

Looking forward, the field is moving toward smart coating systems that can respond to environmental stimuli, self-healing coatings that extend service life, and environmentally friendly coating processes that minimize ecological impact. The convergence of nanotechnology, advanced materials science, and precision engineering is expected to drive innovations in metal foam coating technologies, enabling next-generation materials with unprecedented performance characteristics and application versatility.

The evolution of metal foam coating technologies has been driven by increasing demands for materials that can withstand extreme environments while maintaining structural integrity. Early developments focused primarily on basic protective coatings, while contemporary research explores multifunctional surface treatments that can simultaneously address multiple performance requirements such as corrosion resistance, wear protection, catalytic activity, and biocompatibility.

The primary objective of integrating coating technologies with metal foam fabrication is to overcome inherent limitations of base metal foams, particularly their susceptibility to corrosion, oxidation, and mechanical degradation in aggressive environments. Additionally, coatings aim to impart specialized functionalities that expand application possibilities across aerospace, automotive, biomedical, energy, and environmental sectors.

Current technological objectives include developing seamless integration methods that preserve the foam's porous architecture while ensuring uniform coating distribution throughout the complex three-dimensional structure. This presents significant challenges due to the intricate geometry and variable pore sizes characteristic of metal foams. Research efforts are focused on optimizing coating methodologies that can penetrate the internal structure without blocking pores or compromising the foam's beneficial properties.

Another critical goal is establishing scalable and economically viable coating processes suitable for industrial implementation. While laboratory-scale coating techniques have demonstrated promising results, translating these approaches to commercial production remains challenging. The development of cost-effective coating solutions that can be applied during or post-foam fabrication represents a key technological target.

Looking forward, the field is moving toward smart coating systems that can respond to environmental stimuli, self-healing coatings that extend service life, and environmentally friendly coating processes that minimize ecological impact. The convergence of nanotechnology, advanced materials science, and precision engineering is expected to drive innovations in metal foam coating technologies, enabling next-generation materials with unprecedented performance characteristics and application versatility.

Market Applications Analysis

The integration of coating technologies with metal foam fabrication has created significant market opportunities across multiple industries. The aerospace sector represents one of the most promising application areas, where coated metal foams are increasingly utilized for lightweight structural components that require both thermal resistance and mechanical strength. These materials enable weight reduction of up to 30% compared to traditional solid metals while maintaining necessary performance characteristics, translating to substantial fuel efficiency improvements in aircraft and spacecraft applications.

In the automotive industry, coated metal foams are gaining traction for crash absorption structures, catalytic converter substrates, and heat shields. The market for these applications is expanding as manufacturers seek to meet stringent emissions regulations while improving vehicle safety and performance. The ability of coated metal foams to combine thermal insulation with structural integrity makes them particularly valuable for electric vehicle battery enclosures, where thermal management is critical.

The energy sector presents another substantial market opportunity, particularly in heat exchangers, fuel cells, and battery technologies. Coated metal foams offer enhanced surface area and controlled porosity that significantly improve heat transfer efficiency and energy storage capabilities. The renewable energy market specifically values these materials for solar thermal collectors and advanced battery electrode structures.

Medical device manufacturing represents a high-value niche application area where coated metal foams are utilized for orthopedic implants and tissue scaffolds. The biocompatible coatings applied to metal foam structures promote osseointegration while the porous structure mimics natural bone architecture. This market segment commands premium pricing due to stringent regulatory requirements and specialized performance needs.

Industrial filtration systems constitute a growing application area, with coated metal foams providing superior filtration efficiency for high-temperature gas and liquid processing. The chemical resistance provided by specialized coatings extends the operational lifetime of these filtration systems in harsh industrial environments.

The building and construction sector is adopting coated metal foams for acoustic dampening, fire resistance, and thermal insulation applications. The combination of lightweight properties with enhanced functionality addresses multiple building performance requirements simultaneously, creating value for architects and builders seeking multifunctional materials.

Defense applications represent a specialized but significant market segment, where coated metal foams are utilized for blast mitigation, ballistic protection, and signature management systems. The ability to engineer specific properties through coating selection makes these materials highly adaptable to specialized defense requirements.

In the automotive industry, coated metal foams are gaining traction for crash absorption structures, catalytic converter substrates, and heat shields. The market for these applications is expanding as manufacturers seek to meet stringent emissions regulations while improving vehicle safety and performance. The ability of coated metal foams to combine thermal insulation with structural integrity makes them particularly valuable for electric vehicle battery enclosures, where thermal management is critical.

The energy sector presents another substantial market opportunity, particularly in heat exchangers, fuel cells, and battery technologies. Coated metal foams offer enhanced surface area and controlled porosity that significantly improve heat transfer efficiency and energy storage capabilities. The renewable energy market specifically values these materials for solar thermal collectors and advanced battery electrode structures.

Medical device manufacturing represents a high-value niche application area where coated metal foams are utilized for orthopedic implants and tissue scaffolds. The biocompatible coatings applied to metal foam structures promote osseointegration while the porous structure mimics natural bone architecture. This market segment commands premium pricing due to stringent regulatory requirements and specialized performance needs.

Industrial filtration systems constitute a growing application area, with coated metal foams providing superior filtration efficiency for high-temperature gas and liquid processing. The chemical resistance provided by specialized coatings extends the operational lifetime of these filtration systems in harsh industrial environments.

The building and construction sector is adopting coated metal foams for acoustic dampening, fire resistance, and thermal insulation applications. The combination of lightweight properties with enhanced functionality addresses multiple building performance requirements simultaneously, creating value for architects and builders seeking multifunctional materials.

Defense applications represent a specialized but significant market segment, where coated metal foams are utilized for blast mitigation, ballistic protection, and signature management systems. The ability to engineer specific properties through coating selection makes these materials highly adaptable to specialized defense requirements.

Current Coating Integration Challenges

The integration of coating technologies with metal foam fabrication presents several significant technical challenges that currently limit widespread industrial adoption. Surface complexity represents the primary obstacle, as metal foams feature intricate three-dimensional porous structures with high surface area-to-volume ratios and numerous internal cavities. These geometrical characteristics make it extremely difficult to achieve uniform coating deposition throughout the entire structure, particularly in deep recesses and interconnected pores.

Adhesion issues constitute another major challenge, as the inherent surface properties of metal foams—including variable surface energies and potential contamination from manufacturing processes—can significantly impair coating adhesion. The thermal expansion mismatch between coating materials and metal foam substrates further exacerbates this problem, often leading to coating delamination or cracking during thermal cycling operations.

Process compatibility constraints also limit integration options. Many conventional coating technologies require processing conditions (such as high temperatures or aggressive chemical environments) that can compromise the structural integrity of metal foams, particularly those with lower melting points or thin strut architectures. Additionally, certain coating methods rely on line-of-sight deposition, making them fundamentally unsuitable for coating internal structures of metal foams.

Quality control and characterization present formidable technical barriers. Current inspection technologies struggle to effectively evaluate coating uniformity, thickness, and adhesion within the complex internal geometry of metal foams. Non-destructive testing methods often lack sufficient resolution to detect coating defects in these intricate structures, while destructive testing provides only limited sampling data that may not represent the entire component.

Scale-up challenges further complicate industrial implementation. Many laboratory-scale coating techniques that show promise for metal foams face significant hurdles when transitioning to production volumes. Issues include process time constraints, equipment limitations, and difficulties maintaining consistent quality across larger components or batch processing scenarios.

Environmental and regulatory considerations add another layer of complexity. Traditional coating processes often involve hazardous chemicals, volatile organic compounds, or energy-intensive procedures that face increasing regulatory scrutiny. Developing environmentally sustainable coating integration methods that comply with evolving regulations while maintaining performance requirements represents a significant ongoing challenge for the industry.

Adhesion issues constitute another major challenge, as the inherent surface properties of metal foams—including variable surface energies and potential contamination from manufacturing processes—can significantly impair coating adhesion. The thermal expansion mismatch between coating materials and metal foam substrates further exacerbates this problem, often leading to coating delamination or cracking during thermal cycling operations.

Process compatibility constraints also limit integration options. Many conventional coating technologies require processing conditions (such as high temperatures or aggressive chemical environments) that can compromise the structural integrity of metal foams, particularly those with lower melting points or thin strut architectures. Additionally, certain coating methods rely on line-of-sight deposition, making them fundamentally unsuitable for coating internal structures of metal foams.

Quality control and characterization present formidable technical barriers. Current inspection technologies struggle to effectively evaluate coating uniformity, thickness, and adhesion within the complex internal geometry of metal foams. Non-destructive testing methods often lack sufficient resolution to detect coating defects in these intricate structures, while destructive testing provides only limited sampling data that may not represent the entire component.

Scale-up challenges further complicate industrial implementation. Many laboratory-scale coating techniques that show promise for metal foams face significant hurdles when transitioning to production volumes. Issues include process time constraints, equipment limitations, and difficulties maintaining consistent quality across larger components or batch processing scenarios.

Environmental and regulatory considerations add another layer of complexity. Traditional coating processes often involve hazardous chemicals, volatile organic compounds, or energy-intensive procedures that face increasing regulatory scrutiny. Developing environmentally sustainable coating integration methods that comply with evolving regulations while maintaining performance requirements represents a significant ongoing challenge for the industry.

Current Integration Methods

01 Electrochemical coating methods for metal foams

Electrochemical processes can be used to apply uniform coatings on metal foam structures. These techniques include electroplating, electrodeposition, and anodizing, which allow for precise control of coating thickness and composition. The electrochemical approach is particularly effective for complex foam geometries, ensuring penetration of the coating solution throughout the porous structure. These methods can enhance corrosion resistance, catalytic activity, and mechanical properties of metal foams.- Electrochemical coating methods for metal foams: Electrochemical coating techniques are used to deposit protective or functional layers onto metal foam structures. These methods include electroplating, electroless plating, and anodization processes that create uniform coatings even on complex foam geometries. The coatings can enhance corrosion resistance, electrical conductivity, or catalytic properties while maintaining the foam's porosity and surface area advantages. These techniques allow for precise control of coating thickness and composition.

- Thermal spray coating for metal foam reinforcement: Thermal spray coating technologies are applied to metal foams to enhance their mechanical properties and durability. These processes involve projecting molten or semi-molten materials onto the foam surface using high-temperature, high-velocity gas streams. The resulting coatings can significantly improve wear resistance, thermal insulation, and structural integrity while maintaining the lightweight nature of the foam. Various materials including ceramics, metals, and composites can be applied using plasma spray, flame spray, or high-velocity oxy-fuel techniques.

- Chemical vapor deposition for uniform coating of metal foams: Chemical vapor deposition (CVD) techniques enable the creation of highly uniform and conformal coatings on metal foam structures. This process involves exposing the foam substrate to volatile precursors that react or decompose on the surface to produce the desired coating. CVD methods can penetrate deep into the foam's porous structure, ensuring complete coverage even in internal cavities. These coatings can provide enhanced functionality such as catalytic activity, biocompatibility, or specific surface properties while preserving the foam's open-cell structure.

- Sol-gel coating methods for metal foam functionalization: Sol-gel coating technologies offer a versatile approach for functionalizing metal foam surfaces at relatively low processing temperatures. This wet-chemical technique involves the transition of a solution system from a liquid sol into a solid gel network. When applied to metal foams, sol-gel coatings can provide corrosion protection, thermal barriers, or specific chemical functionalities. The process allows for precise control of coating composition and thickness, and can incorporate various additives to create multifunctional surfaces while maintaining the foam's porosity.

- Polymer and composite coating systems for metal foams: Polymer and composite coating systems are applied to metal foams to enhance their properties and expand application possibilities. These coatings can be applied through dip coating, spray coating, or infiltration methods to create protective layers or add functionality. The polymer matrices can be reinforced with particles or fibers to improve mechanical strength, thermal stability, or specific functional properties. These coating systems are particularly valuable for applications requiring biocompatibility, chemical resistance, or specialized surface interactions while preserving the foam structure.

02 Thermal spray coating techniques for metal foam

Thermal spray coating technologies provide robust surface treatments for metal foams. These processes involve projecting heated or melted materials onto the foam surface to form a coating. Techniques include plasma spraying, flame spraying, and high-velocity oxy-fuel coating. These methods are suitable for applying ceramic, metallic, or composite coatings that enhance wear resistance, thermal insulation, and functional properties of metal foams while maintaining their porous structure.Expand Specific Solutions03 Chemical vapor deposition for metal foam coating

Chemical vapor deposition (CVD) techniques enable the application of thin, uniform coatings on metal foam substrates. In this process, precursor gases react or decompose on the foam surface to form a solid coating. CVD methods can create conformal coatings even on complex foam architectures with high aspect ratios. These techniques are particularly valuable for applying functional coatings that enhance catalytic performance, electrical conductivity, or biocompatibility of metal foams.Expand Specific Solutions04 Sol-gel coating processes for metal foam functionalization

Sol-gel technology offers a versatile approach for coating metal foams with oxide or ceramic materials. This wet-chemical technique involves the transition of a solution system from a liquid sol into a solid gel phase. The process allows for precise control of coating composition and thickness, even on complex foam geometries. Sol-gel coatings can enhance the chemical stability, thermal resistance, and functional properties of metal foams while preserving their porous structure and lightweight characteristics.Expand Specific Solutions05 Polymer and composite coating systems for metal foams

Polymer-based and composite coating systems provide versatile solutions for metal foam integration. These coatings can be applied through dip coating, spray coating, or infiltration methods to achieve uniform coverage throughout the foam structure. Polymer coatings offer benefits such as corrosion protection, biocompatibility, and enhanced functional properties. Composite coatings, combining polymers with ceramic or metallic particles, can further improve mechanical strength, thermal stability, and specialized functionalities of metal foam components.Expand Specific Solutions

Leading Industry Players

The metal foam coating technology market is currently in a growth phase, characterized by increasing integration of advanced coating solutions with metal foam fabrication processes. The global market size is expanding rapidly, driven by applications in automotive, aerospace, and energy sectors. From a technical maturity perspective, established players like Fraunhofer-Gesellschaft, ALANTUM Corp., and HAVEL metal foam GmbH have developed commercial-scale production capabilities, while research institutions such as Tsinghua University, RWTH Aachen, and Virginia Tech are advancing fundamental innovations. Companies like LG Chem, Honda Motor, and Siemens Energy are integrating these technologies into industrial applications, creating a competitive landscape that balances academic research with commercial implementation. The sector is witnessing significant cross-industry collaboration between material science specialists and end-use manufacturers.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has pioneered several innovative coating technologies specifically designed for metal foam applications across multiple industries. Their approach integrates coating processes with foam fabrication through a comprehensive systems engineering methodology. One of their key technologies is the "Hybrid-PVD" process, which combines physical vapor deposition with plasma-enhanced chemical vapor deposition to create multifunctional coatings on open-cell metal foams. This technique allows precise control of coating thickness (ranging from nanometers to micrometers) while maintaining the open porosity critical for fluid flow applications. For biomedical applications, Fraunhofer has developed biocompatible hydroxyapatite coatings applied to titanium foams using a modified sol-gel process, creating implantable structures that promote osseointegration. Their research has demonstrated a 40% improvement in bone-implant interface strength compared to uncoated titanium foams. Additionally, Fraunhofer has developed specialized high-temperature ceramic coatings for metal foams used in industrial filtration and catalysis, capable of withstanding temperatures up to 1200°C while providing protection against oxidation and corrosion.

Strengths: Exceptional coating uniformity even on complex 3D foam structures; ability to create multifunctional coatings with tailored properties; extensive characterization capabilities ensure quality control. Weaknesses: Some coating processes remain at laboratory scale with challenges in industrial scaling; higher production costs compared to conventional materials; certain specialized coatings require precise environmental controls during application.

ALANTUM Corp.

Technical Solution: ALANTUM has developed proprietary coating technologies specifically designed for metal foam applications. Their process involves a multi-stage approach where open-cell metal foams (primarily nickel, nickel-chromium, and FeCrAl alloys) undergo specialized surface treatments before applying functional coatings. The company utilizes both wet chemical deposition and physical vapor deposition (PVD) methods to create tailored surface properties. Their signature technology includes catalytic washcoating for automotive applications, where precious metals (Pt, Pd, Rh) are precisely deposited on high-temperature resistant metal foam substrates. This creates effective catalytic converters with significantly reduced precious metal loading compared to conventional ceramic substrates. ALANTUM has also pioneered hydrophobic/hydrophilic coatings for their metal foams to enhance specific filtration and separation processes in industrial applications.

Strengths: Superior adhesion of catalytic coatings to metal substrates compared to ceramic alternatives; precise control of coating thickness down to nanometer scale; excellent thermal cycling resistance due to matched thermal expansion coefficients. Weaknesses: Higher initial production costs compared to traditional substrates; limited scalability for certain specialized coating processes; potential for coating degradation in extremely corrosive environments.

Key Coating-Foam Patents

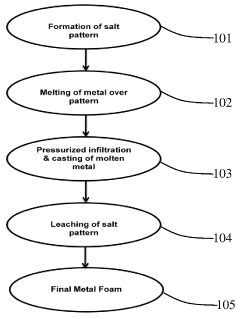

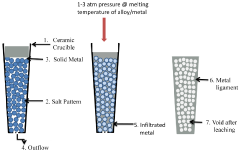

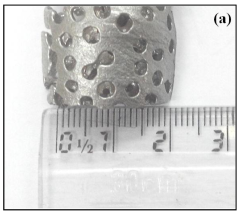

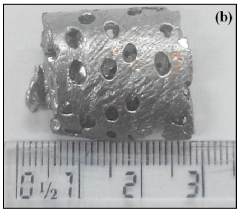

Process for synthesizing metallic foams having controlled shape, size and uniform distribution of the pores

PatentInactiveIN742DEL2015A

Innovation

- A process involving pressurized infiltration and casting of molten metallic materials over custom-made salt patterns, followed by leaching out the salt to produce metallic foams with controlled shape, size, and uniform distribution of open cells, using an inert atmosphere and specific crucible materials.

Method and device for producing composite materials comprising a core consisting of metallic foam

PatentWO2002016064A1

Innovation

- A method and device that involve rolling a cooled metal foam body with heated cover layers to create a metallic bond, using continuous or semi-continuous processes, and employing heating devices to control temperature, with pretreatment of surfaces to ensure cleanliness and oxide removal, allowing for large-scale production with high temperature resistance.

Material Compatibility Analysis

The integration of coating technologies with metal foam fabrication requires careful consideration of material compatibility factors. Different coating materials interact uniquely with various metal foam substrates, creating complex interfaces that significantly impact the final product performance. Aluminum foams typically exhibit excellent compatibility with ceramic coatings such as alumina and titania, while nickel-based foams show superior adhesion with chromium-based coatings. These compatibility relationships are governed by factors including thermal expansion coefficients, chemical reactivity, and interfacial bonding mechanisms.

Surface chemistry plays a crucial role in determining coating adhesion to metal foam structures. Pre-treatment processes such as plasma activation, chemical etching, or mechanical roughening can modify surface energy states and improve wettability, thereby enhancing coating-substrate compatibility. Research indicates that matching the electrochemical potential between coating and substrate materials minimizes galvanic corrosion risks, particularly important in applications exposed to electrolytic environments.

Thermal processing parameters significantly influence material compatibility during integration. The sintering temperature profile must accommodate both the metal foam's structural integrity and the coating material's consolidation requirements. Excessive temperatures may trigger undesired intermetallic compound formation at the interface, while insufficient thermal energy may result in poor adhesion. Studies show that controlled atmosphere processing (using inert gases or vacuum) can prevent oxidation reactions that would otherwise compromise compatibility.

Porosity characteristics of the metal foam substrate directly affect coating penetration and distribution. Open-cell foams with interconnected pores allow deeper coating penetration but may suffer from non-uniform coverage in interior regions. Closed-cell foams present challenges for coating infiltration but offer more predictable surface coverage. Recent advances in suspension and solution-based coating techniques have improved compatibility with high-porosity foams by modifying rheological properties to match specific pore architectures.

Mechanical stress considerations represent another critical compatibility factor. Differences in elastic moduli between coating and substrate materials can lead to stress concentration at interfaces during loading cycles. This mismatch potentially results in coating delamination or cracking. Research demonstrates that gradient coating approaches, where composition gradually transitions between substrate and final coating material, significantly improve mechanical compatibility by distributing stress more evenly across the interface region.

Emerging research focuses on developing adaptive coating systems specifically engineered for metal foam compatibility. These include self-healing coatings containing microcapsules that release repair agents when damaged, and stimuli-responsive coatings that can adjust their properties based on environmental conditions. Such advanced coating technologies promise to overcome traditional compatibility limitations and expand the application range of coated metal foam components.

Surface chemistry plays a crucial role in determining coating adhesion to metal foam structures. Pre-treatment processes such as plasma activation, chemical etching, or mechanical roughening can modify surface energy states and improve wettability, thereby enhancing coating-substrate compatibility. Research indicates that matching the electrochemical potential between coating and substrate materials minimizes galvanic corrosion risks, particularly important in applications exposed to electrolytic environments.

Thermal processing parameters significantly influence material compatibility during integration. The sintering temperature profile must accommodate both the metal foam's structural integrity and the coating material's consolidation requirements. Excessive temperatures may trigger undesired intermetallic compound formation at the interface, while insufficient thermal energy may result in poor adhesion. Studies show that controlled atmosphere processing (using inert gases or vacuum) can prevent oxidation reactions that would otherwise compromise compatibility.

Porosity characteristics of the metal foam substrate directly affect coating penetration and distribution. Open-cell foams with interconnected pores allow deeper coating penetration but may suffer from non-uniform coverage in interior regions. Closed-cell foams present challenges for coating infiltration but offer more predictable surface coverage. Recent advances in suspension and solution-based coating techniques have improved compatibility with high-porosity foams by modifying rheological properties to match specific pore architectures.

Mechanical stress considerations represent another critical compatibility factor. Differences in elastic moduli between coating and substrate materials can lead to stress concentration at interfaces during loading cycles. This mismatch potentially results in coating delamination or cracking. Research demonstrates that gradient coating approaches, where composition gradually transitions between substrate and final coating material, significantly improve mechanical compatibility by distributing stress more evenly across the interface region.

Emerging research focuses on developing adaptive coating systems specifically engineered for metal foam compatibility. These include self-healing coatings containing microcapsules that release repair agents when damaged, and stimuli-responsive coatings that can adjust their properties based on environmental conditions. Such advanced coating technologies promise to overcome traditional compatibility limitations and expand the application range of coated metal foam components.

Environmental Impact Assessment

The integration of coating technologies with metal foam fabrication presents significant environmental considerations that must be carefully evaluated. Traditional metal manufacturing processes are known for their substantial environmental footprint, including high energy consumption, greenhouse gas emissions, and waste generation. When coating technologies are incorporated into metal foam production, these environmental impacts can be either mitigated or exacerbated depending on the specific methods employed.

Surface treatment chemicals used in coating processes often contain volatile organic compounds (VOCs), heavy metals, and other potentially hazardous substances. These materials can pose risks to air quality, water systems, and soil health if not properly managed. However, advanced coating technologies such as plasma-assisted deposition and atomic layer deposition offer more environmentally friendly alternatives by reducing chemical waste and energy requirements compared to conventional wet chemical processes.

Life cycle assessment (LCA) studies indicate that the environmental benefits of coated metal foams may outweigh the additional environmental costs of the coating process. For instance, corrosion-resistant coatings significantly extend product lifespan, reducing the need for replacement and thereby conserving raw materials and energy over time. Similarly, catalytic coatings on metal foams used in emission control systems can contribute to substantial reductions in air pollutants from industrial processes and transportation.

Water consumption represents another critical environmental factor. Traditional coating methods often require extensive washing and rinsing stages, consuming large volumes of water. Newer technologies such as dry coating processes and closed-loop water systems have been developed to address this concern, reducing water usage by up to 80% in some applications.

Energy efficiency improvements are also noteworthy. The integration of coating technologies with metal foam fabrication can be optimized through combined heat treatment processes, where thermal energy used for foam sintering can simultaneously activate certain coating reactions. This approach minimizes the total energy footprint of the manufacturing process.

Waste management strategies for coated metal foam production have evolved significantly. Recycling technologies now allow for the recovery of valuable coating materials such as precious metals from spent catalytic metal foams. Additionally, advanced filtration systems capture particulate matter and chemical residues from coating processes, preventing their release into the environment.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced manufacturing processes, including coated metal foam production. Compliance with standards such as REACH in Europe and similar regulations in other regions is driving innovation toward greener coating technologies that maintain performance while reducing environmental impact.

Surface treatment chemicals used in coating processes often contain volatile organic compounds (VOCs), heavy metals, and other potentially hazardous substances. These materials can pose risks to air quality, water systems, and soil health if not properly managed. However, advanced coating technologies such as plasma-assisted deposition and atomic layer deposition offer more environmentally friendly alternatives by reducing chemical waste and energy requirements compared to conventional wet chemical processes.

Life cycle assessment (LCA) studies indicate that the environmental benefits of coated metal foams may outweigh the additional environmental costs of the coating process. For instance, corrosion-resistant coatings significantly extend product lifespan, reducing the need for replacement and thereby conserving raw materials and energy over time. Similarly, catalytic coatings on metal foams used in emission control systems can contribute to substantial reductions in air pollutants from industrial processes and transportation.

Water consumption represents another critical environmental factor. Traditional coating methods often require extensive washing and rinsing stages, consuming large volumes of water. Newer technologies such as dry coating processes and closed-loop water systems have been developed to address this concern, reducing water usage by up to 80% in some applications.

Energy efficiency improvements are also noteworthy. The integration of coating technologies with metal foam fabrication can be optimized through combined heat treatment processes, where thermal energy used for foam sintering can simultaneously activate certain coating reactions. This approach minimizes the total energy footprint of the manufacturing process.

Waste management strategies for coated metal foam production have evolved significantly. Recycling technologies now allow for the recovery of valuable coating materials such as precious metals from spent catalytic metal foams. Additionally, advanced filtration systems capture particulate matter and chemical residues from coating processes, preventing their release into the environment.

Regulatory frameworks worldwide are increasingly addressing the environmental aspects of advanced manufacturing processes, including coated metal foam production. Compliance with standards such as REACH in Europe and similar regulations in other regions is driving innovation toward greener coating technologies that maintain performance while reducing environmental impact.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!